What do you need to remember when building a foundation?

Pouring the foundation for a bathhouse with your own hands.

The bathhouse stands on a strip foundation made of blocks.

The soil must have high bearing capacity;

- It must have uniform compressibility and not swell;

- The grade of concrete must be at least M-200;

- The type of foundation should be shallow, strip or monolithic, less often columnar;

- The foundation design must provide for a uniform distribution of the mass of load-bearing walls and floors per unit area of the base.

Considering that the weight of modern ecological baths is relatively small, because they are built from natural wooden beams with your own hands, the thickness, width and depth of the foundation are insignificant.

In such cases, an excellent solution is a strip or monolithic reinforced concrete structure; less often, foundations can be poured using concrete blocks and aerated concrete. It is worth noting that recently foundations on screw piles have become popular for bathhouses.

Possible errors and tips

In order not to be left with a broken trough when obvious destruction of the strip foundation of the bathhouse is discovered, you should not make the following mistakes during construction:

- An incorrect assessment of the bearing capacity will usually lead to the destruction of the foundation. When cracks and subsidence are detected, it is urgent to identify weak points and strengthen them.

- The use of low-quality materials and violation of waterproofing technology leads to moisture penetrating into the concrete mass and destroying it. In this case, the surfaces of the monolithic tape are freed from soil and re-coated with bitumen mastic along the entire perimeter.

- If the developer did not take care of the timely removal of the heaving layer of soil from the construction site, then soon the foundation strip will begin to collapse. Therefore, at the preparatory stage, soft soil must be removed to its entire depth.

- If the base of the foundation gets into the soil freezing zone, it will certainly cause fragmented deformation in the tape mass. In this case, it is necessary to dismantle the entire structure and resume construction of the bathhouse.

On what soils should you not build baths?

Types of soils for bathhouse foundations.

Foundation on various types of soil.

It is not advisable to build baths on soft soils, peat bogs and sandy soils with high water permeability. If you already have to fill the bathhouse on them, then a thick sand and gravel cushion is made immediately under the base, which serves as drainage.

It’s easy to do this with your own hands: you need to dig a trench, pour coarse sand and gravel into the bottom and compact it well.

Thus, for bathhouse foundations, dry, homogeneous, dense soil will be optimal. But if there is a need to build a foundation on wet soil that is prone to freezing and swelling, then the depth of the strip structure can reach half a meter or more.

In such cases, it is recommended to immediately carry out geological exploration and establish the depth of soil freezing. The lower edge of the foundation is installed to a depth of 25-30 cm below the lower freezing zone.

Reinforcement

Reinforcing a concrete structure with steel rods is mandatory when constructing any building, including a bathhouse. Reinforce the foundation and other structures according to the following recommendations:

- Prepare reinforcement bars of the required length with a diameter of about 12 millimeters.

- Assemble a reinforcement cage for the strip base, including two tiers of horizontal rods and vertical posts connected with knitting wire. Do not use welding, which disrupts the structure of the metal and reduces its strength. Maintain an interval between vertical bars of 30 cm.

- For a columnar base, prepare groups of four vertical rods connected in a perpendicular plane with round or triangular steel reinforcements at intervals of 30-40 cm.

As for the reinforcement of such a foundation, it is done in the lower and upper parts of it if its depth exceeds 50 cm

Everything is ready, you can start concreting.

Choosing a brand of concrete.

Brand of concrete for the bathhouse foundation.

As a rule, such foundations are built with concrete grade M200, but M350 is considered optimal. To calculate the required amount of concrete, you must first develop a sketch of the future structure.

For example, the size of the structure is assumed to be 6x6 meters, the material is wood. Calculation of the required amount of concrete is done using the formula:

V = S x H . where V is the volume of concrete (m³), S is the area of the foundation (m²), H is the estimated height of the foundation (m).

- Strip foundation area S = 21.80 m²;

- Height of the strip foundation wall H = 0.7 m;

- V = 21.80 x 0.700 = 15.260 m³;

- Area of the columnar foundation (three supports) S = 0.48 m²;

- Height of columnar support H = 0.7 m;

- V₂ = 0.48 x 0.700 = 0.336 m³;

- V = V₁ +V₂ = 15.260 + 0.336 = 15.596 m³;

After rounding, the required volume of concrete solution is obtained in the amount of 16.00 m³.

On stilts

Sometimes, in order to save cement mortar, a pile foundation is made for the furnace. It differs slightly in the method of construction from concrete, except that instead of pouring, a reinforced concrete slab can be used.

Circuit and device

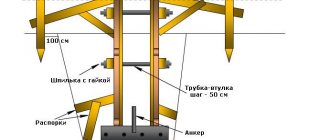

As can be seen in the diagram above, the foundation for a furnace on screw piles is constructed in the same way as a classic foundation, but instead of pouring, it uses piles inserted into drilled wells.

Materials and tools

For installation you need a certain list of materials:

- Cement, coarse sand, crushed stone - for mortar;

- Instead of pouring, you can use a ready-made reinforced concrete slab;

- Waterproofing, which is ideally served by roofing felt or polyethylene film;

- Pipes made of asbestos or polyethylene;

The following tools will be needed:

- Earth drill;

- Container for preparing mortar or concrete mixer;

- Bayonet and shovel shovels;

- Measuring tools: tape measure, corner, level;

- Sledgehammer for installing piles;

Manufacturing technology

If you decide to make a pile foundation for a brick oven in a wooden house, then you must understand that you need an accurate measuring tool and the ability to use a building level - otherwise the base structure may be installed crookedly.

Let's figure out how to properly make a foundation for a stove using pile technology step by step:

- A layer of soil is removed to a depth of 25 centimeters for convenience and so that plant roots do not interfere;

- Then, using an earth drill, four holes approximately 1 meter deep are drilled, each of which should hold the concrete slab on the corner of the surface;

- Crushed stone is poured inside each well and compacted - this will make the foundation for the stove more stable;

- A concrete or asbestos pipe or a roofing felt sleeve is inserted into each well and concrete solution is poured on top.

Then you need to let the solution dry for about 8-10 days, after which you can begin installing the base.

When laying a reinforced concrete slab on piles, each pillar should rest against the corner of the structure as in the photo:

If it was decided to install self-made concrete on the piles, then reinforcement and formwork should be used to properly manufacture the structure:

Separately, a foundation on piles for buleryans and other light stoves should be highlighted; it can be made using metal corners and profiles:

How to pour a foundation for a bathhouse: stages of doing the work yourself.

Bathhouse pouring the foundation.

Sketch. Russian bathhouse with a swimming pool.

Development of a preliminary design for a future bathhouse and creation of a schematic drawing of the foundation. You can do such a project with your own hands in a matter of hours, especially when you have minimal construction skills.

- Preparing the construction site. Strip foundations are characterized by a flat surface, so the soil is leveled and vegetation is eliminated.

- Excavation. Now you need to dig a trench to a given depth, the width should be 20 cm greater than the calculated one so that the wooden formwork can be installed and secured.

- Pour a sand and gravel cushion into the bottom of the trench, moisten it with water and compact it.

- Making wooden formwork with your own hands. It is made from long boards, which are knocked together into shields and installed in the ground near the walls of the trench. To prevent concrete from flowing out through the cracks, it is worth securing sheets of roofing felt or ordinary polyethylene construction film inside the formwork. After the formwork has been installed along the entire perimeter of the future building, you can begin pouring the foundation for the bathhouse with concrete.

- Drive a concrete truck to the construction site or prepare several mechanical concrete mixers. Prepare concrete mortar and begin pouring the foundation mortar in several places at the same time. Filling should be done evenly in layers to completely eliminate the occurrence of air cushions.

- Reinforcement. In some cases, the use of reinforcement is not justified due to the small size of the future foundation. You can do it yourself in a few hours; to do this, you need to lay horizontal reinforcement bars and connect them together with reinforcing vertical belts. You also need to use bolted connections or wire to connect the reinforcement at the corners of rotation and intersection of concrete walls.

- After the concrete is completely poured, you need to cover the structure with film and leave it to dry for several days. In this case, it is necessary to periodically moisten the concrete with water.

Can the procedure be performed in parts?

When building a foundation structure yourself, it is not always possible to fill the entire formwork with concrete in a short time. In such circumstances, phased construction of the foundation is allowed.

The main condition is that the gradual pouring of the concrete mixture must be carried out before the previously poured layers begin to set and harden. The time interval between each stage should not exceed 2-4 hours, depending on the ambient temperature.

Stages of concrete mixture maturation

In a poured cement-sand mixture, two physical processes alternately occur: setting and hardening. The duration of the first stage, depending on weather and climatic conditions, is 3-24 hours.

After the setting phase, the material gradually hardens. This process can last several days or weeks before the concrete composition reaches its design strength. Final hardening occurs on average after 20-30 days.

Rules for step-by-step filling

When building a strip foundation in several stages, you need to follow several recommendations.

The duration of breaks between pouring each subsequent layer is determined taking into account the temperature and humidity of the air. In summer, this interval should be no more than 2 hours; in cold weather, it can be increased to 3-4 hours.

If for some reason the pouring of the next layer has to be postponed for several days, the surface of the foundation should be covered with film to slow down the process of evaporation of moisture from the concrete. In this case, the mixture will remain longer in a state in which gradual filling is allowed.

Horizontal, vertical and diagonal

Methods for phased pouring of LF are classified according to the order of pouring successive layers of concrete:

- horizontal;

- vertical;

- diagonal.

Vertical pouring technology involves creating a foundation in separate blocks, which are created in the formwork, dividing it into several sections using vertical partitions. This method requires more careful calculations and measurements, especially during subsequent leveling of foundation surfaces.

Diagonal pouring is used extremely rarely in the construction of small private houses due to the complexity of the method. This technology is more often used in the construction of structures with complex architecture. This method involves pouring concrete in parts, at a certain angle relative to the horizontal plane.

What else is worth knowing about the features of filling.

Pouring a strip foundation for a bathhouse

We pour the foundation for a bathhouse ourselves.

When pouring the base with concrete, the consistency of the concrete solution plays an important role. Concrete that is too liquid cannot be used; it will form delaminations and the foundation will “float” over time.

Also, liquid concrete will lead to the formation of a water layer on top of the layer, and the solid fraction will settle to the bottom of the trench. The optimal concrete for such foundations should be thick and require sufficient effort to level it.

If the concrete has already arrived at the construction site too thick, then it is worth adding a little water and mixing everything again. It is also worth adding a special plasticizer and frost-resistant additives to the solution. They can be bought at almost any hardware store.

The resulting concrete solution must correspond to the brand; it is better to use a solution of a higher brand than a smaller one. It must also meet the declared parameters of frost resistance, ductility and water resistance.

The formwork should be removed only a few weeks after pouring the concrete solution. This rule is especially true if the climate is quite humid and cool.

After the formwork is dismantled, waterproofing must be installed on the outer surface of the finished foundation. And if there is a basement floor inside the structure, then there is also a thermal insulation layer. You cannot save on insulation, but you can do all the work yourself.

If you strictly adhere to the above stages of pouring the foundation with your own hands, then in a short time and with minimal financial expenses you will get a reliable and durable structure. It is clear that there are other types of foundations that are also suitable for the construction of baths. It’s simply better to choose the optimal design based on the existing situation at the construction site and the soil structure.

Construction technology

Monolithic slab foundations, as a rule, are built on difficult soils, and therefore the most stringent requirements are imposed on their design and construction, as well as on materials, which are regulated by the following regulatory documents: SNiP 3.03.01–87 and SP 50–101–2004.

The construction of all monolithic slabs is carried out according to the same scheme:

- Creating a project.

- Marking the contours of the future structure on the site.

- Preparing the soil for the construction of the foundation.

- Laying utility lines in the ground (sewage, water, etc.).

- Installation of a sand and gravel cushion of the required thickness.

- Laying a thermal insulation layer with its subsequent waterproofing.

- Creation of a reinforcing frame.

- Assembly and careful fastening of formwork.

- Pouring the “sole” with concrete.

If you decide to build a monolithic slab foundation, then you need to proceed according to the same scheme.

Watch this video on YouTube

How to pour the foundation for a bathhouse correctly? Description of all stages of work.

Pouring the foundation for a bathhouse, price for work.

Many regions of our country, unfortunately, cannot boast of solid soils: most territories are characterized by peat bogs, sandstones, loamy soils and other soils that require a high-quality foundation.

This is worth paying attention to, since the foundation is the basis of any structure, a guarantor of reliability and long service life.

We have already written several times about the importance of this issue, so today’s article will not be about choosing the type of foundation , not about which one is better , but will be fully devoted directly to how to pour a foundation for a bathhouse.

Basic principles of construction

Depending on the height of the pillars immersion into the ground, the foundation can be:

- shallow;

- recessed;

- not buried.

In most cases, the first two types of bases are suitable for a bath.

Shallow base

In this case, all platform components are formed into a single strong structure, sensitive to any soil distortion. The structure evenly directs the load over the entire surface of the base. The supports are connected by a solid grillage made of reinforced concrete or metal brackets.

A shallow foundation may have a slight rise in the base, while deformation in level is not allowed above the permissible calculations that are used in the construction business, and on which the structure of the building directly depends.

All calculations for a shallow foundation are carried out in the same way as in the case of other types of foundation.

Recessed base

This type of sole differs in the depth of the pillars and directly depends on the amount of soil freezing. Basically this depth exceeds 0.4 meters. The stages themselves are the same as for the foundation of a small foundation.

You can dig holes with a mechanical or gasoline drill, or with a specialized machine. In the latter case, you will have to turn to construction companies for help.

Despite the small volume of the structure and relatively low weight, on heaving soils it is better to install supports below the freezing point of the ground. Otherwise, when the temperature changes, the foundation may “walk”.

How to properly pour the foundation for a bathhouse: what needs to be done before pouring.

Before pouring the foundation, it is necessary to carry out a number of works that will ensure high-quality preparation and facilitate the pouring process in the future.

Preparatory work.

Frame construction of a bathhouse.

You should start, first of all, by determining the location for your building.

You need to choose wisely and taking into account the requirements of urban planning regulations . taking into account the necessary setbacks from the boundaries of the site, ditches and other buildings.

If the site has vegetation, then it must be cleared of all plantings at the proposed site of construction of the foundation and the surrounding area.

Marking for the foundation.

In the selected and cleared area using available materials:

- pieces of reinforcement, wooden stakes and other means that can act as support points;

- twine, nylon cord, signal (fencing) tape, etc.

Key points are determined, marked with stakes, which are connected along the perimeter with a rope, thus marking the foundation. External boundaries are marked corresponding to the expected dimensions of the bathhouse, or exceeding them. Internal boundaries are marked for strip, columnar and other types of foundation, with the exception of monolithic.

Excavation.

It is necessary to remove the entire fertile layer of soil, or carry out peat removal. This stage involves excavating soft layers of soil that may be mobile. Such excavation is usually carried out to hard layers of soil . Additionally, this guarantees the removal of most organic elements and substances under the bath.

After removing the soft layers of soil, a significant depression appears at the site of the foundation, which in some cases will be filled with water. Therefore, it is necessary to place a pillow under the foundation. Most often, the pillow is filled with sand or gravel, or in layers (first sand, then gravel). It is recommended to spill the sand cushion with water or process it using a vibration plate to increase the density of the created cushion. The pillow must be level.

REFERENCE. It would not be amiss to lay a layer of geofabric before filling the cushion; this will provide additional fixation of the soil, and also ensure that the filling will not “go” underground or be washed out by rain.

Installation of formwork.

The formwork is a frame (most often made of boards, the use of slate and plywood is allowed) for casting the foundation, to create the external boundaries of the foundation according to pre-prepared markings. It guarantees the correct shape of the foundation for the bathhouse, and will also prevent concrete from overflowing to the outside of the structure. The height of the formwork must not be lower than the level of the intended pouring of concrete .

ADVICE. It is recommended that after installing the formwork, lay a layer of polyethylene or other dense material on the bottom, or make formwork with a bottom.

Reinforcement.

The reinforcing frame is made of metal reinforcement through the initial installation of vertical posts into the ground and further laying of horizontal reinforcement (laid in 2 or more layers, depending on the thickness of the foundation). The rods are subsequently fastened perpendicularly and knitted using wire .

Welding of reinforcement, as a rule, is not used, since the structure must be sufficiently ductile.

Watch a short video on how the formwork for a pile-grillage foundation is made. At the same time, you can see how well the reinforcement cage is connected:

IMPORTANT! It is not allowed to install horizontal lower reinforcements directly on the cushion; all reinforcing structures must be immersed in concrete on all sides.

Construction of trenches and cushions

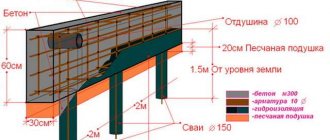

The depth of the trench depends on the depth of the foundation and the thickness of the cushion. The width of the trench is made 10 cm wider than the calculated thickness of the monolithic tape. This is necessary for installing the formwork. When constructing MZLF on loose soils, the trench slopes can be strengthened with boards. Pillowing is necessary to reduce the impact of frost heaving forces on the foundation. The thickness of the cushion, as a rule, is 20-30 cm for slightly heaving and non-heaving soils. For heaving ones - determined according to the table given above.

Correctly backfilling means making 2 layers: the first is coarse sand, which is poured, and then moistened and compacted, the second is fine crushed stone or gravel. Blast furnace or boiler slag can also be used as a second layer. If the groundwater level is high, it is recommended to put a layer of waterproofing under the cushion: roofing felt or geotextile, and fill it on top.

Installation of formwork and reinforcement

The formwork is made from planed boards, the thickness of which is no more than 3 cm. The formwork is mounted in a trench, and its height is 5-10 cm greater than the height of the monolithic tape. A reinforced frame is installed into the finished formwork. Reinforcement of the monolithic tape is carried out in accordance with SNiP 52-01-2003 and SP 52-101-2003. The reinforced frame can contain from 3 to 6 longitudinal reinforcement bars connected to each other by vertical jumpers.

The reinforcement scheme is determined based on the width of the foundation strip. The reinforced frame is assembled from corrugated reinforcement with a cross section of 12 mm, class A3. For a small structure, you can use A500C class reinforcement, the cost of which is much cheaper. The frames are interconnected with an overlap, forming a reinforcement unit. The length of the overlap should not exceed 20 diameters of the rods (20 x 12 = 24 cm). The connections are secured by welding.

For corners where the walls of the future house intersect, it is necessary to strengthen the reinforcement frame by installing additional vertical rods, which are welded to the longitudinal rods. This reinforcement allows the strip foundation to withstand critical loads acting at the intersections of the walls.

You can lay the reinforced frame on a prepared cushion, but it is better to do it on the starting layer of concrete. The thickness of the starting fill should not exceed 20% of the entire height of the tape. Concrete pouring helps create a more even surface on which the reinforced frame is laid. If you decide not to fill the starting layer, then support fungi should be used to raise the reinforced frame above the surface of the pillow by 5-7 cm.

The reinforced frame should be located in space, nowhere in contact with the bedding and formwork.

Pouring concrete

Filling should be done at a temperature of +10 C and above. Before pouring, the formwork must be moistened, then the concrete will lie more evenly. The mixture must be poured in layers, the layer thickness should not exceed 40 cm, optimally 20-30 cm. Each layer is subjected to 5-10 minutes of vibration compaction. This technology does not allow voids to form inside the concrete. To supply the concrete mixture to the formwork, you must use an elastic sleeve or chute.

Pouring the foundation for a bathhouse: work order.

There are many filling techniques, so in our article we will try to cover the most popular topics.

Why is it better to pour in one go?

The strongest and most monolithic foundation fill will be the one that is poured at a time using special equipment. In addition, pouring using a concrete mixer allows you to combine this process with the use of an internal vibrator. A foundation poured in parts is significantly inferior in strength, because when concrete is re-poured onto an already hardened layer, the layers do not adhere to each other . The resulting structure will resemble huge concrete blocks lying on top of each other, but not connected to each other.

Blend recipes.

The composition of the mixture primarily depends on the brand of cement used. The classic recipe consists of cement, sand and crushed stone in a ratio of 1:3:5, or 1:2:3 (we recommend this recipe) . The resulting mixture is diluted with water to the desired consistency, however, the proportion of water should not exceed 0.5.

Crushed stone is an optional additive to ensure maximum adhesion and strength of the composition. Now ready-made mixtures of sand and cement are sold, which need to be dissolved in water. The consistency is most often compared to low-fat sour cream.

We recommend making the concrete solution of such a consistency that it can be molded into a lump that would retain its shape.

Brand of concrete for the bathhouse foundation.

Since the foundation is a serious structure, it is recommended to use cement of at least grade M400-M500.

How to mix concrete.

It is certainly possible to mix concrete manually, however, the amount of the finished mixture is very large. In addition, the manual method guarantees the presence of a large number of air bubbles, which has a bad effect on the quality of concrete. It is recommended to use a concrete mixer; in addition, the mechanical method allows for pouring at a time.

Also watch a video that clearly shows how to mix concrete in a concrete mixer:

Seal.

Immediately after pouring concrete into the formwork, it is necessary to remove the maximum amount of air bubbles formed during the preparation of concrete and its subsequent pouring into the structure. There are several ways to do this:

- bayoneting (repeatedly piercing the surface with a shovel, stick, etc.);

- tapping the formwork around the perimeter (considerable effort must be made);

- using a deep vibrator (can be rented or purchased).

If pouring concrete was carried out in the heat, then it is imperative to cover the surface with plastic film or any other covering material to protect the drying material from cracking under the influence of heat. In winter, it would not be a bad idea to lay insulation, on top of which to put an additional layer of waterproofing for the same reason - insurance against the formation of cracks.

Watering.

There is one rule that faces opponents: the recommendation to moisten the foundation with water a day after it is poured. This advice is not without meaning, since concrete acquires hardness as it hardens, the water film prolongs the drying process, and as a result, the concrete has time to gain even greater strength.

CAREFULLY! Watering with a powerful stream of water is not allowed.

Removing formwork.

The formwork is removed only after the concrete has hardened, as a rule, this period occurs after 5-6 days, the maximum period does not exceed two weeks. Rushing to remove the formwork can lead to uneven drying of the structure, its deformation, and destruction.

How to pour a foundation for a bathhouse if you choose:

The above rules are applied to other types of foundations, taking into account some features.

A strip foundation requires formwork with external and internal boundaries that clearly follow the contours of the building and internal load-bearing structures. On hard soils, a slight deepening of the foundation is allowed. In addition to pouring concrete, it can be made from blocks. Reinforcement is carried out according to the principle shown in the figure below:

Reinforcement of the strip foundation of the bathhouse.

What to do if you can’t fill it at once.

If you prepare the concrete solution manually, then there is a high probability that you will not be able to fill the entire base at once. Pouring concrete in parts is allowed (but not advisable) . however, one simple rule must be followed: each layer must cover the entire perimeter of the foundation . let it be thinner, but remain unified (that is, the layers should be horizontal). Filling with blocks will lead to the formation of vertical joints that will not be firmly connected to adjacent ones. In such places, the foundation will be subjected to increased load, which can lead to its deformation or destruction.

This is a type of foundation rarely used in the construction of baths. But it is indispensable in regions where the soil freezes very quickly, or in areas where frequent flooding is typical.

Slab foundation of the bathhouse.

Shallow columnar.

The construction of such a foundation is much cheaper than a strip foundation . Sand is also poured into the pre-prepared holes for the pillars as a cushion. Tamping is carried out using water poured into the hole. Concrete is poured into inserted asbestos pipes, or around reinforcement inserted into the ground. We recommend that you familiarize yourself with many of the nuances in the article about columnar foundations.

Bored piles.

The main nuance is that it is necessary to drill under the pile to dense layers of soil. However, the construction of such a foundation is available at any time of the year . Read more about pile foundations for baths at the link.

So, we told you how to properly pour the foundation for a bathhouse. As you can see, the process of pouring a foundation is not particularly complicated if good preparatory work has been done and all conventions have been followed. However, this process involves the use of expensive equipment and tools, so sometimes it is justified to conclude a contract with a specialized organization. However, the modern market offers many solutions where you can do it yourself.

Production and installation of formwork

The concrete foundation is poured into a pre-assembled frame structure. To complete the work you will need:

- boards;

- sheet metal.

A formwork structure is assembled from metal or wooden panels, which should rise 20-30 cm above the zero mark. It is important to ensure a smooth surface on the inside of the frame, allowing the panels to be removed after the concrete has hardened.

This element of the bath structure is performed by pouring concrete into formwork made from boards

Ensure the frame remains stationary using vertical posts driven into the soil. After installing the panels, install wooden spacers or metal threaded rods. If necessary, use tie wire to ensure structural rigidity.

Waterproof the frame from the inside of the formwork using plastic film or roofing felt. The panel contour must follow the configuration of the building and have rigidity that allows it to withstand the forces from the mass of concrete. Now you can begin to strengthen the structure using steel reinforcement.

How to properly pour the foundation for a bathhouse (advantages and disadvantages).

The bathhouse is one of the most popular buildings on a summer cottage. Most owners of private houses strive to acquire such a structure.

Unlike the house itself, you can build a small bathhouse yourself.

It is only necessary to select materials and carry out calculations.

But additional knowledge will still be useful.

For example, many are interested in the question: how to properly pour the foundation for a bathhouse?

There are several types of foundations for a bathhouse: pile, strip, columnar foundations. You need to choose one type or another depending on climatic conditions, soil type, and the weight of the building itself.

- The severity of the ceiling, as well as the materials from which the walls and ceiling will be made;

- The design of the entire bathhouse, the number of floors, dimensions and weight;

- Groundwater level, degree of soil freezing in winter, weather conditions, climate, precipitation level.

These factors should be paid attention to first. The choice also depends on financial capabilities, as well as knowledge and skills.

Pouring the foundation for the bathhouse.

Preparing the construction site

Future construction site.

When choosing a place for a future bathhouse, try to allocate the most rocky area for its construction. This will reduce the likelihood of groundwater rising and create an additional, and also quite large, margin of safety for the foundation of a future building.

The most ideal option would be to build walls on a stone plateau or a huge boulder, the area of which will exceed the area of the entire bathhouse. But since the possibility of such an option is negligible, we will have to prepare a fairly strong sole with our own hands.

The order of actions can be determined by the following list of work performed:

- looking for a place;

- clean it of debris;

- remove the top part of the soil;

- strengthen the sole;

- we make the foundation.

Place for a bath

The best place for a bathhouse will be a place on your site that has the most durable and rocky soil. If the composition of the soil throughout the entire site is approximately the same, then it is better to arrange the construction site in that part of it that is least used by you.

Determine the size of the future bathhouse, and add 0.5 m on each side - this will be the location of your construction site. Remove all the debris there, level the soil, and you can begin to strengthen the soil.

Making a sole for a bath

Photo - preparing a place for a bathhouse.

Of course, it is clear that it makes no sense to build a bathhouse without a foundation. After 5-7 years, mold will form on the walls of the bathhouse, and the fungus will not only begin to infect the walls, but will also penetrate the room, and this is a direct threat to people’s health.

And inter-seasonal ground movements will do their destructive work and lead to the destruction of load-bearing walls and partitions.

Therefore, before construction, it is necessary to prepare the foundation for the bathhouse with your own hands:

- The soil must be compacted and moisture must be removed from the walls, which will certainly accumulate on the walls at the junction with the ground. The instructions below will tell you in detail about all the activities that are necessary to prepare the foundation of not only a bathhouse, but also any of the light buildings, such as a barn or gazebo.

- The first step is to remove the top layer of soil. The volume of land removed directly depends on its density and composition. If it is loose chernozem, then you may have to go deeper by 30 cm-50 cm, or even more, but if the soil is compacted loam, then 20 cm is more than enough.

- First, you need to mark the pattern of passing and crossing the walls, after which we begin preparing the site with an ordinary bayonet shovel. The soil is selected not only under the walls, but also under the entire area of the future floor.

- After its removal, we begin compacting the prepared base. To do this, you can use either a vibrating-ramming machine or a log 1 m-1.5 m long and 15 cm-30 cm in diameter with a crossbar nailed to it as a handle.

- The next step is to pour a gravel cushion with a thickness of at least 20 cm. It is better to use marble, granite or diabase gravel, since these types are the most durable and moisture-resistant. You need to fill it in small portions, compacting it thoroughly. After the pillow is prepared, you can move on to the last phase of preparing the base.

How to properly pour the foundation for a bathhouse?

It is difficult to determine the factors and conduct geological research on your own. It is better to contact your neighbors or those who have already carried out construction on plots nearby.

It is imperative to determine the type of soil, so you should not neglect the advice of others.

The most difficult and unsuitable areas for construction are peat areas. If there are no other options, you need to carefully prepare the area: remove the top layers of soil. The process is costly and labor-intensive.

Clay and sandy soils are the most suitable for construction. But if the groundwater level is high, cracks and damage may occur.

If the soil is loose, light, or unstable, a deep pit will be required. Heavily heaving soils require only a pile foundation. Pit preparation is necessary.

How to select the components of a concrete mixture?

We have already found out that the active components in the solution formula are cement and water, which makes it work. Only the grade of cement should not be confused with the grades of concrete, since these are completely different parameters. M of Portland cement means a value indicating the strength of the cement mortar. Therefore, regardless of what kind of concrete is needed for the construction of the future foundation, cement is taken with the marking M400 or M500.

Most often, Portland cement is used to independently mix concrete for the foundation. A pozzolanic analogue can be used if there is no base, as it shrinks greatly in the open air. The slag version perfectly resists ground moisture, but is pleased with frost resistance.

Since the foundation is a predominantly reinforced structure, crushed stone with a fraction of up to 40 mm is needed to mix concrete according to construction requirements. The optimal choice is crushed granite gravel, its rough edges optimize traction. Crushed limestone is not suitable for aggressive groundwater. You need river or sea sand, but in the absence of it on sale nearby, quarry sand will do. The sand must be sifted and washed. The inclusion of clay and organic inclusions of more than 5% is unacceptable.

You don’t need distilled water for mixing, but you don’t need to scoop it out of a stagnant lake of mud either. There should be no biological impurities, oils, or salts in it at all. Typically, concrete producers use potable water. The amount of water is approximately equal to half the mass of cement.

Site preparation.

First, the site is cleared of construction debris. Next, make the markings.

To do this you need to take:

- Reinforcement or pegs;

- Rope;

- Roulette;

- Square with right angle;

- Level and clothespins.

You need to hammer in a peg and measure the length of one wall. Secure with a second peg. Then pull the rope for the perpendicular walls. Angles are checked.

Everything is fixed with clothespins. Then measure the distance between the diagonals.

The pegs must be driven in firmly and the rope must be pulled tightly. The result is a rectangle, the diagonals of which should be equal. Deviations cannot be more than 2 cm.

We are thinking about building a bathhouse - what kind of foundation is suitable for building walls?

When planning to start building a bathhouse, it is necessary to choose a foundation design that ensures uniform distribution of acting loads on the ground and prevents the walls from saturating with soil moisture. To ensure the longevity of the structure, this problem should be taken seriously.

The fundamental part of the building is the construction of the foundation

Various types of foundations are constructed from concrete mortar reinforced with reinforcing bars:

- strip foundation. It is widely used for stone, block and brick buildings, and has proven itself on various soils due to its increased load capacity. The base is made in the form of a solid reinforced concrete strip, repeating the outlines of load-bearing walls and internal partitions. The process of constructing a monolithic tape involves the formation of a pit along the perimeter of the bathhouse with a depth of 0.7-0.8 m and a width of 0.3-0.4 m. A crushed stone-sand mixture is poured into the bottom of the trench, formwork is assembled, reinforcement is performed and concrete is poured. A prefabricated version of the tape base is also possible;

- columnar foundation. Tested in the construction of log baths, as well as frame-type buildings and lightweight buildings made of wooden beams. The base of a columnar structure is made in the form of a group of supporting elements located in the corner parts of the building, as well as in the middle of walls and partitions. Rubble stone, brick, steel or asbestos cement pipes, and reinforced concrete are used to make supports. The columnar design is simple and does not require significant financial costs. Depending on the mass of the bathhouse, the size of the pillars is 15-20 cm, and the interval between them is 2-2.5 m. It is necessary to ensure that the supports are deepened 0.2 m below the soil freezing level;

Various types of foundations are constructed to build a bathhouse

- slab foundation. It is made in the form of a solid reinforced concrete platform, the dimensions of which correspond to the dimensions of the bathhouse being built. A monolithic base is rarely used. It is in demand for soils with close proximity of water layers and soils with a heterogeneous structure. To construct a monolithic base, soil is removed to a depth of 0.3 m. Then the base of the pit is leveled, waterproofing material is laid down and a gravel-sand cushion is formed. The slab is insulated with expanded polystyrene sheets, which, after assembling the formwork structure and performing reinforcement, is filled with concrete. The slab base is a reliable and expensive design;

- screw foundation. It is used to ensure the stability of buildings erected on weak soils with shallow aquifers and on sloping areas. Piles made of metal pipes with a pointed working part and screw blades to facilitate screwing into the ground are used as supports. The depth of screwing in pile supports is determined by the nature of the soil. Depending on the number of supporting elements, installation is carried out manually or using special equipment. After being immersed in the ground, the supports are cut to the required height and filled with concrete.

When choosing the type of foundation structure for building a bathhouse, you should pay attention to a number of factors:

In order for the bathhouse to please you with its aesthetics and cozy atmosphere, you should follow the procedure correctly

- soil properties at the construction site;

- moisture concentration in soil layers;

- groundwater level;

- soil freezing depth;

- total weight of the structure;

- the nature of the relief;

- properties of the building materials used;

- bearing capacity of the foundation.

Having analyzed the nature of the soil and the structural features, it is advisable to decide to build a proven foundation in the form of a reinforced concrete strip for the future bathhouse. This design is the most popular, does not require an increased volume of building materials and can be easily erected independently.

How to pour certain types of foundation?

Pile. Suitable for all soils, can be used even in peat areas, as well as areas with uneven terrain. The size of the piles depends on the weight of the entire building.

If it is large, screw piles will do. But they are expensive, and they are not easy to score. Wells need to be drilled. No formwork is required, which will reduce excavation costs.

Heaving of the soil does not affect the condition of the foundation. There is no need to equip a full basement. This is not required in baths.

Plates . The foundation is suitable for unstable and weak soil. There are two varieties. Each of them has different filling features:

Monolithic slabs. They are made of concrete. Depth – 30-70 cm. At the bottom of the dug hole you need to make drainage from pipes. The bottom is carefully leveled and compacted. It is necessary to arrange a sand cushion: it is made of sand from crushed stone.

The slabs can be ready-made: then they are laid on top of the finished cushion and secured with cement. If the slab is completely monolithic, formwork is made along the entire perimeter of the foundation.

Next, a reinforcing layer is placed in the formwork, and everything is filled with a mixture of concrete. In a month you can begin construction work.

Rubble . Depth – 50-70 cm. A sand cushion is also needed here: it is laid and carefully compacted. Then a layer of crushed stone is laid.

The layers alternate until the pit is 2 thirds full. Next, the foundation is laid out with a layer of rubble stone, secured with clay and cement.

Tape. Better than others for baths. In this situation, it is easier to use a finely sealed one. The depth depends on the weight of the building: it can be from 30 to 100 cm. A sand cushion is left at the bottom, which is then covered with a layer of crushed stone.

Next, you can begin installing the reinforcing layer - the frame. It is filled with a mixture of concrete. The frame cells are fastened together by at least 50%.

The formwork for this type of foundation is formed from the bottom of the trench if the soil is weak and subject to change. It is better to make it from strong boards or durable wood. Inside you need to place layers of a power frame.

Columnar. Another type of common foundation for a bathhouse. Withstands buildings made of both brick and wood. First, they dig holes - places for future supports.

Sand is placed at the bottom of such holes, then it is filled with water and compacted. You will get a dense layer.

Next, construct a brick pillar of the required length. It is held together with mortar. To make the structure stronger, a reinforcing layer is placed inside.

Layers of waterproofing are laid on top of the pillars. If the soil freezes heavily in winter, it is necessary to additionally put a layer of tightly compacted sand in the pits.

Construction of a strip foundation

For small buildings, such as a garage, summer kitchen, bathhouse, you can install a shallow strip foundation. In order to calculate the depth of the trench for such a foundation, it is necessary to study the composition of the soil on the site.

If the soil is stable - not crumbly, moderately moist - a trench with a depth of about 40 cm will be sufficient. For more unstable soils - chernozem, peat, sand - this value should be increased to 70-80 cm.

The width of the foundation depends on the material of the walls of the bathhouse: for light structures 25 cm will be enough, and for stone or brick walls a minimum of 35 cm is required. The trench itself, at the same time, should be even wider - about 5 cm.

A step-by-step description of the process of laying a strip foundation for a bathhouse looks like this:

- The lowest point is found on the leveled area - from there the foundation will be built. In order for melt and rain water not to damage the bathhouse, but to drain from the area around it in a timely manner, it is necessary to make a slight slope. The slope is made in any direction except north (just a couple of degrees is enough).

- Metal rods are installed at the corners of the future foundation, and ropes are pulled with their help. In the case of a strip foundation, there must be two contours (internal and external). Therefore, you need to pull two parallel ropes, between which leave a distance equal to the width of the foundation plus 5 cm.

- They begin to dig a trench. If the soil is too loose, the trench is made in the form of an inverted trapezoid. The bottom of the pit must be level; it is checked using a building level.

- Now you need to make a gravel-sand cushion - it will ensure the stability of the foundation and smooth out possible soil movements. Sand is poured into the bottom of the trench, moistened with water and compacted. Then they pour in gravel, compact it too, and now it’s sand again. The layers are alternated until the trench is half filled.

- In the case of very unstable soils, you can further strengthen the base under the foundation - lay a layer of brick or stone on a gravel-sand cushion.

- Now the construction of the formwork begins. It is knocked down from boards, while all fasteners must remain outside, and there should be no gaps between the structural parts. The smoother the formwork is, the less sanding the finished foundation will have to do.

- Reinforcement made of metal rods and wire is laid at the bottom of the trench.

- Polyethylene or roofing felt is placed on the inner walls of the formwork to protect it from moisture.

- The formwork must be filled with concrete at one time. If you take breaks in the work, the foundation will be layered and fragile. Therefore, it is better to order a concrete mixer and purchase the required amount of ready-made solution.

- The formwork can be removed after a week, and the construction of the bathhouse can be continued only after three weeks, when the concrete has gained sufficient strength.

When building a concrete foundation, it is important to remember that any air bubbles in the thickness of the solution will sooner or later lead to the destruction of the material. Therefore, concrete can be poured from a height of no more than 50 cm, and after pouring, compact it with a vibrator or, at least, pierce the solution with a rod in several places

Marking work

The marking is carried out according to the existing bathhouse design. It will consist of marking the external and internal lines of future walls.

To mark the outer parts of the walls, you need to acquire a construction square, a cord, a tape measure, pegs and a plumb line. Controlling the vertical level with a plumb line, we drive a starting stake into the point where one of the corners of the building will be located.

After this, 4 more pegs are driven into the ground using the same principle, while controlling the accuracy of the angles. We check the correctness of the diagonals of the perimeter of the building. If they are the same, you can proceed to marking the internal parts of the walls, otherwise, we adjust the placement of the stakes, constantly rechecking the parameters of the sides, the correctness of the angles and diagonals.

Next, a cord is pulled from one stake to the next. Its horizontal level will indicate the height of the foundation. To check the tension of the cord, you need to use a level, after which you can begin to mark the internal perimeter along with the partitions.

How to correctly calculate the depth and width

A complete foundation calculation is a complex engineering task, accessible only to a trained specialist.

It is required to perform a comprehensive study of the soil, calculate the weight of the bathhouse without and with a foundation, and take into account a large number of special quantities, coefficients and indicators.

For outsiders who do not have the appropriate education and experience, such a calculation will not be possible.

The solution to the problem will be to contact specialists who professionally deal with such calculations. This option is optimal, but will require certain financial investments.

Another possible way is to use online calculators, of which there are many on the Internet . The results obtained using this method must be duplicated on other resources in order to be able to check the data obtained and select the most reliable values.

Foundation insulation

Schematic representation of the insulation of the base of a bathhouse.

The foundation for a frame bathhouse can freeze, therefore, it is insulated from the outside with various materials. Insulation is carried out before pouring concrete. Sheet material made of polystyrene foam or polystyrene is used; they are optimally suited for these purposes. Sheets with a thickness of 50 - 80 mm are used, with a size of 600 x 1000 or 1000 x 1000 mm.