Different foundations are laid for different structures. The foundation is the basis of the future structure; the service life of the entire structure depends on its design features. However, this basis also requires its own sub-foundation. The integrity of the foundation of the future house depends on the type of soil on which it is placed. Both in the case when there are strong stable soils under the future building, and when there are loams under the house, a cushion for the foundation is organized.

It is recommended to lay it under any foundation, regardless of its size and depth. It is very important to select your own sub-base for a specific type of foundation so that it fully fulfills the tasks assigned to it.

Pillow under the stove

General rules for constructing a foundation cushion

We found out why this element is needed.

Now let's look at the basic rules of construction, where to start in order to build a reliable foundation for a load-bearing structure. The materials are laid in layers, with periodic compaction. For manual tamping, layers of five to ten centimeters are arranged; when using vibrating plates, this figure increases by five centimeters.

Many people are interested in the question of why to lay a cushion under the entire foundation. This measure will ensure uniform settlement of the building.

The dimensions of the width of the pillows in relation to the same value of the strip foundation are made thirty centimeters larger.

What are they and how to choose?

In practice, various raw materials are actively used to install damper gaskets under a monolithic slab.

The choice of material is justified by reasons such as:

- design conditions of construction;

- material capabilities of the customer;

- technical characteristics of raw materials.

Most often, concrete, sand, crushed stone, and sand and gravel mixture are used to make pillows. In multi-story construction, they do not limit themselves to one layer, but build a cushion as a combination of several layers of different materials.

Concrete

In this case, the concrete pad should be considered as a separate structural element, and not part of the foundation slab. To make the substrate, high-strength concrete is used to provide the necessary resistance of the load-bearing structure to the forces of frost heaving of the soil.

The surface of the layer must be leveled strictly to the same level in the horizontal plane so that the structure has a level layout and does not tilt during operation. Since concrete itself is an expensive material, in order to save money, the height of such a layer is reduced by installing a sand base underneath it.

Sandy

- durability of a monolithic slab;

- protection from soil moisture;

- permissible level of load on the load-bearing structure;

- reduces the likelihood of house settlement.

You can limit yourself to a sand cushion under a monolithic slab only when constructing buildings up to one floor high.

Types of sand that are used when backfilling the substrate:

- river - with a minimum amount of impurities;

- quarry - after spilling and washing from clay particles;

- marine – after cleaning and hydromechanical treatment.

From other materials

There are situations when it is necessary to use additional materials:

- When construction is carried out on unstable soils with weak bearing capacity, a sand cushion is not enough to strengthen the base. In this case, crushed stone backfill with a granule size of 20 mm or more is used. This material better resists shrinkage and heaving of the soil in winter, ensuring the integrity and stability of the foundation.

- On clay soil, it is practiced to use a cushion of gravel-sand mixture. In this case, crushed stone can be replaced or diluted with broken bricks or small clastic stones. Such a layer will provide reliable protection against penetration of groundwater into the foundation.

Is it necessary to add sand under the foundation, say FORUMHOUSE experts

One of the most popular threads on FORUMHOUSE is the section on foundations, because our experts are always ready to answer any question. Many novice developers are interested in why a sand cushion is needed for the foundation and whether it is needed at all. In this article we will look for the answer to this question.

Sand bedding is done all the time during most work on the foundation of a house. But some builders believe that it is mandatory in all cases, others believe that it is only under certain conditions, and in other cases it is simply harmful.

Is a pillow needed for a strip foundation?

Almost everyone makes a sand cushion under the strip foundation of a house, since it seems to be a guarantee of its strength and durability. However, many people can pour sand into a dug trench, guided by the principle: “the more, the better, because everyone does this.” Neither the geology of the site, nor the characteristics of the soil and its bearing capacity, nor the groundwater level are taken into account.

I read that a strip foundation must rest on an undamaged (untouched) layer of soil, and does not require a sand cushion. But many of my friends did it before pouring. When asked “why” the answer is “we saw it with our neighbors.”

To clarify, you need to clearly define for yourself: what type of strip foundation for the house we are talking about. Namely:

- shallow - MZFL;

- laid below the freezing depth;

- monolithic;

- assembled from FBS blocks.

Each of these four types requires an individual approach when preparing the base.

Why do you need a sand cushion for a monolithic foundation?

A pillow under a strip foundation may not be made if we are talking about a monolithic foundation. But only if the following conditions are met:

- The soil is not heaving;

- The soil under the base is sandy;

- The tape is poured below the freezing depth, with concrete preparation under the base;

For a prefabricated base made from FBS blocks, a sand cushion is simply necessary, because Only with sand can you level out all the unevenness that remains after sampling (i.e. removing the loosened layer) of the soil. Only sand can be compacted to almost natural density.

If this is not done, the foundation block will lie unevenly on the ground (not with the entire surface of the sole), and there may be voids underneath it. This will lead to uneven pressure from the foundation of the house on the ground. Accordingly, the likelihood of its uneven drawdown increases.

When installing a prefabricated foundation, sand preparation with a thickness of 10-15 cm is performed.

Why do you need a pillow under a strip base?

I once asked the chief engineer of a construction company why there was a sand cushion in the foundation. He said: to level the base to “0” and to save concrete.

If a monolithic strip base is installed, then there is no need to achieve a “mirror” base, because Due to its plasticity, poured concrete fills all irregularities. Accordingly, the sole of the base will rest on the soil with its entire surface and redistribute the load on the ground.

When it comes to MZFL, a sand cushion is necessary because... with its help, heaving soil is replaced with non-heaving soil. Moreover, MZFL requires the installation of a drainage system, an insulated blind area and insulation of the foundation itself. These measures minimize the frost heave forces acting on it.

When installing a sand cushion, it is important to understand what kind of soil is under the future foundation. If the soil has low water permeability (this primarily applies to loams and clays), then sand, being less dense, will become a place where water will constantly accumulate. The result is that over time, the bearing capacity of constantly waterlogged soil will decrease, which can lead to subsidence of the foundation

The result is that over time, the bearing capacity of constantly waterlogged soil will decrease, which can lead to subsidence of the foundation.

The issue of using a sand cushion should be considered based on the specific characteristics of the soil, groundwater level, weight and structure of the building, and freezing depth. A sand cushion cannot be considered a universal means suitable for the construction of any foundation, without relating it to the specific operating conditions of the building.

Backfill for the foundation: sand or crushed stone

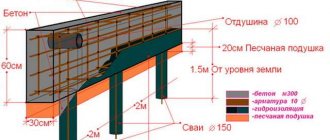

- 20-30 cm is the minimum thickness of the sand cushion;

- To level the base, a thickness of 5-10 cm is sufficient;

- Coarse sand is best suited for backfilling.

Execution of work

We found out whether a pillow is needed for a strip foundation and what materials are best used for this. Now all that remains is to figure out how to properly arrange such a foundation with your own hands.

In order to level the bottom of the foundation trench or pit, a layer of sand or gravel ten centimeters high is poured. In places where it is planned to expand the walls, concreting is used. The same option with a concrete pad is used when it is planned to build a strip foundation with reinforced piles from FBS blocks.

The crushed stone backfill is easy to install; just remember that the height of the embankment should not exceed the base, and the width parameters will be twice as large as the same foundation size. As a rule, the crushed stone layer is thirty centimeters, one share of which is sand.

Having leveled the base, we begin to arrange the pillow. First, a layer of sand is poured, which is spilled with water and compacted. The same applies to the gravel layer.

The most reliable option is a concrete pad. The process of arranging it takes a lot of time, but it can be done on your own. Just remember that you will have to spend money on the necessary materials. The thickness of such a support should exceed the parameters of the foundation by thirty centimeters.

Sand backfill

This type of foundation is the easiest to implement and most economical option, and is chosen by developers who are trying not only to save money, but also to speed up the construction process.

And although at first glance such a base does not inspire confidence in its reliability, it copes quite well with the tasks assigned to it. Sand under the foundation saves it from being washed away and ensures acceptable load effects on its lower part. The bulk material is leveled and compacted with a vibrating plate, periodically sprinkled with water.

If the soil is weak-bearing, gravel is used in addition to sand

Preparatory measures of this kind practically eliminate the shrinkage of the foundation, and here it is very important to perform the compaction correctly

Construction of crushed stone cushion

Before pouring this material, a sand layer up to fifteen centimeters high is arranged, which is leveled and compacted. After this, crushed stone is poured, the size of the stones being 2 - 2.5 cm, and also compacted. The crushed stone layer should be twenty to twenty-five centimeters.

During work, it is necessary to ensure that the stones lie tightly next to each other, filling all the empty areas. To complete this process, you will have to use a vibrating plate, which is guaranteed to help create the desired density.

The construction of the foundation will begin with a crushed stone layer, so the height of the cushion should reach zero level. Such a substrate for a strip foundation allows you to construct objects from any materials.

Concrete pad

Now let's figure out how to mount a concrete mortar platform. This design has only one negative point - it is quite expensive compared to other options, and everything else in this project is a complete advantage.

To begin with, it should be noted that the base will be durable if you follow the technological process, which looks like this:

- the construction site is cleared of vegetation and other debris;

- the soil is leveled;

- a layer of crushed stone is poured, the height of which is ten centimeters;

- compaction is performed;

- a formwork structure is installed around the entire perimeter of the cushion;

- the entire site is reinforced with steel rods before pouring the mortar;

- a concrete mixture is poured, the grade of which is determined taking into account the mass of the future object;

- the solution is carefully compacted with deep vibrators;

- It will take at least four weeks for the structure to fully gain strength.

The basis for the construction of the facility is ideal, but requires significant financial expenses.

Why is bulk material laid?

To briefly answer the question of whether it is always necessary to make a sand cushion under the foundation, the answer will be negative. Bulk material under the sole is needed to perform three functions, which are described below.

Block foundation

The construction of a sand cushion is an event inherited from Soviet times. At that time, the foundation of the house was mainly made from standard factory-made elements, FBS foundation blocks. According to SP 50-101-2004, for a prefabricated supporting part, preparation from bulk material is mandatory.

For a prefabricated foundation, the pillow acts as a leveling base.

The preparation from sand here is justified by the fact that when installing individual elements on the foundation soil, which has even slight differences, they may become distorted. The blocks are not interconnected enough and cannot cope with the uneven ground beneath them. It follows that the first function of the sand cushion under the foundation is the need to create a flat surface for the installation of individual elements. In addition, bulk material, unlike the soil available on the site, can easily adapt to the shape of the supporting part of the building and prevent its displacement during operation.

Monolithic concrete fills all uneven ground.

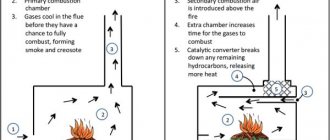

Heaving soils

Frost heaving is a phenomenon that frightens everyone who is involved in construction or who is planning to build a private house with their own hands.

It is important to understand the causes of this problem. It occurs when two factors are present simultaneously:

- water;

- low temperatures.

If you exclude at least one of them, heaving does not occur. Clay foundations are especially prone to this phenomenon. According to SP 50-101-2004, a cushion made of non-heaving (conditionally) materials (that is, of coarse-grained or medium-grained sand or coarse-grained material) is required to be provided for foundations constructed on heaving soils. In this case, only non-buried or shallow-buried supports are considered. Thus, the rise of water from the soil to the base of the building is eliminated, that is, one of the factors for frost heaving is eliminated.

Essentially, a sand cushion protects the sole from rising capillary moisture, which can lead not only to heaving, but also to corrosion of the reinforcement. In most cases, this property is not relevant, since modern concrete mixtures include special additives that increase the resistance of the material to moisture penetration, and only a protective layer is needed to preserve the reinforcement.

https://youtube.com/watch?v=oCBtt4-1d28

If you make a buried foundation, the support of which occurs lower than the freezing thickness of the soil, the second factor for the occurrence of heaving is eliminated - temperature. It is worth remembering that the soil itself is not a source of cold, it comes from outside from the atmosphere, so the deeper the base of the house is located, the higher the temperature next to it in winter. In this case, preparation for protection against backlash is not necessary, since there is no reason why it should be provided. The only exceptions are those cases that involve the presence of other reasons.

Presence of weak soil

Sand preparation will be required if the geology of the site includes fill soil. Such a foundation has a loose structure and is highly not recommended for erecting slab, strip or column foundations on it. In this case, you will need to replace part of the soil yourself. Sand is used as a replacement material.

This reason leads to increased labor intensity of work. The thickness of the layer, which will increase the reliability of the base, can be quite large, sometimes the values reach 1.5-2 m. When laying, the sand must be compacted in small layers (15-20 cm).

If we summarize the reasons why you need to prepare sand with your own hands for the foundation, we can say the following:

- alignment for prefabricated structures;

- elimination of capillary moisture in case of insufficient depth of the underground part of the building in heaving soil (MZLF, shallow slab);

- replacing a loose foundation prone to shrinkage with a more durable one.

In other cases, it is useless, and sometimes can be harmful:

- if the soil on the site does not allow water to pass through well (clay), then all the moisture will accumulate in the sand preparation, like in a trough, which will lead to excessive moisture in the soil near the foundation;

- sand or gravel does not prevent water vapor from penetrating through the bottom; because of this, condensation can form on the bottom of the sole, which negatively affects the structure.

Is she needed?

Despite the important and responsible role of the sand cushion, there are often arguments against its use.

The arguments given by opponents of the bedding are as follows::

- No matter how carefully the sand layer is compacted, some settlement will be present in any case. The thicker the cushion, the stronger the settlement, which creates a significant danger for the belt due to its unevenness. Because of this, the thickness of the bedding is limited - it should not be more than three times the width of the tape.

- A layer of sand poured into a trench dug in clay soil will become an accumulator for moisture. The clay will not let it out of the recess, so a high-quality drainage system is necessary.

- The cushion layer has to be taken into account when calculating the depth of a trench or pit, which increases the volume of excavation work and the amount of excavated soil.

Experts with many years of practice are unanimous in the opinion that the main function of the cushion is to level the bottom of the trench (or pit). It is never possible to create a flat and horizontal area by digging alone.

All attempts in this direction result in a significant waste of time without satisfactory results, so bedding allows you to reduce preparation time. With regard to drainage, the situation is usually known in advance, since the hydrogeological situation at the site is analyzed first.

Therefore, the priority task of the pillow is to form an even and horizontal reference line at the desired height level.

The remaining functions of sand backfill can be considered additional , although they are of considerable importance and are performed quite effectively.

Determining the thickness of a monolithic slab

The thickness of the monolithic reinforced concrete slab, which will be the foundation of your future building, is determined based on the characteristics of the soil of your site. Different soils can support different maximum loads.

The total load on the ground is thus determined from the following initial data:

- The weight of the foundation reinforced concrete slab itself,

- Weights of all building materials that will be used to construct your structure

- A payload that will weigh down your structure. This load includes furniture and various infrastructure.

- Temporary seasonal and climatic loads. It is necessary to take into account the weight of possible snow cover and possible wind pressure.

Practice shows that for light utility and domestic buildings, for example, garages or sheds, it is sufficient to create a foundation slab 10 centimeters thick. To build residential buildings, the thickness of the foundation base is increased to 25 centimeters. This thickness allows for full-fledged multilayer reinforcement.

Document structure

The standard regulates a set of requirements for strip-type foundations and foundations. The main element of this design is a concrete pad reinforced with steel reinforcement, which makes it possible to increase the width of the base of the support, thereby reducing the specific load per unit area. Mandatory requirements for this critical element are provided for by the standard, which regulates the following main points:

- Scope and conditions of application.

- Design features, technical characteristics.

FL foundation pads are manufactured in accordance with GOST 13580 and are high-tech reinforced concrete structures made of heavy concrete

- Specifics of reinforcement.

- Quality control technology.

- Methods of transportation and storage.

Device

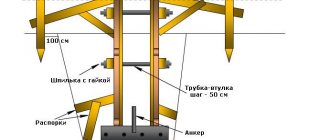

Installation of some types of foundation pads can be carried out independently without the use of expensive equipment and the involvement of specialists. The most effective, but at the same time inexpensive way to arrange a layer is to install a sand and gravel cushion, the installation technology of which involves several stages.

Initially, you should dig a trench, the depth of which will correspond to the beginning of the dense layer of soil. Then coarse river sand should be poured into the prepared ditch. Backfilling should be done in small portions, gradually forming uniform layers 15 cm thick, and alternately spilling them with water and compacting them.

Layers of gravel are laid between layers of sand. Their thickness can vary from 5 to 25 cm, and depends on the type of soil and the number of floors of the house. It is recommended to install a sand-gravel cushion under the entire building: this will ensure uniform shrinkage of the building and prevent cracks from appearing on the walls. The width of the pillow should protrude 30 cm beyond the foundation.

An important condition for arranging this type of layer is the particularly careful compaction of each layer. The density of the freshly poured base for the foundation should be 1.6 g/cm3 relative to the density of the soil.

The construction of a crushed stone cushion is made in the same way. In this case, the two lower layers are sand and gravel, on top of which a layer of crushed stone with a thickness of 25 to 30 cm is poured. The horizontalness of the laid layer should be checked using a building level. The dimensions of the pillow must exceed the dimensions of the foundation by 50 cm.

Arranging a sand cushion is quite simple. To install it, you first need to mark and remove the soil to the required depth. Then, at the bottom of the dug trench, you need to lay geotextiles, which will protect the foundation from moisture. Next, you can begin backfilling the drainage layer, for the formation of which coarse sand is suitable.

The quality of compaction can be checked as follows: you need to step on the pillow with both feet, and then step off it and check for shoe marks. There should be no visible marks on properly compacted sand. Otherwise, you should resume work and achieve a high density of the created pillow.

The thickness of the base layer is calculated individually and depends on the area of the house and the material used to construct the walls. In any case, the total thickness of the sand cushion must be at least 15 cm. Upon completion of the installation work, you need to check the horizontalness again, after which you can begin building the formwork and pouring the foundation.

Application of lean concrete

The use of concrete mixture for foundation preparation is a more expensive technology than the use of crushed stone. In this case, the base material is a mixture of 5-6% cement with a strength class of up to B15 and fillers in the form of sand, gravel or crushed stone. In this case, there should be 3-4 times more stone materials. You can read more about this solution here.

As for the exact composition of lean concrete, it is as follows:

- 2200 kg of sand;

- 160 kg of cement;

- About 75 liters of water.

The thickness of the concrete layer depends on the type of soil, the weight load of the building, the groundwater level, the depth of freezing and can be in the range of 50-100 mm. Before pouring concrete, a membrane is laid in the foundation trench or pit and a layer of crushed stone or a sand-crushed stone mixture 100-400 mm thick is filled. After compaction, the bulk cushion is covered with another membrane layer so that when pouring concrete, the cement mortar does not go down.

Expanded clay can be used as a filler for preparing concrete. However, in this case the amount of cement must be doubled. This mixture has certain heat-insulating properties, but is more expensive and more difficult to prepare.

Using a profile membrane

One of the main tasks of such preparation is to prevent premature drying of the concrete solution, including the seepage of water into the ground. To solve this problem, a type of insulation such as a profile membrane is sold on the modern market. Speed of installation and low price are the main advantages of this material. However, many builders doubt its reliability.

Concrete preparation for slab foundations

The supporting base for the monolithic foundation slab is laid over the entire building area. Under the concrete you need to pour a crushed stone-sand mixture, which you can make yourself or buy ready-made. The underlying layer of sand and crushed stone must be leveled, compacted well and covered with a membrane sheet, but which will be poured with lean concrete.

On dense, stable soils, it is allowed to use a dry cement-sand mixture without crushed stone for foundation preparation. To do this, add 700 kg of sand to each bag of cement (50 kg) and mix well. After this, the mixture is poured into a pit, leveled in a horizontal plane and watered with water through a sprayer. To ensure the necessary moisture during setting, it is recommended to cover the material with film.

Preparation for a monolithic strip foundation, 5 stages

After marking has been completed in accordance with the project and soil has been excavated to the required depth under all walls, the foundation preparation work begins:

- the bottom of the trench is leveled and compacted using a tamper;

- pour a crushed stone layer 50-100 mm thick, compact it and cover it with a layer of geotectile;

- install formwork from boards 150-200 mm wide, with stops installed on the walls of the trench;

- to increase strength, a steel reinforcing mesh of 6-8 mm wire with a mesh size of no more than 150 mm is laid along the entire length;

- pour lean concrete to the top level of the formwork and compact it using a vibrating plate.

Laying geotextile fabric will prevent the cement mortar from flowing downwards from the concrete mixture and will ensure the quality of foundation preparation. It is possible to replace the canvas by pouring a layer of hot bitumen, but such a layer will be more expensive. The reinforcing mesh should be raised above the canvas by 5 cm, resting on stones or special plastic supports. The distance from the outer wire to the formwork wall must be at least 25 mm.

How to make a pillow from crushed stone

Before starting construction work, the base should be covered with finer material. As it, you can use river sand of medium or large size. It does not contain organic substances that can decompose and rot over time. Therefore, it can be used without additional processing. The sand mound should be from ten to fifteen centimeters. After which it needs careful uniform distribution and compaction. If this requirement is not met, the surface may turn out to be uneven, and it is unlikely that this defect will be corrected later.

Only after creating a preliminary layer can crushed stone be poured, the layer of which should vary from twenty to twenty-five centimeters. It, like the sand layer, needs to be well leveled and compacted using a vibrating plate or tamping roller.

If you don’t have such devices in your arsenal, you can make such a tool yourself. To do this you need a log about one meter in size. Two handles are screwed to it, after which the end part of the log is drawn across the entire area of the future foundation. This process is easy to use, you just need to throw a log and when it falls, the sand and crushed stone flooring will be compacted.

This layer will be the beginning of the foundation.

Next, it is necessary to continue work on creating the foundation. The crushed stone layer is covered with mortar. It can be sand-cement, lime-cement, cement-clay. The foundation is laid on a ready-made crushed stone layer. The height is usually chosen from fifteen to twenty centimeters from ground level. The masonry, in this case, can consist of brick or rubble stone. The masonry is reinforced with steel wire. This action is performed to enhance the reliability and strength of the foundation.

Sometimes a pillow is created only from crushed stone. But this only happens if the soil on which the building will stand is sandy. The technology is identical to laying a sand-crushed stone cushion. In addition, the crushed stone base fits perfectly under the foundation, in this case the durability of the foundation is ensured for many years. Crushed stone can easily become a substitute for sand, and its use is indispensable on problematic soils where pouring a foundation is very difficult.

Functional meaning

Any structure exerts some kind of load on the ground. So that it does not sag and the load is distributed evenly, a mineral foundation cushion is placed over the entire supporting area. In addition, the following issues are resolved:

- the construction site is leveled;

- compensates for soil movement during seasonal changes;

- a protective barrier is installed against the direct impact of soil on the foundation;

- the level of soil stability increases, which is especially important for seismically unstable regions;

- a drainage system is provided to remove melt and rainwater from the building.

This or that execution is determined by the state of the working site. This is the type of soil, indicators regarding groundwater, and climatic conditions of the area. The material and design features of the structure being built are also taken into account. The base can consist of sand, gravel and crushed stone, with a dry concrete screed. Before casting the foundation, the cushion is compacted while maintaining a horizontal level.

Tamping machine Source static.tildacdn.com

Types of foundation substrates

Clause 3.3 of VSN 29-85 specifies the materials that can be used for arranging a pillow:

- Sand of coarse or medium fraction;

- Small crushed stone;

- Boiler slag

and other non-heaving soils with a dispersion index D less than 1.0. In practice, sand, sand-gravel or sand-crushed stone cushions are used, which are less heaving in nature than the native soil at the construction site. In order to correctly determine the structure of the anti-foaming substrate, it is necessary to take into account the physical properties of the materials.

For sandy substrates, gravelly sand of a coarse fraction or clean river sand of a medium fraction is considered the most suitable. For a cushion under the foundation of a house, light and thin fractions of sand materials that have deteriorated compression resistance are not recommended. When using them, significant shrinkage is possible.

When choosing the thickness of the sand cushion, they are guided by the data from Table 5 of Section 4 of VSN 29-85, which recommends a maximum ratio of the thickness of the cushion to the width of the foundation equal to 3 to 1. That is, the sand base can be backfilled with a thickness three times greater than the width of the foundation. Typically, the thickness of the bedding is at least 20-30 cm in order to protect against capillary rise of moisture in the sand.

In accordance with clause 3.4 of VSN 29-85, the sandy material of the cushion must be protected from siltation by the surrounding soil, for which builders are required to make protection from geotextiles or polymer materials that prevent the soil from mixing with sand.

For weak-bearing soils, you can make sand-gravel or only gravel pillows in accordance with the recommendations of clause 8.7 of SP 50-101-2004. The crushed stone cushion requires good compaction.

Regarding the use of crushed stone in pillows, experts believe that it is correct to use it as a compacting material as part of a sand-crushed stone system. The sharp edges of crushed stone of a fraction of 20-40 mm, when compacted, are driven into a dense layer into the main soil under the sand base, thereby giving additional strengthening and a stable position to the base of the building.

It is best to compact the pillow using special impact or vibration machines.

An individual, competent approach to filling pillows under strip foundations allows for significant savings in the construction of residential buildings without compromising the strength and reliability of the structure.

Good publicity

Kinds

Foundation cushions can be made of various materials, the choice of which depends on the number of storeys, soil conditions, seismicity and purpose of the structure.

Sand

The most inexpensive building material used when arranging cushions for light frame or wooden one-story buildings. With a layer thickness of 25–30 cm, the sand reliably protects the foundation of the house and acts as a compensator for soil shrinkage. When constructing a cushion, both river and quarry sand can be used. The main advantages of using this inexpensive material are its availability, ease of installation, low thermal conductivity, which significantly reduces the heat loss of the building and high degree of compaction.

The disadvantages of sand include the impossibility of its use in the construction of multi-storey buildings and industrial enterprises, as well as the irrationality of its use on soils with high groundwater levels. In cases where the aquifer level is unstable and experiences seasonal fluctuations, a drainage system should be installed before constructing the cushion.

Sand and gravel

This option is the most common for forming pillows; it is widely used in the construction of private residential houses and summer cottages. Such a cushion is formed on weak-bearing soils and requires careful compaction. The mixture must have a medium-grained structure; the use of sand dust or fine-grained sand is unacceptable.

Crushed stone

Quite durable material that evenly distributes the weight load over the entire base area. It is used to form foundation cushions in houses not exceeding two floors. To form the crushed stone layer, sand and gravel are used as auxiliary components, the proportion of which should be at least 30% of the total thickness.

Concrete

It is the most expensive and reliable material, and is used in the construction of multi-storey residential buildings and industrial buildings. The concrete pad acts as a compensator for the reaction of problematic heaving soils and takes on the entire weight of the structure. The concrete pad is a block of reinforced concrete, marked FL, which means strip foundation

Gravel

The use of this material as a pillow in the construction of multi-story buildings requires the presence of coarse-grained elements, the size of which varies from 2 to 4 cm.

Each of the materials used to create a foundation cushion has unique technical characteristics or combines several properties inherent in its constituent components. Thus, when forming a crushed stone layer, the mandatory components are sand and gravel, without which the functioning of the cushion will not be complete. Therefore, when choosing the right material, it is necessary to take into account the totality of all factors affecting the strength and durability of the foundation.

Making the pillow right

If the base is of poor quality, then the walls may be cut, the base will be destroyed, and other problems will appear.

Geotextiles must be placed under the base of the foundations. This product reduces the risk of moisture penetrating the base material. Next you need to pour a layer of the selected material.

When all the material is filled in, close the water-repellent material. At the end, sand is added, but no more than half a centimeter, so that a shallow foundation on a sand cushion does not deteriorate the properties of the protective coating.

Sand cushion on clay is also used in house construction, but sometimes it is better to resort to more durable options. The decision is made depending on the soil on which the building will be built. If the groundwater is near the surface, it is better to create a solid base to avoid problems in the future.

According to SNIP - building codes and regulations, what kind of sand is used and the height of its embankment is determined from calculations and terrain conditions. If they are normal, then:

- For a strip foundation, a fifteen-centimeter embankment is sufficient. After compaction it should be up to 30 cm high.

- A tiled base requires a backfill of 10-15 cm, and a brick base - 25 cm.

- If the foundation is on columns or piles, then a mixture of crushed stone and sand up to 30 cm, and sometimes up to 60 cm, is required.

If the area is swampy or the groundwater is too close to the surface, then you need help from people who understand these issues. They will determine what the sand cushion under the foundation is for in this case and what to make it from. It is not advisable to use a regular layer for such cases. To increase efficiency, it is necessary to continue drainage and drainage.

The purpose for which an intermediate link is installed between the soil and the foundation is to connect the building to the ground.

During pouring, you need to follow a number of recommendations:

- Form slopes with a steepness of 1:1.15.

- Sow grass, make turf and strengthen the soil in other available ways.

- Make a slope of at least three degrees from the center to the outside.

- Geotextiles must be placed under the base of the MIT foundations.

For ordinary sand, any available means is suitable, but if you add gravel, you will need heavier artillery in the form of:

- vibrolegs. To operate it, a motor is installed that runs on diesel fuel. The large heel compacts the material.

- vibrating plates. Suitable for slab-type foundations;

- vibratory roller It is used to compact the sand layer on large construction sites.

This approach to creating a substrate has many advantages:

- no need to spend a lot on materials;

- mail does not suffer from excessive load;

- there is no need to rent expensive construction equipment, since the embankment can be made more dense using affordable means.

Therefore, such foundations are very popular in construction. They ensure the stability of the foundation and protect the house from shrinkage, destruction of the base and other damage that can entail significant financial costs.

Reinforcement with reinforcement

Providing the necessary strength is achieved by reinforcement produced according to one of the following design solutions:

- single-layer mesh, woven structure;

- welded two-layer mesh frame.

Foundation blocks mainly transfer the load to stable soil layers or to a prepared pad

The first option is used for narrow slabs up to 1.6 meters wide, and the second option is used for standard sizes of products increased to 3.2 meters.

The standard obliges, when installing a flat mesh or volumetric reinforcement frame, to maintain a distance from the reinforcement to the outer surface of at least 30 millimeters. A layer of concrete of the specified thickness will reliably protect steel reinforcement from the penetration of moisture, the destructive effects of corrosion.

Steel reinforcement, securely concreted in the cushion, comes out and forms a mounting loop. This element is necessary for movement during installation. The installation diagram for the rigging brackets is given in the appendix to this standard. The document regulates six options for fastening elements depending on the mass of the slab.