Home / Types of ceilings / Wooden / Antique ceiling made of unedged boards - features and application

You can assemble a huge number of different designs from unedged boards. The edges of such boards have a natural shape and are not subjected to special processing, like their main surface. However, despite its outward appearance, you can even assemble a ceiling in a living room from an unedged board if you decorate it in an “antique” manner. In technical rooms, such coatings can be used in their natural form, without bothering to make the surface look beautiful.

Flaws

Even the best method of repairing floors has its drawbacks.

A rather specific drawback that antique-style wooden ceilings have is their susceptibility to pests. Partially, this problem is solved by treating all parts with a special impregnation, but in country houses it is rarely possible to completely get rid of pests. The second significant disadvantage will be the high cost of such repairs. Some breeds are very expensive and of course, these will be the varieties with the most beautiful texture. However, modern industry has launched the production of fairly accurate imitations of expensive species, even from chipboard.

Thermal insulation

Since warm air particles rush upward and remain there until they find a way out, an important part in the improvement of the bathhouse is the thermal insulation of the ceiling. It is reproduced using available materials, such as expanded clay, earth with sand, dry earth, sawdust mixed with cement, as well as more modern material - mineral wool

A more expensive material such as perlite would be an excellent option. It is one of the environmentally friendly

It is reproduced using available materials, such as expanded clay, earth with sand, dry earth, sawdust mixed with cement, as well as a more modern material - mineral wool. A more expensive material such as perlite would be an excellent option. It is one of the environmentally friendly.

You can increase the thickness of the insulating layer using wood chips mixed with cement or other insulating materials.

Features of work when creating different designs of wooden ceilings

If you want to create a ceiling from boards, you should choose one of the existing options for its construction. The first involves the creation of false ceilings. This technology is the most reliable, but is expensive. To lay finishing materials, floor beams with thick bars or hewn logs should be installed. These items are expensive. They are installed on the crown, and depending on the type of roof, they can be attached to the walls. Boards are nailed to the beams. This design looks quite massive and durable.

You can stuff lumber from above, as a result of which movement along the roof or ceiling area will be safe. When filing the ceiling, steam, heat and waterproofing should be installed.

The ceiling made of boards can be arranged according to the principle of laying a panel system. This technology involves the assembly of shields from two bars, which are installed in parallel. The boards must be packed transversely. The shields should be raised to the ceiling and reinforced. Outside, if desired, you can lay heat and waterproofing. If beams are used to create the base, this option will be the most preferable, because it has the required strength.

Panel ceilings, however, have a disadvantage. It lies in the fact that the structure will have significant weight. In order to raise the shield, you should enlist the help of several people. The structure will need to be held for some time until it is strengthened. The ceiling made of boards can be arranged according to the principle of a flooring system. This method is the simplest when using a board. The technology is relevant if the span length is no more than 2.5 m. In this case, lumber is fastened simultaneously at both ends. It will be impossible to move on such flooring.

According to experts, when performing ceiling repairs, it is better to prefer the third option, since it is less labor-intensive and does not require significant financial costs. If a house is being built, saving is not recommended. In this case, it is better to stick to the first method. The floor beams will also serve as the base of the roof.

Processing lumber for the ceiling

Everyone knows that wood is prone to rotting in a damp atmosphere, and bark beetles also love it. Therefore, lumber cannot be used without pre-treatment. It is also desirable to impregnate it with fire-retardant compounds. But it’s also clear that you really don’t want to use chemicals in baths: this is a place for healing, with which chemicals don’t “fit in” in any way.

Chemicals may not be used, but there are traditional methods of treatment that are no less effective. One of these is treatment with hot drying oil and molten wax. When done correctly, it simultaneously protects against fungi, rot and bugs.

Read more about what kind of wood is best to use for the ceiling in a bathhouse.

Choice of material and design

To frame the ceiling with boards, a beam frame is constructed

The most popular of the wood-plank set are tongue-and-groove boards for the ceiling and lining (eurolining). The clapboard board is narrow, with a relatively weakly expressed texture. They paint it in different ways, which allows you to achieve an interesting effect by alternating stripes of different tones. In beam-lined structures, deck boards for the ceiling or façade boards appear. There are also options with parquet/laminate.

Wooden floor beams are not always hidden: they are quite aesthetically pleasing

When looking for a semi-finished product suitable for decorating the interior space, it is worth familiarizing yourself in advance with the existing methods of laying out the components of the future “dome” and critically assessing your capabilities - material and physical. You can get down to business on your own only if you know how to properly hem the ceiling with a board.

The deck board is strong, impressive and has a well-developed texture

If there is no experience, it is better to entrust the fate of the repair to the builders. They know which elements will be most suitable for the hemming/padding system you have chosen and what should be added to this set. Most likely, a cycle of preparatory work will be required on the ceiling, wood (if it is not impregnated with bio- and fire-resistant substances), and the load-bearing profile.

A coffered wood ceiling is beautiful and modern, but it won’t be cheap

Types of wooden structures

A ceiling lined with parquet boards can become the “highlight” of a design project

There are many construction and finishing technologies. Let's dwell on the most mastered methods of how to line a ceiling with a board or planks/boards that imitate it. Here are the final ceilings:

- Hemmed - made of lining, boards, panels. Easy to manufacture, beautiful, mounted on a pre-assembled frame. Among the current tree species are linden, oak, plus common conifers (pine, larch and some others).

- Relief - most often this is a ceiling made of unedged boards or timber (chipped). Provides a unique pattern. Imitation of logs/beams with a block house is also attractive - quality, simplicity and speed of assembly operations.

- Caisson (slat) is the pinnacle of skill and sophistication in the art of decoration. The result is a harmonious combination of box-shaped caisson modules with alternating slats and flat depressions.

Beautiful examples in the interior

The finishing of the ceiling with dark-tinted panels will be matched by snow-white wall columns, decorated with clapboard, emphasizing the style of the room and creating contrast. And furniture made of natural wood in colors with the ceiling will add harmony to the interior. All the beauty of the solid textures will be highlighted by the lighting located along the perimeter of the ceiling in the form of built-in devices, and the sconces on the columns with yellow lamps will set off the furniture upholstery in beige tones.

Abandoned wooden beams in the form of dark brown logs, made of larch, will create a rough antique effect in a house in the village. Combining such a unique ceiling in contrast with light-colored walls, one can see the effect of monumentality bordering on simplicity. A wooden ceiling, decorated with plaster bas-relief around the edges, will emphasize the eco style, and if you choose furniture with glass elements, the design of the room will be more sophisticated.

Not only do stylish plasterboard structures have several levels, the use of wood is also an interesting and unusual option. Due to several levels, the space is zoned, giving the ceiling visual complexity. It is possible to create a lattice structure from slats or panels, and arrange the squares straight or diagonally. You can emphasize the originality of the design with decorative beams fixed at the end; it is enough to coat the wooden surface with varnish or oils, emphasizing their texture. And harmonious lighting will perfectly highlight the elements, giving the interior uniqueness.

You can see how to cover a wooden ceiling in this video.

Materials for filing the ceiling

The most popular of them:

- board or lining;

- plastic panels;

- MDF panels;

- drywall;

- suspended ceilings made of fabric or PVC film;

- ceiling tiles.

An interesting effect is also achieved by combining different materials, for example, plasterboard with lining or with suspended ceilings. By combining different textures, you can achieve not only an interesting design, but also make the ceiling more practical, hide defects in the beams and highlight the advantages of the room.

The original option is a plasterboard ceiling with protruding beamsPrices for lining

lining

Ceiling with natural wood

Sheathing a ceiling with boards is quite simple. Since wooden floors and sheathing have the same coefficient of thermal expansion, the boards can be attached directly to the beams using screws or nails.

We suggest you familiarize yourself with How to hem ceilings in a private house

Advantages of the material:

- low price;

- goes well with other finishing materials;

- installation is easy to do with your own hands;

- environmentally friendly material;

- can be painted in any shade.

Minuses:

- Requires regular treatment or painting to protect against aging;

- fire hazard.

Plastic panels

Finishing the ceiling with plastic panels is quite simple. The panels are attached to special guides or with self-tapping screws directly to the beams only if they are well aligned and in the same plane. If it is necessary to level the height, slats are attached to the beams below, and panels are attached to them.

Ceiling finishing with plastic panels

The individual strips are connected using a tongue-and-groove lock, thereby creating a smooth surface without cracks or gaps. If you seal the connections with silicone sealant, you can create a vapor-tight seal.

Advantages of the material:

- low price and large assortment of shades;

- light weight, no load on the floors;

- does not require painting or processing;

- the panels are not afraid of moisture, do not rot, and can be easily washed with warm water.

Minuses:

- plastic is a fire hazard; it is undesirable to use it in rooms with stove heating;

- The material is fragile, chips and damage are possible.

MDF panels

The difference between MDF panels and plastic ones is that they do not tolerate moisture and become deformed when wet. Therefore, they cannot be used in the bathroom and on the balcony. MDF panels often imitate the texture of wood, so they can be used instead of lining or boards, since their processing and fitting are much simpler and their weight is less. They are attached in the same way as plastic ones directly to beams or slats.

Ceiling cladding with MDF panels

Advantages of the material:

- inexpensive and easy to process;

- good thermal insulation properties;

- light weight.

Minuses:

- fade when exposed to direct sunlight;

- due to their small thickness they are prone to sagging, they need to be fastened in increments of no more than 60 cm, and the construction of an additional frame may be required.

Drywall

Plasterboard ceilings are puttied and painted with water-based interior paints in any desired shade. A ceiling finished with gypsum plasterboard sheets fits well into various interiors, which is why it is so popular. Plasterboard finishing can be combined with wood or suspended ceilings.

Installing drywall on a ceiling is more difficult than wood or panels. Due to the different coefficient of thermal expansion and the large size of the sheets, they cannot be attached directly to the beams. Drywall is mounted on special hangers and guides that have a flexible connection with the ceiling beams.

Drywall prices

drywall

Advantages of the material:

- it is inexpensive;

- easy to process and allows you to create any designs, including curved ones;

- easily painted in any shade;

- the material breathes and does not contribute to the formation of condensation;

- goes well with any decoration.

Minuses

- the rather heavy structure creates a load on the floors;

- afraid of water leaks, deformed and wet;

- fragile material, may break if impacted.

How to make a rough ceiling using wooden beams - installation options, instructions

The rough ceiling in wooden houses is an important element of reliable and high-quality finishing. Its arrangement should be given increased attention, then it will look attractive and last for many years. To make a rough ceiling finish with your own hands, you need to have minimal skills in performing construction work.

If in houses built of brick or concrete, floor slabs are laid between floors, then in wooden buildings beams are used. It is to them that the elements of the draft ceiling are attached. To complete this work will not require a lot of effort, time and finances.

Features of the installation of interfloor ceilings

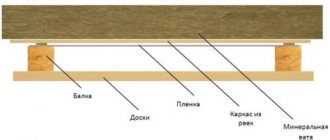

Before making a black ceiling, in order to obtain a high-quality result, you should understand what constitutes an interfloor ceiling in a wooden building. It consists of several layers and each performs a specific function. Provided that all elements are assembled correctly, the ceiling will be reliable and will last for a long period.

The interfloor ceiling in the basic version has 5 layers:

- Plank floor. If there is another floor on top, you also need to lay a floor for it. The plank layer can be rough, for finishing, it can be used as a finishing option.

- Vapor barrier. Despite the fact that some owners do not make this layer, to obtain a high-quality result it is advisable to lay a vapor barrier material.

- Insulation. Creating thermal insulation is necessary to keep the house warm. This is especially important when there is an unheated attic or roof above the ceiling.

- Waterproofing. This layer is needed to protect the wood from destruction due to moisture.

- Rough ceiling in a wooden house. It is used to attach finishing trim. It is also a support for waterproofing, insulation and vapor barrier.

There are different options for completing the final finishing of the ceiling. The most popular is the use of plasterboard boards. To secure them, a metal frame is assembled. This finishing method is practical, easy to implement and inexpensive. The result is excellent if everything is done correctly.

To install a rough ceiling on wooden beams, first boards are attached to them, then insulation and waterproofing are laid, and then all that remains is to finish the ceiling surface with plasterboard or other material.

When the ceiling is already ready, then you can begin laying the flooring on the floor above, for which a vapor barrier is laid on the insulation, and boards are placed on top of it. Many homeowners, after attaching these lumbers, do no further finishing, thereby using them for finishing purposes. A plank ceiling in a wooden structure also looks very beautiful and impressive.

Tools and building materials

To build rough ceilings in a private house, you can use a 25 mm board. It is secured with nails "slant" or using 45-55 mm self-tapping screws. These fasteners are able to securely hold the structure.

The boards under the finishing will not be visible, so their appearance does not matter and you can save money on this material. The main requirement for the board: it must be strong and even. If it is placed on top of beams, you also need to have cranial bars available.

You can use another option, which will require durable sheets of plywood. To fasten them, a frame is assembled from slats or bars.

A good way to create thermal insulation is to use 50% sawdust and mineral wool. First you need to pour sawdust, and lay mineral wool on top of it. The result is a heat insulator that perfectly retains heat in a house where the ceiling is built on wooden floors.

Today, there is a wide range of insulation materials on sale for use in residential premises, and in addition, you can choose any materials at your discretion. Since the board is attached directly to the beams, it is more convenient to use. There will be no need to spend money, time and effort on constructing the sheathing.

Tools you should prepare:

- saw or jigsaw;

- screwdriver;

- hammer;

- stapler

Rough ceiling made of boards on wooden beams

There is a certain sequence of actions on how to properly hem a ceiling with a board, which involves two stages:

- The boards are secured to the joists by nailing them or tightening them with self-tapping screws.

- Insulation and waterproofing are laid on top of them.

When performing the work, you need to cut all the boards to the required size so that after their installation there are no cracks or gaps in the ceiling surface. This stage should be approached with utmost care. Only through serious preparation can you build a high-quality ceiling that will not cause problems for a long period.

There is an option to hem the ceiling with a board in a private house, placing it below the joists. It is simple and practical. By using it, you can build a ceiling as quickly as possible, and every home craftsman can cope with this work if he has the desire and appropriate skills. This design has a drawback. Since the ceiling will cover the beams, if necessary, it will not be possible to reach them quickly and easily.

But there is another way to fasten the boards, which has a more complex implementation - in this case they are placed on top of the beams:

- first, cranial bars are secured to the joists;

- then boards are laid on them;

- then a thermal insulation and vapor barrier layer is installed, and they can be placed both under and on top of the boards.

Typically, this option is used when it is planned to use beams as a decorative element, as a result of which they remain visible after the completion of the interfloor covering. This method allows you to create a textured interior that looks stylish and impressive.

Rough plywood ceiling

Plywood is considered an ideal material for making a rough ceiling on beams. With its help, it will be easy to make a base for placing the cake from an insulating, waterproofing, vapor-permeable layer.

When the ceiling is hemmed with plywood along the beams, its sheets are exposed to a minimum of mechanical and thermal load. For such work, the dimensions of the material used must correspond to the interbeam distance.

The sequence of manufacturing this type of rough ceiling:

- if necessary, assemble a slatted frame and attach it to wooden beams from below;

- cut sheets of material 4-6 millimeters thick are hemmed to the sheathing;

- Sound-insulating and heat-protective mats and waterproofing films are placed on plywood.

The work on arranging the rough ceiling is carried out in such a way as to subsequently use the lattice frame and beams as the basis for installing finishing plasterboard panels.

The thickness of the plywood is selected taking into account the load on the ceiling surface. The fact is that plywood sheathing in a wooden household can perform not only an auxiliary, but also a main function. An excellent finishing material for cladding ceilings are laminated panels with a cross-section of 10 - 20 millimeters.

Further design of the ceiling surface

When the rough ceiling is ready, the final finishing begins. When using plasterboard sheets, it is enough to make a metal frame and secure them. There are other options for finishing the ceiling surface.

If a rough ceiling is created using wooden beams under a tension fabric, the work should be approached thoroughly, since haste in this case is unacceptable, especially when there is not enough experience.

Using a floor board

An original solution is to use tongue-and-groove boards for the ceiling. This has a great advantage, since the floor boards have a mounting groove, thanks to which, in the event of a change in humidity or temperature, cracks and crevices will not appear at the joints of wooden products.

Creating a ceiling from tongue and groove boards can be called the best choice of material - it allows you to create a perfectly flat surface. If there are differences, they will be almost unnoticeable.

Thus, if a floorboard has been chosen for finishing the ceiling, a number of nuances must be taken into account:

- You should not purchase too thick lumber for the ceiling;

- A 20mm material thickness will be sufficient, and in some cases less.

As an option, you can use a durable parquet board to decorate the ceiling, because such material will give the room a special atmosphere. By the way, many designers, in order to achieve original solutions when decorating walls and ceilings, opt for parquet.

Pros and cons of covering the ceiling with boards

Advantages of finishing the ceiling surface with boards:

- The material is highly durable. To do this, it needs to be treated qualitatively with special compounds.

- When using wood finishing, the thermal insulation characteristics of the room are improved.

- Lumber on the ceiling soundproofs the room.

- Simple installation that any home craftsman can easily handle.

- Wooden plank ceilings have an attractive appearance.

This finishing method also has disadvantages:

- Instability to humidity and water. Their constant exposure leads to the fact that lumber begins to rot.

- Intolerance to sudden temperature changes.

- Special products will be required for care.

- When purchasing materials from expensive wood species, the cost of the ceiling is significant.

- Over time, the ceiling surface may lose its original appearance.

Taking into account all the listed pros and cons, it is necessary to decide which wood material is best to use for the design of the ceiling.

There are several types of boards for the ceiling of a house:

- floor board;

- lining;

- Planken.

Preparatory stage

In most cases, beams are the basis for interfloor ceilings in wooden houses. They are installed with their ends on the load-bearing elements of the structure and are easily subject to additional processing. In addition, such a base can perform not only a supporting, but also a decorative function. In particular, if the ceiling is hemmed along wooden beams from above, the beam becomes part of the interior decor of the premises.

If we talk about the tools that may be required when performing work, they are prepared according to the list:

- jigsaw;

- screwdriver;

- drill with a set of wood drills;

- hammer;

- fastening elements (corners, screws, nails);

- stapler;

- pencil;

- tape measure and building level.

In addition, gloves and safety glasses will be required. If mineral wool is supposed to be used as insulation, it makes sense to take care of a respirator.

Decorative structures made of polyurethane

They are also very convenient for masking communications and unattractive structural details. Using polyurethane elements, they decorate not only the ceiling, but also other surfaces. For example, interior boards can be used to very beautifully emphasize corners or decorate walls.

Polyurethane beams are easily mounted to a load-bearing wooden block or metal profile using self-tapping screws. To prevent the metal heads of the screws from spoiling the overall appearance, they are recessed deeply and painted over with a wax pencil to match the color of the surface or covered with plugs of the appropriate shade.

An even simpler way to install polyurethane beams is with liquid nails using small wooden blocks to additionally secure the ends of the beam with self-tapping screws, as shown in the instructions below.

The joints of the beams are covered with special decorative belts that skillfully imitate forging: they are available in several colors to match different types of metal.

In addition to decorative belts, massive “antique” chains and ropes of rough texture are used to decorate beams. Lamps are selected so that their design matches the overall style of the room. Polyurethane false beams, hollow inside, perfectly hide communications, so spotlights are often built into them, giving the interior an elegant, original look.

Preparation for work

At the first stage, you need to take care of the availability of tools, namely:

- square;

- screwdriver;

- hacksaws;

- cord;

- pencil;

- with a hammer.

A hacksaw can be replaced with a chainsaw if you have one in your arsenal. You can even rent such an instrument. When hemming, the most commonly used lumber is a planed tongue-and-groove board. Its width should be 100 mm, while the thickness can vary from 16 to 22 mm. A wider board is easier to install. Usually the base is coniferous wood. The ceiling is thermally insulated only if the house has an attic without heating. The ceiling should be insulated. If the attic is planned to be insulated, sound insulation is laid on the floor between the room and the attic. To do this, the sheathing is nailed to the laid attic floor beams.

If you plan to install a ceiling made of boards, then you need to take care of preserving the cladding after installation. To do this, paint or colorless varnish is applied to the material. When arranging a rough ceiling, the first step is to attach a vapor barrier to the floor beams. An unedged board is attached on top, maintaining a certain distance between layers. Thermal insulation should be laid on top of the boards. Afterwards you can start processing the overlap on both sides.

Wooden floor installation

A wooden floor consists of beams covered at the bottom and top with molded or sheet material. The following materials are used as binders: boards, plywood, OSB, chipboard, fiberboard and other materials. Between the filings, and in the attic floor sometimes on the filings, layers of heat and vapor barrier are placed.

Having repeatedly observed a boiling kettle, many people have a stereotype that steam only rises upward. This is wrong. Or rather, seeing steam from a kettle, we are observing another physical phenomenon. Water vapor contained in the air in a “dissolved” state always moves towards the lowest temperatures. Almost throughout the year, steam moves from a warm room to the street and only on rare summer days, when the temperature “outside” is higher than in the house, in the opposite direction. The vapor barrier should be the first structural layer encountered in the path of steam movement. In the attic floor - from below, in the basement - from above. There is no need to install it between floors, since the difference in air temperatures in rooms separated by floors is zero or close to this figure - steam exchange does not occur between these rooms or it is negligible. A vapor barrier is installed to protect the thermal insulation material from moisture vapor. This is its only purpose. If the walls of a log house are painted from the inside with oil paints or sheathing is made and covered with vapor-proof material, then it is imperative to calculate and install supply and exhaust ventilation in the house. Otherwise, the air humidity inside the room will go beyond the maximum permissible level - the house will turn into a steam bath.

Sheathing of interfloor and attic floors can be done by sewing it to the beams from below. But you can do it another way: on “turtles”. Basement floors are made using this type. Quarters are cut out of the beams on both sides and their profile becomes similar to a skull, hence the name. You don’t have to cut out the quarters, but make them by sewing longitudinal bars. Boards are laid on the “cranial” ledges or “cranial” bars, resulting in the lower part of the floor, which is also the ceiling of the interfloor or attic floor. The boards laid on the “skulls” can not be fastened with anything and the ceiling can be made nailless.

Insulation and vapor barrier are laid on the ceiling, after which the floor of the room is laid. Previously, a plant layer of earth was used as thermal insulation, and fatty clay was used as a vapor barrier. The use of earth made the ceiling thermally inert. It warmed up for a long time and cooled down slowly. The thermal inertia of the ceiling was especially pronounced in the summer: heating up during the day, it cooled down all night. Thanks to this, it was not hot in the hut during the day, and not cold at night. Modern insulation, unfortunately, does not give such an effect.

You can read about the properties of modern thermal insulation on another page of the site. The table shown below characterizes the properties of natural heat insulators; it is taken from the book by A. M. Shepelev “How to build a rural house” and is given “as is.”

Types of wooden ceilings

If we talk about the design of wooden ceilings, then the most popular ceiling made of boards is undoubtedly the hemmed one. It is called hemmed because the boards or wooden panels are attached to the ceiling base (or frame) from below and seem to be hemmed to it.

More often than others, plank ceilings are used when cladding houses with wooden floors, less often in houses with concrete floors.

The materials for making wooden ceilings are as follows:

Lining, eurolining or tongue-and-groove boards for the ceiling are the most common option for installing a hemmed wooden ceiling. This choice is largely due to the ease of installation of the material and the beautiful surface obtained as a result. To produce such materials, various types of natural wood are used - linden, pine, oak and others. The boarding of the ceiling is done using a frame mounted on the ceiling base. The finishing elements are connected to each other using a tongue-and-groove system.

A ceiling made of parquet boards in the interior of a house can look very original

- Panel false ceiling made of wood. It differs from the previous version in that it uses not individual boards, but wide ceiling panels assembled from wooden panels and covered with veneer on the outside.

- Relief false ceiling. This can be a ceiling made of unedged boards, chipped timber, a house block and other types of wooden materials characterized by a figured, uneven surface. Each of them allows you to achieve a unique pattern, texture and shape of the ceiling surface.

- Coffered ceilings. Ceilings of this type are assembled from special box-shaped modules called caissons. Coffered structures are complex in design, but at the same time they look very impressive.

Exterior view of a wooden coffered ceiling

Ceiling installation when the attic is cold

When the building is one-story, and only the roof is on top, the installation of the ceiling in a private house is carried out as follows.

Step one - filing the ceiling

. For this you need a shield made of boards. The material for it is ordinary edged or tongue-and-groove boards with a thickness of 25 millimeters or more. They are fastened “in space” using long nails, leaving minimal gaps. The tongue and groove boards are hemmed with a groove from the wall, from which the installation of the cold ceiling starts.

When deciding what to make a ceiling from in a private house, you can opt for lining it in another way - plywood or OSB, at least 15 millimeters thick (read: “Ceiling with plywood”). But it should be taken into account that in terms of one “square” this option is much more expensive and the possibility of the structure sagging under its own weight and the weight of the insulation increases.

As an alternative, in private houses of old construction, the board panel can be placed not below the beams, but laid on top of them. Thus, the height of the rooms will not be reduced, and the living space will not be reduced. If necessary, you can make a crate. You should not worry about the appearance of the rough ceiling, since finishing the ceiling in a private house will cover the surface, and the beams, painted in the desired color, will decorate the interior of the room.

Step two - vapor barrier of the ceiling

. First of all, you should take care of the vapor barrier. On the one hand, this layer should prevent the heat-insulating material from becoming damp, and on the other hand, due to radiation, it should reduce heat loss. This can be achieved using aluminum foil. Also used as a vapor barrier is foil insulation based on foamed polyethylene - this relatively recently appeared vapor barrier material for the ceiling creates an obstacle to heat loss due to both radiation and convection. When a chimney is laid in the ceiling, there must be a distance of at least 30 centimeters between the chimney and combustible material.

Step three - insulation of the floor

. The installation of a ceiling in a private house with a cold attic involves the use of insulation materials, the choice of which is huge (read: “How to insulate the attic of a private house”).

The most popular among them are:

- Mineral wool

. This material (see photo) is non-flammable and has excellent thermal insulation properties, but over time they begin to deteriorate. The fact is that even completely dry mineral wool begins to cake after a certain period. If the vapor barrier is not done well, this insulation picks up moisture and ceases to perform its intended function. It is impossible not to mention such a disadvantage of mineral wool as the presence of volatile small fibers that irritate the respiratory system. Therefore, they need to be isolated from living quarters especially carefully. The cost of mineral wool is affordable. When insulating the ceiling with mineral wool in a private house, it must be handled with care and not compacted, since the thicker the layer, the better the thermal insulation. - Basalt wool

. The ceiling in a country house is often insulated with this type of mineral wool. But there is a difference between these two materials. Basalt wool retains its shape better and practically does not cake, but, unfortunately, it can pick up moisture. - Styrofoam

. This thermal insulation material is flammable. Controversy continues regarding their release of styrene. Although foam plastic intended for insulation must meet environmental standards, in reality this indicator depends on the manufacturer. As for the thermal insulation properties, this material is excellent, since there is practically no heat loss due to air convection inside the foam layer (read: “How to insulate a ceiling from the inside in a private house”). This insulation does not change its shape and size - even after 10 years, the volume of foam sheets between the beams will not change from the moment they were laid. The material is considered non-hygroscopic and moisture-proof. There is an opinion that its use allows you to avoid making a vapor barrier at all. But thermal insulation using foam plastic is expensive and unaffordable for many consumers.

Tools and materials

To cover the ceiling with boards you will need the following material:

- clapboard or board made of natural wood (pine or other durable types that are easy to process);

- slats 4x2 cm with cross-sectional parameters;

- decorative strip for ceiling plinth or fillet;

- varnish or special paint for wood.

Tools and consumables:

- measuring instrument - tape measure, square, construction ruler;

- building level with alcohol capsule;

- hammer;

- screwdriver or screwdriver with a set of bits;

- a hacksaw or jigsaw, a power tool of this type is also suitable;

- the fishing line is thick;

- impact dowel with casings, size 6x60;

- screws with parameters 2.5x2.5.

- drywall or fiberboard;

- insulation;

- roofing felt;

- nails of the required thickness and length;

- polyurethane foam.

Advice To ensure that the boards hold firmly and are positioned evenly, the installation of sheathing is required. Depending on the direction of the facing material, a rail will be installed on the ceiling with a frequency of 0.3 m.

Board for bath-barrel

A barrel sauna is a popular stationary or mobile version of a home sauna. If we are talking about making it yourself, then you will need a rather specific type of lumber.

The board for the barrel bath is quite thick - 4-5 cm, and its sides are rounded for a “moon groove” connection.

You can buy such a board ready-made, or you can order it to be made.

The wood that is suitable for a barrel sauna (!about cedar barrel saunas here) is the same that is suitable for a regular steam bath. First of all, these are deciduous species - linden, ash, alder, aspen, etc.

Conifers are undesirable here too. However, many offer barrel boards made from the same cedar. If the board was kiln-dried and there was a procedure for removing the resin, maybe it’s worth it.

? Laying over old floors

The first thing you should make sure of before starting work is whether the old floor can continue to withstand heavy loads. If there are no doubts, then you can move on to the repair measures themselves. The sequence is as follows:

- Roughly sand the old flooring and remove any accumulated dust.

- Install waterproofing.

- Lay new floorboards perpendicular or diagonal to the old ones.

Installation of solid boards over existing wood flooring

If you don’t want to experiment with a new laying direction, then use plywood as a base for the new floor. By choosing sheets with a thickness of 12 mm or more and roughly sanding the plywood surface, you can install the floorboard in the usual direction.

Important! If the strength of the old floor is still in doubt, then it is recommended to carry out complete dismantling and start work from the concrete screed. It is not advisable to carry out any construction work yourself

Even the simplest activities require certain knowledge and professional training. The work of the construction team is a guarantee of high quality and excellent results

It is not advisable to carry out any construction work yourself. Even the simplest activities require certain knowledge and professional training. The work of the construction team is a guarantee of high quality and excellent results.

Modern trends, including interior design, force us to look for new solutions. For example, in the arrangement of the ceiling. Suspended and tensioned structures made of plasterboard and PVC are already considered traditional. I want something new, extraordinary. Why not then put a floor covering on the ceiling? For example, a parquet board. After all, who said that this cannot be done?

How to choose for different rooms?

Lining is relevant for the kitchen. It has water-repellent properties, which is indispensable for this room. The tongue-and-groove design of the lining makes it easy to embed a hood into the ceiling or make holes for pipes, and its suspended structure is convenient for carrying wires and communications. The same material is appropriate in the bathroom or toilet. Often, laminated wood parts or coated with several layers of varnish are used on the kitchen ceiling. This is necessary for quick and practical cleaning, and will also prevent the formation of fungus and mold.

The color scheme of the ceiling in the kitchen is light shades, providing visual spaciousness to the room. If desired, you can use bright colors, combining them with pieces of furniture.

The living room in a private house is the place where the whole family gathers, so finishing the ceiling with wood will create coziness and comfort in this room. For example, wide beams or a panel and slatted design would be appropriate for a living room. And the presence of a fireplace in the room and wooden furniture will perfectly complement such an interior. High ceilings in the living room can be enhanced with dark wood, shading them with light sources. At the same time, several lighting options can be used in one room, for example, spotlights mounted in beams, and main chandeliers and spotlights directed at each other. Such light illumination will help emphasize the texture of the wood on the ceiling and also divide the living room into zones.

In the bedroom, depending on the style of the room, slatted or beamed ceilings can be used. This room is a corner of peace and tranquility, so massive details are not needed here. The main colors for this room are pastel colors - light beige, cream, powder color, light blue, lavender, olive. In this case, it will be necessary to paint the wood, but if you still want to use textured options on the ceiling, then you should choose species of light shades. The best option for a bedroom would be to make the ceiling and floor from wood. This combination will add softness and warmth to the room. The same ceiling can be chosen for the hallway.

Installation

It is quite possible to sheathe the ceiling using wooden beams with your own hands. To do this, you first need to prepare all the tools, finishing material, as well as glue and mixtures for wood processing. In the case where the beams will act as the basis for the ceiling, they should be carefully checked for the presence of fungus and mold. If there are defects, the logs must be treated with an antiseptic solution, and cracks and chips must be filled with putty.

After completing the preparatory work, you can perform installation, which consists of several stages.

- First of all, you should create a vapor barrier layer and cover the beams. This is best done using plastic film or parchment, which can be easily attached with a stapler. Then the logs should be lined with any rough material; most often, edged boards are used for such purposes. If the ceiling is crooked and the ceilings have differences in levels, it needs to be leveled.

- The next step in the work will be laying thermal insulation; it will retain heat in the room and will not allow cold air flows from the roof or interfloor ceiling to pass through. This is especially true for the cladding of the first floor in apartments. Mineral wool or polystyrene foam is used as insulation.

- After installing the thermal insulation, an additional layer of vapor barrier is laid. Today, there are many materials that can be used to provide natural air exchange to structures, but the main one is considered to be membrane polyethylene.

- The final stage is the construction of a rough base. The covering is sheathed with plywood or corrugated sheets.

If the work is carried out in a private house, then the finishing should be done taking into account the functional purpose of the attic. In many buildings it can serve as a residential attic, or simply act as a non-residential space. For an attic that will house a full-sized room, it is necessary to add aluminum foil to the floor layer; it will help avoid heat loss in the house. In addition, when decorating the attic, a layer of sound insulation consisting of sawdust and mineral wool is laid.

A ceiling covered in this way should not only be beautiful, but also maintain the microclimate of the room. The aesthetic appearance of the entire structure will depend on the correct installation of the finishing coating. Therefore, work must be done slowly and adhere to all cladding technologies. To simplify installation, it is recommended to first draw up a ceiling diagram and indicate in it the installation of heat, steam and sound insulation.

Material selection

Blanks for rough flooring

When deciding how cheap it is to sheathe a plank ceiling, you should consider all available materials.

And first of all, slabs and unedged boards will come into our field of vision - these budget materials are widely used for arranging floors, which will then be hidden under the finishing:

Using unedged boards as flooring

- Rough filing of the ceiling with boards is carried out if we need to lay the foundation for installing insulation or a suspended structure.

- For work we use either a slab or an unedged board of a suitable size. The thickness of the parts should be at least 25-30 mm.

- To ensure that the ceiling made from unedged boards is sufficiently reliable, we remove the bark from all pieces, and then saturate the parts with wood antiseptics.

Advice! If possible, thin edges of both unedged panels and slabs should be cut off, forming side edges of at least 10 mm.

Low-grade edged boards can also be used for this purpose, but in this case it is important to carefully sort the workpieces, removing parts with cracks and other large defects

Lining

In the minds of most craftsmen, the ideal board for the ceiling in a wooden house is lining.

And there really is a rational grain in this:

Lining fixed on beams

- The material costs relatively little, and you can find it almost everywhere.

- The technology for installing lining has been proven, so almost anyone can cope with the task.

- The sheathed surface turns out to be quite attractive, especially if you choose modifications with minimal chamfers.

At the same time, it should be noted that standard lining is quite narrow, so it must be installed on the ceiling in such a way that the joint lines are a visual continuation of the wall cladding. Otherwise, your eyes will ripple, because the ceiling, unlike the walls, is usually almost completely open.

tongue and groove floor board

As an alternative to lining, many craftsmen are considering floor boards.

In this case, the casing will not experience any special loads, so you can purchase the thinnest – up to 20 mm – blanks:

Tongue and groove boards are somewhat more reliable than lining

- For work, both a regular edged board and modifications with tongues are used. A tongue-and-groove ceiling board is easier to install; in addition, locks on the side edges allow you to create a more reliable connection.

- To fasten parts, it is better to use nails or screws rather than clamps. Still, long panels are quite heavy, so a margin of safety will not hurt.

- Instead of solid wood blanks, parquet boards, which are veneered multilayer products, can be used. Firstly, it looks more attractive, and secondly, it tolerates changes in temperature and humidity much better.

Parquet boards are also suitable for this purpose.

Planken

However, the board on the ceiling in the house does not have to be a material strictly for interior work.

Facade panels (the so-called planken) are also quite suitable for this purpose:

- Products of this type undergo multi-stage heat treatment, which minimizes the influence of temperature and humidity on the geometry of the cladding.

- The moisture resistance of the panels significantly expands the range of their applications: if you are thinking about how to make a ceiling in a bathhouse from boards so that it does not get wet, feel free to choose façade varieties.

Straight plank is suitable not only for facades

The use of special protective equipment allows us to preserve the natural texture and color of natural wood, so that our ceiling will not look faded even ten years after covering.

Note! Sometimes planken is tinted, which allows not only to preserve, but also to emphasize the characteristic pattern of wood fibers. Finally, it is worth paying attention to the installation

Straight plank attaches to any sheathing very quickly, so filing will not take much time

Finally, it is worth paying attention to the installation. Straight plank attaches to any sheathing very quickly, so filing will not take much time

finishing a wooden house

/ Blog Wooden house construction

A board as a finishing material for the ceiling of a house made of chopped logs can become a real “highlight” of a log house. Ceiling cladding made of boards can be of any kind; let’s look at the most popular types.

There is no specialized board for the ceiling; modern finishing technologies have made great strides forward and any type of board can be mounted on the ceiling - unedged, classic flooring, thermowood boards.

Unedged board - antique finish

An unedged board is obtained by cutting a log lengthwise, the edges are not cut off, so the top and bottom surfaces are smooth, and the edges follow the natural curves of the workpiece. To decorate the ceiling, use an unedged board with barked and unbarked edges.

Stages of preparing unedged boards

- Logs of natural moisture are used to make boards 25 mm thick;

- If you decide to use a debarked board, then manually remove the bark from the edges using a scraper or a landing stage;

- The cleaned workpieces are stacked to dry in natural conditions;

- The required number of boards for cladding the ceiling are processed on a planing machine, after which they are carefully sanded;

- After installation, the boards are cleaned and treated with protective compounds.

An unedged board is indispensable when implementing a design project in any ethnic style.

Country and Russian, rustic and chalet, the “antique” concept – a ceiling made of uncut boards is appropriate everywhere.

The boards are stuffed in two layers so that the gaps in the first row are covered with the sheathing from the second. Beams in such an authentic interior are most often made from untreated logs or rough-hewn beams.

The cost of unedged boards for finishing the ceiling

The cost of unedged boards made from coniferous wood is less than from “durable” deciduous trees (for example, oak). Also, the price depends on the type of lumber, of which according to GOST 5. On average, the cost of 1 m3 of unedged boards is from 2 thousand rubles. up to 5 thousand rubles

Lining

Lining is a classic for the ceiling in a house made of chopped logs. Lining comes in several categories; the “extra” class material includes lumber of excellent quality. Such lining costs a lot, but the ceiling finish is very smooth, without flaws.

A tongue-and-groove board is lumber with a tongue-and-groove fastening, which is called “tongue and tongue.” When installing such cladding, there are practically no gaps left; if there are any, they are formed due to the profile.

You can diversify the appearance of a ceiling trimmed with clapboard using the following techniques:

- Partial ceiling finishing;

- Installation of lining in different directions;

- The use of two or more types of lining of different colors;

- Installation of decorative beams.

Batten

The floorboard, oddly enough, is also suitable for the ceiling. It also has a “tongue”, so it is installed according to the same rules as lining. The main criterion for choosing a board is the lack of relief.

The floor board is characterized by great strength, because the floor must withstand heavy loads.

This is not relevant for the ceiling , so lumber about two centimeters thick will do.

The range of species offered is much larger than that of classic lining, so if you wish, you can even choose boards from exotic wood.

The ceiling can also be covered with traditional parquet. In this case, finishing will be cheaper, since the parquet is veneered with valuable species, and is not made entirely of them.

After installation , the finished coating is obtained; it does not need to be further decorated.

For parquet, you can use not only paint, oil, colored wax or varnish, but also bleaching, staining, and brushing.

to buy ready-made parquet ; products can have tongue-and-groove fastenings, but the new rotary-corner joint has almost replaced the classics.

Planken - thermowood

This is an excellent (but also the most expensive) ceiling option. Planken is a board that has gone through three stages of processing - drying, heat treatment and special hardening.

After all stages are completed, the wood acquires new physical and mechanical characteristics: it does not absorb moisture, is not susceptible to the influence of pathogenic bacteria, insects and rodents, and lasts much longer. In addition to the mechanical parameters, the planken also acquires a new appearance - a smooth surface with a clear, pronounced wood texture.

Due to its moisture resistance , thermowood (this is another name for planken) can be used to decorate the ceiling in the kitchen and bathroom; it can be used to cover ceilings on the terrace, balcony and open veranda and, of course, in the bathhouse.

Planken can have a straight or beveled section. The second option is more suitable for walls, and the direct option is recommended for decorating ceilings. Thermowood for finishing has its own special fastening system, which creates gaps between products.

Due to the natural gap, the ceiling is perforated - this ensures good ventilation of the structure. This cladding looks great in rooms with high ceilings.

Ceiling made of boards and beams in the attic

When covering the ceiling with boards in the attic, it is necessary to achieve complete tightness, which will reduce the risk of the structure getting wet and blowing through.

This is true not only for wooden paneling, but also for any false or suspended ceilings.

The ceiling in the attic is the roof slopes with rafters and beams, which are the load-bearing elements of any roofing structure.

Load-bearing elements can be hidden under the skin, but most often they are left in plain sight, as this is unusual and original. If there are no beams on the ceiling, then they are imitated. To do this, a timber is installed on top of the finish.

Rafters are usually hidden under boards and used as lathing for thermal insulation materials. In the attic, the ceiling is always insulated, as well as in a house where there is no attic space, as this increases the energy efficiency of the log house. The need for internal insulation of the ceiling always arises, regardless of the external insulation of the roof.

The comfort in the attic and the durability of the wooden ceiling depend on the quality of thermal insulation work

There are many rules for arranging a “roofing pie”. The most important thing is that the joints of the parts of the membrane material are well taped and not simply fixed with staples.

Plank cladding needs constant circulation of fresh air. To do this, leave a small gap between the boards and the base.

Features of the use of wood in ceiling construction

To finish the floor using ceiling boards, you need to know what types of wood can be used for this purpose, as well as familiarize yourself with the technologies for implementing such a project.

Before you start finishing the ceiling with edged or unedged boards, you should consider several important points:

- The cost of products made from different types of wood differs. Therefore, you should not be surprised that the costs of decorating the ceiling surface may ultimately turn out to be different. In addition, the final cost depends on the use of different parts. As for the availability of products, lining for ceilings is the best choice, since at an affordable price it has a different profile and therefore the ceiling made of boards looks different.

- All wood is sensitive to sudden changes in air temperature and humidity. For example, as a result of changes in humidity levels, cracks appear on wood products. When the temperature changes, the lumber begins to dry out, which leads to the appearance of cracks and cracks in them. In addition, changes in the degree of humidity can provoke a corrosion process on the boards for the ceiling of the house. To avoid unwanted problems with the wooden products used, they are necessarily treated with special impregnations to prevent the appearance of mold, mildew, cracks and other things.

- Everyone knows that wood burns well, so you need to take care to comply with fire safety rules. To reduce the likelihood of fire, any areas on the ceiling where the plank ceiling will come into contact with electrical wiring or heated surfaces should be insulated by attaching a metal sheet. The wires are laid in a special corrugated hose.

- It should be remembered that before attaching the boards to the ceiling, it is imperative to install the sheathing. As a result of its creation, the height of the room decreases. If the room is already low, then this circumstance should be taken into account.

- Even when a ceiling is built from edged boards and laid end-to-end, cracks will still appear, so they will need to be sealed periodically. The only way to avoid this is to use a technology called “tenon and groove”. As a result of using this method, the joints of the boards always have an attractive and neat appearance.

Ceiling made of boards: features of natural coating (22 photos)

In modern interiors, the use of natural materials is actively developing. A ceiling made of boards allows you not only to perfectly stylize the room in a retro style, but also fills the concrete housing with the coziness of a warm wooden house. There are different ways to install such a ceiling, in which both processed lumber and unedged boards can be used. How to hem the ceiling with a board will be discussed below.

Pros and cons of wooden ceilings

The ceiling made of wooden boards has its positive qualities and disadvantages.

Disadvantages of wooden ceilings:

- If in a house or non-residential premises where a ceiling of this design is installed, the air humidity exceeds the norm, then deformation of the material is possible.

- High-quality lumber is much more expensive than synthetic finishing materials, so with a large surface area, lining the ceiling will cost a pretty penny.

- Sudden changes in temperature can also cause the ceiling board to warp.

- Low fire safety.

Advantages of a wooden ceiling:

- Has excellent sound and thermal insulation.

- You can install it yourself.

- Has high strength.

- Has an attractive appearance.

- Environmental Safety.

- Aesthetic appearance.

There are much more positive qualities than disadvantages, which can be successfully combated by treating the material with special compounds that protect natural wood from destruction and deformation.

Wooden ceiling installation

One of the most common materials used for ceiling cladding is clapboard. A ceiling made of this material has high aesthetic values, and the cost of lumber will be significantly lower compared to parquet boards.

Installation of clapboard boards is carried out in several stages:

- Preparing the base.

- Ceiling markings.

- Installation of the frame.

- Fastening the lining.

Each stage must be carried out in accordance with the technical requirements for installing wood flooring.

If a wooden ceiling made from edged boards is installed on a concrete base, then before starting installation work it is necessary to thoroughly clean the surface. If there is an old finish, it must be dismantled, and if there are cracks on the surface of the base, the ceiling must be puttied.

The surface, leveled and free of dirt and dust, must be treated with antiseptic compounds. This treatment helps prevent damage to wood by various bacteria and fungi.

Correct marking of the ceiling surface allows you to make the ceiling perfectly flat. Marking is carried out using a building level and a painting cord, which is installed in perfectly even parallel lines at a distance of up to 10 cm from the concrete floor.