Insulation is a mandatory procedure that must be performed after the construction of any wooden structure. In this case, it does not matter at all what wood material the house is built from. Both timber and log buildings need insulation, since both are susceptible to deformation and the formation of cracks during shrinkage. Previously, caulking with natural materials was widely used for this purpose. This time-tested method is still in demand today. However, recently modern technologies have replaced traditions, and many people prefer an alternative method to outdated and labor-intensive caulking - sealing. At the same time, old masters are skeptical about new techniques. Let's figure out what is actually better, more profitable and more reliable: a warm seam or caulk.

Pros and cons of materials used for caulking and sealing

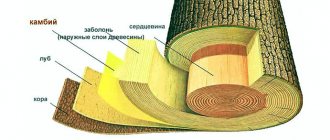

Despite the fact that both caulking and sealing pursue the same goal - sealing cracks formed as a result of shrinkage and insulating the house, different materials are used in each work. To caulk a wooden house, natural insulation materials are used - moss, tow, jute, flax wool, which are driven into the inter-crown cracks using a special tool - a wooden or metal spatula. It was no coincidence that the choice fell on these materials: in addition to the fact that they are environmentally friendly, they have other important characteristics.

Advantages of natural insulation:

- resistant to temperature and humidity fluctuations,

- have low thermal conductivity,

- are characterized by hygroscopicity.

But on the other hand, natural materials are fertile soil for the proliferation of microorganisms and insects that can settle in insulation that is regularly exposed to moisture and dampness. Among all natural materials, only moss has antibacterial properties, so it does not face a similar fate. But today moss is extremely rarely used for caulking. Another disadvantage of natural insulation materials is that they are of particular interest to birds, which take the material into their nests. To avoid such developments, it is necessary to treat the insulation with special impregnations or paint it.

Sealing of inter-crown joints using the new warm seam technology is carried out using acrylic or silicone sealants.

The insulation has the following advantages:

- elastic,

- quickly fills any, even the smallest crack or crevice,

- has the ability to stretch, shrink and take the desired shape,

- not afraid of dampness and moisture,

- tolerates extreme plus and minus temperatures well,

- not subject to rotting, not interesting to insects and birds,

- has a long service life of more than twenty years.

Manufacturers claim that sealants are environmentally friendly and absolutely safe for humans. At the same time, they contain chemical components: various thickeners, plasticizers, fillers, surfactants. However, it is not completely known how sealing materials affect health over long-term exposure. Therefore, the statement about their harmlessness is, at least, unfounded.

Features of the use of tow

Tow is a coarse fiber used in construction for insulation and filling cracks and gaps.

So, what is tow and how does the process of caulking a log house with this material take place? In ordinary language, tow is a rope, but not quite an ordinary one. It is absolutely unsuitable for making yarn. This coarse fiber has long been used to caulk cracks in wooden houses. And this tradition is still alive today.

Tow for caulking a log house is sold in almost any hardware store. The cost of tow is relatively low. And compared to sealant, tow is much cheaper.

There are several types of tow: linen, hemp and jute. It all depends on the base raw materials that are used in its manufacture. Hemp tow is most often used in shipbuilding. In everyday life, linen or jute is used.

Jute tow is an excellent material for insulating a log house. It holds heat well and is not susceptible to moth damage.

But the latter costs much more. But it is more durable. And its technical qualities are excellent. Due to the fact that it serves as an excellent insulator, in winter you can save a lot on energy costs when heating your home. It is not susceptible to moths. Saves construction costs.

But it is important to carry out this procedure on both sides. If you wish, you can do it yourself. But if you have free funds, then entrust this matter to professionals.

If you decide to do the process of caulking a log house yourself, you should do it in the warm season.

Caulking should be done carefully and carefully, starting from the bottom tier and moving along the perimeter of the log house.

Scheme of caulking of a log house with tow.

After caulking, the log house is moved from the external walls to the internal ones, and so on several times.

There is an opinion that such a tradition as caulking a log house with tow has long outlived its usefulness. After all, the construction market offers a lot of different sealants for every taste and budget. But there is also the opposite opinion that tow is an environmentally friendly material. It allows the tree to breathe. And people leading a healthy lifestyle prefer to use only it.

Now let's look at another method of treating seams for log houses: sealant.

Labor intensity of work

Those who are faced with a choice: sealant or caulk also need to evaluate both works from the point of view of labor costs.

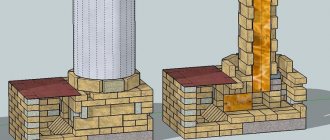

Caulking is a complex, labor-intensive and very responsible job. Today, a caulker is a rather rare profession; it requires high skill and great patience. Caulking is not done quickly, since it is necessary to carefully caulk every centimeter of the surface, without missing a single small crack or damaging the walls. It is also necessary to take into account that when caulking, the height of the house increases by an average of 10 cm. If the technology is not followed and the caulking is incorrect, you can get a distortion in height, which results in deformation of the entire structure. Therefore, it is not recommended to caulk the house yourself; it is advisable to entrust this work to professional craftsmen.

The process of sealing joints and cracks with sealant is not particularly difficult; installation work is carried out quickly without noise and dust. Sealed seams do not in any way affect the height of the building, which remains at the same level. The main thing in work is not to deviate from technology, which also requires professionalism.

Jute

Photo: jute tape for caulking a log house, bathhouse and jute rope - intended for finishing the space between the logs - the inter-log seam.

The most popular natural sealant due to the ability to use it to give a variety of inter-crown cracks an attractive appearance. The jute seal is made from purified fibers of the tree of the same name, as a result of which the cord made from this material has excellent strength. Jute trees grow in water throughout Southeast Asia. This explains its excellent resistance to high moisture.

Advantages of jute

Thanks to these unique properties, the sealant made from it is very popular for caulking various inter-crown cracks. By well concentrating moisture in the inter-crown space, jute uniquely prevents the creation of favorable conditions for the formation and growth of colonies of mold, fungi, and destructive bacteria. The dense structure allows you to create a reliable insulating barrier, preventing the penetration of unfavorable atmospheric factors over a long period. The unique ability of jute not to deteriorate under prolonged exposure to high temperatures and high moisture promotes its use as a decorative frame for various cracks in the inter-crown zone of a log house.

Elasticity of the insulation used

A wooden house is necessarily subject to shrinkage, which leads to its deformation.

The result of this process is the expansion of the inter-crown cracks. The natural materials used to make caulk cannot expand in size, and therefore they are not able to fill the enlarged holes. The sealant is elastic and has excellent adhesion to wood. It is tightly fastened to the crowns of the logs, forming a monolithic film that stretches or contracts simultaneously with the movements of the wooden structure. All cracks and gaps remain completely covered with elastic film.

How to caulk correctly

The caulking process involves insulating the seams between logs using fiber tape. Practice shows that only if the joints are sealed, high-quality thermal insulation can be guaranteed. The tape, in turn, should be knocked into a tight roller. It is necessary to ensure that the fiber ribbon does not twist, because... twisted fibers have significantly lower thermal protection efficiency.

Financial side of the issue

Based on the cost of the material and caulking work per linear meter, caulking is one of the cheapest ways to insulate a wooden house.

But you need to take into account that caulking is carried out at least twice: immediately after the construction of the house and a year and a half after construction, when the building is partially settled. In some cases, after final shrinkage after 5-6 years, a third caulk is required. In addition, to achieve a good effect, it is necessary to insulate the structure both outside and inside. Sealing a log house is more expensive (both the work itself and the sealant), but it is carried out only once. A single application of sealant lasts for several decades. At the same time, it is desirable to seal the seams on both sides, but not necessary; it is enough to only perform external insulation of the house. As a result, the cost of cheap caulk will be higher than the cost of a more expensive sealing procedure.

Some characteristics

In order to keep a log house warm, cracks and crevices must be sealed during its construction.

When the tightness of a structure is broken, many unpleasant problems arise that require immediate solutions. This includes a sharp increase in energy costs as a result of a decrease in room temperature. And the appearance of mold due to wetting and damage to the wood. A sharp increase in humidity in the house.

But the most global one is the rapid destruction of the structure itself. In this case, you can lose your property or invest considerable funds in its restoration and repair. Therefore, it is better to take care of this problem in advance and solve it at the very beginning.

There are two main ways to eliminate gaps and cracks in buildings made of logs: caulking the log frame with tow or using sealant. Which way is better? What are their differences? How durable is this or that material? In order to answer this question, you should consider each option separately.

Recommendations for choosing insulation

Both methods: caulking and sealing are used to insulate a log house made of rounded logs, as well as houses made of ordinary, profiled and laminated timber. At the same time, for a log house with a triangular groove, it is recommended to use caulk as insulation. With such cutting, a significant space is formed between the logs, which can only be closed with natural insulation. The sealant is not able to fill large voids.

On the contrary, it is better to insulate houses made of profiled timber using warm seam technology. Due to the interlocking joint, it is quite difficult to caulk the seams, but the sealant can easily fill the existing cracks.

Advantages of sealant

Since the sealant allows you to insulate a bathhouse with less effort than caulking, this material has already gained a certain share in the market. Let's consider its advantages using the example of TORVENS bath sealant:

- Elasticity up to 300%.

- Effectively removes water vapor.

- Retains its properties at temperatures from -50 to +160 °C.

- Withstands high humidity typical for any bath.

- The sealant does not contain harmful substances.

- Easy and quick to apply to seams - no specialist help required.

- Birds and insects ignore the sealant.

- The end result looks nicer than most caulking options.

- Lasts much longer without the need for regular updating.

- A layer of 2 mm dries in just 24 hours.

Durability

The service life of these sealant options is 30 years, which is a recognized European standard.

| Remmers acryl 100 | from 30 years old |

| Ramsauer acryl 160 | from 30 years old |

Let's compare with inexpensive sealants

| Eurotex | from 3 to 8 years |

| VGT | from 2 to 8 years |

You should be very responsible when choosing a sealant brand or seek advice from certified professionals.