The bathhouse is a unique place. Here you can take a break from the hustle and bustle of your days, relax after hard working days, and meet with old friends. An important attribute is wooden doors for a bathhouse. Choosing doors is a rather difficult task, because the operating conditions are quite complex. Wood is affected by high temperatures and high humidity.

Requirements for a bath door

A real traditional Russian bathhouse is built from wood. The interior of the room is also made of wood. In order not to violate long-standing traditions, the door should also be made of wood. But it is very important that the door leaf can withstand temperature changes and constant exposure to moisture. Also, the door leaf should look stylish, because bath procedures are not only health benefits, but also real relaxation for body and soul. Therefore, aesthetic characteristics are very important.

Wooden doors to the bathhouse have many different advantages:

- High-quality wood is environmentally friendly;

- The smell of natural wood not only gives a pleasant feeling and helps you relax, but also has a positive effect on health;

- Wood has a low level of thermal conductivity and retains heat well in steam rooms and saunas;

- Doors are often made in a classic style and will bring pleasure to connoisseurs of bath traditions.

But among the advantages there are also several disadvantages. Since the door leaf is constantly exposed to steam, moisture, and high temperatures, the product may become deformed or shrink over time. So, you have to remove the canvas and rearrange it so that it then falls into place and the door can close tightly again. If it doesn't close tightly enough, steam escapes from the room.

This is the only drawback that wooden bath doors have. Nothing more can be said about the minuses.

What must be in the bathhouse

The bathhouse can be visited for many reasons:

- For good health;

- To have plenty of time to chat with comrades and friends;

- To spend a pleasant time with your family.

There are different reasons for going to the bathhouse. That is why many people who own a private house try to place a steam room on the property. The design of baths can be very diverse, but there are some mandatory attributes that are present in any steam room:

The process of preparing a place for installing a door to the dressing room

- Entrance door.

- Waiting room.

- Locker room.

- Swimming pool in the bathhouse.

- The steam room itself.

This is something that must definitely find its place in the space of a built or purchased bathhouse for placement in the private sector. Particular attention should be paid to the front door. It is due to this that the required temperature is maintained in the bathhouse, even if it is winter cold outside.

Entrance metal-plastic door with window

Types of doors

Wooden doors for a bathhouse can be made in the form of a solid structure. Among the advantages of this design are lower susceptibility to deformation and resistance to high temperatures. The cost of solid wooden doors is quite high, but the quality is also high. Take a look at what bath doors look like. These wooden doors are very traditional, you can see one of these in the photo below:

Combined models are also popular - glass inserts are built into the canvas. Often, they use not ordinary glass, but special glass. It is highly durable and can withstand high temperatures. It can be of several types. Thus, there are tempered glass, transparent, frosted or corrugated.

TOP 5 main types of wood for lumber

| Photo | Name | Rating | Price |

| #1 | Larch | 100 / 100 | |

| #2 | Cedar | 99 / 100 | |

| #3 | Pine | 98 / 100 | |

| #4 | Fir | 97 / 100 | |

| #5 | Spruce | 96 / 100 |

Larch

Larch is a special type of softwood often used for lumber. In strength, it is second only to yew and oak, and its ease of cultivation and processing ensures a low price compared to elite types of wood. It is slightly susceptible to environmental influences and is resistant to moisture and sun. This is a good material that is used for floorboards, floor beams and creating walls.

Larch Pros

- high strength and moisture resistance;

- durability;

- low susceptibility to warping.

Minuses

- high thermal conductivity;

- There is a possibility of internal cracks appearing due to improper drying technology.

Cedar

Cedar is an expensive wood used for finishing buildings and creating load-bearing structural elements. In fact, products made from real cedar are almost impossible to find on the CIS market, because it grows only on a few islands in the Mediterranean. The alternative used is Korean pine, often named after this rare tree.

Cedar Pros

- resistance to rot and wormhole;

- high strength;

- minimum defects (radial cracks or ring delaminations).

Minuses

- has a specific woody aroma;

- Cedar wood is very expensive.

Pine

Pine wood is considered universal in woodworking because of its qualities. It has a lower density than larch, but processing costs are lower. Pine contains a high proportion of resins, so its durability is high. This material is used for beams, boards, logs and beams, as well as facing material. It is pine that is most often used to produce lining.

Pine Pros

- environmental friendliness;

- strength;

- long period of operation;

- easy repair.

Minuses

- pine wood is soft, easily scratched and damaged;

- Resin stains may form on the walls.

Fir

Fir is rarely used for lumber, because it requires lengthy processing. This wood has high natural humidity and low moisture yield, which is why it needs to be dried long and hard using special ovens. Therefore, this material is used only for cladding.

Fir Pros

- wood is practically odorless;

- does not contain resin.

Minuses

quickly rots and is destroyed by wood-boring insects.

Spruce

Spruce lumber has a low price and is widely available. It is a simple wood often used for cladding. Spruce timber is almost never produced; more often it is used to make saw logs or lining.

Spruce Pros

- spruce wood is practically not subject to warping;

- sticks well.

Minuses

- high humidity;

- large deformation during drying;

- a large number of branch bases.

Materials

As for the breed, it is most often linden. However, sometimes some other types of wood can be used.

Linden has all the necessary characteristics that are relevant in baths and saunas. For example, linden wooden entrance doors for a bathhouse can last a very, very long time. The door leaf has high strength and resistance to operation in adverse conditions. Linden also emits a very pleasant aroma. Linden sheets retain heat well, which is very important for a bathhouse. Such products do not swell, do not emit resins, and are very pleasant to the touch. Linden is an excellent solution both as an entrance and as a door to a steam room.

Linden is not the only material used in the production of bath doors. In addition to linden, abash, Canadian cedar or ash are successfully used in industry. The technical characteristics of these breeds practically do not differ from each other - the only difference is the cost. But at the same time, all the characteristics are kept at the linden level. Therefore, it is considered the most optimal and affordable option.

But fashion is slowly taking its toll and many people prefer oak products. The main difference between these wooden doors to the bathhouse is the greater weight of the door leaf and higher durability.

General recommendations for choosing door leaves

Here, not only the personal preferences of the owner are taken into account, but mainly the specifics of the bathhouse, the size of the room, and the predominant material in the arrangement. For example, glass doors are very popular for saunas. This is explained more by the interior features than by technical nuances.

Doors for Russian bathhouses are traditionally purchased from wood. Since they have high heat resistance, they fit perfectly into the overall design and have an affordable price.

Although metal sheets and products using PVC have recently appeared, wooden and glass options are still not inferior in popularity.

Doorway

In bathhouses of modern design, special stoves or electric fireplace systems are used. Thanks to this equipment, the room is constantly maintained at comfortable and required temperatures. If cold air enters a room, it will heat up almost immediately. Even more - modern equipment requires a constant small flow of air to operate. The wooden door for the bathhouse at the bottom has a small gap, which solves the problem of ventilation.

The optimal size for a doorway in a steam room is 1.8 x 0.8 m. At the same time, the ceiling height should be approximately 2.2 m. You need to know that in a traditional steam room the distance from the top door strip to the ceiling should be at least 40 cm. All depends on the door design. In the case of a wooden door, there may not be a threshold.

Technology for manufacturing and assembling a wooden door for a bathhouse

A wooden door is the simplest and most affordable design option for a bathhouse.

To perform self-assembly and installation of the product, you need to prepare the following lumber:

- Boards with a tongue-and-groove base for a leaf 20 cm thick, 210 cm long (the quantity is determined by the required door width).

- Wooden beam for strengthening the canvas with a section of 3 × 2 cm.

- Wooden beam for strapping 3 × 3 cm.

- Beam for the door frame 11 × 6 cm.

- Foam for sealing.

- Anchors.

- Carpenter's glue for joining parts.

- Self-tapping screws for wood.

- Set of hanging hinges.

- Handles and latch.

Working tool kit:

- Electric jigsaw for cutting wood.

- Screwdriver for self-tapping screws.

- Planer for stripping the blade.

- Clamps for installing the canvas.

- Medium grit sandpaper.

- Perforator and feather type drills.

- Calipers.

- Construction level.

- Yardstick.

- Hammer and scissors.

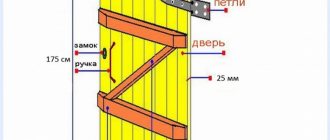

To properly assemble the door structure, you will also need a drawing indicating the dimensions of all parts and the order of their installation.

Determining the dimensions of the structure

The dimensions of doorways in self-built baths may differ slightly from standard ones. Before you make a door to the bathhouse with your own hands, you need to decide on the dimensions of the future structure:

- Using a tape measure, measure the width and height of the doorway strictly vertically and horizontally to avoid possible distortion.

- Subtract 5 cm from the resulting width value and 3 cm from the height value. These are the dimensions of the door frame without a threshold. The thickness of the threshold is determined after the door leaf is manufactured.

- From the width of the frame, subtract the width of the timber for its manufacture and an additional 6 mm for the gap on both sides of the structure - the width of the door structure is obtained.

- The height of the door is determined as follows: the width of the beam is subtracted from the height of the door frame and an additional 17 mm for ventilation gaps - 4 mm at the top and 13 mm at the bottom.

If the result of the calculations has a slight discrepancy with the standard size, you can make a standard structure with a width of 80 cm and a height of 200 cm.

Door leaf manufacturing process

- The boards are cut to length, and the height of the finished structure will be 200 cm, taking into account the length of the board and trim. The timber is mounted around the perimeter of the door, so first determine the cutting length of the lumber: 200 cm - 6 cm = 194 cm.

- Calculate the required amount of material for the canvas. The width of the door with the trim is 80 cm, without it – 74 cm. The standard width of the board is 20 cm, so cutting is done along the board.

- On the first element, a special tenon with a smooth and cleaned end is made with a plane.

- The prepared boards are laid on a perfectly flat surface and connected into a single structure. Check the geometry of the canvas.

- The strapping beam is cut into 4 pieces: two 200 cm each, two 74 cm each.

- The boards are glued together with wood glue, which is poured into the grooves made. The finished canvas is reinforced in the corners with clamps. For ease of assembly, a mallet is used, which ensures that the boards shrink tightly into the grooves. The canvas is placed under a press for 3 days to dry.

- The dried canvas is sanded using a plane to obtain a smooth and even surface.

- The strapping is made from timber. The parts are fixed to the end parts of the canvas using self-tapping screws, and at the corners they are fastened with an overlap or a tenon. Self-tapping screws are recessed into the wood by 3 cm.

- The bars are fixed to strengthen the structure. For the front door, the slats are mounted on the outside, for the steam room - on the inside.

Installation of door structure and fittings

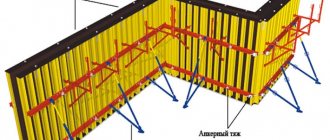

The next stage of work is installing the frame in the doorway. It is important to remember that the box is mounted in compliance with the general geometry of the structure to prevent it from skewing and tilting.

- The width of the assembled box should exceed the width of the finished canvas by 8 cm. The racks are assembled from timber, in which a longitudinal groove is made for installing the canvas. The permissible technical gap between the frame and the door leaf should be 2–3 mm, taking into account the expansion coefficient of wood during swelling.

- A horizontal post is inserted into the opening, supported by beams, then the lower post is placed as a threshold. The geometry of the structure is checked using a building level. Wooden blades are driven between the wall and the frame to secure the structure. The box is secured to the wall using long anchors. The gaps are filled with polyurethane foam and decorated with platbands.

- After assembling the frame, the door leaf is installed. To do this, apply markings for the loops. The first hinge is installed at a level of 30 cm from the top level of the door, the second at a level of 55 cm, and the third at a level of 25 cm from the floor. This arrangement will prevent skewing and deformation of the door.

- The hinges are fixed to the door leaf with self-tapping screws. Next, install the handles and latch on the inside of the door. The door is mounted in a frame on hinges.

- They check the tightness and ease of opening of the door leaf.

Door fittings must be made of high-quality materials with low thermal conductivity and high resistance to high humidity. Therefore, it is better to choose wooden handles and latch, as well as brass hinges treated with anti-corrosion paint.

Door to the steam room

More stringent requirements are imposed on this wooden bath door. It is necessary to choose a solid structure that is made entirely of wood. Experts recommend using single-leaf door leaves for steam rooms that open outward. Despite the simplicity of execution, this design is very effective.

It is believed that the door leaf should not be equipped with locking systems, but at the same time the leaf should close tightly and not open. To achieve this effect, the canvas and jamb are installed at an angle relative to the floor so that the canvas is securely held under the weight of the canvas.

It is also believed that solid wooden bath doors should be no higher than 1.5 m, and their width should be no wider than 50 cm. The door threshold should be from 10 to 15 cm in height.

Step-by-step production

The plan according to which the bathhouse is being built is as follows.

- Any building, as you know, begins with the construction of a foundation, which is the foundation. When the required dimensions of the bath have already been calculated, trenches are made and filled with everything necessary, after which the solution can be mixed.

- The next and equally important stage is the construction of walls, the material for which is most often wood. The logs are stacked on top of each other exactly until the intended height of the structure is reached.

- Next, you can make the roof. This is a complex process that begins with the installation of the ceiling beams, followed by the installation of the roof itself, which includes sheathing, which involves fastening boards, decking, vapor barriers, insulation and, finally, waterproofing.

- After this, you can begin installing the floor and heating stove. The installation of the floor, like the manufacture of the roof, is carried out on beams. Once the construction of the floor is complete, it’s time to move on to installing the stove. It is best to first determine the location for installing the boiler. To simplify temperature control, you should choose the adjacent wall between the dressing room and the steam room.

Quality and safety

Like any thing, wooden bath doors must meet certain requirements. The product should reduce heat loss as much as possible. There should be absolutely no gaps or even small cracks between the canvas and the box.

As for the front door, it serves as a kind of shield, which must be very strong. Any door panels that will be installed in baths or saunas must open outward - this is a safety requirement.

The fittings, in particular door handles, require special attention. Both hinges and handles must be treated with special solutions or varnishes that can protect the metal from corrosion and damage. Iron handles can reach very high temperatures. Therefore, you can get seriously burned by it. It is recommended to purchase products made from alloys that can withstand high temperatures without heating up. Brass hinges are recommended. They are not subject to corrosion.

Despite the fact that the entrance wooden door for a bathhouse does not actually solve important problems and is not exposed to steam, it should still be treated with a solution. Varnishes or solutions for treatment must have moisture-repellent properties and prevent swelling and deformation. If you treat the canvas with this complex, the product will last for many years.

How to choose the right one

In steam rooms, only doors made of tempered glass with a leaf thickness of more than 6 mm are installed. The swing door should open outwards. There should be no locks or latches on it. The door fitting must be made of stainless steel, aluminum or brass. It is better to choose accessories only with coating.

The most practical are doors that are hung on 3 or more hinges. The optimal size of a glass door for installation in a steam room is 600x1800 mm. This corresponds to an opening size of 700x1900 mm. Other criteria for choosing doors include the quality of the fittings. It shouldn't be heavy.

Fittings not suitable for glass doors:

- from soft metals;

- PVC;

- EVA.

The hinges must be heat-resistant and moisture-resistant.

Choosing a door: what you need to know

When choosing a suitable product, in order not to make a mistake, you should take into account both important characteristics and finances. The best option from both a functional and economic point of view is a blind door structure made of linden.

If your goal is to surprise guests and friends with traditional and impeccable bath interiors, you should think about purchasing luxurious linens made from valuable species. For those who want the interior to be not traditional, but rather modern, it is recommended to opt for elite combined models with tempered glass inserts.

Safety in a bathhouse is very important and wooden bathhouse doors must meet all its requirements. So, for a steam room it is necessary, as already noted, to choose the right fittings. Experts and those who like to take a steam bath in a traditional Russian bath do not recommend fashionable stone products - they become very hot during the process and you can get serious burns from them.

Fire safety for a door to a steam room is also an important requirement. The canvas should be as fire resistant as possible. Today there are many compounds on sale that will give wood these necessary properties. They can also significantly extend the life of the product.

Which model to choose is a personal matter for the person who chooses the door. You just need to remember about resistance to humidity and high temperatures - this is the key to high quality.

Kinds

Wooden doors are classified depending on their design and location. Each variety has characteristics, strengths and weaknesses.

Massive

These are structures made of several boards fixed with glue. After joining, a solid shield is obtained, which is leveled with a thicknesser and covered with decorative compounds. Massive doors are the most expensive.

Advantages:

- high strength;

- environmental friendliness;

- good heat and sound insulation;

- attractive look.

Flaws:

- Heavy weight. The canvas must be secured with additional fasteners.

- High price.

The remaining disadvantages relate to the wood itself - low resistance to moisture, expansion and drying out when the temperature changes.

To protect wood you need to use special impregnations.

Paneled

These got their name from the paneled inserts. More often it is made of pine, which is sheathed with MDF, veneer, and varnished. Advantages:

- light weight;

- attractive appearance;

- durability, reliability;

- resistance to temperature changes;

- possibility of replacement and restoration of individual elements.

There are no serious shortcomings, but manufacturers often use low-quality raw materials to reduce the cost of the production process and do not comply with technology.

typesetting

This is a type of paneled canvas. They have the same advantages and disadvantages. Stacked structures are assembled from individual blocks of the same or different sizes, which are fixed with glue or tongue-and-groove joints.

Frame

The structure is a rectangular frame made of wooden boards, inside of which there is a cellular seal. The frame is sheathed with MDF sheets and other materials:

- Veneer - thin plates of natural wood. They have a natural woody structure. To make veneer last longer, it must be coated with impact-resistant varnish.

- Laminate is a coating consisting of thick paper, which is covered with a protective layer on top.

- Eco-veneer is a modern substitute for natural veneer. This is a film made from natural ingredients.

- PVC is a plastic covering of different colors.

Classification by location

Depending on the location, there are two types of paintings:

- Interior - simple canvases without locks.

- Entrance doors have a complex system of locks. Made from several layers of wood.

Entrance doors are heavy and require more fasteners to install them.