Traditional types of heat-insulating materials have their own specifics. It is generally accepted that to obtain a sufficient effect it is necessary to install thick insulation. In this case, problems arise with finishing, difficulties with installing hanging furniture or equipment.

Often, the installation of thermal insulation becomes the reason for the non-use of surfaces convenient for placing hanging objects or for laying communications. Sometimes it is impossible to change the surface level, and insulation becomes impossible.

However, today there is an effective and practical way to solve the problem - applying heat-insulating paint. This is relatively new material that should be examined more closely.

Types of thermal paint

Paints with heat-insulating properties differ according to several criteria: by purpose, by type of base, type of filler.

By purpose

Depending on the type of base on which the paint is applied and the operating conditions of the coating, it is divided into 3 categories:

- for external work - finishing facades, foundations, walls of unheated basements, etc.;

- for interior work - heat-insulating paint for walls, their insulation from inside the premises;

- for pipes - gas, water supply, heating, ventilation, chimney, as well as for thermal insulation of various containers and equipment.

Tanks with thermal insulation coating Source prom.st

Based on

The basis for the production of heat-insulating paints are polymer acrylic compounds and aqueous emulsions and dispersions.

Acrylic paints, after application and drying, form a dense waterproof layer on the surface. They can be tinted in any color and painted after drying. Tinted compounds are resistant to ultraviolet rays, almost do not fade or tarnish. The durable coating serves as additional waterproofing and can be washed using detergents and soft brushes.

Facade thermal paint Source bnhp.ru

Water-based insulation paint does not contain harmful compounds; it is more often used for interior work. Emulsion compositions are not resistant to moisture and are easily washed off with water. Dispersive ones have better durability and a wider scope of application.

By filler

Special properties of such paint are given by fillers, without which it would be an ordinary decorative composition. They are the ones who turn it into liquid insulation, as they have the ability to retain heat. The most common fillers include:

- fiberglass;

- foam glass;

- perlite;

- ceramic granules.

Fiberglass insulation is known to everyone in the form of glass wool in mats or rolls. The heat is retained by the air enclosed between numerous glass threads. In paint, the place of air is taken by a polymer, whose thermal conductivity is higher, so it cannot be equal to glass wool in insulating properties. But the fibers prevent it from cracking and make the coating elastic and durable.

Foam glass filler consists of tiny granules of molten glass filled with air.

Granulated foam glass Source stroynet.ru

Perlite is a volcanic glass formed when igneous lava slowly cools. The porous rock is crushed and loose insulation is obtained.

The most effective filler is ceramic microspheres filled with highly rarefied air, which practically does not conduct heat. This material is a NASA invention created to protect space rockets from overheating. Acrylic heat-insulating paint for pipes and other structures can contain up to 80% ceramic filler, which provides very high protection against heat loss.

See also: Catalog of companies that specialize in finishing materials and related work

What it is

Thermal insulating paint is an energy-saving coating consisting of a polymer composite containing microscopic hollow ceramic granules.

This is a paint that belongs to the category of innovative materials that can provide both the basic task of paintwork materials (waterproofing and decorative coating) and the thermal insulation function. A thin layer of coating can replace traditional types of thermal insulation, which allows you to solve a lot of problems with the volume or weight of insulation.

Externally, the material resembles familiar acrylic paint.

The material consists of several components:

- binding material (water-based acrylic paint, ensuring adhesion and an even layer of coating);

- filler (hollow ceramic spheres 0.01 mm in size);

- additional components (silicone, latex, rubber granules 0.02 mm in size).

In addition to the basic components, the thermal insulation paint may contain pigments. By default, the material is white or gray. However, thermal insulation can be made to order in any color at the request of the client.

Features and Benefits

Liquid thermal insulation in the form of paint is not capable of providing complete protection of structures from heat leaks, but it has its own characteristics and some advantages compared to traditional insulation.

- Very low thermal conductivity, averaging 0.0012-0.002 W/(m*K).

Thermal conductivity of other materials - for comparison Source tinkoffjournal.ru

- The insulation layer is minimal compared to other materials, not exceeding 4-6 mm, which allows you to save useful area during interior work.

- Excellent adhesion to any base materials from wood and concrete to glass and plastic.

- Anti-corrosion and anti-condensation properties due to the waterproofness of paints.

- High heat resistance, resistance to sudden temperature changes, maintaining properties in the range from -40-60 to +120-250 degrees, in which other materials cannot withstand.

On a note! Thermal insulating paint for pipelines has the highest heat resistance. It can be applied to surfaces with temperatures up to +150 degrees, which allows you to not interrupt the operation of heating and hot water supply systems while insulation work is being carried out.

Using thermal paint you can significantly reduce heat loss in pipelines Source germetik-universal.com

- The biostability of the paint is also at a high level - it is not damaged by rodents, insects, or mold.

- The coating is resistant to sunlight.

- Warm colors are lightweight and do not weigh down the structure.

For reference! A 10-liter bucket weighs no more than 4-5 kg.

- The material is easy to apply with your own hands; you can do without a spray gun or other special equipment by using a regular brush.

- The coating is repairable: areas with damaged insulation are simply touched up.

- The biggest advantage is the ability to thermally insulate objects and structures that are complex in shape, to which it is impossible to apply traditional types of insulation (boilers, equipment, various containers), as well as the ability to use them in hard-to-reach places.

- Environmental safety and non-flammability allow the use of such compositions even in children's and medical institutions.

- The service life of the coating is at least 10 years, some manufacturers provide a guarantee of up to 40 years.

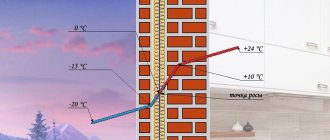

Fighting condensation with heat paint

Liquid thermal insulation allows you to avoid the manufacture of complex structures necessary for attaching a thermal insulation layer near the roofs of hangars and residential buildings. Painting pipelines of engineering systems is much cheaper than protecting pipelines with polystyrene foam shells, winding with basalt wool, and then waterproofing the insulation.

Condensation control is available to a home craftsman with minimal painting skills. Liquid thermal insulation is sold in convenient buckets and jars, is completely ready for use, and has instructions for use. The weight of the roof practically does not increase when applying a millimeter layer, while the comfort of using the premises increases many times over.

Paint selection

When choosing a liquid coating for thermal insulation, you must first take into account the place of its application and the type of surface on which it will be applied. Technical characteristics are also taken into account - consumption, temperature range for work and operation, service life, etc. Price, manufacturer reputation, and customer reviews also play a significant role.

Recommendations for selection

The main selection criteria relate to the place where the paint is applied.

- Thermal insulating paint for heating pipes, hot water supply and gas transportation must be as heat-resistant as possible.

- Compositions for interior work should not contain toxic substances.

Walls covered with liquid thermal insulation Source akterm.ru

- The main requirement for external thermal insulation is high levels of water resistance, resistance to ultraviolet radiation and temperature changes, and impact strength.

Recommendations for calculating volume

Since the paint layer is on average 1.5-3 mm, its consumption is quite large, which requires a preliminary calculation of the required volume of the mixture. To do this, you will need to know the area of the surface to be coated, the type of base, the presence of defects on it (irregularities, cracks), and the number of layers of paint.

The average consumption is always indicated on the packaging in the instructions for the composition, but it depends on the absorbent characteristics of the surface, so it is better to make the calculation with a margin of 5-10%. And if there are significant defects on the surface, it may take an additional amount of paint to level them, and the overspending will be even greater.

In order for thermal insulation paint to serve its life properly, the coating must have a certain minimum thickness, which depends on the type of base:

- metal – 2.5 mm;

- brick, cellular concrete – 2.5 mm;

- wood – 2 mm;

- concrete – 1.5 mm.

Thermal insulation of a facade made of concrete blocks Source kraski-net.ru

To find out the required volume, the surface area is multiplied by the number of layers and the consumption rate per layer.

Varieties

The type of warm paint is conventionally divided according to two characteristics:

- composition: acrylic or water base;

- by area of application: for indoor work, for pipes, facade - exclusively for outdoor work.

Thermal insulation paints for interior work

For work inside buildings, both acrylic and water-based compositions are suitable. An important task is to determine the functional load, as well as study the composition, which should not contain toxic components. To treat pipes, heating mains, and gas pipelines indoors, use interior paint, preferably acrylic-based, and for painting cold walls, you can use a water-based composition.

Insulating paints for exterior work

For outside work, it is necessary to select thermal insulation materials taking into account the functional characteristics of the surface and environmental conditions (humidity, frost, sunny side). It is better to choose a mixture with minimal water resistance and the highest vapor permeability, so that heat will be retained and the treated surfaces will not deteriorate.

Main manufacturers

Minimizing heat loss is the task of most people who do not want to spend money on paying endless bills. The production of such materials is relatively new, but today there are leaders in the market in terms of quality and price:

- Corundum;

- Thermalcom;

- Keramoizol;

- Mascoat;

- RE-THERM;

- Armor;

- Akterm.

Rules of application

Insulating paint for walls and other structures is no different from regular paint in its application method. The coating is created using standard tools - brush, roller, sprayer. Sometimes spatulas are used.

It has excellent adhesion to all materials, but will not adhere to loose or crumbling surfaces. Therefore, the base must be prepared before painting. This will not only enhance adhesion, but also reduce the consumption of rather expensive paint. Preparation consists of simple activities;

- removing the crumbling layer;

- cleaning from dirt or rust;

- priming.

Advice! Look for recommendations on choosing a primer on the paint package.

Work is carried out in the temperature range recommended by the manufacturer. As a rule, the air temperature should not be lower than +7 degrees, although there are special compositions for winter application. Pipe paint can be applied to a hot surface with temperatures up to +120-150 degrees.

The coating is created in several stages, applying 2-4 layers in succession.

What is it used for?

The name itself - heat-insulating paint - speaks about the purpose of the material. The coating protects surfaces from heat loss, forming a barrier from direct contact with the external environment.

Expert opinion

Torsunov Pavel Maksimovich

The specificity of the material is such that one cannot expect a thermos effect from it. However, in most cases it is quite enough to reduce heat loss to an acceptable minimum.

In addition, the method of applying the material allows you to insulate bases of complex shapes - curved, embossed, with a lot of small details.

At the same time, heat-insulating paint practically does not change the dimensions of the base, which makes it possible to insulate structures and sections of utility networks located in limited spaces - in shafts, boxes, in crowded and cramped conditions.

Considering that 1 mm of thermal insulation paint is equivalent in performance to 50 mm of mineral wool (or other similar insulation), the use of the material will only expand and become more common.

Brands and manufacturers

Thermal insulation paint is produced by many domestic and foreign manufacturers. Among the popular and well-established brands among consumers are:

- Corundum;

- Akterm;

- Isollat;

- Astratek;

- Thermomet;

- Armor;

- Keramoizol;

- Thermosilate;

- Tezolat;

- Thermion;

- RE-THERM;

- Ceramic;

- KARE.

Almost all manufacturers produce a whole line of thermal paints that differ in composition and purpose. They can be easily distinguished from each other even by name. For example, the companies Korund and Bronya classify their products as follows:

- Classic - a universal composition for internal and external use, thermal insulation of walls, roofs, pipelines made of different materials;

Application of liquid thermal insulation

A very important feature of liquid thermal insulation is its anti-corrosion protection, which perfectly protects any surface from the harmful effects of the environment. Anti-corrosion painting is created for any metal equipment that can be used in conditions of high humidity. This is a very useful thing for oil pipelines, gas pipelines, as well as pipes through which hot steam passes (stoves, saunas).

This coating can be applied to the exhaust systems of any modern vehicles. It is possible to provide reliable protection to all kinds of engine parts, as well as metal surfaces that can be used during installation at temperatures from -60 to +650 degrees Celsius. They can also be influenced by an aggressive environment and other factors.

Among the aggressive factors it should be noted:

- Salt solution.

- Petroleum products.

- Mineral oils.

The electrostatic field is not an obstacle to the application of heat-resistant paint, or rather, our liquid thermal insulation. The insulation does not lose its properties even at temperatures below zero. The anti-corrosion and insulating properties of liquid thermal insulation help to avoid:

- The effects of high temperatures on a material or surface.

- Atmospheric precipitation.

- Humidity.

- The harmful influence of an aggressive environment.

At the same time, good vapor permeability is maintained. Liquid thermal insulation can be used as a fireproof finish for both ceilings and walls. Heat-saving paint is sold in specialized stores. Before the main work, the surface should be prepared.

To make it convenient to apply heat paint on surfaces, you should prepare the area to be treated in advance. To do this, you do not need to have special knowledge or skills; it is enough to remove any peeling, staples and other sharp irregularities from the surface. Next, let's talk about safety precautions.

Liquid heat insulator is a chemical product, which means it should be applied carefully and carefully. It is best to follow all safety regulations and also store the substance in the proper place so that the suspension does not lose all its protective properties. Thermal insulation paint can harm the body if it accidentally gets into the stomach; to prevent this from happening, you should carefully apply the substance to the material

Nano insulation - paint for wall insulation, simply has a special manufacturing technology and more effective insulation characteristics

Thermal insulation paint can harm the body if it accidentally gets into the stomach; to prevent this from happening, you should carefully apply the substance to the material. Nano insulation is a paint for insulating walls; it simply has a special manufacturing technology and more effective insulation characteristics.

If you don’t know how to protect yourself when applying insulation, you can watch a training video that will help resolve this issue. Any heat-reflecting material can be insulated with good insulation.

Paint consumption and approximate cost of 1 sq. m depends on the manufacturer brand you choose. Thermal insulating paint does not differ much in its purpose, but may differ in some storage features, methods of application, choice of material to use, and much more. Nano insulation will be a good choice in any situation, but its cost will be significantly higher than that of conventional thermal insulation, but the degree of thermal protection is higher.

The liquid thermal insulation coating on which the insulating paint is applied must be appropriate. You can read more about the effect of an insulator on a particular material or surface on our website. Experts will help you determine which liquid thermal insulation for walls or which paint insulation suits you best.

Thermal insulation paint or liquid insulation for walls presented on our website will help to effectively protect any surface and material from heat loss, as well as any other negative impact. Liquid insulation for walls has an expiration date and operating instructions.

The temperature at which thermal insulation paint is used affects the external insulation of walls, or more precisely, its quality. For thermal insulation of walls, it is better to buy products from a trusted manufacturer. Liquid thermal insulation for walls from the inside is actively used by many construction companies and private work groups.

Video description

Features of the use of Bronya Classic heat-insulating paint are described in the video:

- Facade – paint for thermal insulation of external walls;

- Winter - a composition with special additives that allow application at low air and surface temperatures;

- Anticorrosive is a product for insulating pipelines and other metal structures, including rusty ones.

Astratek has a different classification - Universal, Metal, Facade.

All compositions for thermal insulation of pipes and metal structures have anti-corrosion properties and prevent the formation of condensation. As a rule, they are produced in gray color, while wall and facade insulators are white, which makes them easy to tint to give the desired shade.

Types of liquid thermal insulation Termion Source pk-altermo.ru

It is important! When purchasing paint “in reserve,” be sure to check the storage conditions. Not all compositions can withstand freezing and thawing without loss of properties.

How to correctly calculate consumption

Thermal insulation compounds are not economical in consumption. Such paints are expensive. Before purchasing, it is advisable to calculate the required quantity of products. This indicator depends on the area to be painted and the number of layers.

Expert opinion

Zakharova Irina Yurievna

Cleaning professional with 15 years of experience. Our best expert.

Ask a Question

Consumption rates for any paint are given in the instructions. Usually per sq. meter takes 0.5-1 liter of composition. The surface area for painting is calculated as follows: multiply the length by the width (you get the figure in meters).

Paint consumption also depends on the thickness of the coating, the number of layers, surface porosity, and method of application. Spraying with a spray gun allows you to save composition.

Briefly about the main thing

When there is no desire or opportunity to use conventional insulation, you can consider the option of thin-layer thermal insulation using special paints. They contain gas-filled granules or fibers that provide the coating with the ability to retain heat. Such paints are indispensable for insulating pipelines that have complex shapes and structures that are difficult to insulate. They do not create excessive load, do not eat up useful space, and cover the object with a continuous, seamless warm layer, under which mold or rust does not form. In the case of insulating walls with warm paint, it can serve as an excellent base for painting or wallpaper.

Ratings 0

Surface preparation

Before applying paint, it is necessary to properly prepare the surface. On a dirty, uneven base, the coating will not last long, and therefore all efforts and financial costs will be in vain.

Dust, dirt and oily formations are carefully removed from the surface. All cracks and cracks are sealed. They also get rid of uneven surfaces by using a metal brush, grinder or sandblaster.

Note! In the case of concrete, the surface should be cleaned of the so-called “cement laitance” - dust, which greatly impairs the adhesive qualities of the coating.

When the surface is cleaned and leveled mechanically, a primer is applied. VL-02 or VL-023 are most often used as priming compositions.

Classification of thermal compositions

The classification of the dye is carried out in two directions.

Two types according to manufacturing method:

- water CM - covers the pipes of the heating system, does not contain toxins;

- Acrylic-based CM is universal and interacts with many materials.

Three types depending on the place of application:

- universal CM - walls inside rooms and on the street side, ceiling, floor are covered;

- energy-saving façade paint – the moisture resistance indicator is high and allows the material to be used for painting the surface outside;

- heat-insulating paint for pipes - protects water and gas pipelines, pipes of ventilation and air conditioning systems.