The roof structure is a complex system. It consists of several layers of dissimilar materials, each of which performs its own unique function.

To ensure comprehensive protection of the building from environmental influences, it is necessary to carry out all installation work with high quality, as well as the correct choice of basic and insulating materials. This whole process is briefly called roof insulation.

The standard composition of the roofing cake includes:

- Internal finishing layer;

- Lathing design;

- Vapor barrier material;

- Counter-breach;

- Thermal insulation (does not apply to a cold attic);

- Waterproofing layer (read about chimney waterproofing here);

- Ventilation shafts or gaps;

- Roofing covering.

Next, we will look in detail at the roof vapor barrier and how to lay a vapor barrier on the roof without the use of special tools.

Vapor barrier functions

One of the conditions for long-term operation of the roof is a ventilated roofing device. Air gaps in a properly designed roof help regulate the temperature in your home, keeping your home warm in winter and cool in summer. The air rising from living spaces is warm and humid; Once in the under-roof space, it cools down. In this case, water vapor collects in condensate and tends to settle in the roofing pie. Over time, if the roof is unprotected, the insulation becomes damp, and the wood of the rafter frame becomes susceptible to mold.

The solution to this problem is the use of special protective layers in the roofing pie. For normal functioning of the roof, waterproofing is installed on the outside of the insulation (under the roof covering); under the insulation there is a vapor barrier sheet, which has the following functions:

- Insulation protection . Vapor barrier, installed in accordance with the technology, blocks the penetration of condensate into the heat-protective layer. This preserves the performance characteristics of the material and the efficiency of insulation of the building.

Place of vapor barrier film in the roofing pie Source stroyfora.ru

- Protection of the rafter frame . A vapor barrier installed according to the rules will protect wooden rafters from getting wet and rotting.

- Increased service life of the finishing coating . The lower surface of the coating is protected from moisture much worse than the front surface. The vapor barrier film protects the inside from harmful condensation.

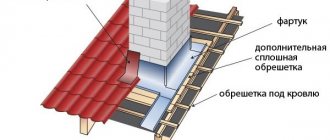

Waterproofing metal roofing

Waterproofing the roof of a house under metal tiles deserves special attention, since during its operation the humidity and temperature of the under-roof space are of great importance. The insulation film used for metal tile roofs is a reinforced woven lattice made of polyethylene fiber, covered on both sides with polyethylene film. Thus, the material has strength as well as excellent waterproofing characteristics. It is not cheap, but at the same time it is able to ensure the long-term performance of the roofing functions.

Waterproofing a metal tile roof is carried out so that fresh air has the opportunity to move from the eaves to the ridge, and then exit through the ventilation holes. Before laying waterproofing on the roof, a gap of 4-5 cm should be created between it and the insulation to ensure ventilation, for which it is necessary to fill the rafters with bars of the appropriate cross-section. The same gap must be provided between the tiles and the waterproofing material, which is also achieved by using bars.

A ventilation gap of 5 cm is required along the ridge, and the lower edge of the waterproofing must reach the gutter so that moisture can easily flow into the drainage system. The only material that is laid directly on the insulation is a superdiffusion membrane.

It is important to understand that the correct choice and subsequent installation of waterproofing will bring no less benefit than the roofing material itself, providing the roof and the entire house with effective protection and durability.

Source

Material requirements

The main property of all vapor barrier materials is their ability to resist steam penetration. The lower the vapor permeability, the less water vapor is able to pass through the layer of material, and the better protective properties it has. There are three classes of materials on sale; they differ in two interrelated parameters: resistance to vapor permeability and mechanical strength:

- 1 class . Rigid foil-based materials with the highest vapor permeability resistance.

- 2nd grade . Materials based on polyethylene or polypropylene.

- 3rd grade . Soft materials with low (50-100 times lower than 1st class) performance.

Vapor barrier and vapor diffusion in the roof Source krovlyakrishi.ru

Additional requirements are imposed on film materials that are important for the durability of the roof:

- Lifetime . Installation of a roof vapor barrier with a service life of 10-15 years is impractical for modern roofing structures designed for 20-25 years. After 10-15 years, the vapor barrier layer will no longer cope with its responsibilities, which will begin to affect the condition of the entire roof. Replacing the film in this case is an extremely troublesome (and expensive) task, often associated with disassembling the structure.

- Operating parameters . Materials that can properly perform their functions over a wide temperature range are valued. Most film products are designed for operation in the range from -70 to +100°C.

- Elasticity . A parameter that is important both for ease of installation and during operation, when pressure is exerted on the film by a layer of insulation.

Elasticity is one of the important properties Source iobogrev.ru

Standards

It is possible to carry out high-quality roof waterproofing only when the materials used meet the following standards.

Their main property should be immunity to water, as well as water resistance. It will be good if such materials are also excellent in terms of thermal insulation - this will make it possible to save on insulation. An important feature of waterproofing materials will be their high elasticity, since rigid materials are difficult to use when covering roofs, especially when it comes to some complex shaped options. When creating waterproofing for certain categories of roofs, it is necessary to select materials that have excellent vapor permeability. This parameter will be extremely important when there is a living space under the roof of the building - a room or, say, an attic. No less important aspect than the above will be the strength of waterproofing materials

Everything that will be used for waterproofing must have the ability to withstand physical stress and be as impervious to physical damage as possible. Some fragile or not very strong materials simply cannot be used, since even the slightest disturbance in the structure of this or that material can cause water to begin to get inside and destroy the material, and cold will begin to get inside the building.

- Some people, in the hope of saving money, simply trim the roof with good material. They mistakenly believe that its strength is sufficient to protect the building from almost all negative natural factors. They are right that such material can protect the building from low temperatures, scorching sun or wind. But water will easily penetrate into holes and cracks, destroying this coating inside and provoking corrosion with fungus. It is precisely because of the fight against the phenomenon mentioned above that it should be understood that it is impossible to do without roof waterproofing.

- And for the material to be suitable, you should know about standards such as vapor permeability, especially if we are talking about an insulated roof. This property allows water to escape from the insulating layer under the roof, from where it will simply erode. If the vapor permeability of the material is low, then water will collect in the material, transforming into condensate, and will simply begin to destroy it, as a result of which the insulation will ultimately lose all its useful properties and characteristics. If we talk specifically about materials with high vapor permeability, then they can be called a superdiffusion membrane, which is usually placed directly on the insulating layer, which makes it possible not to make any intermediate frame. If the roof is not insulated, then it can be waterproofed with a material that has low vapor-permeable characteristics.

- Another important point is water resistance, which was also mentioned above. It is expressed in maintaining contact with water for as long as possible. When finishing a flat roof, it is necessary that the water-repellent surface be high, because water tends to linger on a roof of this type. If the roof is pitched, then this indicator will be no less important due to the fact that the roofing material often has so-called sagging or depressions, which is why water can linger there. If we take it according to the standard, the waterproofing layer must withstand a pressure of one and a half meters of water column. As a temporary roof, you can use a membrane with a water column of four meters.

- If you decide to use a waterproofing film as a temporary roof, then it must still have excellent characteristics in terms of withstanding the effects of solar radiation.

- And the last important parameter will be mechanical strength. It’s just that during the process of laying materials on the roof, some elements may disrupt the film integrity. Where deformations and breaks occur, leaks may appear. The integrity parameter is measured in units of weight per square meter. A film with a value of 100 grams per 1 square meter will be reliable.

Types of films

The construction market offers rolled vapor barriers, created using several technologies and having a different set of properties and service life. Certified products are supplied with instructions detailing the parameters of the material and its purpose - familiarity with this information will help you make your choice. The roofing films offered on the market can be classified in two ways:

- According to the material . Modern vapor barrier sheets are made of polyethylene or polypropylene.

- By functionality . There are vapor barrier, waterproof and anti-condensation materials. The purpose determines which side the vapor barrier is placed on the roof.

Polyethylene films

A single-layer under-roofing film with a low density, which, however, can provide sufficient tightness and protect the insulation from moisture. The main advantage of this insulating material is its budget cost. The main danger is low quality: manufacturing defects are common on the surface of the thinnest films, and their service life is short.

Reinforced polyethylene film Source donnews.ru

See also: Catalog of companies that specialize in roof repair and design.

Reinforced polyethylene

In terms of vapor permeability, reinforced polyethylene films are comparable to the previous type. The thin fabric is reinforced with a pressed frame made of polymer threads, which increases its strength and durability. The material has a disadvantage - during thermal lamination (gluing layers), the junctions of polyethylene with the reinforcing mesh become thinner, forming microscopic cracks. Western European manufacturers have practically abandoned the production of reinforced polyethylene film, since it is not able to provide stable vapor blocking.

Polypropylene films (vapor barriers)

Reinforced propylene films compare favorably with polyethylene materials by having a longer service life, increased strength and a higher degree of vapor barrier. Polypropylene protection is resistant to ultraviolet radiation and low temperatures, is quite elastic when stretched and does not tear at bends; the combination of qualities makes it possible to install water vapor barrier on the roof in winter.

Anti-condensation films Source info-krovlya.ru

Bag fabrics

The vapor barrier fabric looks like burlap; made from polypropylene threads laminated with polyethylene melt. Vapor barrier is characterized by high mechanical strength, but weak vapor protection, which forces it to be used primarily in the construction of cold roofs.

Which side should the hydro vapor barrier be laid on?

According to all the canons of physics, when the temperature decreases, vapor from the air always condenses, turning into liquid. In construction, this rule is always taken into account when arranging structures operating at the junction of the temperature difference between the room, insulation and the street, the ground. These include the roof, walls, base, and floor. Without high-quality insulation, a large amount of moisture accumulates on surfaces and in the structure of materials. This inevitably leads to deterioration of the properties of the foundations and their gradual destruction.

To avoid the negative consequences of the condensation process, when constructing critical structures, a specialized film is used - hydro-vapor barrier. Which side to put it on correctly is an important question.

Installation of water vapor barrier: which side?

There are several types of films. According to their structure they are divided into:

- Single-layer and double-layer (multi-layer);

- Diffusion;

- Anti-condensation.

The main task of builders is not to make a mistake on which side to lay a particular type of water vapor barrier, depending on the installation location. Incorrect application will lead to the opposite process: subsequent condensation of moisture on the surface of the membrane, as evidenced by the photo of improper arrangement of water vapor barrier.

Which side to lay a single-layer hydro-vapor barrier?

Simple single-layer films are made from polyethylene. Sometimes it is additionally reinforced with a polymer mesh to add strength. This material retains water, but allows steam in, in both directions. Therefore, the choice of installation side does not play a special role here .

It is only worth noting that such products have lost their relevance due to low efficiency and the emergence of membrane films.

Which side should the diffusion hydro-vapor barrier be laid on?

Modern film water vapor barrier for roofing is produced using a woven method from pure, 100% polypropylene. Its structure, if you look closely under a microscope, is a network of thin threads. Their interweaving forms microscopic cells. Their size is not sufficient for the unimpeded passage of water molecules in a vapor state.

High-quality diffusion hydro-vapor barrier for floors or roofs is made in two layers. Its specificity lies in its operation on the principle of a valve: passing steam from the air in only one direction (from an area of high pressure to an area of low). When there is oversaturation of moisture in the air in the room and under the influence of steam pressure (diffusion), water molecules literally seep through the film and excess moisture is removed outside.

Such material is laid when organizing a system of ventilated facades, on top of mineral insulation with the obligatory arrangement of a ventilated gap. This water vapor barrier is suitable for floors and walls.

Diffusion films usually have markings for installation, which are different for each manufacturer. Before installation, you must carefully study the instructions. Often such material is made dark and rough on the back side, lighter and smoother on the outside.

Installation is carried out with the light (water-repellent) smooth side facing away from the room in the following cases :

- for insulation when arranging the under-roof space;

- under insulation when laying the floor on concrete or soil;

- external thermal insulation when installing ventilation facades.

When installing a floor under a screed, protecting walls and ceilings in wet rooms (for example, baths, saunas), the water-repellent side should face the inside of the room:

Which side should the anti-condensation hydro-vapor barrier be laid on?

To give the material improved vapor barrier properties, one side of the diffusion film is coated with a special moisture-absorbing hydrophobic coating, polyester fabric, or an aluminum reflective layer is applied. Such membranes are called anti-condensation and superdiffusion. Due to the absorption of condensate, this hydro-vapor barrier is best suited for cold roofs: pitched type with metal decking. The absorbed moisture prevents the formation of metal corrosion. The additional layer provides better thermal protection.

Antioxidant hydro-vapor barrier is installed in the same way as diffusion barrier: with the water-repellent side facing away from the material that needs to be protected from moisture . Typically, manufacturers apply markings on the outer (water-repellent) side such as: “This side up”, a logo or brand designation.

Video description

About the types and choice of vapor barrier in the following video:

- Superdiffusive . They are characterized by high vapor permeability, which allows the membrane to be laid directly on the thermal insulation layer. There are single- and double-sided membranes. In the first case, it is important that the vapor barrier is laid in a strictly defined way - with the correct side inward. In the second case, the material is spread out in an arbitrary manner (it does not matter which side is top or bottom).

Expanded polystyrene

Another popular insulation material is cheaper than mineral wool. However, it is a less flexible material, which makes it difficult to fill the entire space between the rafters. Therefore, you should be especially careful when choosing the sizes of polystyrene foam boards and their exact location.

There are two main types of polystyrene:

- EPS - polystyrene foam boards with a thermal conductivity coefficient of 0.030 - 0.042 W/(m*K),

- XPS – extruded polystyrene with a coefficient from 0.029 to 0.034 W/(m*K).

A steel grid is installed under the laid polystyrene foam slabs, and a second layer of expanded polystyrene is installed under the rafters to avoid thermal bridges.

Subtleties of vapor barrier installation

The main question that arises when installing a vapor barrier for a roof is which side to lay the material on, and in which part of the roofing pie. The location depends on the type of roofing structure being constructed:

- Insulated attic and mansard roof . In this case, it is important to protect the thermal insulation layer from fumes penetrating from the lower rooms. Therefore, the film is spread under the insulation (from the inside), on the rafter structure or rough sheathing. Panels of rolled material are laid horizontally and overlapping, secured with nails or staples.

Ceiling vapor barrier Source pedkolledj.ru

Technology of use

Laying vapor barrier material is an important technological operation performed during the construction of a roof, the quality of which determines its reliability, service life and strength. Installation of vapor barrier is carried out from the inside of the attic room after the roof truss frame is ready in accordance with the following rules:

- The vapor-blocking fabric can be laid along or across the rafter legs of the frame.

- Be sure to start installation from the roof ridge, placing strips of material overlapping with an overlap of 10-15 cm.

- The material will be fixed using construction staplers or galvanized nails.

- The joints between the strips are hermetically connected using special adhesive strips located along the edges of the canvas.

- After installing the waterproofing, a glazing bead treated with an antiseptic is nailed along the rafters so that the sheathing does not touch the membrane.

Important! The vapor blocking film has two sides, which differ in the nature of the surface and properties. When installing, you need to place the canvas with the rough anti-condensation side down.

Video description

About diffuse vapor and waterproofing in the following video:

- A two-layer anti-condensation film is spread with the smooth side facing the insulation, and the rough side facing the source of warm, humid air, the living quarters.

- The foil film is laid with a metal layer to the living spaces - this way it can return some of the heat inside, increasing the thermal efficiency of the building.

- Diffusion double-sided membranes provide the roofing pie with the ability to “breathe”. If both surfaces of the membrane are identical, it is laid on either side. If you have chosen a one-sided membrane, it is better to check the data on the front and back surfaces with the manufacturer (in most cases, the membrane is adjacent to the thermal insulation with a rough surface).

Laying a vapor barrier in a roof with steep slopes Source bostonglobe.com

What is “Izospan”

Russian “Izospan” has a number of advantages over other materials:

- The film has high tensile strength.

- It meets all environmental requirements.

- The film can withstand significant temperature increases.

- The material is easy to cut and does not tear at the bends.

- All positive properties remain for a long time.

Izospan is a durable, high-strength product that has been tested by practice and time. There are quite a lot of varieties:

Insulated roof using Izospan V.

- Izospan A is a film membrane that protects the structure from wind and moisture. Effectively removes water vapor and condensation from internal roof structures.

- Izospan AS is a three-layer membrane for vapor barrier. Used to protect the roof from rain and snow, from wind and moisture from the insulation. Suitable for insulated roofing with any roofing materials.

- Izospan B is a two-layer vapor barrier film for universal use. Used to protect the roof of buildings when insulating attics.

- Izospan S is a two-layer film for installing hydro- and vapor barriers. Can be used without roof insulation.

- Izospan D is a universal film for vapor barrier and waterproofing of roofs, foundations, and interfloor ceilings.

- Izospan SL is a tape for gluing and sealing joints of membranes with pipes, ventilation systems and other structures.

- Izospan FL is a special metallized tape for sealing joints of vapor barrier film with various enclosing structures.

Stages of installation of a vapor barrier layer

The installation instructions specified by the manufacturer must be followed; Moreover, the rules allow for the installation of film materials both before and after the installation of the roofing pie. The progress of work on laying vapor barrier is as follows:

- Before installation, you must read the instructions from the manufacturer and determine the side of the material whose function includes contact with steam.

- Select the spreading method , horizontal or vertical. Most manufacturers accept both arrangements; In the instructions you can find out about acceptable options and layout details. The direction of the layout is affected by the slope of the slopes. On a flat roof, the roll is rolled out horizontally, perpendicular to the rafters. On a steep roof, the film is laid along the rafters.

- With any installation method, the material is laid with an overlap , the amount of which is often indicated along the edge of the film. The instructions also indicate other values (which depend on the steepness of the structure).

Cellulose

The cellulose in pellet form is blown under pressure to ensure that even the smallest nooks and crannies between rafters are insulated. In addition, the treatment can be carried out even through small openings, which in case of repair allows you to avoid confusion and disassembly of roof elements. Similar to spraying polyurethane foam, this process is quick and precise. The thermal conductivity coefficient is about 0.037 W/(m*K).

Blowing out the cellulose can also be an easy way to fix faulty insulation. This is a good option for insulating the roof from the inside.

Video description

About the membrane installation technology in the following video:

- The main condition for installation is that the film is fixed without tension , with a sag of approximately 2 cm. The reserve is created due to the ability of the wooden frame to change its dimensions with the change of seasons (with changes in humidity); otherwise there is a risk of the film tearing.

- For horizontal installation, installation is carried out from above (from the ridge). The strips are laid with a reverse overlap (the lower strip overlaps the upper), for additional protection of the insulation; they are connected with tape and secured to the structure with galvanized nails or a stapler.

- If the thermal insulation layer is not dense, the rolled sheet is fixed using slats , which must be antiseptic.

- Particular attention is paid to junction points (attics, windows, hatches, pipes, ventilation ducts); they are isolated especially carefully.

Fixing the film Source pro-uteplenie.ru

How to properly install hydro-vapor barrier

When waterproofing a flat or pitched roof, the vapor barrier film is attached not only horizontally, but also vertically.

Installation of water vapor barrier is carried out in two ways:

- Horizontal installation of film. In this case, the film is laid on the rafters, the distance between which does not exceed 120 centimeters. When installing the film, do not allow it to come into contact with the thermal insulation. Also, it should not sag by more than twenty millimeters. Next, a counter-lattice is attached to the rafters on top of the film, on which the roof sheathing is subsequently constructed.

- When installed vertically, the film is secured using galvanized flat-head nails or mechanical staplers. The film is attached to the load-bearing elements of the roof along the inside of the insulation.

Recommendations for laying film

- The overlap of the film, regardless of the method of fastening, must be at least 100 millimeters;

- The joints of the film strips must be made airtight. To do this, the joints are glued with a special connecting tape;

- After laying the film, special slats should be installed to ensure ventilation of the under-roof space;

- When purchasing material, you should carefully study the instructions, recommendations and inscriptions located on the building material. In this case, errors will not be made during its installation and operation. Then the question of which side to put the hydro-vapor barrier on the roof will disappear by itself.

In this video you will learn how to waterproof a roof with your own hands:

Membrane structure and operating principle

The most popular for their performance characteristics are breathable multilayer membranes, which are designed to create reliable vapor barrier protection.

They consist of three layers, each of which performs an important function. The first layer prevents the penetration of steam into the insulation, the second provides the necessary strength of the base, and the third protects against moisture from the outside.

Each individual layer has the necessary perforation for good air exchange. The first layer removes excess moisture, allowing dried air to penetrate. The reinforcing layer retains warm air masses inside thanks to a special weaving of threads. The third layer provides a sufficient level of traction inside the structure.

Some types of membranes have an additional anti-condensation layer based on viscose or cellulose. It retains excess moisture deposited on the paper fibers. To naturally remove moisture from the membrane, a technological gap of 2.5 cm is provided between the vapor barrier and the finishing surfaces.

Do-it-yourself insulation of a flat roof

External insulation of a flat roof includes the installation of a vapor barrier layer, laying thermal insulation, waterproofing, and then a roll covering. The final layer is the laying of bulk material.

Before starting work, you need to clean the roof surface from debris, dust, and level it. Then install a vapor barrier as described above. After this, glue the insulation boards using cold mastic or special glue. The slabs are laid with a semi-overlapping seam, which ensures uniformity of the coating. It is permissible to lay several layers of slabs staggered and glue them with tape. This method of installation will prevent the occurrence of cold bridges.

Next, waterproofing is laid. The fire method of gluing a waterproofing carpet is often used: a cement-sand screed is laid on the slabs in a layer of at least 3 cm. After laying it, you need to wait until the concrete gains the necessary strength, then clean the surface from sagging and dirt. The waterproofing layer is glued using short-term exposure to fire. The gluing method is described in great detail on the packaging of the material. As a result of exposure to fire, the insulation does not lose its properties. After this, a rolled roof covering is laid and expanded clay or other similar material is poured.

Does vapor permeability change when changing sides?

All of the above modern barriers are divided into the following types:

- for one-sided installation, which need to be rolled out only on a certain side, and it is recommended not to confuse them;

- and for double-sided use, usually with membranes that can be laid on either side.

You will be interested to know that for the first time, membranes that already had such properties as modern roofing membranes were used in astronautics! And from there they began to be used in construction and in many areas of the national economy. And until recently, there were not as many problems with their installation as there are today.

But now there is a strong opinion among ordinary people: if you lay the vapor barrier to the roof insulation “on the wrong side,” then the entire structure will not last long. In fact, the correct choice of side affects exclusively the service life of the interior finishing of the roofing pie, because the rough side has the same abilities as the smooth side and has absolutely the same vapor permeability. But how much it will retain droplets of condensate there is a little-studied question.

Roof insulation

In addition, if the roof is insulated, thoroughly waterproofed and provided with effective ventilation, this will allow, in addition to effective energy saving, to expand the living area of the room due to the resulting attic, which can be made as cozy and comfortable as all other rooms.

If the roof is located above a non-residential attic and consists of rafters, sheathing and roofing, then insulation is not always necessary. The attic is continuously ventilated, and the temperature and humidity in it are almost the same as the outside air. In such houses, the main thing is to carefully insulate the attic floor.

But if under-roof thermal insulation is installed, the temperature and humidity of the air inside the attic floor differ significantly from the air outside. Moisture rises along with the warm air and comes into contact with the colder, lower surface of the roof. This causes condensation to form on it. Also, moisture can penetrate into the roof elements, which is facilitated by inaccurate laying of the vapor-proof layer on the inner surface of the insulation, insufficient overlap of the vapor barrier strips, their loose fit to the walls and pipes, accidental ruptures, etc. Therefore, first of all, when insulating the roof, you need to take care of the device reliable vapor barrier located on the interior side. On the roof side, the insulation is protected by a layer of waterproofing laid along the rafters or a special flooring.

Such protection of an insulated roof on both sides is quite reliable, but sometimes this is not enough. It is necessary to provide a way to remove moisture that accidentally gets into the insulation. This effect is achieved by air circulation in cavities, one of which is located between the roof and the under-roof waterproofing, and the other is located between the under-roof layer and the thermal insulation layer. In order for outside air to freely enter these cavities and be removed from them just as easily, it is necessary to install vents in the roof overhang and in the upper part of the roof. To ensure free movement of air between the roof and the under-roof waterproofing, lay counter battens along the rafters. Their thickness determines the size of the air cavity. Air enters this cavity through holes located in the side overhangs of the roof.

How to avoid the problem of high humidity

After thermal insulation work, the humidity inside the room may increase, which negatively affects the microclimate. There are several reasons for this.

- Insulated structures have gaps or cracks, which means their integrity is compromised. Therefore, before starting work, it is necessary to carefully check all the bases and eliminate all existing defects in advance.

- There is no vapor barrier layer or it is damaged. In this case, moisture does not leave the room, but accumulates in the insulating material. Therefore, it is imperative to use a vapor barrier film, gluing the joints of the sheets with a tape specially designed for this.

- The system of natural and forced ventilation of the room was broken. For example, during the renovation, the ventilation holes were moved or blocked, the shaft was blocked, and metal-plastic windows were installed. All of the above actions lead to a decrease in air circulation due to excessive tightness of the structure, so it is necessary to periodically ventilate the room or take care of installing supply and exhaust ventilation.