0

7525

03.04.2014

Door closers are designed for automatic, smooth closing of doors. The use of a closer is a prerequisite when installing an intercom and a combination lock; in addition, closers are used in public institutions, on entrance doors and gates, and in private households.

How to install a door closer

Installation instructions for the finishing mechanism

When installing the finishing mechanism on interior doors yourself, rack structures equipped with a lever mechanism are usually used. Devices equipped with a slider rod are rarely used for such purposes.

The installation technique for all types of finishing structures is practically no different.

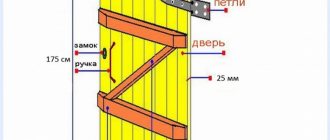

Definition of installation diagram

First of all, the procedure for installing a door closer on your own is determined. The installation technique will differ depending on the direction of opening of the door leaf:

- The canvas opens to the finishing device. In such a situation, the body is mounted on the canvas, the lever mechanism on the box;

- The sash opens from the closer. The body is mounted on the door jamb, a sliding channel is fixed to the door leaf;

- It is also necessary to take into account that the adjusting bolts are placed in the direction of the door hinges.

Using a template

The product delivery package necessarily includes an installation diagram made in actual dimensions. The areas for fixing the product body and the lever mechanism are clearly marked on it. This makes it much easier to install the mechanism yourself.

At the same time, the template provides all possible options for attaching the door closer: for external and internal door opening, for right-handed and left-handed leaves. The template also suggests a class of door blocks for which the product can be used.

Performing installation

Before installing a closer on the door yourself without a specialist, a product template, which is included in the product package, is attached to the plane of the door leaf. It must be applied to the fastening area exactly according to the diagram and secured with transparent tape. After this, the points for drilling holes for fasteners are marked on the canvas using a center punch.

The procedure for installing the mechanism:

The housing is installed and secured with mounting bolts. Correct installation is determined by the position of the adjustment screws.

A lever structure is mounted on the opposite side of the door. Sometimes it is included in the package already assembled. The hinge is temporarily removed until the closer operation is adjusted.

Next, the knee is mounted - the non-adjustable part of the lever mechanism. To install the part, the axis of the finishing device is used. Fastening is carried out using a special wrench and nut.

If the door is expected to close silently and smoothly, the knee is fixed perpendicular to the door leaf, and the lever is fixed at an angle. The connection of the elements of the finishing device is carried out only with the door tightly closed. If the purpose of installing a closer is finishing force, then the rigid lever is fixed perpendicular to the door leaf. This installation scheme is used for doors with latches and seals.

At the next stage of installation, it is necessary to adjust the length of the adjustable elbow to the rigid mechanism. This technology makes it possible to strengthen the spring of the device and speed up the closing of the door when closing.

The final stage of self-installation of the finishing mechanism is the connection of the individual elements of the knee with a hinge.

If the model of the closing device is suitable for installation on door blocks made of any material (steel, wood, plastic), then the delivery set must include fasteners for all types of doors.

How to properly install a door closer on your own is shown in detail in the following video:

Features of non-standard installation

In some cases, it is necessary to use a non-standard technique for installing the finishing device on door blocks, for example, with a heavy metal leaf. For this, corners and plates are additionally used. Such fastening elements are already included in the package of individual products. But, often they have to be purchased separately.

In case of a deep entrance opening, which does not allow installation of a lever bracket on the frame, a construction angle is additionally used. Sometimes it is used to mount the housing and working system.

Installation of the housing is not always possible due to the design features of the door block. For example, the door block is equipped with a high glass insert. In such situations, the device body is mounted on a special plate. They are also used for leveling and fixing the body of the supply system when there is not enough space above the sash to fix the lever mechanism.

Connect the lever to the rod

When the rod and lever are fixed, it is important to give the desired position, which will determine the speed of movement of the door before closing. The position and length of the two-piece rod can be adjusted with a long grub screw. It rotates and changes size at the same time.

Installing the rod perpendicular to the door leaf will help to achieve smooth finishing. To do this, make a setting and reduce its size. If there is a door latch, the pull must be strengthened to overcome the resistance. The mechanism is untwisted and adjusted to make it longer.

Correct adjustment of the closer

It is not enough to know how to install a door closer; you also need to understand the basics of its debugging. The mechanism requires adjustment both immediately after installation and during further operation.

The main parameter that needs adjustment is the speed of movement. If you notice that the door is not opening quickly enough, adjust the spring compression by loosening the locking nut.

Serious variations in driving speed are eliminated by rotating the first of two control valves. It can be turned no more than two turns in any direction. The second valve allows you to adjust the clap force.

Adjusting spring compression

For entrance doors during cold weather, additional adjustment of the first valve is required. This is because the oil used in the mechanism becomes more viscous and the operating speed changes.

If there is a need to hold the door in a certain position for a long time, use the door closer option called “hold-open”. To do this, open the door 90 degrees and tighten the latch. Now the opening will occur as usual until this angle is reached, and after that the latch will operate. To close, simply pull the door towards you.

Hold-open mechanism

This function is not available in every device, but if you plan to frequently ventilate or move large items in and out, it is better to purchase just such a door closer. Because if the door with a closer is secured with foreign objects, for example, a brick, this will create an excessive load on the mechanism and may subsequently lead to breakdown.

If your device cannot be debugged, the reason may be due to incorrect installation. To eliminate this, check that the adjusting nut is in the correct position and that the lever is located at right angles to the door structure. If you suspect errors during installation, the mechanism should be removed and, checking the diagram, reinstalled.

What is a closer?

Main advantages

Closers have already proven themselves to be useful devices with high performance characteristics, which include both technical and design parameters. Those who have already installed the device and are using it point to a set of advantages of the mechanism, which, moreover, does not require special care measures and is quite practical to use.

So why are closers in demand? The following advantages of the device can be highlighted:

- The materials from which the door closers are made are completely safe for both children and adults. They do not cause allergies and therefore are used every day, even in everyday life.

- Correct operation of the closer helps eliminate sounds coming from the street, thus increasing the sound insulation of the room.

- You can stop being afraid of drafts and wind. Accordingly, in the room on the front door of which the product is placed, heat is better preserved and accumulates faster.

- Whatever the model of the device, regardless of the design features, any closer should be configured according to the technological map. You can also find out how the device works and what set of functions it has in this map and instructions.

Device mechanism

Even if you are not a beginner and are familiar with the basics of product installation, we still recommend that you carefully study your particular model before the installation and use process.

In general, the door closer is always equipped with a frame and a lever, which together allow you to open and close the door. Depending on the material from which the door is made, the spring of the device is selected; the main parameter here is the weight of the door. The spring is contained in a special housing filled with technical oil. Hydraulic channels allow the oil to move freely in the space of the container, returning the spring to its place after it has been compressed.

How to adjust and correct the operation of the device? It is enough to arm yourself with screws located on the end of the frame. Newer mechanisms have a built-in additional valve that slows down the speed of door closing, which causes them to move gradually and finally slam, meaning the structure is pressed tightly against the door frame.

Types of door closers

Devices located at the top of the door, found in shops and office premises, are produced in greater quantities. The lever can be a knee or a sliding tire.

If it is impossible to make holes in the door, floor products are used. They are located in a recess in the floor surface under the door axis. The inconvenience is that this model cannot be equipped after the doors are installed; it is laid out at the stage of construction of the building.

There are also hidden mechanisms on sale that are fixed inside the door panel into a groove located on the side or at the top of the door structure

Please note that this example is applicable for doors of significant width (from 4 cm or more)

If you want the door to open and close with greater force, you should choose the right spring device. We do not recommend choosing an easy opening; it is better to stick to the golden mean.

Additional functions

Expensive, high-quality devices are equipped with additional functions that simplify the use of the mechanism. Among the most common:

- Control over the speed of closing the door structure (two methods). The first provides for changing the speed in the main range, the second is capable of reducing the range of door movement during closing.

- Fixing the door in the open position. It can be useful when transporting large loads indoors, and is also suitable for ventilation on summer days.

- Wind brake. Thanks to this function, the force applied to open the door is softened. Useful to avoid sudden opening of the door during strong winds, which protects the door from hitting the wall surface.

- Closing delay. Closing occurs more smoothly, allowing a group of people to easily exit the room.

How to repair a door closer

In order to fix a door closer breakdown with your own hands, you must first of all figure out its cause. The most common causes of malfunctions are:

- weather conditions - rain, constant humidity, temperature changes (dangerous for metal outer parts and plastic boxes);

- quick closing of the door manually at a speed that does not correspond to the set settings;

- blocking a door that does not have an “open door” function with any objects;

- incorrect choice of closer, the power of which is not enough for a heavy door. The mechanism will be overloaded, which can also occur if you hang and roll on the canvas, as children like to do.

Frequent breakdowns.

- Oil leakage may occur due to a crack in the housing. Without oil, the closer will turn into an ordinary spring and will slam the door with a deafening roar. The malfunction must be eliminated very quickly, otherwise the entire mechanism will have to be replaced. If you find a small leak, you can use sealant. If there is a significant gap and a large loss of oil, repairing the closer will not help; the device will have to be replaced.

Sometimes when manufacturing a product, manufacturers allow it to be underfilled, then it must be topped up with regular synthetic motor oil or shock absorber fluid through the screw holes.

Bar deformation

You need to pay attention to this element first. The rod can be made of ordinary steel and rust

The rusty areas should be cleaned and treated with anti-corrosion lubricant.

The break is eliminated by welding and thoroughly cleaning the seams. Curves and bends can be smoothed out with a hammer, but there is a risk that the part will not withstand the load and will burst. If the damage to the part is too serious, it is better to replace the damaged fragment with a new one.

Closers for kitchen cabinets

Closers for kitchen furniture are devices that ensure smooth closing of doors on cabinets. They prevent the door from moving too strong and too quickly and block impacts of the facade against the body. Their main function is to ensure the safety of door hinges and protect furniture parts from chips, cracks and scratches.

Operating principle

The devices differ depending on the mechanism of action, but in all cases the general principle works:

- the door rests on a special rod;

- the resistance of the rod is provided by a spring or capsule filled with oil, gas, polymer;

- when you press the door, it acts on the rod, the spring contracts or the composition is forced out of the capsule;

- the door movement slows down.

Advantages and disadvantages

Advantages of using door closers:

- smooth closing of the doors guarantees careful use of furniture, protection from damage to parts and fittings;

- ensure a tight fit of the door to the body, preventing its spontaneous opening;

- a correctly selected device does not require frequent replacement, maintenance and repair, and is durable;

- liquids and gases used in the design are enclosed in a sealed chamber - they do not harm the surface of the furniture;

- Many structures can be repaired if they break down; removable parts can be replaced with new ones;

- There is a large selection of devices on sale - it’s not difficult to choose the right one based on type, price and even color;

- installation is accessible to a non-professional with minimal skills in using tools.

Minuses:

- require care and precision during installation and configuration, otherwise their work will be ineffective;

- complex designs look bulky and do not add aesthetics to the appearance of the furniture;

- high-quality fittings are not cheap.

Where is it wise to install a door closer and where is it not worth it?

Most often, devices are installed on those doors for which it is important to be constantly closed: street and entrance doors. When installing the housing, they try to place it not outside, but inside the house or apartment

Frost-resistant models exist, but they are much more expensive, require more frequent maintenance and still have temperature restrictions. It is not recommended to install door closers on lightweight interior panels, especially those with glazing or stained glass. Frequent activation of a spring that is too strong can lead to loosening, rattling and even glass falling out

When installing, they try to place the housing not outside, but inside the house or apartment. Frost-resistant models exist, but they are much more expensive, require more frequent maintenance and still have temperature restrictions. It is not recommended to install door closers on lightweight interior panels, especially those with glazing or stained glass. Frequent activation of a spring that is too strong can lead to loosening, rattling and even glass falling out.

The door to the sauna also requires external installation of a door closer or a recessed structure. A conventional device will quickly fail due to changes in temperature and humidity.

Where to put

Most often, closers are installed on external and entrance doors, as well as on gates and entrance gates. They can be found in apartments and country houses, in office buildings and commercial facilities.

In some door models, the door closer is included in the basic package. The closer must be installed on fire and evacuation doors, entrance areas with an intense flow of visitors, and in access control systems.

On doors, the housing must be indoors. The external location causes corrosion and negatively affects the operation of the hydraulics. Only frost-resistant models, protected from external factors, can be used outdoors.

Installing a door closer (methods and types of installation)

There are as many manufacturers as there are instructions for installing door closers. However, the principle of installation of structures is similar, so for some types the fastening is the same. The door plays a role, or more precisely in which direction it opens. For interior paintings this does not play any role. For street doors, the mechanism is installed from the inside to prevent moisture and dust from getting on it.

The door opens towards itself; we attach the door closer to the top near the hinges. The door opens on its own, we attach the body of the closer to the frame (wall), and the lever directly to the door leaf itself.

Installing a door closer on a metal door

The first thing that comes to mind is doubt about installing the door closer and it seems that this task is impossible, but in fact even a beginner can cope with it. Each door closer should come with instructions with a template that will make all the work easier.

How to install a door closer on a metal door:

Attach the diagram on the inside of the canvas so that the mechanism is located in the upper corner (from the hinge side), and the lever is on the box or wall. For convenience, secure the diagram with tape. Apply marks through it for future attachment points and drill out using a metal drill. Next, we screw the body and the claw from the lever to the box (and initially divide the lever into 2 parts). Then we put it on the shaft and secure it. We take the side lever and place it so that it is perpendicular to the door, and attach it to the main lever. After this work, all that remains is to set the closing angle and speed; this is all regulated using a special key. The work is done, put on the protective cap.

Installing a door closer on a plastic door

We apply the template to the door leaf and leave marks for the holes. The hole should not exceed a depth of more than 1.5 cm. We install the housing so that the adjusting screws are on the hinge side. And then we install it, just like for a metal door.

Options for correct installation of a door closer

Correct installation of the closer requires a competent approach to work, and take into account some nuances:

- The diagram that you will find upon purchase will be made on a scale of 1 to 1;

- The kit includes two fasteners, one for plastic and wooden doors, and the second for iron structures. All you have to do is figure it out and mark the fasteners;

- It is worth preparing in advance the tools that will be useful for installing such a system;

- Do not adjust the closer unnecessarily, or at least until you have read the instructions.

Description

The door closer is a modern invention. This device appeared after metal doors quickly rushed to be installed in all entrances of our country. Due to the fact that when opened inaccurately, the door produced a deafening roar throughout the entire entrance, a need arose for a device that would soften the speed of opening/closing the metal door.

Closer on a metal door

And so a closer appeared that solved the existing problem. And now not a single office, entrance, or store can do without this incredibly convenient device. The device operates on the hydraulic principle: thanks to external force pressure on a spring located in the closer.

It is interesting that at the dawn of their appearance, only a few reputable companies and the entrances of wealthy residential buildings could afford to install door closers due to their exclusivity and lack of mass production. But with the establishment of conveyor production, the problem of the high cost of door closers disappeared, and now these products are quite affordable for everyone. In addition, the design of the device has been extremely simplified.

And if earlier, installing a door closer required calling a specialist, now any man with “hands” can easily handle installing the device on his own, guided by common sense and detailed instructions. In addition, no special tools or expensive fasteners are needed.

But this information will help you understand how to lubricate butterfly door hinges to prevent them from squeaking.

Video showing installation of a door closer on a metal door:

Door closer functions

Let's find out why this device is needed.

- The closer allows you to eliminate loud slamming of the door, which will save the hearing of those around you, a lot of their nerve cells, and, in addition, will keep the door leaf in its best condition.

- The mechanism will allow you not to worry about whether you closed the door behind you. This device will gently and smoothly “bring” the metal door to the desired closed position.

- The presence of this mechanism significantly extends the “life” of the door block and locks.

Mechanism installation

When purchasing a product that will be installed on the door with your own hands, you must keep in mind that the kit should include:

- Closer.

- Pulling from levers.

Device kit

- Hardware for fastening.

- Diagram or drawings of the closer for installation of the structure.

Mechanism installation diagram

Installation of fittings can be done on the entrance block: on the box and on the canvas, which depends on the purpose of the structure.

Installation happens:

Internal, as in the photo. This is the most common method of installing structures for external doors, with the product mounted in the opening.

Internal installation of the closer

External.

The included installation diagram, made in full size, allows you to install the accessory efficiently and avoid errors in the process.

For this:

The installation diagram is taped to the door.

Door closer installation

- Further actions are carried out according to the instructions offered by the instructions:

- Marking is being done.

- Holes are drilled.

- The body is attached.

- The linkage is installed.

Mechanism fastening

These are two halves connected to each other by thread.

- The lever is adjustable in length, which determines the opening angle of the door, approximately 90°.

- With proper installation of all structural elements, the device will work efficiently, without failures.

Examples of installation of structures

Setting up the closer

Correct adjustment of the installed elements can be carried out if you understand the screws that are part of the structure.

Device setup diagram

Many models have special screws located on the decorative cover of their case. On some, the screws are located on the end side of the body and are marked with numbers 1 and 2. Screw 1 adjusts the change in the door opening angle; it can reach 180°. Screw 2 changes the speed of closing the sash.

When adjusting the closer:

- The opening angle of the door leaf varies from 90° to 180°.

- The closing acceleration is adjusted by adjusting screw 2.

- The door opens to the working angle and is released.

- By rotating screw 2, the smooth movement of the door leaf is adjusted in the last 15° to ensure its reliable closing.

- There is no need to put in much effort when making adjustments.

- After 1/4 turn of the screw, the doors will close slowly.

Adjusting the closer

The closer can be used for a long time if the adjustments are made regularly. It must be borne in mind that forcibly holding the door for ventilation and supporting it with various objects can lead to an increase in the load on the seals and the closer piston.

This will cause oil to be squeezed out of the housing and the closer to fail. Only a specialist can answer the question of how to properly fill a door closer. Each design has its own characteristics.

Door closer care

Mechanism design

To maximize the service life of the door closer, you need to maintain the serviceability of this mechanism and regularly check the condition of its main parts:

- To avoid problems with corrosion, metal fragments should be regularly processed and lubricated for smooth operation.

- It is necessary to periodically adjust the settings in accordance with the door parameters.

- You cannot place anything under an open door.

- You cannot pull the door towards yourself to speed up this process.

- It is contraindicated to “help” the door close by holding it.

Whether it is a built-in closer or any other type, with proper installation and operation, such a device will allow you to control the process of opening and closing the structure. This will prevent glass from breaking and sometimes walls falling out in your home when installing metal doors.

Some tips for using the door closer

Proper use and timely maintenance can significantly extend the life of an important and useful device for creating home comfort. The designers designed it to be strong and durable, designed to withstand tens of thousands of opening cycles. The main thing is not to interfere with the mechanism in fulfilling its duties as a gatekeeper.

Operating rules are given in the user manual. You need to study them carefully and do not forget the main points:

- You should not speed up the movement of the blade by holding or leaning on it.

- It is unacceptable to place stones, boards or other objects under the door to block the structure while carrying things or ventilating the premises. To do this, you need to disconnect the levers. Some models have an open locking mode.

- Bags and other heavy objects should not be hung on door handles and children should not be allowed to ride on them.

Failure to comply with these simple and reasonable requirements will lead to increased wear and premature failure of the closer. Most models cannot be repaired and will have to be replaced.

You can install the door closer yourself, following a simple sequence of operations. This requires precision and accuracy. Following simple operating rules will extend the life of the closer.

Briefly about the main thing

The installation of door closers is carried out in several stages: choosing an installation scheme, working with a template, directly installing the elements of the device and its final configuration.

The specificity of the installation lies in the variability of its execution. The design can be mounted in a hidden version, when the device is not visible to the eye, and in a surface-mounted version, where the lever and body of the device are located directly on the doors.

The standard method of installation is considered the most common, but it may be necessary to carry out complex installation of the structure, where additional elements such as plates and angles are used.

Do-it-yourself door closer adjustment

What to do if the door closer stops functioning as it should? If the door slams and closes too quickly? Don’t rush to call a specialist right away; adjusting the door closer yourself is not as difficult as it might seem at first glance. First, let's look at what is a cause for concern when calibration may be required.

Firstly, this is a planned event, that is, it needs to be done once or twice annually. Like any other device, it may get slightly damaged during use. If you fix a small problem during a routine inspection, you can avoid larger repairs later.

Secondly, adjustment is extremely important during the changing seasons

Temperature changes and climate change do not have a beneficial effect on any mechanism, and it is important to remember this. Since most door closers operate using an oil filler, which changes its properties when the temperature rises and falls, you need to adjust the operation to the current time of year

In the winter cold, the oil thickens and the door moves more slowly, but in the summer, in the heat, it softens, on the contrary, and claps are heard more often. If you tighten the mechanism, the problem will disappear.

Thirdly, it is necessary to correct the device in case of problems

If you start to notice that the door closer slows down or, on the contrary, closes the door too quickly, you need to urgently inspect and fix the problem.

Photo from dveridoma.net

But if during the inspection it turns out that the closer is broken, adjustment is unlikely to help; most likely, additional repair measures will have to be carried out.

Next, we will talk about how the work of adjusting the device occurs; this knowledge can be useful not only to those who have already encountered the problem, but also to those who want to install the mechanism on their door, because during the initial installation it also needs to be rebuilt.

We will talk about standard overhead models; almost all manufacturers produce just such.

Selecting the door speed

The closer, as a rule, has several functions and each action can be adjusted. How quickly the door closes behind you will depend on how you configure this function.

Find two screws on the device body, the first is responsible for the speed of movement. It cannot be turned endlessly; in order to adjust it, you only need to turn it once. In this way, the tension inside is adjusted, the spring is tightened stronger or weaker - in one direction you weaken the pressure, and in the other you increase it. Accordingly, the looser the bolt is tightened, the freer the movement.

Important

Do not turn the screw twice - this can lead to damage: depressurization will lead to oil leakage.

Installing the exhaust

How to adjust the door closer so that the door does not slam? This mode is good for calibrating the smoothness of closing. Before closing completely, the door slows down and only then fits tightly to the frame.

To set the required indicators, let’s work on the second screw on the body - if you turn it, you can set the closing function - when the door leaf is at a position of 10-15 degrees relative to the frame, it will slow down and gently pull in.

Calibrating the open position

Sometimes it is necessary to keep the door open for a certain period of time. Many manufacturers have foreseen this situation and created the necessary function.

Photo from the site xn--56-6kch4danr.xn--p1ai

To adjust, open the door 90 degrees and tighten the locking element. This will allow you to leave the entrance open, but only when the door leaf reaches this exact position. If you need to close it, pull it towards you and the lock will be removed automatically.

This is interesting

If the door does not open wide enough, the lock will not work.

As you can see, there is no difficulty in such manipulations, but for a better understanding, we recommend watching the video “How to adjust the closer on the front door with your own hands.”

Video “Adjusting the door closer with your own hands”

What to do if nothing works out?

It happens that the door closer is adjusted with good information preparation, the instructions are at hand, but still the result cannot be achieved.

The range of modern door closers is very diverse.

In this case, the point is the wrong choice of this part, especially for heavy metal entrance doors. Most likely, the European standard index does not match the weight or width of the door, the fastening angle is incorrectly attached, or the holes for the screws on which the closer is held are shifted.

In this case, the question of how to adjust the closer is not correct, since you need to change the intercom doors, or, more likely, remove the closer and install a new, more powerful one

You should also pay attention to the lever; it must be perpendicular to the plane of the door. If it is misaligned, one of the closer links may need to be moved.

When purchasing door closers, know that adjustment is simple, especially if you have not lost the instructions.

Types of door closers

The mechanism works on the following principle - when opening the door, a person exerts forces on the spring inside the device. Then, the spring returns to its original state, controlling the closing of the door. Closers differ in the type of fastening and can be hidden, floor-mounted or overhead.

Overhead mechanisms

Overlay mechanism

These door closers are often found on the doors of offices, shops, and entrances. The device is mounted to the top of the door and operates from a gear drive or on a sliding rod. In the first version, the design looks like a small box with two levers, one of which drives a gear connected to a toothed pin with a spring. These devices are ideal for heavy entrance doors.

The second option is a mechanism with a sliding rod. It has two functional pistons - opening and braking. This design is more compact than the previous one and is completely hidden under the casing, which increases its reliability.

Floor structures

Floor closer

This type of door closer is installed in a recess under the door and is almost invisible. The mechanism consists of a rotation shaft, which is connected on one side to a spring, and on the other to the door fasteners.

The design is convenient for controlling the opening of glass doors, including pendulum ones (swinging in both directions). These closers are more often used in shopping centers with many glass partitions. The need for their use, as a rule, is determined at the stage of drawing up the project of the facility.

Hidden devices

Hidden type devices are divided into two main subtypes - with a sliding rod and closing loops. The first are not much different from the overhead mechanisms described above; the difference is only in their smaller size and installation principle. One of the parts of the device cuts into the upper part of the door frame, and the second (designed to move the rod) into the lower part.

Closer hinges

The second type (hinges) is the smallest of the structures designed for closing doors. It is used for doors with low mass, usually interior doors. Its disadvantages include difficulties during installation (the need to accurately adhere to the axis) and a short service life due to the fragility of the device. If you compare two types of hidden closers, it is more practical to give preference to the more durable first.

Device and principle of operation

Most modern devices of this type are based on a spring, which is compressed when the door is opened. When the pressure on the door stops, the spring relaxes, returning it to the closed state.

Door closers can be of different types, types and colors

The main difference between different types of closers is the method of transmitting force to the spring: there are devices with a hinged rod or with a sliding channel. But in general, the principle of operation is this.

By opening the doors, we activate a gear that transmits force to a rack (hidden in a metal cylinder) filled with oil. The rack drives a piston, which pushes the spring, compressing it. When the piston moves, oil flows from one part of the chamber to another, providing a certain resistance and slowing down the movement of the door leaf.

The internal structure of a door closer for an entrance or interior door

As soon as the pressure stops, the spring begins to expand, pushing the piston in the opposite direction. At the same time, the oil again flows from one part of the device to another, slowing down the slamming.

As you can see, the speed of movement of the door and the force required to open it depend on several factors: the power of the spring, the ease of movement of the gear, rack and piston. The degree of viscosity of the oil also has a great influence: at low temperatures it becomes more viscous and flows worse; at high temperatures, fluidity, on the contrary, increases, doors close faster. Therefore, the door closers on the entrance doors have to be adjusted with each change of season.

In addition to devices that use gears to transmit torque, there are mechanisms with cam elements. The cams have an uneven, heart-shaped shape; turning it also changes the force required to open the door and the speed of its return to the closed state. This makes it possible to make smoother adjustments. However, the most common mechanisms on the market are those with gears: they are more reliable.

Types of door closers

Regardless of the physical principle of operation (spring, pneumatics, hydraulics), all devices are divided into three types:

- External top.

- Hidden inside the door leaf.

- Floor hidden.

The mechanisms hidden inside the leaf are most often installed during the production of doors. And they go on sale assembled.

Floor-mounted hidden closers are installed mainly on glass doors of public buildings - in supermarkets, cinemas. The mechanism itself is hidden under the floor covering, only the drive lever is visible.

The mechanisms of each type differ in the power of the force. A light closer is selected for a small door. Also, closers are available for sale even for heavy garage doors.

Features of installing hidden closers

Flush mounted devices belong to one of the following types:

- Floor-standing. Usually used for glass doors, less often - for wooden, PVC and metal doors, when design requirements exclude hinged installation. The mechanism is recessed into the floor - only the mounting plate is visible. Such devices are susceptible to contamination and damage and are not suitable for outdoor installation. Adjusting them is quite complicated and requires special tools.

- Upper. They require special care when marking and installing. They can work on street doors because they suffer less from dirt and damage.

- Built into hinges. Used for double-sided doors, such as arched or saloon doors. They are used where there are large reverse flows of people: subways, shopping centers, etc.

- Hidden in the door leaf. The grooves into which the mechanism is mounted are selected for them. Adjustment requires special tools.

Hidden automatic door closers are limited in size, so their spring strength is insufficient for heavy metal panels. In this case, you will have to return to the classic design of the device.

Installing the door closer of most hidden models can be done by hand, but a higher level of plumbing and general construction skills will be required.

Installation of the closer and its adjustment

How to install the door closer correctly? Each device comes with detailed instructions that describe step-by-step guidance for installing and configuring door hardware.

Installation of closer

Installation of an overhead closer on a gate or door is carried out according to the following scheme:

- marking the installation area of the closer. Currently, almost every device comes with a template that facilitates the marking process. The location of the fasteners is marked on the template. In order for the marking to be as correct as possible, the template is fixed to the door leaf with tape or other means, and the upper part of the template should be located strictly along the edge of the door leaf, and the vertical part of the sheet should be parallel to the axis of the door hinges;

Determining the location of mounting bolts using a template

- drilling holes. After determining the location of the bolts (4 pieces for the closer and 2 pieces for the guide), it is necessary to drill holes. The diameter of the drill is selected according to the corresponding parameter of the fasteners;

Preparing holes for fixing the device

- We carry out the final installation of the guides with the closer, that is, fixing the individual elements of the device on the door;

Fixing the closer on the door

For convenience, installers recommend attaching the guide part first, and then the closer body.

- at the last stage, the guide (rod) is connected to the main part of the device.

Connecting individual elements into a finished device

- checking functionality and making adjustments if necessary.

Depending on the type of device, the installation diagram may differ slightly from that presented above. However, the basic installation steps are the same.

Adjusting the closer

After installing the closer on the door, the final adjustment of the device is made. During the adjustment process you can configure:

- door closing speed, which ranges from 180º (full opening) to 15º (limiter);

- final slamming speed, which occurs from 15º until the door leaf is completely closed.

To adjust, you will need a hex wrench, which is usually supplied with the closer.

The adjusting screws are located on the side of the main unit of the device.

Bolts for adjusting the speed of the closer

Adjustment is made by rotating the corresponding screws:

- clockwise. At the same time, the closing speed increases;

- counterclock-wise. The door closing speed is reduced.

Closer adjustment diagram

The optimal setting for the device is one in which the door closes completely in 5–6 seconds.

How to install the door closer with your own hands and make final adjustments to the closing speed of the device, watch the video.

If you choose the right door closer and install it according to the instructions supplied with the device, then the door hardware, designed for smooth closing, will serve for a long time without breakdowns or failures.

Using a weight as a slamming mechanism

This method is becoming one of the oldest and is rarely used today. With this method, a cable or rope is attached to the door leaf, the second end of which is passed through a wheel attached to the wall or frame. A weight is attached to the end, which closes the door. Its weight has to be selected manually, since there is no exact formula for calculating it.

The advantages of this method include its low cost, simplicity and efficiency. If necessary, you can even lock the door.

The obvious disadvantage is that while moving, the load swings and hits the door or frame. In order not to spoil the surface, it is placed in a pipe with the appropriate diameter. This approach will preserve the door and give the composition a more attractive and neat look.

Installation progress

To know how to properly install a purchased door closer, you need to understand what type of traction device is installed. It can be standard, sliding or with a fixed rod

Even at the purchasing stage, pay attention to the strength and durability parameters so that the installation of external and internal door closers does not go down the drain. There are also standards for this

The design of the door closer must match the overall style of the room.

A good door closer should have a European rating of EN1154, a durable metal body, and anti-corrosion coating. Don’t forget that the external door closer will be visible to everyone, so you need to select it based on the style of the room or try to make it invisible by choosing the minimum size and color to match the door.

Preparatory stage

So, you have the purchased device in front of you, but how to install a door closer? The manufacturers took care of this and included instructions in the box. It is usually clear, visual and contains a description of how to install the door closer.

Pay attention to your door. It can be: left-sided, right-sided, opening outwards or inwards

Of course, for entrance doors it is better to install the structure inside to avoid the harmful effects of frost and heat. Although many modern models are designed for a range from -35 to +70, the device may still fail in severe frosts.

The choice of door closer type is determined by the design of the door.

You need to know how to install a door closer depending on its orientation. If you open it away from you, the body is attached to the door frame, and the lever is attached to the door itself. If you need to pull the door towards you, the body should be attached to the top of the door leaf, from the hinge side, and the lever to the frame, slightly higher. In order to install the door closer with your own hands, you need to close the doors and start working, following the following algorithm.

Fastening process

Take from the delivery set a diagram that corresponds to your type of door. Attach it to the top of the door (it is made on a 1:1 scale), where you are going to attach the door closer. The line of the door itself will be highlighted on the diagram, so you can attach the diagram along this line and fix the sheet for convenience with tape at the top, on the frame.

This is necessary in order to mark the locations for the holes. Take a sharp pencil and draw dots through the paper. Installing a door closer on a wooden door will be easier, since mounting holes can be drilled without difficulty. Aluminum doors will require bonnets.

You will need 4 holes for the closer and 2 on the box. When the holes are ready, you need to secure both parts with the self-tapping screws that come with the door closer. This can be done with a screwdriver with a suitable pattern.

But there are also subtleties in how to install a door closer. For example, it is difficult to calculate the forces on a plastic door when preparing holes, since the material is soft and pliable.

In this case, the points should only be slightly expanded, leaving the work of cutting through the material directly to the self-tapping screw. Next, both attached parts need to be fastened with a common screw to obtain a lever. It should be at a right angle to the door leaf.

Final stage

After installation, you need to adjust the device by tightening the screws. The ideal closing speed can only be determined in practice by closing and opening the door several times and adjusting the closer depending on the results.

It is important to know that there are two screws in the design. The lower one is responsible for the door closing speed in the range from 0 to 15 degrees of deviation from the plane

The top one takes responsibility for the range from 15 to 180 degrees. If you look closely at the screw, you will notice that turning it to the right will slow down the process, and turning it to the left will speed it up.

Preparing doors for installation

Before you figure out how to install a door closer, you need to prepare the door itself. Check if they are installed correctly? Are the hinges installed correctly and is the door rubbing against the floor? All this can have a detrimental effect on the installed closer, which will either work incorrectly or not work at all.

In addition, it is recommended to check the condition of those same hinges, make sure that they function well enough, in extreme cases, they must be lubricated with grease or any other available material of a similar effect. The doors must work perfectly, which, in addition to the normal operation of the closer, can also guarantee the reliability of the door itself.

In addition, it is necessary to take into account some features of the type of closer, and there are only a few of them, or rather three.

The first and so-called standard type of door closer is the overhead door closer. It does not have a special design and is a regular overhead spring (the spring is hidden inside), which is screwed to the door using the simplest method - with screws (the other part, respectively, to the door).

The second of the existing options can be called a floor closer, which is really second not only in number, but also in convenience, since even in comparison with a surface-mounted closer, which is also much inferior to a higher quality, hidden one, the mechanism can ruin the interior, since its installation on the floor is extremely very noticeable. Although it would still be stupid to criticize this choice, since with proper installation and some interior solutions you can achieve an attractive appearance. Despite some inconveniences, the floor closer is the most reliable and can last approximately twice as long as other options.

The third type of door closer is a hidden door closer. Perhaps the most attractive option, since its design allows you to hide the closer inside the doorway.

Versatile functionality of door closers

- Let's say there is a gusty wind outside, there is a draft in the house, or a person opens the door with special effort. A specially designed adjustable hydraulic damper then prevents sudden opening of the doors. With its help, the door leaf will not hit the adjacent wall and will not break.

- The door to the room must remain open for a long period of time. Then a closer is used, the mechanism of which fixes the door in the open position.

- In some situations, a certain pause is required between the moment the door opens and the moment it begins to close. Typically, warehouses work this way, and the door in a home pantry also functions in a similar way. Install closers with a closing delay function.

- Double doors will require a mechanism that can coordinate the closing of both leaves uniformly and at the same time.

- For “cold” doors you will need a closer, the design of which has a “thermal shutter” system. The system reacts to temperature changes, which leads to its contraction or expansion. This is an opportunity to compensate for changes in oil viscosity.

Standard gradation of door closer “sizes”

- When selecting the right model, you need to focus on the maximum performance of your doors. For example, if the blade is 900 mm wide, but at the same time weighs 70 kg, then you will need to purchase a door closer with size EN-4.

- For maximum consumer convenience, developers of such mechanisms often provide a certain range of their capabilities. For example, the technical documentation may set the limits “EN-2 ÷ EN-4”. The specific amount of force in this case will be determined only by the installation features of the closer.

- In those rare situations when the effort of one closer may not be enough, they resort to installing them in pairs.

- It is worth purchasing the model that best suits the existing doors. Understating the characteristics will lead to rapid failure of the closer. Too large a size means unnecessary difficulties with normal door opening.

- If you plan to install the closer on the street or in an unheated room, you must check whether this option is available on a specific model. The problem is a significant change in the viscosity of the oil in the hydraulic system due to thermal changes. Typically, the product data sheet indicates the permissible operating temperature range.

- You can immediately evaluate the functionality of the selected model. Basic adjustments of most door closers include changing the spring force, speed and force of closing the door in the sector from 180 to 15º and in the final section (finishing) - from 15 to 0º. In addition, other parameters may be provided:

— A special adjustable hydraulic damper will help prevent sudden opening of doors due to excessive force or in a draft or gusty wind. It will protect the doors from breaking, from hitting adjacent walls, and will prevent accidental injuries.

— Often the operating conditions of the premises require leaving the door open for a long time. To do this, you will need a closer with a locking mechanism in the open position.

— There are situations when after each opening of the doors and before they begin to close, a certain pause is required, about half a minute (for example, warehouses, storage rooms, utility rooms). This feature can also be implemented in closers with a closing delay function.

— If the doors have an elastic seal, or they are equipped with latches, the function of precise control of the speed and closing force will be useful.

— If the doors are double-leaf, then an additional mechanism may be needed to coordinate the uniform closing of both leaves.

— For “cold” doors, it is better to purchase a closer with a “thermal damper” system, which, in response to changes in external temperature, expands or contracts, compensating for changes in the viscosity of the oil in the hydraulic system.

Approximate procedure for installing a door closer

Since the most common door closers in apartments are those with a hydraulic rack and pinion system and a lever mechanism, the installation process will be discussed using their example. By and large. Installing door closers with a slider system is not particularly different, and in some cases it is even a simpler task.

First of all, you should decide on the installation diagram, which depends on the direction of opening the doors: