Ventilation in a bathhouse is not only comfort, but also an urgent necessity. It is needed both during and after bath procedures:

- During the process, it is important that no one gets burned . The danger of carbon monoxide poisoning always exists - this is the result of incomplete combustion of fuel. Therefore, ventilation is necessary for the safety of people in the bathhouse.

- In addition, the air that is inhaled and exhaled becomes “waste” and must be removed, replacing it with new air with a higher proportion of oxygen.

- regulate the temperature while monitoring the condition of people using ventilation, especially when you need to do this urgently.

- Any stove runs on oxygen (combustion is oxidation), so it also needs ventilation. And with the right device, you can also get fuel savings .

- And finally, drying after, on which the durability of the structure, especially its wooden parts, directly depends. Ventilation can be a good prevention of fungi and rotting .

At the same time, bath ventilation is quite complex and varied in design. Of course, the issue can be reduced to financial investments, but in reality you just need a good ventilation specialist who will find the optimal solution in each specific case. We will consider all the possibilities and features of the ventilation device in the bathhouse.

Is ventilation necessary in a traditional Russian bath?

In the old days, Russian baths were not specially equipped with a ventilation system, and served well for many years. Air exchange in them occurred naturally. This was facilitated by log walls without insulation or cladding, between the crowns of which air leaked. As well as brick wood stoves with a blower, fired directly from the steam room, the chimney of which served as an exhaust hood.

Nobody thought about how to do ventilation in the bathhouse, and there was no need for it, since the bathhouses were small and consisted of a maximum of two rooms - a dressing room and a steam room, in which they steamed and washed. For such small buildings, the burst air exchange that occurs when the door is opened when entering and exiting the steam room was sufficient. And at the end of the procedures, it and the stove door were left ajar until the room was completely dry. Damp warm air was drawn into the chimney.

In the Russian bathhouse there was no special air exchange system Source dveribani.by

The possibility of burst ventilation can be provided in modern baths if you make an opening window on the wall opposite the door to the steam room, and diagonally from it. They are opened briefly before the next batch of steamers enter, only to freshen the air, but not to chill the room.

If you are building a Russian bathhouse without any frills, many separate rooms, with a traditional stove, you don’t have to think too much about how to make a hood in the bathhouse so that there is no dampness. A door, a small window, a good stove draft and mandatory ventilation after everyone has washed are enough.

Pipe channel

It is allowed to make a ventilation duct from asbestos-cement or plastic pipes with a diameter of 12.5 - 15 cm. For forced ventilation, pipes with a cross-section of 10 - 12.5 cm are required. They are mounted for smoke and ventilation ducts in brickwork strictly vertically, fixed with sand-cement mortar.

If the brick wall is half a brick thick, then using pipes for ventilation is the optimal solution. In this case, the pipes are not placed in the masonry, but between two walls, sealing the joints with mortar and plastering.

When designing a house in brick walls, the deployment of ventilation ducts is provided for in the drawings. Otherwise, you will have to install overhead channels.

The need for ventilation in modern baths

Modern baths have become completely different over the last century. Today they are built from different materials, not just logs. They are clad on the outside, insulated and clapboarded on the inside, literally sealing the building. They make several isolated rooms - a steam room, a washing room, a locker room, a relaxation room, a bathroom, and sometimes a swimming pool and a kitchen.

Plan of a modern bath complex Source remoo.ru

The principles of heating have also changed: stoves are often made with a firebox from a dressing room, and many people prefer electric heating devices, which do not require a chimney, to work with wood. And in order not to go outside in bad weather, such complexes are often attached to the house or placed directly in it.

The desire for convenience, comfort and beauty can lead to undesirable consequences and even harm your health if you do not think about how to properly ventilate a bathhouse. The most common consequences are carbon monoxide poisoning, rotting of wooden structures and the appearance of mold, the spores of which are not at all harmless.

How much does it cost

When planning to make ventilation in the sauna with your own hands, you need to know that its cost will cost approximately 24-38 thousand rubles. Everything will depend on the cost of components.

- A ventilation valve can be purchased for 650-1500 rubles.

- A grill for 300-400 rubles.

- Supply and exhaust system for 18,500 rubles.

Creating a high-quality air exchange system is an important part of the operation of a sauna, so the selection of its components, as well as the installation process, must be approached thoughtfully and in a timely manner.

Methods of natural ventilation

Dense and heavy cold air always sinks down, and heated air is displaced by it and rises. This is how moving air currents arise in rooms with any heating device. But without an influx of fresh air, it is not renewed, but simply moves.

If you make a hole in the lower part of the wall, air from the street will flow through it if its temperature there is lower than in the room. And through the hole at the top it will be pulled out. This is natural ventilation.

Scheme of the movement of air masses in a heated room Source e-derslik.edu.az

This elementary law of physics is used when thinking about how to make ventilation in a bathhouse with your own hands without using any mechanisms. As a rule, natural ventilation without forced air intake is quite enough for a small bathhouse. Unlike residential premises, where in summer it can be as hot as outside, the temperature in the bathhouse is always higher.

But it is necessary to maintain a comfortable temperature for receiving procedures, and in such a way that drafts do not form and there is no sharp change from heat on the shelf to cold on the floor. To do this, air flows must move along a certain trajectory, which is set by placing supply and exhaust openings in specific locations.

Ventilation through the chimney

The easiest way to solve the problem is how to make ventilation in a steam room if it contains a furnace firebox with a blower. It will serve to remove exhaust air through the chimney, in which draft occurs during fuel combustion. But this scheme will only work if there is an influx of air from outside.

Ajar door to the steam room Source prodverivdome.ru

Inflow can be ensured in the following ways:

- from time to time slightly open the door to the steam room;

- make a small gap of 1 cm in the door or leave the same gap between the door and the floor;

- if the log house of the bathhouse is not sheathed, such a gap can be left between the first crowns located below the floor level, provided that the boards are not laid tightly;

- make a special opening in the wall opposite the stove at a height of 20-30 cm from the floor.

In any of these cases, the cold flow penetrating into the room moves towards the heat source and displaces the air already heated by it upward. As it moves, it warms up the entire room, gradually cooling down and descending. Here it is drawn into the ash pit and discharged through the chimney to the street.

Air movement pattern Source i.ibb.co

Note! This scheme only works if there is draft in the chimney, which occurs when wood burns. In the absence of combustion, air exchange practically stops.

This method of making ventilation in a steam room is not the most reliable and effective, since most of the fresh air is immediately drawn into the stove. Therefore, even during the construction of the bathhouse, it is advisable to think through other options for installing vents in the walls.

See also: Catalog of projects of houses with a bathhouse made of timber

Ventilation through vents

To ensure that air exchange does not depend on the operation of the stove, special openings are installed in the walls for air inflow and outlet. It is guaranteed to work subject to the following conditions:

- the exhaust hole is placed under the ceiling of the bathhouse - where heated air accumulates;

- the supply opening should be located low above the floor on the opposite wall, the closer to the stove, the better, so that the cold currents drawn in do not hit the legs;

- the optimal vertical distance between the vents should be 150-200 cm;

- The cross-section of the exhaust opening must be larger.

Cold air immediately enters the heating zone Source ventilation-conditioning.ru

The ideal location of the supply air is behind the stove. Entering the room, it immediately begins to warm up, displacing the already hot air mass upward and towards the hood. Therefore, cold streams and levels with noticeably different temperatures do not form in the steam room.

If you want to know how to properly make ventilation in a bathhouse and steam room, provide this diagram at the design stage and before installing the stove. It is also important to make sure to make a difference in height between the ventilation holes. If they are located at approximately the same level, this will lead to a draft and rapid passage of fresh air in a straight line, without circulation in the room.

Advice! It is best to make an exhaust vent directly above the shelf to allow hot air to flow into it and quickly remove waste materials.

Natural ventilation hood Source stroyfora.ru

In order to be able to regulate ventilation or limit the access of too frosty air into the steam room, you need to provide covers or valves for the vents.

The benefits of natural ventilation are that it works without the need for devices that require mains power and can break down. Its installation and operation do not require large expenses.

Importance of the system

Even in ancient times, architects understood that the lack of fresh air in a bathhouse could quickly cause the appearance of dampness, mold, and fungal spores, which inevitably leads to the destruction of the structure. That is why, even in ancient times, builders left small gaps between the logs - they helped improve air exchange and high-quality ventilation. Nowadays, these primitive technologies have been replaced by modern, efficient systems that require effort, money and time for planning and installation.

Some homeowners skip this stage of work, but this is a very big mistake, since after a couple of years such buildings will simply become unusable due to constantly high humidity, and if the bathhouse is built using frame technology, then its service life will be even shorter. The first sign of the destruction that has begun will be a musty smell, which will be most noticeable when the stove is lit. This will negate any pleasure from the procedure. Being in such a steam room is not only unpleasant, but also quite dangerous for life and health, since carbon monoxide, fungal and mold spores accumulate in the air, which provoke the development of dangerous diseases of the bronchopulmonary system.

Effective ventilation in a bathhouse must necessarily comply with basic requirements and safety principles:

- Correct redistribution of air masses. As you know from a school physics course, high-temperature air masses rush upward, while cold ones, on the contrary, descend. Therefore, the flow should be directed so that the feet do not freeze and the sunbeds have a comfortable temperature.

- Maintaining a given heating level in the steam room. Ventilation under no circumstances should interfere with the functionality of the steam room, that is, cooling the air is unacceptable.

- Use of water-resistant materials. To arrange steam rooms and organize ventilation in them, it is necessary to use materials that are resistant to humidity and elevated temperatures.

The main difficulty in creating an effective air exchange system is that it is faced with the task of quickly removing hot humid air from all areas of the bath, but at the same time it is necessary to prevent the temperature in the hot steam room from dropping, so modern systems, as a rule, use the installation of hoods that do not allow cold air to blow in from the street. The presence of such systems is of fundamental importance for buildings equipped with solid fuel and gas stoves, since such schemes require a large volume of oxygen to support the combustion process.

Methods for installing forced ventilation

It is not always possible to provide natural air exchange of acceptable intensity. Such ventilation does not work well both in bathhouses with a large number of rooms, and in those that have a common wall with the house or are built into it.

In such cases, they resort to a device for forced injection and/or release of air, artificially creating flows or forcing them to move faster. To do this, fans are built into the system - exhaust or supply.

Supply fan installed in the corresponding hole Source engvent.ru

See also: Catalog of companies that specialize in the construction of baths, ventilation and air conditioning equipment

Depending on the type of object, one of the following types of forced ventilation is used:

- supply and exhaust when both types of fans are used. A rather rare option in private baths, since they do not require high ventilation intensity;

- supply , with mechanical suction of air through the supply opening and increasing the pressure in the room, due to which the exhaust air is squeezed out into the hood. Its main drawback is the too active supply of cold air masses;

- exhaust , the operating principle of which is the opposite: a fan in the exhaust hole forcibly removes polluted air outside, creating a vacuum inside, forcing clean air from the street to fill the vacated volume, entering the supply hole.

If you choose how to properly make a hood in a bathhouse, then preference should be given to the last option as the most optimal.

Fan on the exhaust vent Source stroi-remontirui.ru

Fan selection

Any mechanisms operating in a bathhouse must withstand difficult operating conditions: high humidity, heat, frequent temperature changes. Therefore, the fan is selected primarily based on these requirements.

Technology for laying ventilation ducts

When there is a plan for arranging a ventilation system in a house, it remains to be implemented. To do this, all the components of the future system specified in the previously drawn up diagram are purchased. Each home will have its own characteristics.

For natural air flow inside the house, windows with micro-ventilation or wall valves should be installed

When installing natural-type systems, ventilation shafts are first laid out in the wall - separately for the kitchen, furnace/boiler room, bathroom or bath and toilet rooms. Then decorative grilles are installed. In order for these channels to fulfill their role, one must not forget about the permissible height above the roof level.

As an option, you can install ceiling grilles in the rooms if the attic has a window for free air circulation

If you need to arrange mechanical or mixed type of ventilation in the house, then you need to install ventilation pipes. The attic space is used for this. When this is not possible, ventilation ducts are installed under the ceiling of the house. Then they have to be disguised in any convenient way.

Supply and exhaust openings in ventilation pipes are decorated with air distributors. If necessary, the receiving and ejection equipment can be equipped with an electric heating system. If necessary, check valves should be installed, carefully treating the joints with sealant.

Ventilation pipes are secured with clamps or other fasteners provided for these purposes. All joints are reliably sealed. In the future, this will be the key to excellent operation of the entire system.

Pipes can be used with rectangular or round cross-section. The diameter of the ventilation pipes is selected according to calculations

Fans are installed according to the instructions supplied with them. If complex systems are to be installed, then the equipment is installed as recommended by the manufacturer. Otherwise, you may lose warranty service.

Video description

It is easy to find units on sale that are specifically designed for baths and saunas - these are the ones shown in this video:

It is also necessary to decide on the power of the device, since excess power is completely unnecessary here and is even contraindicated. This is easy to do if you know the volume of the ventilated room and the air exchange rate recommended for baths, which is 5.

For example, for a 2x3 m steam room with a height of 2.2 m, the fan power is calculated as follows:

2 x 3 x 2.2 x 5 = 66 m3/h

Advice! Buy a device with variable adjustable power and a timer that will periodically turn the device on and off. You can fully automate the system by including humidity and temperature sensors configured to certain values, upon reaching which they will start the fan.

If desired, you can assemble an automated system with remote control Source nevoton.ru

Such devices, depending on the design, can be installed directly in the exhaust vent (duct fans) or on the wall behind it.

Installation

You can make a pipeline for ventilation of various bath rooms with your own hands. To do this, you need to draw up a project, prepare consumables, tools, and perform work.

Preparation and design

Principles for assembling a ventilation system:

Air should enter and exit the premises in equal volumes

To regulate the flow, it is recommended to install special dampers. The deflector cannot be placed higher than 50 cm above the roofing. For a forced system, it is important to install a grill over the outlet channel. For saunas, it is better to combine a forced ventilation system with a natural one. Installation rules:

Installation rules:

- Hang doors on the ventilation windows, which will be equipped with special dampers.

- Until the room warms up, the valves must be closed completely.

- The hood should be located at a distance from the ceiling so that dampness does not accumulate in the rooms.

- Vents must be made after the decorative finishing of the walls.

Materials and tools

Consumables, tools:

- metal or wooden grilles for exits and entrances of ventilation lines;

- tow or moss for sealing cracks in the walls of the log house;

- galvanized steel sheets;

- special fan;

- bolts, bars;

- ventilation valves;

- boxes for ventilation;

- mosquito nets;

- sealant, mounting tape;

- hammer, pliers, metal scissors;

- grinder, drill, screwdriver, chainsaw.

- clamps, fasteners.

Step-by-step execution of work

To assemble a pipeline for ventilating bath rooms, you need to select a working scheme:

- Place the entrance window at a distance of 50 cm from the floor next to the stove. The exhaust vent with fan is located 30 cm below the ceiling on the opposite wall.

- Two windows should be placed on the wall opposite the stove. The first should be located 30 cm above the floor, the second - 30 cm below the ceiling.

- Place the inlet hole at a height of 20 cm from the floor behind the stove. The second window should be placed on the opposite wall, at a distance of 20 cm below the ceiling. It is recommended to equip it with a hood.

Video description

The following video shows an example of such a combination of ventilation and heating:

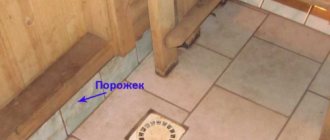

- If the floor in the steam room and washing room is made in the form of a flooring with slots on a concrete base, an exhaust duct can be made under it by combining the underground of the two rooms and equipping it with a fan. In this case, it is simply necessary, since the trajectory of the movement of air masses is complex, and natural ventilation is unlikely to cope with its task. A channel through a hole in the foundation removes moist exhaust air to the street. The supply opening should be located as close to the stove as possible so that the cold air begins to heat up immediately after entering the room. If openings are made in the walls between adjacent rooms, it will circulate throughout the entire volume, simultaneously warming both the washing room and the rest room.

Scheme of ventilation of a bathhouse through the underground Source youtube.com

Types of ventilation systems

The ventilation device in the bathhouse varies according to the design of the room and its total volume. Natural ventilation is based on the difference in temperatures and pressures inside and outside. In order for it to work efficiently, air input is organized near the stove, at a level of 25-35 cm from the floor. The exit hole is made on opposite walls approximately 15-25 cm below the ceiling

But it is important to take into account that this scheme is not good enough for steam rooms, since it is relatively cold down there, and always hot at the top

Natural air movement in such a situation is too difficult to organize; you will have to very carefully and carefully arrange the components of the ventilation system. A forced circuit does not always require the use of electronic control systems, with complex panels and so on. There are simpler options when ventilation windows, placed in a special way, are complemented by an exhaust fan. The combination of such components is especially effective when the bathhouse is located inside the house, the windows are not placed inside the outer wall, but are connected to the exits by a long box for ventilation. Duct fans must be selected very carefully, because their operating conditions in baths differ from normal parameters.

The peculiarity of such devices is the increased waterproofing of electrical circuits and main mechanical parts, and their adaptation to operation at high temperatures without consequences for equipment. The state of supply ventilation and its arrangement in each room is adapted to individual characteristics and the type of bathhouse. It follows that the time spent on calculations and thinking through the project is not wasted - it will save a lot of money and time, and get the optimal result sooner.

As is already known, the majority of projects involve the location of introductory windows near the stoves at 0.25-0.35 m from the floor. With this design, the stove transfers heat to air coming from outside, and a flow appears moving in the direction of the hood. Having covered the entire distance, the hot and street flows ultimately cover the entire volume of the steam room, and the area where the top shelf is located is heated the most.

In the second option, by installing an exhaust fan, you can mount the inlet and outlet openings on the same wall. The air flow is directed first in the direction of the heating device. Having received a thermal impulse, it begins to rise to the ceiling and moves in a wide arc that covers the entire room. This approach will be effective if the bathhouse is built into the house and has only one external wall, and there is no need to install a ventilation duct.

If a bathhouse with a leaky floor is created, the introductory window is placed in the same place as in the first case, directly next to the stove. When the heated air gives off heat in the upper part of the steam room, it cools and sinks to the floor, leaving through the holes in the flooring. This technique improves the evaporation of water accumulating below and allows you to delay the failure of the wooden floor. The hood is placed either in the next room or in isolated channels that do not allow air to return to the steam room. The complexity of the flow path makes the use of a fan mandatory. This option is used very rarely, since it is not easy to calculate everything accurately and provide details properly.

Another type involves a continuously operating furnace, the vent of which replaces the hood. For inflow, a window is made under the shelf opposite the stove itself and at the same level. Cold air displaces the heated mass upward, and when the parts of the flow that have given up heat descend, they go into the ash channel. There are even more complex systems, when a pair of inlet and a pair of outlet ventilation windows are placed (necessarily with a forced type of circulation). It is quite difficult to regulate complex complexes, but their effectiveness is higher than in simple cases.

The Bastu system is the placement of supply openings (with adjustable valves) behind or under the stove. The organization of vents under the stove is not necessary, although it is highly desirable. Through these openings, air enters the room from the underground part of the bathhouse, which is connected to the outside atmosphere by the foundation vents. When a bathhouse is made in a previously prepared room, you need to choose a room with a couple of external walls; when preparing the basement, choose an angle that meets the same requirements. The dimensions of the inlet and outlet openings are calculated according to general rules.

Arrangement of supply and exhaust openings

When designing a bathhouse, you must immediately provide for the location of vents in the walls or foundation. It will be easier to make them during the construction process, rather than punch them after completion. In the case of forced ventilation, their dimensions are not particularly important, since a fan of calculated power will provide the necessary air exchange.

It is easier to lay a piece of pipe when pouring it into the foundation than to drill a vent in hardened concrete Source readmehouse.ru

Another thing is how to properly make ventilation in the steam room of a bathhouse if the use of mechanisms is not provided. For good natural air exchange, the cross-section of the supply opening must be sufficient. It is calculated according to a standard that regulates the dependence of this section on the volume of the room. For each cubic meter of ventilated space it is necessary to install a vent with a cross-sectional area of 24 cm2.

If we take our example with a steam room 2x3x2.2 m, then its volume will be equal to 13.2 m3. Multiplying it by 24 we get 317 cm2. To determine the diameter of a round hole with such an area, use the converted formula for the area of a circle: divide it by Pi and take the square root from the resulting value. The radius of our hole is equal to 10 cm, so its diameter should be 20 cm.

The radius is found using the inverse formula for the area of a circle Source ds04.infourok.ru

It is even easier to find the length of the side of a square hole - it will be approximately 18 cm. The sides of the rectangle are also selected in accordance with the cross-sectional area - for example, 10x32 cm.

To arrange round vents, steel or plastic pipes of the appropriate diameter or slightly larger are used, and the channels in the rectangular wall are made in the form of wooden boxes made of boards.

The exhaust hole, as already mentioned, should be made larger than the supply hole. The gaps between the wall and the walls of the channel are filled with tow, other insulation, or foamed.

Another important point in such a matter as making an outlet in a bathhouse is protection from the outside from the penetration of insects, rodents, and debris into the channel. To do this, cover the hole from the outside with a mesh or lattice.

Ventilation grille with insect mesh Source www.video-sovety.ru

And inside, to regulate the intensity of the air flow, valves are installed, partially or completely blocking the holes when necessary. For example, in winter, the draft, due to the huge difference between the low temperature of the street air and the high temperature in the bathhouse, increases so much that the cold currents do not have time to heat up from the stove and quickly cool the room. It is reduced using a valve, leaving only a small gap or completely blocking the vent for the duration of the procedures.

Where to place the cold air vent

The lower vent is responsible for the influx and supply of cold air. A pipe is laid under it during construction or a shaft is left. Bottom hole installation options:

- In the wall, opposite the stove.

- Under the sun loungers, you can’t see it there, and there are no drafts. However, to adjust the position of the damper, you have to bend down under the shelf, which is inconvenient. The situation is corrected by opening the upper outflow, and after the procedures both outflows are opened - both the upper and the lower.

- Behind the stove, if the stove is not installed in a wall and there is access to it. The cold stream immediately warms up, causing the coals to burn hotter.

Outflows are made either in the wall or in the ceiling, providing a place for them in the project.

Useful tips

In winter, it is better to avoid using supply fans because they tend to draw in too cold air. If the air outside is very dirty, special filters must be used. When calculating the required power of ventilation devices, it is worth focusing on the requirement to refresh all the air in the bathhouse in a maximum of 15 minutes. Supply and exhaust devices are ideal for the steam room, but in the waiting room and relaxation room you can safely limit yourself to the natural circulation mode

When choosing locations for vents outside the building, you need to pay attention to the aesthetic qualities of the structure; the same requirement applies to pipes leading outside, to aerator fungi and valves

If a swimming pool is equipped in the bathhouse, the air in this part should be 2-3 degrees warmer than in other parts of the room, and its humidity should not exceed 55-60%. The use of flexible air ducts is considered a much better solution than the use of rigid pipes. Taking into account all these recommendations, you can easily create a ventilation system with your own hands or have it checked by specialists.

To learn how to make ventilation in a bathhouse with your own hands, see the following video.