In heat and mass transfer, air condensation is one of the fundamentals of the theory. Considering humidity is important in many areas of construction and design.

Before calculating the dew point when insulating walls, you need to figure out what this indicator is and what initial data is needed to find it.

To keep your house dry and warm, you need to correctly calculate the dew point when insulating the walls.

Areas of application

There are many areas that take this temperature into account. One of the areas is aviation. During aircraft operation, condensation may form on some of its parts and freeze. This leads to freezing of the engine, metal structures of the flying vehicle and its breakdown.

In forestry, fire conservationists use dew point to calculate fire hazard class.

Experts calculate the likelihood of forest fires and develop protective measures.

Most often, determining the point is necessary in construction and agriculture.

Video: Dew point - insulating the house wisely

Construction

In construction, this value is determined when insulating the facades of buildings and private buildings. If you do not take into account the indicator or calculate it incorrectly, due to settling moisture, the wall finishing material will deteriorate or pathogenic flora and mold will appear.

Agriculture

In agriculture, experts determine the likelihood of damage to crops due to weather conditions, knowing the point and atmospheric humidity.

When cultivating new plants, breeders try to create varieties that condense moisture on the vegetative parts. Such plantings can exist with little precipitation.

Comfortable values for a person

For most people, conditions with a point value in the range of +10…+15℃ are optimal. If the indicator increases, then the person feels discomfort. When the point value is less than +10℃, the environment becomes dry, and from +15℃ humidity begins to be felt. If the indicator is above +20℃, it becomes stuffy. People with heart and respiratory problems are more susceptible to environmental parameters than others.

The dew point temperature determines the comfort level of living in the house

How to calculate the dew point when insulating walls

Only a specialist can make an accurate calculation. But when choosing insulation yourself, you can find out the approximate point values in several ways.

Formula for calculating dew point temperature

The calculation using the formula is considered quite accurate, but gives a deviation of 0.5℃.

Formula for calculation: Tp=(b*f(T,Rh))/(af(T,Rh)) , where:

- f(T,Rh)=(a*T)/(b+T)+ln(Rh/100);

- a = 17.27 and b = 237.7 are constants;

- T —air temperature;

- Rh —relative humidity.

Using an online calculator

Not every person is able to calculate the value using the formula. For such cases, we came up with an online calculation calculator. All you need to do is enter the temperature and relative humidity. The result will appear on the monitor.

Application of devices

To calculate the value, you first need to determine the parameters by which the calculation will be carried out. This is done using meteorological instruments. To avoid using a separate thermometer and hygrometer (a device for measuring humidity), a thermohygrometer was invented. It simultaneously measures the necessary parameters and displays the values on the screen.

Using a thermohygrometer you can calculate the dew point temperature

In addition, there is a device that itself is capable of calculating the point. The tool is brought to the desired surface, records the values and stores them in memory. The results can be transferred to other media for later use.

Using table data

Using the table, you can quickly determine the point, knowing the necessary parameters. The value you are looking for is at the intersection of the column and row of the two indicators. However, the tabular data provides only approximate results.

Water vapor in the wall - where does it come from?

In order to understand what consequences will result from the absence of a ventilated gap in walls made of two or more layers of different materials, and whether gaps in walls are always necessary, it is necessary to recall the physical processes occurring in the outer wall in the event of a temperature difference between its inner and external surfaces.

As you know, the air always contains water vapor.

The partial pressure of vapor depends on the air temperature. As temperature increases, the partial pressure of water vapor increases.

During the cold season, the partial vapor pressure indoors is significantly higher than outside. Under the influence of pressure differences, water vapor tends to enter an area of lower pressure from inside the house, i.e.

on the side of the material layer with a lower temperature - on the outer surface of the wall. It is also known that when air is cooled, the water vapor contained in it reaches extreme saturation, after which it condenses into dew.

Dew point

- this is the temperature to which the air must cool so that the vapor it contains reaches a state of saturation and begins to condense into dew.

The diagram below, Fig. 1, shows the maximum possible content of water vapor in the air depending on temperature.

| Fig.1. Dew point temperature chart. The maximum possible vapor content in the air depending on temperature. |

The ratio of the mass fraction of water vapor in the air to the maximum possible fraction at a given temperature is called relative humidity,

measured as a percentage.

For example, if the air temperature is 20 ° C and the humidity is 50%, this means that the air contains 50% of the maximum amount of water that can be there.

As is known, building materials have different abilities to transmit water vapor contained in the air, under the influence of the difference in their partial pressures. This property of materials is called vapor permeation resistance,

measured in

m2*hour*Pa/mg

.

Briefly summarizing the above, in winter, air masses, which include water vapor, will pass through the vapor-permeable structure of the external wall from the inside to the outside.

The temperature of the air mass will decrease as it approaches the outer surface of the wall.

Dew point determination table

According to the table, at a humidity of 60% and a temperature of +20℃, the value is +12℃.

| Relative humidity, % | Thermometer temperature, ℃ | ||||||||||

| 0 | 2,5 | 5 | 7,5 | 10 | 12,5 | 15 | 17,5 | 20 | 22,5 | 25 | |

| 20 | −20 | −18 | −16 | −14 | −12 | −9,8 | −7,7 | −5,6 | −3,6 | −1,5 | −0,5 |

| 25 | −18 | −15 | −13 | −11 | −9,1 | −6,9 | −4,8 | −2,7 | −0,6 | 1,5 | 3,6 |

| 30 | −15 | −13 | −11 | −8,9 | −6,7 | −4,5 | −2,4 | −0,2 | 1,9 | 4,1 | 6,2 |

| 35 | −14 | −11 | −9,1 | −6,9 | −4,7 | −2,5 | −0,3 | 1,9 | 4,1 | 6,3 | 8,5 |

| 40 | −12 | −9,7 | −7,4 | −5,2 | −2,9 | −0,7 | 1,5 | 3,8 | 6,0 | 8,2 | 10,5 |

| 45 | −10 | −8,2 | −5,9 | −3,6 | −1,3 | 0,9 | 3,2 | 5,5 | 7,7 | 10,0 | 12,3 |

| 50 | −9,1 | −6,8 | −4,5 | −2,2 | 0,1 | 2,4 | 4,7 | 7,0 | 9,3 | 11,6 | 13,9 |

| 55 | −7,8 | −5,6 | −3,3 | −0,9 | 1,4 | 3,7 | 6,1 | 8,4 | 10,7 | 13,0 | 15,3 |

| 60 | −6,8 | −4,4 | −2,1 | 0,3 | 2,6 | 5,0 | 7,3 | 9,7 | 12,0 | 14,4 | 16,7 |

Calculation using the formula with the same initial data:

Tr=(237.7*((17.27*20)/(237.7+20))+ln(60/100))/((17.27-((17.27*20)/(237 ,7+20))+ln(60/100))=12℃

The result shows that the tabular data and the mathematical calculation coincide.

Calculations

Depending on the location of the dew point - further or closer - the wall will remain dry or begin to constantly get wet. The condensate temperature corresponds to the following factors:

- humidity in the building;

- temperature in the building.

When the temperature is + 20 degrees, the humidity is approximately 60%, condensation falls on any surface with a temperature less than + 12. At a relative humidity of 100%, the point is equal to the actual air temperature. It turns out that condensation falls out everywhere.

Determination of dew point position

Before determining the position of a point in the wall, several indicators are recognized:

- ambient and indoor temperature;

- humidity outside and inside the building;

- wall thickness.

Video: Thermal engineering calculation. Dew point

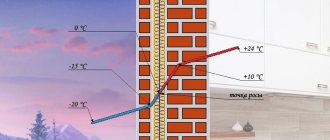

In uninsulated walls

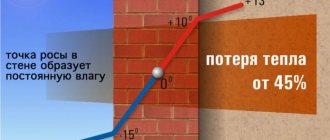

Uninsulated walls lose a lot of heat, the point is located directly in it. The material becomes damp and becomes moldy. Due to temperature changes outside and inside, the wall is subject to destruction.

In externally insulated walls

In this case, the point is insulated, and the wall is protected from weather conditions. The ceiling is always dry, and the heat in the room is retained.

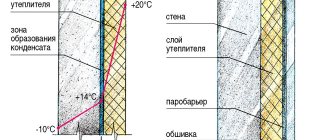

In internally insulated walls

The wall outside begins to freeze and collapse. Condensation accumulates between the outside and the insulation because the point is in the middle of the layers. This leads to the proliferation of pathogenic flora.

The importance of calculations

The air entering the street during the cold season becomes sharply supercooled and manifests itself as settling moisture. Any materials whose temperature is below the dew point become a surface. As a result, when the temperature outside decreases, the walls are constantly damp. This is a favorable environment for mold and pathogens, which then enter the air inhaled by a person and provoke dangerous diseases of the respiratory system, for example, asthma.

A building with damp walls will not last for a long time - it begins to undergo continuous destruction, which is constantly intensifying. Thus, it is important to make correct point calculations at the design stage. Then it is important to choose the right materials:

- for the construction of walls, their thickness;

- for insulation, their thickness.

They also determine the method of insulation - inside or outside. Be sure to select a method for organizing ventilation and heating systems in order to maintain an optimal microclimate - this is 18-23 degrees Celsius and 40-50% humidity.

The point at which condensation forms is easy to calculate yourself. To do this, it is enough to take into account the climate of the region. In addition, to obtain more accurate results, you can hire specialists from a construction company. There are always people there who do these calculations professionally.

Thermal insulation material

To protect buildings from heat loss, high humidity and point shifts, it is insulated with thermal insulation materials. In winter, insulation helps reduce heating costs, and in summer it keeps the room cool. Each product has its own areas of application and properties. Eco-friendly and easy-to-install materials are used in construction. The required type of insulation is selected for certain conditions.

With proper insulation from the outside, the dew point will be located inside the insulation

According to their form, materials are divided into:

- roll;

- leafy;

- bulk;

- single.

By structure:

- fiber;

- cells;

- grainy.

Raw materials can be organic, inorganic and mixed.

Main characteristics of insulating materials:

- thermal conductivity;

- moisture absorption;

- porosity;

- humidity;

- density;

- vapor permeability;

- specific heat;

- strength, etc.

Penoplex

Penoplex is also called expanded polystyrene. Unlike foam polystyrene, the material has a higher density and is less subject to mechanical damage. It almost does not conduct steam due to its low vapor permeability coefficient. However, it belongs to group IV of flammability (it ignites quickly).

Penoplex is recommended for external wall insulation

Penoplex of the “comfort” category is produced for insulating walls, terraces, loggias, and balconies. Its thermal conductivity coefficient is 9 times less than that of mineral wool. The material requires little time to heat the room after cooling due to its low heat capacity. The operating temperature range is -70…+70℃. Penoplex of this type does not have the best sound insulation, has the lowest density and lower tensile strength compared to other materials.

Penoplex for walls is suitable only if an effective ventilation system is installed in the room to maintain comfortable humidity.

A 2 cm wide layer of polystyrene foam retains heat almost as well as 40 cm of mineral wool or 37 cm of brickwork.

Styrofoam

Polystyrene foam is a material characterized by lightness and buoyancy. It is resistant to fire, but when exposed to fire it begins to melt. The material is easy to process and is not subject to infection by fungi and mold.

Polystyrene foam is obtained from foamed polymer raw materials: polystyrene, polyethylene, polyvinyl chloride or polyurethane. It consists of small identical balls that are fastened together. High-density rigid foam is used for insulation. The panels are easy to connect using rubber or epoxy adhesive.

The temperature range is not important for polystyrene foam, but the material is subject to mechanical damage.

Slabs 5 and 10 cm thick are used as thermal insulation. But, despite the structure, the material is sound-permeable.

Polystyrene foam is one of the most common materials for home insulation.

Mineral wool

Thermal insulation material consists of compressed fibers. Glass, basalt and slag are used as raw materials. The starting material is melted and spun into fibers. Their length is 2-60 mm. The air pores of the mats fill approximately 95% of the total volume. The product is easy to produce and has a low cost.

Mineral wool has many qualities suitable for home insulation.

Due to its porosity, cotton wool allows air and steam to pass through, maintaining air exchange. At the same time, it does not burn and is resistant to moisture, has good sound insulation. But the material has 2 drawbacks:

- contains phenol;

- Flying pieces of cotton wool, falling on human skin, cause itching.

Possible consequences

Improper installation of thermal insulation can lead to unpleasant consequences. The material is applied only to the facade, since additional insulation from the inside is considered impractical for the following reasons:

- Living space is decreasing.

- The wall freezes because the heat from the room does not reach the ceiling. As a result, condensation penetrates inside the thermal insulation. The wall is wet and subject to corrosion.

Poor installation results in wall destruction. If the surface under the insulation is uneven and old, it will have to be reapplied, after making repairs. If the insulation on the outside is not additionally covered, then in one season it will become wet, become unusable and begin to move away from the walls. The thermal layer must be protected from the external environment.

Video: Removing the dew point from the wall

Experts' opinion

Experts believe that the best thermal insulation option is mineral wool. If installed correctly, the material will not cause harm and will last a long time. The main thing is to avoid high humidity. To do this, the cotton wool is additionally covered with a film that limits the access of moisture.

Another option is to install breathable materials on both sides of the insulation that will release liquid to the outside. It is recommended to lay polystyrene foam or expanded polystyrene in combination with materials that do not allow water vapor to pass through and prevent moisture condensation.

How to avoid moisture in mineral wool insulation?

So, the dew point itself is not dangerous. Problems arise when it appears in the wall, where moisture accumulates in winter. Therefore, it is necessary to make a calculation in advance of the moisture accumulation of a multilayer enclosing structure during the heating season, using, for example, one of the online calculators. As a rule, moisture accumulation is within acceptable limits, provided that there are no obstacles in the insulated wall for steam to escape to the street.

A few tips on how to prevent fiber insulation from getting wet. They largely coincide with the recommendations for the construction of non-insulated aerated concrete walls:

- It is impossible to install finishing materials with low vapor permeability close to such insulation, for example, decorative concrete stones, clinker tiles, facing ceramic bricks, etc. They “lock” moisture in the wall. Use façade systems with a ventilation gap.

- In structures with a ventilation gap, cover the insulation only with vapor-permeable windproof membranes (in no case with ordinary films, they have low vapor permeability).

- Use only those systems of “wet” type plaster facades that are recommended for aerated concrete (that is, they have high vapor permeability of all layers). In particular, the facade cannot be finished with high-density cement plasters (more than 1600 kg/m3).

- Install thermal insulation and finishing after excess initial moisture has left the aerated concrete wall.