The design and appearance of the entrance door to the bathhouse can rightfully be considered the hallmark of the establishment. The first important element that greets lovers of light steam has always been and will be the porch and, of course, the door. Its finish, shape and design of the canvas. From how well the entrance layout is chosen, you can judge the quality of the steam room and all the most important attributes, without even entering the room.

What should the entrance door to the bathhouse be like?

The premises of a bathhouse, no matter what kind, Finnish, Russian, Turkish, due to the specifics of its use, is always in very difficult conditions. Hot steam and high humidity inside the bathhouse are combined with a piercing wind outside. To this we need to add the constant movement through the entrance doors to the bathhouse from the street. In such conditions, an ordinary trap at the entrance to the bathhouse turns into a skewed fence. Bathhouse doors, at a minimum, must meet three basic criteria:

- The door leaf should fit as tightly as possible to the frame and seal, water vapor should not freeze and “grab” the door like concrete, even in the most severe frost;

- The design of the entrance doors is carried out with the maximum level of thermal insulation. The door leaf remains the weakest element of the bathhouse, through which a large amount of heat escapes;

- High structural strength. In terms of the number of opening and closing cycles, the street entrance door for a bathhouse, awnings, doors, door leaf and handle experience a load comparable to the total load of all door systems available in the house.

For your information!

It is forbidden to make the entrance to the bathhouse from an all-metal sheet; in the event of a fire, such a structure heats up in a matter of minutes, splits and wedges itself in the door frame, also metal. It is impossible to touch the red-hot metal lining with your hand, not only to open it and leave the bathhouse. Therefore, the design of the outer surface of the canvas must be non-flammable, heat-resistant and have a very low thermal conductivity coefficient.

Decor

Decorating bath doors is an important point in the design of a building. After all, not all decorative methods are suitable for rooms with high humidity. For example, wallpaper or vinyl stickers would be inappropriate here, because after a short period of time they will simply peel off.

Iron and glass structures do not need additional decoration, as they themselves look very aesthetically pleasing. And it’s difficult to decorate metal or glass without special equipment.

It is possible to make carved canvas at home. Two methods can be used for this: overhead and on the surface of the tree itself.

The applied method uses carved elements that are attached to the canvas using glue. This method is good because it does not require removing the product from its loops, and the patterns themselves can be purchased ready-made.

Carving a door leaf is a complex and painstaking job. You can use blind and slotted threads. Carved doors, as a rule, are installed at the entrance of a building to add a luxurious and solid appearance to it.

Antique structures will look very organic in a bath structure. This design will create a rustic atmosphere of past centuries, which will allow city visitors to feel like real villagers. You can age wood yourself. This may require staining or brushing technology.

Often, owners of a sauna building think about whether it is necessary to paint wooden door panels, because inside the building there is constant high humidity, which can damage the paint. Designers advise painting wood with a paint and varnish that can withstand any external influences.

What are the entrance doors to the bathhouse made of?

Of course, a special material for making the front door has not yet been invented; the entrance to the bathhouse vestibule is made according to samples and diagrams of conventional door systems.

The entrance door for the bathhouse is made using the most traditional materials:

- Completely wooden, or with internal metal inserts;

- Metal, often with wood lining inside and metal on the outer lining of the door leaf;

- Plastic, with or without a metal frame.

The wooden entrance door to the bathhouse is considered the most common; it is made of wood in 70% of cases. The metal structure is installed in bathhouses and dachas, in country houses located far outside the city. Plastic doors are used for bath buildings attached to the house, and they are very beautiful, and there are no problems with steam and excess moisture.

Pros and cons of bath doors

The main advantages of doors for bath rooms:

- Energy saving - they prevent the removal of heat from the steam room or washing room, thereby significantly saving fuel and electricity costs.

- They have excellent hydro- and vapor barrier. Door structures for the washroom and steam room are designed in such a way that dampness and steam do not penetrate into the dressing room.

- They are distinguished by a variety of shapes, structures and textures.

- They can be very ordinary, or they can become a bright decoration of the interior.

Each room needs its own door with certain standards made from specific materials.

The only disadvantages of bath doors include low-quality raw materials and improper use.

Options for entrance doors for baths

When choosing the most suitable entrance option for a bathhouse, it is necessary to take into account the design of the porch, facade and the fact how often the bathhouse needs to be used. It is no secret that a bathhouse built on a suburban site, in addition to its main functions, is often used as a guest or fishing house, a warehouse for country property and furniture, and a place for temporary storage of building materials and crops. In each case, entrance to the premises is issued according to its own separate criteria.

Metal entrance doors for bathhouses

For a sauna building that spends the winter in a country house or is built at a considerable distance from the owners’ home, the optimal choice would be a metal door to the sauna. Of course, no one will install steel armor, but external cladding of thick metal and reinforced enclosed canopies are usually considered the norm for such conditions.

The design of a metal entrance door for a bathhouse is usually somewhat different from the accepted standards for residential buildings and apartments.

Of the metal parts in the construction of the bathhouse, only a steel corner profile is used, on which the awnings are attached, and a protected case for the lock. Everything else is made from moisture-resistant wood. The result is a durable and not too heavy door structure that is easy to open and close and will not break the facade of the bathhouse.

It is clear that for brick and stone baths you can install the entrance door of a regular apartment design, without any modifications to the structure. In this case, the entrance to the room is arranged according to a double scheme, with a mandatory second warm wooden door and a ventilated air gap of 25-30 cm between the two door leaves.

A metal entrance door to a bathhouse made of wood, for example, timber or rounded logs, is made taking into account the possible settlement of the building. Variable humidity indoors leads to the fact that the size of the doorway may change, so the door frame is attached to the walls using a tongue-and-groove pattern.

The frame and frame of bathhouse doors are made primarily of oak or larch in the form of a double wooden frame, separated by a layer of waterproofing, two layers of insulation and a vapor barrier film. A vertical sheathing is sewn between the inner wooden frame and the outer metal sheet. The result is a structure reminiscent of a ventilated façade of a building, but with an increased layer of thermal insulation.

One circuit of the door seal on the entrance door of the bathhouse is mounted on the inside of the door. Soft sponge rubber is used as a sealing material.

The second contour of the silicone seal is installed along the contour of the outer metal cladding of the entrance door. If the wooden entrance door to the bathhouse does not need to be sealed at all, then the metal must be protected from water condensation freezing at the joints. Otherwise, after another winter visit to the bathhouse, the next time you simply won’t open the front door.

Bathhouse entrance doors made of wood

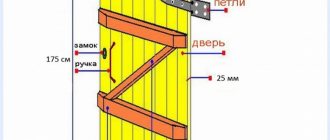

The door leaf for a standard entrance to a bathhouse is made according to two standard schemes:

- Construction with a double wooden frame, with polystyrene foam insulation laid inside and upholstery of the outer surface with waterproof material, for example, clapboard, plywood, OSB board;

- The classic scheme, in which the door leaf is made of tongue-and-groove boards, reinforced with transverse bars and a frame made of spruce wood.

The first version of a wooden door is usually decorated with protective coatings made of PVC film or painted with weather-resistant paints. Thanks to the presence of insulation, such a “sandwich” design retains heat well and at the same time remains insensitive to water vapor.

A similar scheme is used mainly for second warm doors or for attached baths, the entrance to which is located inside the house, from the summer kitchen, or any other protected room. The door leaf at the entrance to the dressing room of the bathhouse is traditionally designed in the style of finishing the walls and the interior itself.

The second type of doors is called cold or black. A panel made of knocked down tongue-and-groove boards does not retain heat well, so immediately behind the threshold of the bathhouse there is a cold vestibule in which equipment, firewood, and care products are stored. The function of the cold sheet at the entrance to the bathhouse is to protect the room from rain, snow and uninvited guests. Smoke and water vapor escape well through the black doors; there is no dampness or fungus in the cold vestibule.

The entrance structure must be treated with impregnations to combat pests; the outer cladding is usually impregnated with drying oil compositions or coated with weather-resistant varnish. If there is no protective canopy at the entrance to the bathhouse to protect the surface from sunlight, then it is best to use special weather-resistant polyurethane or acrylic paint.

The lower edge of the canvas must be raised above the level of the threshold to avoid swelling of the wood from flowing condensate. In addition to possible troubles with the door structure jamming, the ends of the tongue-and-groove boards that rest against the threshold beam do not dry out normally and remain wet, most often becoming affected by fungus and rotting. To avoid getting wet, the threshold at the entrance to the bathhouse is raised above the ground level by at least 25-30 cm, or steps are abandoned altogether.

Cold circuits are used mainly in summer baths in a country house or countryside.

Plastic for the entrance to the bathhouse

The use of plastic doors for arranging the entrance to a bathhouse has become popular relatively recently. The oldest plastic structures are no more than 15-20 years old, and during this time the plastic assembly has shown its best side.

Formally, two types of doors are classified as plastic:

- Aluminum entrance doors with PVC coating;

- Entrance plastic structures based on a polyester frame and polypropylene panels.

Both options initially appeared in wide use as entrance doors for light frame houses, summer kitchens, covered verandas, and all kinds of extensions to houses.

Only later did plastic doors begin to be used to arrange the entrance to the bathhouse indoors. A plastic door has several undeniable advantages. Firstly, the appearance of an entrance lined with PVC looks much more attractive, even if the door is installed in a doorway of log walls. It was the elegant decor that prompted the owners of personal baths to install plastic door systems.

PVC doors retain heat well and are not afraid of dampness and pathogenic microflora, temperature changes and sunlight. A lightweight door leaf with an aluminum frame is calculated by manufacturers for 20-25 years of service.

Moreover, leading manufacturers of door fittings and metal-plastic systems produce special models of doorways designed specifically for the equipment of the entrance group and the interior of the bathhouse.

In such designs, the internal lining is made of heat-resistant polyurethane, so even sparks from a stove or an open fire in a bathhouse cannot cause a fire in the door leaf. The door lock is equipped with a special reset mechanism; if absolutely necessary, without a key, you can unlock the awnings with one movement from the inside and freely exit the bathhouse onto the street, even if the lock is jammed. The third advantage is the ability to design a plastic surface with imitation wood, carved patterns, and decorative elements made of steel and bronze.

What manufacturing options are there?

The quality and service life of the door block depend on the material from which the door block is made. Different raw materials are selected for different purposes.

Tree

Traditionally, wood was used in baths. The floor, walls, ceiling are all wooden, doors too. You may be given several options:

- Linden. A universal material, used to create doors of any type. The main advantages are low price, pleasant aroma, does not rot. A very good choice.

- Aspen. The wood does not swell, does not heat up, and is suitable for decorating a washing room - it is used for finishing floors, ceilings, walls, and doors. The price of solid aspen is low, it is easy to process, which has a positive effect on the cost.

- Pine. The low price is explained by the wide growing area and ease of processing. Like all coniferous plants, pine smells good and does not rot. Heats up quickly - so this is a bad choice for those who like high temperatures (above 65 degrees). The ideal temperature is 45-50 degrees.

- Larch. Solid larch will decorate the steam room - it is recognizable due to its texture and pattern, which only becomes more expressive under varnish. Since larch is a coniferous plant, it produces phytoncides that kill harmful microorganisms and bacteria.

- Oak. Expensive, durable, weighs a lot, looks solid. Suitable if you want to impress guests. The only negative is that it cracks when overheated, which makes wood an unsuitable option for a steam room.

Wood is used for entrances to interior rooms. An array is taken - this reduces the likelihood of the slightest cracks and joints appearing. It is recommended to use durum varieties. Choose a water-based, non-toxic varnish.

Plastic

Plastic doors are often used at the entrance. They retain heat well, do not deform from cold, and fungus does not form on them.

Plastic is a poor material for rooms. This is an artificial material that, when exposed to heat, releases toxic substances and becomes deformed.

Metal

Metal doors are ideal as entrance doors. There is no need to care for them - the metal is not subject to mechanical damage and is resistant to mold and mildew. Thanks to the thermal insulation lining, it does not release heat and does not allow cold to penetrate inside.

Metal bath doors are not used for rooms because they have high thermal conductivity, heat up quickly, and are easy to get burned on. Also, when humidity is high, condensation forms, so the metal rusts.

Glass

A very stylish option - 8 mm thick tempered glass. The main advantages are appearance, heat resistance (withstands up to 300˚C), variety of decor. There are frosted glass designs, glossy, patterned, transparent, of any color. Glass is easy to clean, safe, and has low thermal conductivity.

The lower part of the glass sheet is shorter according to manufacturing standards, which allows air to circulate. This is important in a sauna, but unacceptable for a bath. Therefore, it is recommended to leave glass doors for the sauna, and use wooden or combined doors in the steam room.

Combined

They are made of wood, glass is used for decoration - decorated inserts, windows. The combined door combines traditional and modern visions of the bathhouse, which makes it more attractive from a design point of view.

Buy or make it yourself

It should be taken into account that the raw materials for insulation must have good waterproofing. This will help you feel comfortable in the bathhouse when it’s cold outside, and not overheat when the sultry sun is doing its best to heat the room additionally.

Decorating a dressing room with a glass door

Good insulation material will certainly help not only to keep you warm, but also to keep the heat out when it’s summer outside. Making the door and its insulation yourself or enlisting the help of professionals is, of course, everyone’s business.

Wooden door for dressing room

Diagram of a wooden door If you plan to independently install, manufacture and insulate a door structure, you should consider the following factors:

- You must have the skill to perform such work. Otherwise, there is a risk of spoiling the material and not getting what you want;

- To make doors with your own hands, you need to have in your luggage high-quality materials and decent fasteners;

- Also, the master must be able to work according to instructions and diagrams. Without experience, such manipulations will be difficult to perform.

Drawing and names of elements of an insulated dressing room door

If you lack the above skills, it is better to purchase a ready-made door and prefer installation of the structure by a professional. This will help you always feel comfortable, harmonious and complete in the bathhouse space.

Option for decorating a dressing room and a wooden door

Adviсe

Experts have prepared several useful recommendations.

To ensure maximum comfort in your bath room, you should pay attention to some recommendations from experienced professionals. For example, it is better to install a sauna on the south side, since in winter, when you sometimes want to take a steam bath, it will be easier to get to the entrance due to the fastest snow melting on the side closer to the south

In addition, it will be preferable if the windows face west, since in the evening the room will be illuminated by rays for much longer. Also, for constant air circulation and excellent heat maintenance, it is recommended to build a bathhouse from wooden logs.

How to treat wooden doors before varnishing

In principle, the technology for preparing a wooden door for varnishing is no different from that described above in the first section. Of course, if the door is old and needs to be re-varnished, then several additional operations are added, which increases the restoration time. How it all happens.

First of all, you need to get rid of the old layer of varnish. This can be done manually by sanding the surface of the door leaf with sandpaper, or use a sander. The main thing in this matter is to use fine-grained sandpaper.

Please note that you cannot use a special solution, which craftsmen call a remover, to remove varnish. The liquid will begin to soak into the wood and change its color.

If the door were to be painted later, then the remover could be used. Then the product is examined for the presence of small and large defects, which must be repaired with wood putty. After the putty solution has dried, the sealing areas are sanded to give a smooth surface. After which an antiseptic is applied to the canvas, preferably in two layers. Next, the door is treated with a primer. If there is a need to change the color of the wood, to make it darker, then now it is covered with stain. And the last stage is varnishing, which must be carried out in two layers.

Please note that all applied layers must dry before laying the next one. This is a guarantee of the quality of the final result

Another point - varnish, impregnation and primer must have the same base. If this rule is not followed, then there is a high probability that the materials will peel off from each other. Therefore, it is necessary to purchase them from one manufacturer.

A mandatory requirement for any door system is ease of opening and closing. But what to do if the doors are swollen and in order to enter or leave the room you have to spend a lot of time and make enormous efforts? This is a common problem for wood products, so even if everything is fine now, there is no guarantee that there will be no problems in the future. Our review will make it possible to find out why it occurs, what methods can be used to combat it, and what preventive measures exist.

Warming the bath from the cold

Insulation from the inside is a mandatory aspect when building a bathhouse. This step will help reduce heating costs, maintain the desired temperature and speed up the heating of the room.

Thermal insulation materials are usually divided into two types:

- organic origin;

- inorganic origin.

Not only the thermal insulation and moisture-resistant characteristics of the insulating material, but also its environmental friendliness are considered a very important factor. In order to prevent heat from escaping outside, the base is often sheathed with foam boards, secured with glue. To insulate the walls of the bathhouse, lathing made of bars is used. If necessary, insulation is sometimes placed not in one layer, but in several at once. Sheathing with clapboard is the last stage, in which a small gap is left to prevent the material from rotting.

Ceiling insulation should not be ignored, otherwise 15% of all heat will be lost. The ceiling in the bathhouse is insulated using foam boards, which significantly reduces heat loss. After the seams are sealed with special foam and vapor barrier materials are used, you can begin covering with boards.

Which material to choose

The modern market offers many types of thermal insulation materials:

- mineral basalt wool;

- staple fiberglass;

- hardboard;

- expanded polystyrene, etc.

Which one is better to choose for a bath? One of the main criteria is fire safety. The insulation must be highly resistant to fire and not emit harmful substances when heated.

Vapor permeability also matters. We must not forget that the door, like the bathhouse itself, is made of wood, and this is a natural, “breathable” material. If air access is blocked on at least one side, the wood will become damp and rot, and this will significantly shorten its service life. Therefore, it is extremely undesirable to use adhesive-based polystyrene foam boards for baths.

One of the best options based on the above requirements would be foil-coated polyethylene foam. It is a lightweight, non-flammable material that can reflect heat back.

Option with additional wooden frame

Materials you need to prepare:

- wooden beams 20 x 20 mm;

- insulation;

- aluminum and construction nails with heads or self-tapping screws;

- sheet of fiberboard or wooden plywood.

For ease of operation, the bath door must be removed and laid on a flat, solid base.

Wooden blocks must be nailed along the entire perimeter of the canvas, so that their edges protrude beyond the boundaries of the existing canvas by 10-15 mm. Using aluminum nails, it is necessary to nail the insulation onto the frame, folded in half so that it protrudes beyond the edges of the frame by 10-15 mm.

The mechanism of action of this design is that the door itself becomes warmer, and when closed, additional sealing is provided due to the insulation bent outward, nailed with an overlap.

Laying insulation into the inner chamber

If the bathhouse has a three-dimensional door, then it must have insulation in its cavity. If cold drafts appear in the bathhouse, the insulation must be replaced. In all likelihood, it has fallen into disrepair. To do this, the door removed from its hinges must be disassembled and the old insulation removed from its cavity. Having laid the new material, the canvas must be re-assembled and installed in place. All wooden parts must fit very tightly to each other, and there must be an air gap in the cavity of the canvas.

Installation of a thermal circuit on a door

One of the most popular ways to insulate a door is to install a thermal circuit. The work is performed as follows:

- Thin wooden slats 1.5 × 2 cm are placed around the perimeter of the door leaf with a space of 1.5 cm from the edge.

- A hardboard filler is installed inside the contour and secured with metal construction brackets.

- A two-layer insulation made of felt or foil insulation is installed on the circuit. A piece of material is first cut out with 6 cm allowances and fixed to the contour with aluminum nails.

- Next, the counter-lattice is installed and the cladding is done with wooden clapboard.

When closing the door leaf, the insulated structure will protect against the penetration of cold air and retain heat inside the room.

Replacing or repairing a door frame

Often cold air from the street enters the dressing room, since the door threshold has already rotted.

The moisture that accumulates in the bath contributes to this. Replacing or repairing a bathhouse door with your own hands, if the log house was assembled according to all the rules, will not be easy. But this operation can also be simplified, making repairs easier for yourself.

Saw the threshold and the top beam of the door frame without touching the fastening tenons of the frame. If the side posts are also damaged, you need to saw them too.

Now you can easily remove the damaged parts and replace them with new ones, cut to size. And the strength of the door frame, the evenness of the walls and stability will not be affected.

There are two ways to make a new bathhouse door with your own hands, it all depends on the available material.

If there is a beam with a thickness of 100 mm and a depth of 150, then it is enough to cut out the parts required in size, which are then inserted in place of the old door frame.

It should be inserted from the side of the vestibule, collecting the parts into a tenon. The space between the box and the wall is filled with insulation (moss, tow, foam, etc.). Make sure that it is no wider than 5 mm, otherwise the influx of cold air will not be avoided.

If there is no timber at hand, use a 50 mm thick board to repair the bathhouse door. With your own hands you need to choose a quarter of its depth for the porch. The remaining operations are performed in the same way as in the first option.

Ensure a tight connection between the sawn parts and the rest of the door frame using self-tapping screws.