Briefly about the main thing

To process lining in a bathhouse, materials that are resistant to temperature changes, humidity, and washing are used.

Also important is inertness to fungus, mold, bacteria, and a safe composition for humans. When heated, many materials release toxins and other harmful substances, so the use of antiseptics, fire retardants, drying oils, varnishes with solvents and acrylic resins is unacceptable for the steam room.

For walls and ceilings, impregnations, mastics, oils and some varnishes are used. For shelves only oil or wax based formulations. This prevents the formation of a thick film to avoid burns.

Bleach is used in any room of the bathhouse, but before further processing of the wood, it is necessary to wait until the chlorine evaporates and the hydrogen peroxide decomposes.

Antiseptics and fire retardants are classified as pre-treatment agents for wood, but are not used as independent coatings. They protect the lining and help reduce the consumption of the finishing coating.

Tikkurila is an effective product for interior painting of baths

The Finnish brand Tikkurilana has been in demand not only among domestic consumers for many years, but also abroad. Products from the Biotex, Vivacolor and Tikkurila brands satisfy the needs of the most demanding developers. Special products from Tikkuril and other manufacturers are applied to various interior elements in the bath or sauna. Tikkurila brand preparations recommended for interior work.

- Soupy Arctic. Reliable impregnation, the application of which protects wood from the effects of microorganisms. It has dirt-repellent properties. This representative from Tikkuril is used to cover the walls and ceilings of steam rooms.

- Supi Laudesuoya. The drug is applied to the shelves and backs of the bath. It is better to paint shelves with an oil or wax composition rather than an alkyd one.

- Supi Saunavaha. Natural wax is the main component of this product produced by Tikkurila. It makes the use of the product universal and has no restrictions.

- Supi Saunasuoya. When applied, the light matte finish and natural grain of the wood are preserved; it does not absorb water, dirt and dust. It is recommended to paint the walls, ceiling, and benches in the dressing room twice with this Tikkuril product. In the steam room it is used for the ceiling, but in one layer.

Metal equipment, including stoves installed in baths or saunas, also require careful care. Thermal silicone-aluminum paint Tikkurila is widely used for these purposes. It serves for finishing and protects the metal from exposure to steam and high temperatures.

Types of coatings

The wood in the bathhouse is coated with paint to reduce exposure to moisture and high temperature.

The steam room and washing room are subject to the greatest load. However, this load is different.

- In a sauna, the air temperature can rise to 110°C. However, the humidity here is low. Paint for such a room must withstand heat, but may be sensitive to water.

- In the steam room, the humidity is much higher - from 70 to 100%, depending on the type of bath. The temperature is noticeably lower – it rarely rises above 60°C. The finishing material must be resistant to both water and steam and temperature changes.

- In the washing room, the temperature is not higher than a comfortable +30°C, but the humidity here can be high - 90–100%. The paint chosen is as waterproof as possible.

In practice, painting the inside of a bathhouse, especially a log house, is not a good idea. Any paint will be less resistant to the above factors than the wood itself. But if there is no other way to protect the finish, they also resort to painting.

Oil impregnations and varnishes

Effect of oil impregnation against moisture

A bathhouse is a structure used with a certain frequency. The high temperature in the steam room is maintained only during the procedure. Then the room is specially ventilated, cooling to a low temperature.

In this mode, the boards are more likely to dry out and become covered with cracks rather than mold and rot. Therefore, oil impregnations and varnishes are best suited for treating the steam room.

The oil penetrates the top layer of the wood, forming not a film, but a structure impenetrable to water. At the same time, the wood continues to expand normally and decrease in volume as the temperature changes. This way the oil prevents cracks from appearing.

Antiseptics for bath floors

The floor in the bathhouse is covered with antiseptic impregnations against rotting.

It is not enough to paint the steam room or sauna in the bathhouse - you need to take care of protection from rotting. The weak link in this room is the floor. Water flows onto it, steam is deposited, and it comes into contact with a cold concrete base or soil. To prevent the wooden floor in the bathhouse from rotting 5-6 years after construction, it must be treated with antiseptic impregnations.

Liquids based on substances that have a disinfecting effect:

- Acrylic-based water-based compositions. Moisture-resistant, prevent the growth of fungus, but are not very effective. More suitable for processing the dressing room.

- Organic – based on oils. They are better absorbed by wood and are moisture resistant.

- Products based on wax and urethane oils are absorbed to great depth. In addition to the water- and dirt-repellent effect, they give the timber and lining velvety and softness.

- Combined compositions increase both water resistance and fire safety.

It is strictly forbidden to use compounds that release toxins when drying to treat wood.

Water-dispersed impregnations

Acrylic paints reduce the harmful effects of moisture on wood

You can paint the logs inside the sauna or steam room with water-soluble paints.

The floor and walls in the steam room are painted with water-dispersed acrylic paint. It is quite resistant to temperature changes and does not prevent the penetration of steam. The hiding power is usually low, but the wood can be given any color. The downside is its low durability, the paint washes out quite quickly.

Paint for a bathhouse in a washroom should be as resistant to water as possible. The best products are latex or polyurethane based. For a dressing room or rest room finished with plaster, you can use any compositions marked “for interior decoration.”

The paint forms a film coating on the surface of the wood. And oil compounds penetrate inside, so in the steam room the walls are treated with impregnations.

Wax-based impregnations

Wax paint does not allow moisture to pass through, so it is well suited for baths and saunas

Wax is offered in liquid - viscous composition, and solid. The latter is somewhat more difficult to apply without the habit, but the treatment is carried out less frequently. The product does not create a sticky film and does not attract dirt.

If you only need to protect surfaces from water and steam, wax is more suitable. It is transparent, does not hide the structure of the wood, has some antioxidant activity, and therefore prevents the darkening of the wood.

Water-based polyurethane varnish

This is a kind of resin solution, where water, ethanol, and ether are used as a solvent. For the bath, choose water-soluble varnishes. They are resistant to high temperatures and to acids, oils and salts.

Polyurethane varnish is wear-resistant. Since it is based on water, the varnish layer does not create increased tension on the surface of the wood, and therefore is not prone to cracking. And since the resins polymerize already during drying, there is no subsequent peeling.

Painting inside depending on the purpose of the room

Everything is simple here. You most likely already understand the principle: coatings that can evaporate harmful organic compounds when the temperature rises can only be used where they are not threatened by temperatures of this kind.

Steam room

However, this principle can be considered too general, but specifically - how to paint the walls in the steam room of a bathhouse?

How to paint lining in a bathhouse - Supi Arctic and Supi Saunasuoja

In fact, there is a whole range of coatings on sale, designed separately for the ceiling and floor, walls, steam room shelves and stove painting.

Let's look at wall products using the example of the famous Finnish one. It offers water-based acrylate varnishes, which are called Supi Arctic and Supi Saunasuoja (“Supi” is the general name of the series for baths and saunas), and are suitable for covering walls in the steam room, washing room and in all other rooms (if desired).

The company guarantees that the film formed on the surface will not only repel water and dirt, but will also be able to resist the appearance of mold and blue stains on wooden surfaces. By the way, they can also be used on concrete.

By themselves, these compositions do not provide color, but Tikkurila offers a variety of colors that will suit any design.

We are not advertising to anyone, we simply assume that you can build on what is described and look for similar acrylate compositions from other companies. The Finns passed temperature tests and found them safe.

Washing

Acrylates are also suitable for washing. But let us add that, due to lower temperatures, other coatings can be created there - with the same drying oil, which should not be used in the steam room.

In other words, you have two options to choose from - acrylate varnish or oil- and wax-based impregnation (there are only oil-based ones).

What is suitable for the rest room and other rooms

By all other rooms we mean the rest room, dressing room, bathroom, but not the veranda, because exterior varnishes and paints are used there.

REMEMBER! It is not advisable to use coatings designed for outdoor use in the interior.

Since all of them are not directly exposed to water, you can use any options that are suitable for residential premises. There are no special bath specifics here, everything is determined by the design and material of the walls - we have already talked about how coatings for surfaces made of different materials differ.

As an example, let’s name water-dispersion paints, washable acrylic paints, acrylate varnishes, polyurethane varnishes, etc.

Types of premises

Fortunately, there are not many rooms in the bathhouse (in a standard one). Therefore, we will quickly go through the options of what paint to paint the inside of the bathhouse.

Steam room

This is the most problematic room. Many people believe that there is no need to paint anything there at all, but the price for such a decision is rapid darkening of the wood (and almost everyone has a steam room traditionally made of wood or lined with wood), cracking of the wood (this happens more often from poor ventilation during drying), susceptibility to rotting and mold damage (linden and aspen are very unstable species).

So the absence of any protective coatings, on the one hand, should be considered environmentally friendly, and on the other, costly in terms of future repairs.

You can paint the inside of the steam room with both paints and varnishes, but let them be water-soluble paints. And it would be nice if the label mentioning GOST standards stated that this composition is applicable in the steam room.

Washing

Both silicone and acrylic paints are suitable here. In general, everything that patiently endures the effects of moisture.

Other paints will crack and peel off in pieces under constant exposure to water.

ADVICE! Water dispersions do not tolerate frost well: if the water in the paint freezes, then after defrosting it will lose its quality. Therefore, buy them in the warm season, produced recently.

Impregnations and varnishes are also suitable for painting washing areas.

Again we draw your attention to scuba gear

Of course, in the second case, it is better to paint when it is possible to ensure the best ventilation and the absence of people. Don't forget to use respiratory protection.

IMPORTANT! Remember that enamels and alkyd paints are fire hazards, but water-soluble paints are not.

Tools and technologies

The main tools for painting with almost any composition have been and will be the following:

- brush;

- roller;

- spray gun.

In addition, you can buy some types of paints in aerosol cans, but their cost is significantly higher than their counterpart in a can.

Brushes come in different types: from

natural bristles, artificial and mixed bristles. All of them are used for applying paints to one or another prepared surface. It is better to apply water-soluble paints using artificial bristle brushes; they do not retain water.

The brush is wetted by a third in the paint, on both sides. After that, with short (!) strokes. The direction of the strokes should always be along the grain of the wood.

Rollers are also different:

- foam;

- velor;

- fur;

- polyamide.

With the exception of foam rubber, all can be used for applying paints on any basis; foam rubber is suitable for water-soluble paints and nothing more.

The spray gun is convenient, but not as accessible as brushes and rollers. You will find varieties for water-soluble and alkyd paints, with an upper or lower location of the tank for the spray composition.

The paint is supplied under air pressure from the compressor, so you must first adjust its viscosity (using a solvent) and then adjust the air supply. This is often done experimentally. First, the maximum spraying is set, the flow of paint is checked - if it falls in the smallest drops, everything is fine, otherwise a solvent is added in an amount of 5% of the volume. Check again.

The air supply is calibrated by the type of drips under the stained spot: if they are at the edges, then the air flow should be reduced, if under the middle of the spot, then increase it.

The paint should be applied evenly, perpendicular to the surface, from a distance of 15 to 25 cm . Overlap the layers, but make sure that the width of the overlap is not more than half the area already painted.

Requirements for decorative coating

When choosing paint for decorating the interior of a bathhouse, you should take into account that this material must meet the following requirements:

- protect the wood surface from the effects of aggressive environments that occur in the steam room and dressing room;

- withstand exposure to high air temperatures;

- maintain the integrity of wood and extend its service life;

- provide treated surfaces with an attractive appearance.

Remember that the time during which you can use the bathhouse without major repairs depends on what you paint the inside of the bathhouse with.

In addition, the following factors must be taken into account:

- the type of wood used;

- the ability to perform additional coloring;

- surface condition before treatment.

Special materials should be used for surface treatment

For those craftsmen who have not yet decided how to paint the inside of the bathhouse, it should be noted that most often special varnishes with special properties are used for this purpose:

- High coefficient of vapor permeability. This allows you to avoid the appearance of mold, prevents the appearance of fungi and bacteria, and prevents the formation of condensation.

- The ability to apply a new layer without cleaning the surface from the previous one.

- The presence of pigments that emphasize and highlight the natural texture of the wood with which the steam room and dressing room are decorated.

If you are not satisfied with varnish, acrylic bath paint is an alternative: you can use water-based mixtures inside. Considering the resistance of acrylates to low temperatures, this same type of decorative finish can also be used for facade work (the instructions for use confirm this).

Photo of a steam room whose walls are varnished

The advantages of paint over varnish include a large range of colors and a long service life of the decorative coating.

What to consider when choosing impregnations

Some impregnations contain substances that, when heated, are actively released into the environment and can cause poor health. Therefore, they can be used in any room of the bathhouse, except for the steam room. This applies to synthetic-based substances - they can be used in rooms with a normal microclimate and temperature (rest room, dressing room). Compositions for treating wood in the steam room and washing room must have an organic basis.

Wooden coverings can be protected from moisture by:

- Varnish coatings. But they are not suitable for the steam room. As a decorative layer and protection from high humidity, varnish on the floor can be used in rooms with high traffic - a dressing room and a rest room.

- Impregnations. These are colorless compositions containing phytoncides. They suppress and prevent the occurrence of fungus and mold.

- Antiseptics containing fungicides are applied under the paint.

When purchasing a composition, you must read the instructions; usually there is a note on the package stating that the impregnation is intended for use in baths and saunas.

Acrylate-based antiseptics

With the help of such compounds you can not only protect the tree, but also give it a new shade. Acrylic impregnations are destructive for most pathogenic organisms. Before applying this composition, it must be diluted with water.

Such compositions have the following advantages:

- They are not afraid of temperature changes, so they can be used in any bathhouse.

- They are not afraid of moisture and have water-repellent properties.

- They are vapor permeable, that is, they do not clog the pores of the wood.

The acrylate-based antiseptic SENEZH “Sauna” is very popular. It is specially designed for comprehensive protection of wood in saunas and baths. The antimicrobial effect ensures the destruction of viral bacteria.

Impregnation for wood on an acrylate basis "SENEZH Sauna"

Features of the material include:

- Long-term protection of wood from negative influences in difficult microclimates.

- Preventing the spread of infections.

- Eco-friendly safe composition.

- No smell.

- Water- and dirt-repellent properties.

- Preserves the natural aroma of wood and ensures its vapor permeability.

- Creates a moisture-resistant protective layer.

- Does not affect the change in wood shade.

- Prevents wood from deforming when repeatedly wet and dry.

- Has fire-resistant properties.

"SENEZH Sauna"

Is it possible to treat the floor in a bathhouse with drying oil?

After application, the drying oil polymerizes and a durable protective film appears on the surface, which does not allow moisture to pass into the wood. It is recommended to use drying oil on a natural basis in the bath, and especially in the steam room. When heated, it will not release toxins or odor.

The composition of natural drying oil includes vegetable oil - tung, linseed, sunflower and others. Sold as a clear oily liquid. When applied, it does not “clog” the pores of the wood.

It is convenient to apply drying oil with a brush

Choosing paints for concrete floors

There are four types of paints used to paint concrete floors: acrylic, epoxy, acrylic-silicone and alkyd-urethane.

Acrylic

Such paints are resistant to water and temperature. Paint for concrete floors makes the surface matte, semi-matte and glossy.

To dissolve acrylic paints, use plain water and acrylic thinners. The painted surface is ready for use after 48 hours.

This type of floor paint should not be used on concrete floors that have previously been painted with epoxy or polyurethane products.

Epoxy

Two-component paint compositions are mixed with a construction mixer before starting the painting process.

Before using paints, the floor is treated with a primer - an epoxy compound diluted 25% with ordinary water.

Complete drying is achieved after 7 days, but the surface can be used within 24 hours. Concrete floor paint has a limited range of colors.

Alkyd-urethane

The materials are distinguished by a high degree of concealment and require painting the floor in several layers. Concrete paint is resistant to rapid abrasion and temperature conditions. White alcohol (15%) is used for dilution.

The paints are distinguished by a wide palette of colors and an attractive gloss of the painted surface.

How to apply antiseptics correctly

Before treating the floor in a bathhouse, it is necessary to sand it in order to remove the damaged outer layer and increase the absorbency of the wood. The floor must be dry and clean before treatment.

Apply impregnation in several layers. Each subsequent layer is applied to the completely dried previous one. The air temperature in the room should not be lower than +5 degrees.

Impregnation of wood with antiseptic

If the tree is already affected by mold, then you must first take measures to eliminate it by treating it with special antiseptic compounds or replacing the boards with new ones.

Features of choosing a coloring composition for a bath

The difficulty of choosing is due to temperature and humidity. The heat is much stronger in the room closer to the ceiling, and with strong heating, as mentioned earlier, coloring pigments release toxic substances into the air.

Therefore, in a steam room, it is advisable to treat the ceiling and upper part of the room with impregnations. Like paints, they differ in their composition and release form; they can be water- or oil-based.

Before purchasing, it is important to determine the area where it will be used (ceiling, floor, walls, etc.). The choice is also influenced by subsequent processing, namely, whether the surface will subsequently be covered with a decorative layer or not. The next factor is ease of application, as well as the degree of moisture protection. The optimal product is considered to have good moisture-proof and steam permeability properties.

In the steam room, it is advisable to treat the ceiling and upper part of the room with impregnations.

How to cover the lining inside a bathhouse - instructions for use

Wood is rightfully considered the most popular material in the construction of a bathhouse. In this case, either round timber or timber is usually used. Such lumber is usually made from softwood.

Despite all their undeniable advantages: low cost, ease of processing, durability, heat and frost resistance, when used in construction they have one significant drawback - at high temperatures, coniferous wood begins to release resin.

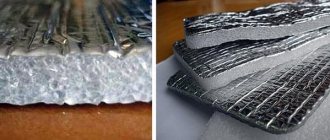

Comes in different sizes and shapes

On the one hand, not everyone likes the smell of resin; on the other hand, touching hot resin with open areas of the body is fraught with serious burns.

That is why clapboard lining of interior walls is widely used in construction.

This helps not only improve the aesthetics of the interior, but also has other undoubted advantages:

- A layer of lining made of moisture-resistant wood helps protect external walls from dampness and rotting, and creates additional thermal insulation for the interior.

- A wooden board with pleasant and beneficial aromatic properties helps enhance the beneficial effects of bathing procedures.

- Using different types of wood and different coatings, you can create unique decorative effects.

Selection of paint and varnish materials for interior work

Requirements for coating materials vary depending on the processing area. The steam room is considered the most problematic place. Oil-based coatings better penetrate deep into the natural structure of the material, prolonging its service life, but at the same time they are characterized by increased toxicity and an unpleasant odor due to the presence of solvents in their composition. They are ideal for treating the outside of walls, as well as the dressing room.

Water-soluble impregnations are suitable for this area. They are based on acrylic, and an additional component is color, which gives the surface a particular shade. This impregnation can be used to treat the structure both inside and outside. However, despite all the advantages, acrylic compositions have a significant disadvantage - over time they are washed out of the wood structure.

In order for the surface to retain its properties for as long as possible, it is necessary to paint it periodically. Another option is to apply a waterproofing compound first and only then impregnation.

How else can you paint a bathhouse inside a steam room? Instead of drying oil, you can use paraffin oil or any other composition intended directly for the steam room. This oil is distinguished by its safety for health while maintaining characteristics similar to drying oil.

In the bathhouse, surfaces are treated with impregnation several times a year.

In order for the surface to retain its properties for as long as possible, it is necessary to paint it periodically.

The least heating zone in the steam room is the floors. Therefore, the answer to the question of how to paint the floors in a steam room in a bathhouse is quite simple - any oil impregnations or acrylate compounds. For wooden floors, you can use water-based varnishes, which do not have an unpleasant odor and are much easier to apply. When choosing a water-based varnish, it is better to give preference to European manufacturers, since the quality of these particular products is much higher.

You can often find concrete flooring. This coating must be painted. Epoxy, polyurethane and acrylic mixtures are suitable for this.

For wooden floors, you can use water-based varnishes, which do not have an unpleasant odor and are much easier to apply.

Popular formulations

Finnish "Tikkurila"

Tikkurila is a well-known company not only in its homeland, whose products are often chosen by Russian residents. With all the wealth of choice of its other products, Tikkuril sauna and bath impregnations are quite few in number, and it would not be difficult to list them:

- Supi Laudesuoja is the same paraffin oil mentioned above. It is intended to cover only the shelves with them.

- Supi Saunavaha - the composition is not fully indicated, but the manufacturer says that it contains natural wax. Can be used not only for shelves, but also for walls, ceilings, doors and window frames.

Sauna impregnation Tikkurila Supi Saunavaha for baths and saunas, colorless 0.9 l. Photo Petrovich

There are also a couple of acrylate compounds - these are water-based varnishes, which already contain antiseptics, although only against mold and blue stains. The names are: Supi Arctic and Supi Saunasuoja. Both are suitable for walls and ceilings and should not be used for floors.

ATTENTION! Finnish impregnations for baths and saunas do not differ in variety at all. If you look at Teknos products, it turns out that they are the same, only the serial name Supi must be replaced with Satu.

"Neomid"

is also familiar to many thanks to its advertising. She has a variety of antiseptics that are suitable for internal and external work, as well as for protecting wood used in particularly difficult conditions (we are talking about contact with water and soil).

But these are antiseptics that are suitable for use in residential and non-residential premises, not only in the bathhouse. Among the specialized products, there is such impregnation for baths as “Neomid 200” and “Oil for baths and saunas”.

"Neomid 200" is an antiseptic that can be used anywhere inside the bathhouse, including on the shelves.

Water antiseptic for baths and saunas Neomid 200 Proff 1 l. Photo by Leroy Merlin

“Oil for baths and saunas Neomid” is an impregnation for baths against moisture and rotting at the same time. Let us explain: usually they exist separately and are applied in different layers. First, the wood is impregnated with an antiseptic, and only water-soluble ones are used inside the bath, and then it is coated with oil or paint. Here it’s “two in one” – both oil and antiseptic. In any case, this is what we understood from the characteristics given on the manufacturer’s website.

There is also a wood bleach “Neomid 500” - it can also be called an impregnation. It is used when the surface of the wood has darkened or become stained with mushrooms. In this case, the treatment leads to an almost instantaneous change in color to the original one.

: "Aquatex" and "Eurotex"

Those who are hearing about these impregnations for the first time may want to watch the video we found. It describes their properties and scope of application:

GOL sauna

Many people know Palizh tinting materials and paints from the Udmurt company “New House”. She also has a GOL series, one of the directions of which is impregnation for baths and saunas GOL Sauna. There is everything you need for a bath - impregnation for the shelf, another impregnation for walls, ceilings, doors and windows, and a third for the floor.

The manufacturer claims that all formulations simultaneously protect against moisture and fungi. Impregnation for baths and saunas is an acrylic coating. The one intended for the floor is already an alkyd composition, that is, paint based on organic solvents. Well, the one for the shelves is some kind of secret product containing “natural wood softener.”

The readers have the same request - if anyone has used it, tell us about your impressions.

"Estate 409"

A very budget option for acrylic coating with an antiseptic included in it is impregnation for baths and saunas “Usadba 409”. That is, you don’t even need a primer - fungicides and insecticides are already included in the composition. In addition, it contains a tannin inhibitor, a substance that causes wood to darken over time.

In general, we can say that this is cheap acrylic paint or varnish (and cheapness here, by the way, is not at all an indicator of poor quality, rather an indicator of mass and therefore cheap production), to which everything possible has been added.

It's supposed to be usable everywhere except shelves and floors (that's what we think). Moreover, it is specially designed for wet rooms, therefore the steam room and washing room are the main candidates for painting with “Usadba 409”.

In our opinion, this is a very competitive option. The Finns also calmly add antiseptics to their acrylates. Another question: do their compositions match? But here you can trust the manufacturer’s certificates, if he has them and demonstrates them to the buyer.

As for color, the impregnation is colorless and there are no colors for it. Maybe it's for the better

Features of protection of different parts of the steam room

Of course, you can saturate the entire steam room and the furniture in it with one composition. And then coat it with one varnish. Moreover, the products currently produced are rarely limited to one protection function. They usually combine, for example, impermeability with antibacterial effects. But the conditions affecting different parts of the steam room are still somewhat different. Therefore, the processing requirements are also different.

Ceiling

Perhaps the least requirements are placed on this part of the steam room. It is exposed only to the temperature effects of steam. Water almost never reaches it. Therefore, it can simply be coated with a specialized bath varnish.

The ceiling in the bathhouse must be reliably protected from dampness and temperature Source eco-ceiling.ru

On our website you can find contacts of construction companies that offer bathhouse construction services. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

Floor

Unlike the ceiling, all the water that is used in the steam room ends up on the floor. Therefore, the anti-water protection for floor boards must be very good. In addition to antibacterial and anti-water impregnation, it is advisable to cover the floor with a protective layer of varnish. But not every varnish is suitable for the floor. The protective layer should not be slippery. This is a must to protect the floor. Of course, the soles of your feet should not stick to the floor. Do not think that repeatedly coating the floor with varnish increases its safety. The thick layer of varnish cracks and water reaches the wood. In addition, the wood cannot “breathe” through such a coating and will still deteriorate.

When building a bathhouse, do not forget about impregnating the logs on which the floor boards are laid. This, of course, is not the inside of the bathhouse, and there are no special protection requirements for them. But if water gets to them, then sooner or later the floor inside the bathhouse itself will suffer, no matter how well it is protected.

Walls

Most of the impregnation for the bathhouse inside is spent on protecting the lining, which is usually used to line the walls. Therefore, you should not use impregnations and varnishes that, when heated, can release strong-smelling substances. And do not cover it with a protective layer that does not allow the wood to “breathe.”

Shelves and benches

The shelves are the main part of the entire steam room, for which it is, in fact, built. Lying on it should be comfortable, pleasant and safe for health. Wood is a poor heat conductor, so even at high temperatures you won’t get burned by it. It’s another matter if it is covered with a protective film, which can cause a burn if touched. Therefore, it is not recommended to use paints or varnishes for it. It is better to apply a special impregnation for the bath. Often such impregnations are wax-based.

The requirements for the safety and convenience of the surface of shelves and benches are so high that there are bathhouse lovers who believe that wood should be natural for them and not covered with anything at all. But this is still suitable for small bathhouses, where simple shelves can be replaced. And when real furniture masterpieces are built, it is better to find a high-quality composition and ensure their durability.

It’s not enough to create beauty – it also needs to be protected

Criterias of choice

For all its advantages, wood is susceptible to moisture. Over time, it dries out, darkens and begins to rot. Mold and microorganisms may appear on it. All this is true for normal external conditions. And in the steam room the conditions are extreme. Even in the dressing room there are no such impacts on the walls and floor. The influence of sudden changes in temperature and humidity in the steam room accelerates the destruction of wood. When exposed to high temperatures, conventional protective coatings can release harmful substances.

In addition, a steam room is not just a room in which a person is located. He remains there naked, his body in contact with wooden surfaces. And on some it even lies. This means that for shelves and benches you need to choose wood protection that will not be unpleasant upon contact.

Most often in the steam room they try to preserve the natural color of the wood, selecting species that look beautiful. But if you want to paint part of the steam room, then you need to take this into account when choosing an impregnation. Not every impregnation is suitable for subsequent painting.

Wood color after different impregnations Source elka-palka.ru

It is clear that it will not be possible to find the same impregnation for a bathhouse outside and inside. Even different parts of the steam room may require different protective equipment. Wood treatment in a steam room should be carried out with compounds adapted to its conditions. And the choice must be based on the following criteria:

- Which part of the steam room is the product intended for?

- Will it be primary impregnation of wood, or re-coating of a previously protected surface?

- Method of applying a protective substance to a wooden surface - with a brush, roller or spray

- Are there plans to further paint the impregnated wood?

Surface preparation and painting process

Whatever you paint the steam room in the bathhouse with, first the surface needs to be prepared, and taking into account the material (wood), this process is a necessity. First you need to prepare all the tools and the coloring composition itself. It is advisable to familiarize yourself with the recommendations of the masters. This is especially important to take into account for people who are encountering such work for the first time. Surface requirements:

- The surface shade should be uniform. The heterogeneous structure is degreased;

- Professionals treat the wood with hot drying oil, which helps stop the growth of bacteria;

- Using special equipment it is necessary to sand the surface.

The paint is applied with a roller, brush or spray gun. The last option is suitable for people who have experience working with such equipment. Otherwise, it is impossible to achieve the desired result.

Professionals treat the wood with hot drying oil, which helps stop the growth of bacteria.

Painting the wall surface

In this case, when painting walls with any material, be it water-based emulsion or latex composition, outside or inside the house, you should remember some nuances, then your plastered wall will turn out beautiful and of high quality. Work process:

- Before painting external or internal walls, you should prepare its surface. In this case, such preparation is one of the important stages before holding special events. Thanks to the latest technologies, before painting, the surface can be cleaned using a special device, as well as putty or cement-sand mortar. If this is not done, then your eyes will catch a “web” of cracks and chips.

- Using a brush or roller, all dust and debris are removed from the surface, then it is primed, as mentioned above, all measures are carried out specifically in order to reduce the cost of materials. For this type of painting, you can use any acrylic-based primer.

- To choose a painting method, you should focus on the paint used, or what features the given structure has. If an alkyd composition is used during the work, and this is a production room, then there is no way to get by using a spray gun. When all these activities are carried out in the living room, it is best to use a brush or paint roller.

- Preparing the paint. If we are talking about alkyd or oil paint, a solvent is used to achieve the usual thickness; if the composition has a water-based material, then in this case you will have to resort to color saturation before you can achieve a good result with the paint.

- Painting the outside or inside of the house on the surface is done with a roller, all movements are performed “from top to bottom”. With this type of work, the interior or exterior wall will look the same tone.

Before you start painting, the surfaces must be cleaned of dust and dirt and thoroughly sanded. If this is not done, then small fibers of wood will rise when painted with water-based varnish, and the ceiling or wall will look like a hedgehog because of this.

It needs to be sanded so smoothly that if you move your hand, it will be impossible to drive away a splinter. Then apply an antiseptic primer, which will serve as additional protection and contribute to a more even application of the paint.

After the primer has dried, sanding must be repeated to remove any remaining fluff.

Alternative coloring agents for baths

How to paint the walls inside a bathhouse if you don’t want to use toxic substances? Use folk recipes. In ancient times, people used natural substances in the form of oak bark decoction. It gives the wood a dark but natural shade. You can get a fire-fighting composition by mixing starch and ocher.

A combination of flax drying oil and beeswax in equal proportions is also known. To this day, people still use linseed oil and even vegetable oil as impregnation. However, time-tested, natural ingredients cannot withstand any competition with modern industrial drugs.

Oak bark gives the wood a dark but natural shade.

Regardless of the quality of the materials used, experts advise carrying out antiseptic measures by impregnating the wood at least once a year. It is important to follow all recommended actions. For example, despite the “perfect” composition of modern products, none of them will last long if applied to an unpolished surface. The main objective of the coating is not only to improve aesthetic results, but also to extend the operational life of the wood. Therefore, when purchasing ready-made preparations, you need to pay attention to highly specialized paints, impregnations and varnishes intended directly for baths and saunas.

Bathhouse exterior painting technology

During the process we adhere to the following algorithm of actions:

Carefully sand the wooden surface. If the log house is not new, then remove the top darkened layer and treat it with a bleaching agent. We remove dust from the wall. You can use an air compressor or vacuum cleaner for this purpose. After blowing, wipe the wood with a semi-dry cloth. We impregnate the surface with an antiseptic primer and sand it after hardening. We treat the wood with a fire retardant. Some bioprotective substances already contain a fire-fighting substance. Apply the first thin and even layer of paint (if you are using a spray gun, hold it at a right angle to the wall being painted) and wait for it to dry completely. This usually takes 12-24 hours depending on weather conditions. Sand the surface with 120/140 grain paper. We paint the wall again using the same technology as the first time. Apply a thick layer of paint to the ends of the logs 4-5 times

They have a rough surface, and therefore absorb significantly more coloring matter. Please note that the lower three logs must be processed with special care, since they are more exposed to negative atmospheric influences than others.

How and with what to treat lining in a steam room - practical tips

Building a bathhouse is a complex process that includes many different tasks. The basis of the bathhouse is a log house, which is additionally lined inside. The lining most often used is lining made from alder, aspen or spruce, which have high strength and resistance to steam and moisture.

However, the natural properties of wood are not always enough. In a bathhouse, wood is exposed to moisture and hot steam, which leads to deformation of the skin. To avoid damage to the wood, it is necessary to additionally treat its surface. In this article we will tell you how to treat the lining inside a bathhouse so as not to change it every year.

What properties should the surface have?

The Abashi breed is very beautiful and bright.

When choosing lining for the interior lining of a bathhouse, you should pay attention to some requirements for the materials used:

- Low heat capacity. As a rule, heavy and hard rocks have the ability to accumulate heat, heating up significantly. Wood with low density, in this case, is much better suited for indoor use.

- Moisture resistance. The tree should absorb moisture well, but at the same time give it out, maintaining a stable balance. An area that accumulates a significant amount of moisture inside eventually becomes wet and slippery, which, you see, is not the best option for a bathhouse.

- Chemical and biological stability.

Indoors, when it is actively used, conditions constantly arise that can be called stressful for the tree:

- High temperature, periodically replaced by low, and in winter, negative air temperature;

- High humidity, significant concentration of water vapor in the air;

- Exposure to detergents that create an aggressive chemical environment.

Graph: at what temperatures does fungus occur?

Under these conditions, the risk of wood damage by rot, mold and various fungal diseases increases significantly.

Therefore, for long-term and enjoyable use of a bathhouse on your site, you must follow short and simple rules when selecting materials for its finishing.

Video - how to choose lining in a store:

For lining used in the interior of a bathhouse, the most suitable domestic types of wood are:

And also exotic ones that are gaining popularity:

Properties depending on breed

Installation of brick partitions in baths

If you were still in doubt up to this point, check out this list:

- The metal structure heats up very quickly, which does not allow the body to adapt to the high temperature.

- A metal stove cools down as quickly as it heats up. You have to constantly monitor the temperature by adding logs, which is not very economical.

- The material lined with brick will not heat and dry the air so quickly, which means the atmosphere in the steam room will be more comfortable.

- There is a high probability of being burned on the walls of a metal structure. People sitting next to the stove will not feel comfortable.

All these small shortcomings can be easily eliminated with the help of cladding, which will increase the performance of the stove, improve its design and neutralize harm to health, because people go to the bathhouse to improve their health, and not vice versa!

This is the most optimal solution in terms of efficiency and labor costs - to combine the advantages of a metal and stone stove.

At the moment, factories are producing stoves that are initially designed for further lining with brick; this design is the golden mean that will allow you to profitably equip an excellent steam room.

For lining the furnace you need to use only these types of bricks:

- red ceramic brick;

- fireclay brick.

Do not take sand-lime brick. It is great for cladding a house, but it is not suitable for lining a sauna stove. Lime-based bricks are simply not able to withstand constant temperature changes and high humidity in a steam room.

After just a few weeks of use, it will begin to deteriorate. And from a decorative point of view, it is not suitable and additional cladding will still be required.

Fireclay brick

Outwardly, it is, of course, inferior to red ceramic brick, but this issue can be resolved with decorative finishing cladding.

If there are no remaining bricks on the farm, it is better to buy a new one! Give preference to ceramic red brick. Its specific gravity is much lower than that of fireclay. It demonstrates excellent technical properties, reliability and durability. And externally, the stove, lined with red ceramic bricks, will delight you for many years with its stylish, authentic look.

The process of lining a sauna stove with bricks is not very complicated, and if you strictly follow the detailed instructions, even a beginner can handle it.

Brick lining scheme

Valuable tips for painting a log bathhouse

Let's summarize: the main goal of modern paints for timber is to protect wood from blue stains, mold, UV rays and any other atmospheric phenomena. But in order for the protective coating of the timber to do its job 100%, you must do everything correctly.

Tip #1. Paint the sauna frame yourself

If you paint a log house yourself, you will gain a lot of advantages. After all, it is quite difficult to judge the quality of the team’s work only by the appearance of the bathhouse, and their main task is to create a finished beautiful object. And, unfortunately, workers often leave unnoticeable small gaps in the processing of the log house from the outside. Over time, these places become a source of problems such as rot, mold and destruction of the walls of the bathhouse from the inside.

Tip #2. Properly prepare the log house for painting

First of all, it is important to properly prepare the surface of the log house for painting. To do this, you need to remove all dust and foreign debris.

It is advisable to rinse the bathhouse walls thoroughly with water using a hose and a stiff brush. Then dry well. If necessary, sometimes it makes sense to carry out serious grinding:

If you notice any lesions at this stage, treat them with Woodmaster Frost Whitening Solution. And for cracks and small defects Eurotex is more suitable.

Advice: if you notice traces of mold on the logs of a new bathhouse, it is advisable to consult a mycologist before painting: it is still “harmless” mold or a real destroyer.

In addition to standard cleaning and sanding of the log house, you need to take care of its protection. If you are not sure of the quality of the delivered timber, do not make do with a standard antiseptic - it is better to use Language, which kills all spores. And as a topcoat, choose a Fungicide, which will help prevent the appearance of algae and mold on the surface. In extreme cases, you need to clean the walls well and apply a clear coat of Log washadvance.

Tip #3. Paint the ends with lime or a modern equivalent

This is done in order to force water vapor to move along the log and escape through the ends. This is a natural process that occurs due to the difference in temperature indoors and outdoors, and here the steam room is at particular risk.

If in this case the park runs along the fibers, and not across, this is how moisture moves in a growing tree, well, what should you do if you have to.

Tip #4. Don't leave any gaps

During the process of painting a bathhouse, it is important to ensure that there are no unprotected gaps, which can easily cause many problems. Therefore, add a signal color to a colorless antiseptic, and then leave it to dry for 3 days during a period without rain, so that the active substances are fixed in the wood and the effect is achieved

Tip #5. Choose the most beautiful paint!

Modern manufacturers offer not only compositions that simply paint over the substrate and hide the natural grain of the wood. Today, decorative protective and decorative texture paints for log baths are in fashion, which not only preserve the wood from atmospheric agents, but emphasize its beautiful texture!

And it has additional valuable features. For example, today the following texture paints for Russian log baths are especially in fashion:

- “Favorite Dacha” is an economy-class paint to protect the log house from blue stains, ultraviolet rays, and fungus - and all this without a primer.

- “Aquatex” is a paint with an antiseptic and a modern ultraviolet filter. On the surface of the walls of a log bathhouse, it creates a semi-matte elastic coating, and also without priming. Moreover, it can be applied even to damp wood.

- The “Aquatex Extra” variety is a protective coating, an elastic coating made of natural oil and microfiber. This paint has ultraviolet protection in two ranges.

- In order to paint an old bathhouse, Aquatex Restorer paint is more suitable for you: you will be very surprised by the result.

The appearance of the bathhouse should please the eye and warm the soul!

Based on the article https://cdelayremont.ru/banya-svoimi-rukami

Painting a brick oven

Preparatory stage: If there are minor defects (depressions, bumps, potholes), first plaster and level, and cover the seams with a clay solution. You can learn how to prepare a good clay solution from the corresponding article, which is on the blog...

Plaster is made from clay and crushed asbestos. The resulting mixture is carefully applied to a well-heated stove.

How to paint: The two most popular proven folk methods are lime or chalk. The third method is again heat-resistant paint, which is also used for iron sauna stoves.

Cooking and painting with chalk

Stages:

- Pour the pieces of chalk into a container (bucket, basin), fill with slightly warm water so as to cover the surface and leave for at least one hour;

- In another container, mix animal glue with warm water in a ratio of 25:1. Animal glues include gelatin, casein, albumin, and bone.

- Mix both solutions and bring to a homogeneous consistency. “To check the quality of the solution, drop it on a piece of glass or mirror placed vertically. If the density is normal, then the droplet will slide down by 2-3 cm.”

- Apply two or three layers. Each subsequent one, only after the previous one has dried. “For a more “clean” whiteness, you can add a tablespoon of blue to a bucket of the finished solution. It will remove some of the yellowness.”

Cooking and painting with lime

Steps:

- Solution proportions: 1 kg of lime / 1.5 liters of water at room temperature / 1 tbsp. spoon of drying oil / 25-30 grams of blue / 1 tbsp. spoon of salt. Mix. “The most durable whitewash is made from freshly slaked lime, and salt is added to make the lime coating less dirty.”

- Apply in two or three layers. Unlike whitewashing with chalk, each subsequent layer of lime whitewash is applied to the wet previous one. “If the stove in the bathhouse was previously painted with chalk, and you intend to use lime (and vice versa), the surface must be thoroughly cleaned of old paint.”

Dyeing process

Features of applying decorative composition

Before painting the inside of the bathhouse, you should select the tools used for this purpose. After all, the quality and appearance of the surface also depends on this.

There are two main options:

- Spray. Thanks to it, you can paint the surface as quickly and efficiently as possible. In addition, this method practically does not raise wood fibers, so the walls will not need to be thoroughly sanded after treatment.

- Brush. Despite the seeming archaism of this device, many experienced craftsmen advise using it, especially when applying the base layer.

Paint brush

Work order

Painting the inside of a bathhouse begins with purchasing the necessary materials and equipment.

For ease of presentation, the process itself is divided into several stages:

- Prepare the area for work. Considering that you will have to paint not only the walls, but also the ceiling, you should make sure that there are stools, stepladders or scaffolding that allow you to gain access to any point in the room.

- Clean the surface. This phase is very important. You should sand the wood very carefully so that when you run your hand over it, you don’t get a splinter in your palm and feel a smooth surface. A vacuum cleaner or damp cloth will help get rid of dust and sawdust. For best results, you can treat the surface with white spirit.

- Apply a base coat of paint or varnish. Wait until it dries and sand the surface again with fine-grained sandpaper.

- Cover the wall with a second layer, for which it is better to use a sprayer. Before doing this, you need to cover the areas that will not be painted with paper and masking tape.

Before painting, you need to thoroughly clean the surface

Proper processing of lining

Having decided how to cover the lining in the steam room of the bathhouse, you can proceed to the processing itself. To perform high-quality impregnation that will last a long time, we recommend that you read the following instructions:

- Processing lining in a steam room begins with preparing the wood itself. Clean it from various contaminants with sandpaper or other suitable method. It is also recommended to wash the boards with an aqueous solution of soda (300 g of soda per 10 liters of water);

- Next, you need to degrease the surfaces. Remember that not only the lining itself is impregnated, but also the frame to which it is attached;

- Sand surfaces with pumice to obtain a smooth finish;

- Next, you need to apply an antiseptic that will protect the wood from fungus and mold;

- Now you can saturate the paneling. When choosing impregnation for the dressing room, pay attention to the humidity of the air in it, as well as the temperature of the steam. If the indicators are approximately equal to the indicators inside the steam room, then it is necessary to use the same impregnation.

By doing all the work correctly, you can achieve an excellent result, as in the photo.

If you decide to paint wood, then you next need to decide how to paint the lining in the steam room of the bathhouse. Often, a special acrylic varnish is used for this, which can withstand high temperatures and does not release toxins, but special paint can also be used.

To paint the lining with high quality, you must follow certain rules:

- Painting of the lining is carried out in warm and dry weather.

- You can paint with a roller or brush, moving them parallel to the wood fibers so as not to leave streaks on the surface.

- Stir the paint thoroughly before applying to obtain a uniform color.

- Apply the paint in a thin layer - this will allow you to achieve the best coloring result.

Important nuances and recommendations

When painting the inside of a bathhouse, you should not skimp on finishing material, since it not only allows you to get the desired interior, but also protects the structure itself from negative factors, such as fluctuations in temperature and humidity. It is optimal to apply one coat of paint, wait for it to dry, and then repaint. The end surfaces need to be painted inside a little more thoroughly - up to 3-4 layers, since they absorb paint very intensively. If, after applying the first layer of paint, visible irregularities, gaps or roughness appear on the surface, they must be removed first by sanding and then by applying 2-4 layers of paint.

The log house and lining can be coated with waterproof varnish

So, painting the walls from the inside in a bathhouse is an extremely important process that allows you to achieve not only pleasant aesthetic results, but also significantly extend the life of the room itself. Protected wood will slow down the processes of destruction of its structure, which will avoid repairs for a long time.

Manufacturers

Bath paint is produced by domestic and foreign manufacturers. Its price depends on the material used and the quantity in the jar.

Belinka

The manufacturer's product range consists of paints, glazing compounds, varnishes, and impregnations. They have a wide range of colors, which allows you to bring any design idea to life. When using materials, the structure of the wood is preserved. Belinka produces polyacrylate paints that have water-repellent and vapor-permeable properties.

Tex

Paint from the Russian manufacturer Tex has protective qualities, which guarantees an increase in service life. The company produces soil and glaze antiseptics, drying oils, wax compositions, and fire-retardant impregnation. This allows you to choose an acceptable option for painting the bathhouse.

Saikos

The compositions of the German manufacturer are developed on the basis of natural oils and waxes. This ensures the preservation of the structure for many years.

What types of paints are there?

Universal fire protection products, as the name suggests, perform the functions of an antiseptic and a fire retardant at the same time.

Some compositions have a tinting property, or require subsequent painting and act as a primer. Along with impregnations, there are varnishes and paints that perform the functions of fire protection and protection against insects.

The purpose of the primer is to strengthen the wood structure and enhance adhesion (“sticking” of paint to the surface being painted). Some primers contain bioprotective components. When choosing a primer, you must follow the paint manufacturer's recommendations: the compositions must be compatible.

Stylistic design of the dressing room

Having finished the interior with wood, you can choose an interior option that is close in spirit:

Visiting a bathhouse with friends and relatives is a special event. Such a vacation involves a radical change of scenery and relaxation. Therefore, choosing a style for a dressing room is an important point, which is based on individual preferences.

Original interior and dressing room design

Many people can do the interior decoration of a bathhouse. The technology for cladding walls, ceilings and floors must be followed. This will create and maintain a healthy indoor microclimate. For interior decoration, the owner can use his construction experience, and the hostess can use her design skills. Joint creativity will be a special source of pride in front of friends and relatives.

Source

Coating instructions

When painting stoves yourself, it is important to follow the sequence of operations and adhere to the technology, then the bathhouse will be protected. When painting stoves yourself, it is important to follow the sequence of operations and adhere to the technology.

When painting stoves yourself, it is important to follow the sequence of operations and adhere to the technology.

Tools and materials

In addition to paintwork materials and brushes, you will need sandpaper or a metal brush to remove rust, and a solvent to degrease steel. It is necessary to cover the floor and wall so that there are no smudges.

In addition to paintwork materials and brushes, you will need sandpaper or a metal brush to remove rust, and a solvent to degrease steel.Surface preparation

The metal is pre-cleaned to a metallic shine. After removing dust, wipe the surface with a solvent.

The metal is pre-cleaned to a metallic shine.

Work algorithm

Mix the paint before use, start painting from hard-to-reach places, then cover the remaining areas. Coatings are applied in one layer, unless otherwise specified by the manufacturer.

The paint is mixed before use.

How long does it take for the coating to dry and after what time can it be heated?

It is better to wait 5 days after painting, only then start lighting the stove. Paint for a metal stove in a bathhouse dries on average from 72 to 96 hours, depending on the plasticizer.

It is better to wait 5 days after painting, only then start lighting the stove.

Interior decoration of the dressing room

The bathhouse is a place for relaxation and restoration of health. Therefore, finishing the dressing room with block house and stone is becoming increasingly popular. This is due, first of all, to the environmental friendliness and safety of the material for the health of vacationers. Bath finishing technology has its own characteristics. To perform high-quality installation with your own hands, you should familiarize yourself with it.

An example of a classic interior decoration of a timber dressing room

A little about the floors in the waiting room

Agree that it is unpleasant to step on a cold, not necessarily concrete, floor with warm feet. Selecting the right materials for a dressing room is not as easy as it seems. The dressing room is a place where people run out in negligee, and from which moisture gets onto the floor, spreading through the holes and cracks. It refers to a space where there is high humidity and evaporation. The floor surface should be comfortable, warm, non-slippery when wet, and promote health.

Wooden floor installation

It is made with first or second grade wood, well dried and without traces of fungus and parasites. The humidity of boards made from pine or larch should be no more than 10%; logs are selected according to the same criteria.

Attention: Wood of the second, sometimes third grade is used as beams or logs.

Which wood is best for a dressing room?

The main advantage of finishing a dressing room with wood over its more modern artificial “brothers” is that, in addition to good performance qualities, this natural material is capable of releasing an aroma with certain healing effects. Therefore, let’s return to the classics and consider which wood to choose so that the finishing of the dressing room inside meets all the parameters of a proper bathhouse:

Selection of materials or what they offer

The important point, as presented in the video, is to create a relaxing, comfortable and pleasant atmosphere inside the room for long conversations with friends. Preference is given to the traditional, original Russian style of finishing the bathhouse. Deciduous wood (birch, linden, aspen) and coniferous (spruce, pine, fir), the presence of a samovar, spoon, matryoshka, drying bag, bagel. The waiting room must meet certain requirements:

Attention: The dressing room is arranged with shelves for shoes, with comfortable seats; if the bathhouse is heated with coal, you need a special box with a lid and a space around the box that is convenient for cleaning.

The materials for finishing the dressing room are not as important as when finishing a steam room or sink (see Interior finishing of a bathhouse sink using different materials); panels made of coniferous trees, for example pine panels, can also be used. The temperature in the dressing room is low and there is no need to worry about resin discharge. You can order the finishing of the dressing room to specialists, but there is a second option, doing the work yourself, which is much preferable, and the price is lower, and the savings have never hurt anyone. Pine panels emit a pleasant aroma that has the smell of pine needles and has a beneficial effect on the human body. Instructions for performing panel installation work are provided below:

Headlining

The most suitable option is to trim it with clapboard. The technology for installing a false ceiling is similar to the process of finishing walls with wood. Maintaining a technical clearance for ventilation of the cladding will extend its service life.

The ceiling is the weakest point in the dressing room. Warm humid air from the steam room and temperature changes are the cause of condensation on it.

Therefore, waterproofing is a must. The recommended thermal insulation material is mineral wool. Video instructions for finishing the ceiling in the dressing room.

How to properly heat a sauna

It is no coincidence that since ancient times a good bath attendant has been valued “worth his weight in gold.” So, the temperature regime is directly dependent on how correctly the bathhouse was heated. Here is an example of a simple but correct fire method:

- We prepare several types of firewood: aspen, pine and birch.

- The bathhouse should be heated with pine firewood, since pine is a resinous tree, its smoke leaves a layer of soot on the walls of the chimney and the stove itself, for this reason the next step is to add aspen firewood, they do not produce much heat, while aspen smoke perfectly cleans chimneys;

- During the heating of pine and aspen firewood, the air in the bathhouse, the stove and the stones warm up a little, usually to a temperature of 10-15 degrees, in a medium-sized and well-insulated bathhouse;

- Then medium-sized birch logs are laid;

- At the end of the firebox, birch butts are laid; they will give heat to the stove, which will allow the created temperature regime to be maintained for a long time.

Speaking in conclusion about what temperature should be in the bathhouse, we can answer with great confidence that it is within 60-120 degrees Celsius. To monitor temperature and humidity, you can purchase a thermometer and moisture meter. And we remind you that with a properly constructed sauna and heater, you will feel comfortable even at high temperatures. Help you build and design your own forge of health and longevity. Warming you up, as they say, to the “bones”.

Wall decoration

For installation of any type of coating, it is recommended to provide insulation, waterproofing and, if necessary, a ventilation gap.

Block house and clapboard finishing

Sheathing material of this type requires the construction of a bathhouse frame, which makes it easy to waterproof and insulate the walls. It is worth noting that the lining is often mounted vertically, and the block house horizontally. Therefore, the guides for the first finishing material are mounted horizontally (perpendicular to the installation), and for the second type vertically.

The process itself can be divided into the following stages:

This technology is aimed at maximizing heat retention, and the ventilation gap allows the cladding to be ventilated. There should be no difficulties with clapboard covering. It is mounted using hidden nails or clamps. Fastening materials are selected with an anti-corrosion coating.

Additional components are produced for the lining: corners, plinths, connecting strips. Coniferous wood can also be used, unlike a steam room.

When installing block houses, difficulties may arise with corner joints. They will have to be cut at an angle of 45˚. Interior finishing of this type is similar in method of fastening to clapboard cladding, and its appearance resembles rounded logs. It is not recommended to cover the walls in the dressing room with protective compounds, especially the one that borders the steam room.

Facing with tiles or natural stone

If the bathhouse is made of logs or timber, then you will first have to cover the walls with plasterboard, which will make it possible to insulate and waterproof them.

The installation technology is as follows:

This cladding is more suitable for the wall adjacent to the steam room. Once heated, it will transfer heat to the rest room for a long time and evenly. The decoration of the dressing room with a block house and stone looks interesting. The roughness and simplicity of the lines makes the interior especially cozy. In the case of brick buildings, the outside walls should be insulated using a ventilated façade system.

Insulation scheme for a brick bath

It is good to waterproof the inside before covering it with wood. These measures will significantly reduce heat loss during operation and protect the structure from destruction under the influence of moisture.

service life of wallpaper in an apartment

Types of floors

The baths themselves are different - summer temporary huts with a pouring floor, solid all-season buildings made of wood, brick, foam blocks or frame. But in general, we can say that the floors can be either wooden or concrete (in the steam room, provided that gratings are installed).

Concrete floors are often turned into tiles in steam rooms and sinks, and they don't need painting, so we won't cover them in this article.

Wood

Wood, especially in such a humid environment as in a bathhouse, needs protection. There are several types of protection:

- impregnation;

- varnishes;

- paints.

Impregnations

These are compounds that penetrate the wood to a certain depth, performing one or another function. Some impregnations protect against mold and insects, others make the wood non-flammable or difficult to ignite, and still others make it waterproof. You can find out more about them here.

INTERESTING! Nowadays, many impregnations are made according to the “two in one” principle - it is both protection against moisture and an antiseptic. But fire retardant (from fire) must be purchased separately.

Lucky

As for varnishes, it is clear that you can use them not in all rooms, but only in conditionally “residential” ones. Although, some owners also paint the floors in the steam room and washing room with varnish.

Professionals say this: alkyd varnishes smell very long and very unpleasant, although they are inexpensive, water-based varnishes smell much less, both in strength and in time, and are much more pleasant to use.

BUT! A dispute immediately arises over imported or local products. There is an opinion that water-based varnishes are only good from Western Europe, while in the CIS and Eastern Europe they are of poor and average quality.

The price of Western European varnish “bites painfully” if the bathhouse as a whole is budget-friendly. And since few people live in the bathhouse during the period of its construction and finishing, there will be no one to be poisoned by alkyd vapors. True, the smell will completely go away only after a few months. But the price is low.

You can also paint a wooden floor in a bathhouse with “vodnik” - a water-based varnish. Remember that the addition of polyurethane gives more hardness and wear resistance to your coating. Acrylates are less resistant to wear. But again, who goes to the bathhouse a lot and constantly? So these varnishes are also suitable.

Paints

- water;

- organic solvents.

The latter smell very strongly and for a long time. Organic solvent paints include:

- enamels;

- alkyd paints;

- oil paints.

Only acrylates are soluble in water; after drying, they polymerize and no longer dissolve in water.

Acrylates are more expensive than paints based on organic solvents, but they are safer than them, have no odor that can cause poisoning, and dry quickly. But you need to paint in two layers.

For dry rooms, any type that suits your liking and pocket is suitable.

Concrete

Actually, an alternative to laying tiles could be the decision to paint the concrete floor in the bathhouse.

What does paint do? Concrete without any coating will gradually deteriorate under constant exposure to water. Of course, this is not a quick process if the cement is of high quality, but it is better not to have reasons for repairs for as long as possible.

In general, paints for concrete are quite specific; on sale you will find the following varieties:

- epoxy;

- acrylic;

- polyurethane.

ADVICE! Since we are talking about floors exposed to water, pay attention not to those varieties that are intended for industrial premises and are characterized by increased wear resistance to abrasion, but to those that, for example, are created for covering concrete pools - an excellent option for washing and steam rooms

You may be interested in more detailed material devoted to the analysis of all types of paints that can be used in a bathhouse.