Approximately 95% of those planning to build a wooden bathhouse inevitably stop at the question: which is better - from rounded logs or from profiled timber (the remaining 5% focus on personal taste and do not look for alternatives). Despite the fact that these materials are more than a century old, discussions on this issue continue to this day.

This article provides a comparison of timber and logs, as building materials for a bathhouse, according to objective criteria. Most likely, after reading it you will make your choice.

Conditions for objective comparison

But first, let’s agree on what kind of log and what kind of timber we will compare with.

We reject the following options:

- debarked log;

- carriage (Norwegian hewn log);

- profiled log;

- glued logs;

- planed timber;

- laminated veneer lumber;

- forced dried lumber.

That is, we will compare a rounded log and a profiled timber made from solid wood. Humidity is natural .

Advantages and disadvantages during construction

timber

Bathhouse made of laminated veneer lumber

Deadlines. To build a log bathhouse from timber, it takes from 2 to 7 weeks. These are average statistics for a neat small bathhouse. The start-up period after assembly of the building depends on humidity.

Shrinkage. Depends on the material. Glued gives the smallest (1-2%). Profiled and dried, up to 5%, with natural humidity, up to 10%;

Labor intensive. When using profile timber, there is an option to build the “desired house” yourself, without involving competent builders. Well, let’s say in a company of 3 people, plus the necessary tools and available mechanisms.

Finishing. Again, it depends on the type of timber. If you use a profiled one, finishing is generally not needed. If you build it from ordinary non-core material, you will have to spend money not only on finishing, but also on caulking.

Log

Deadlines. With similar dimensions, a log bathhouse can be built in the same time. This is provided that the logs are already ready. However, you will have to wait about a year for the “ribbon cutting” with a broom under your arm.

Shrinkage. On average, over a year, the log house will “sag” by 8 - 12%

Labor intensive. It is not easy to build a bathhouse without qualified builders or an experienced consultant. There are moments, ignorance of which leads to bad consequences.

Finishing. You need caulking (more than once) plus sanding.

Results

Based on the results of all of the above, we can conclude that profiled timber for the construction of a bathhouse is objectively better . It is more technologically advanced, easier to work with, lighter and warmer than logs.

However, many people like rounded logs because of their appearance . And according to all the criteria described above, this material is not critically behind timber. Therefore, if you like a log, it is not only possible to build from it, but also necessary. Moreover, modern technologies and developments in this area compensate for many of the disadvantages of rounded logs - shrinkage, cracking and other advantages and disadvantages equally, so that it looks like an objective comparison)

Features of each material

timber

It is obtained from a log, processing it from all sides using sawing. As a result, the desired section is obtained. Common section shape: square or rectangle. A triangle would not be appropriate here.

Construction from profiled timber

Feedstock:

Usually coniferous species - pine, larch, fir, cedar. Less commonly deciduous - oak, birch, aspen, linden. I don’t want to force my opinion on anyone, but Siberian cedar is the best option. The smell alone is worth it... In the old days, for example, the log house was built from aspen, the beams to support the ceiling were made of oak, and the interior was made of birch. This spoke about the taste and capabilities of the owner.

Types of timber:

- Unprofiled. Classic timber, made from solid wood. Has regular straight edges.

- Profiled . The edges are equipped with grooves (ridges) for counter connection with a similar beam. Its use allows you to avoid caulking, as well as changes in the geometry of the building structure due to shrinkage.

- The carriage is the so-called half-beam . Only two opposite sides are cut from the log. The other two remain semicircular. A log frame made from a gun carriage looks attractive and deserves due attention.

- A few words about laminated veneer lumber . Its supporting structure is 50-70% stronger than solid wood, however, the price is much higher. You can read more about it here...

“Connoisseurs of traditional bathhouses may have questions about the environmental friendliness of laminated veneer lumber. And although all manufacturers assure you of complete safety, it’s up to you to decide.”

The key point is humidity. It is better to use one that has been dried in a heat chamber. It is more expensive, but allows you to avoid the consequences inherent in timber with natural moisture.

“It’s better not to order a finished log house, because some timbers may “lead” when drying and subsequently they will become a “propeller”, which means they will have to be changed.”

Log

Well, what can I say. It’s a log, it’s a log in Africa too. But let's figure it out.

Raw materials. The same as for timber. More often coniferous, less often deciduous lumber.

Types of logs:

- Rounded . Another name is calibrated. How are they different from ordinary ones? Initially, the log has a conical shape, but with the help of special machines the “extra” part is cut off and it becomes cylindrical, i.e. a given "caliber".

- Planed . Processed with an electric planer. In this case, the top layer is removed slightly (not like the rounded ones). However, the shape here is conical. In terms of operational parameters, it is more durable for a bathhouse than the above.

- Shaped . Its technology involves removing the top layer of bark. The log retains its natural resin content, which allows it to last much longer than a rounded one.

These are the main types of processing of logs for building a bathhouse.

“Some experts believe that “cylindering” violates the integrity of the fibers (since not only the bark is cut, but also the upper, most durable part of the tree) and there is a risk of premature rotting.”

“Knowledgeable people advise buying timber cut down in winter and preferably in northern latitudes. It initially has lower humidity and higher density. It’s not for nothing that the winter forest is considered the best.”

If we talk about a log house, then, according to experts, it is better to use material with natural moisture. Why? A log house made from dried logs will not shrink normally. It does not dry out as expected, but on the contrary, it swells. As a result, the logs begin to “stick out” from the building. In addition, a dry log on a construction site will begin to absorb moisture, which can cause it to bend.

There are no questions about the environmental friendliness of logs - a natural product (if it is a forest, not near a nuclear power plant).

“When purchasing a finished log house, be sure to check for numbering on the crowns. Otherwise, the assembly will turn into a game - “find an unknown puzzle.”

All. Go ahead.

Inertia: which walls retain heat longer

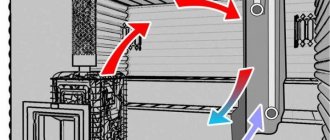

The ability of walls and ceilings to accumulate heat affects the duration of maintaining microclimate parameters acceptable for bath procedures, without additional firebox. A wall with a higher average material density and lower hygroscopicity accumulates more heat. Visiting the bathhouse in several sessions after one fire will allow you to:

- log bathhouse;

- thick-walled brick;

- and, to a greater extent, a bathhouse made of blocks of porous concrete with a predominance of non-communicating and, especially, non-through pores.

Walls made of a wooden frame, sheathed on both sides with lumber or panels, filled with insulation, are less massive than others, their density is small and average. With good insulation, they retain heat well, but do not accumulate it. When the air inside the bathhouse has cooled (through the doorway, windows, ventilation holes) and the firebox is finished, there is nothing in the frame bathhouse to heat it again.

Smooth out temperature changes in a non-inertial building:

- brick oven;

- internal partitions made of porous concrete;

- insulated floors with drainage via a drain.

Massive wooden walls (made of timber or logs), for the same reasons that the air enclosed by them takes longer to heat up, will maintain its temperature after the heat source stops working.

Information. According to SNiP, the difference in air temperature in the room and the inner surface of the outer wall should not exceed 4 °C.

The same goes for humidity. What will absorb excess steam and return it when there is a lack of it in the air, a frame bathhouse or a log house? The ability to create an inertial microclimate distinguishes timber products. Of all the wooden elements of a frame bathhouse - lumber - only the plank lining may not be insulated from steam.

Which one is easier to build?

A frame bathhouse is built faster and is easier to erect. Its design gives greater freedom for interior planning and finishing. This advantage is not the only advantage inherent in frame buildings.

The construction of a structure from a solid log is a more labor-intensive process, requiring significant effort and time.

Variety of architectural forms

Baths are usually built in a regular rectangular or square shape. For this form, it does not matter what technology was used to build the structure.

Photo from the Modultron company website

If we are talking about building an original shape - polygonal, with curves, complex shapes, with decorative elements, it is better to give preference to frame technology.

Constructing buildings of unusual shapes from timber is much more difficult and expensive.

Possible defects

If all stages of construction are carried out in compliance with technology, no defects should appear. The table below shows possible defects and ways to prevent or eliminate them.

| timber | Frame |

| In a timber building, cold can come from cracks at the joints of the crowns. They appear when insulation is of poor quality, or if the lumber initially had high humidity and decreased in size as it evaporated. | When constructing walls, cavities (cold bridges) may form. In a frame building, cold bridges can run across the entire thickness of the wall. To cover them, an additional layer of insulation is applied. |

| Solid lumber can dry out over time. Cracks appear on it. If treated incorrectly or untimely, bugs may appear in the tree structure. | If the insulation was installed incorrectly and not hermetically sealed, the vapor barrier was damaged and the material began to get wet, and the room would begin to rot from the inside. To avoid such problems, you need to properly arrange the ventilation system and use only high-quality materials for insulation. |

Important! Correcting defects in the walls of a frame bath requires opening the structure and removing the finishing. This is quite an expensive process!