Most owners of country houses and summer cottages prefer to install their own heating system by building fireplaces and stoves. This, of course, requires certain experience, knowledge and understanding of construction technology.

Gate valve - photo

One of the necessary elements for a stove to ensure its efficient operation is a chimney gate valve. In this article we will try to explain to you the principle of its operation and the step-by-step process of creating and installing it yourself.

Today, a stylish fireplace or an exclusive stove is no longer a luxury item and, if desired, you can build it yourself. In this article we will describe in detail what a chimney gate valve is, its main purpose and installation features.

Gate - what is it, device, purpose

A device designed to change the working cross-section of the smoke exhaust duct is called a damper. Simply put, this is a damper that reduces or increases the clearance of the chimney. With its help, the intensity of fuel combustion is regulated, and the draft after heating is blocked to preserve heat in the stove.

Traditionally, such a damper is mounted in the upper part of the stove chimney with access from inside the room and is a thin steel or cast iron plate that moves in one plane along a special frame. The principle of its operation is quite simple - in order to reduce or increase, completely open or close the working lumen of the smoke exhaust path, you need to push in or, conversely, pull out the plate. Another modification has a slightly different device and mechanism of action - rotary. The plate in such a device does not extend, but rotates around its axis.

The rotary gate is equipped with a special adjustment handle with position fixation Source static-sl.insales.ru

The gate control can be manual or electrically driven. This depends on the model, installation location and maintenance principle of the heating unit. Since such dampers are installed not only on basic brick or iron stoves and fireplaces, but also in the chimney systems of heating boilers and ventilation.

Functions

In most cases, the stove damper performs the following number of functions:

- Optimizes traction for weather conditions.

- Sets the intensity of fuel combustion, adjusting it to the needs of the consumer.

- Prevents the formation of hyperthrust during strong windiness.

- Promotes economical fuel consumption.

- Minimizes heat loss after heating.

- Protects the lower sections of the chimney from precipitation.

- When installed in a ventilation system, it prevents overheating of the motor.

Important! Closing the smoke exhaust channel with a damper must be carried out in a timely manner, but only after complete combustion of the fuel. Otherwise, if you close it too early, carbon monoxide, which is dangerous for all living things, will begin to enter the room, or if you close it too late, most of the heat will leave the firebox, and the stove will not be warm enough.

Scheme for installing a damper frame in a brick stove pipe

Advantages and disadvantages

The chimney damper has the following advantages:

- Possibility of adjusting the traction force.

- Effect on flame intensity.

- Rational fuel consumption.

- Better heat retention.

However, it has some disadvantages:

- Difficulty cleaning the chimney duct.

- Deterioration in the operation of the gate mechanism (jamming, decreased traction) due to improper installation.

- Correct adjustment requires some experience and skill.

If the installation requirements are met, the gate valve will last at least 10-15 years, and in ideal operating conditions - no less than the service life of the stove itself.

On a note! The more the valve is extended from the pipe or the rotating segment is at a stronger angle, the faster the combustion products will exit and the more intense the combustion.

Functions, purpose and characteristics

This special partition is a mandatory part of the channels responsible for the smoke exhaust. Its presence guarantees the safe operation of the installed stove or fireplace, as it ensures the fire resistance of the entire heating system in the room. It completely duplicates the cross-section and area of the chimney lumen. When closing, seasonality should be taken into account, since in winter it is allowed to retract the damper half its length, and open it completely in summer. Solid overlap is prohibited.

Its maneuverability makes it possible to increase or decrease the pipe cross-section, which increases or decreases the air supply after the stove is fired, respectively.

Externally, this damper looks like a small metal plate, which is adjusted using a handle located outside. This provides manual adjustment, allowing the owner to independently change the position of the partition. Regardless of the type of structure, it is mounted by placing it inside a pipe and then securing it with a clamp.

The chimney damper is responsible for several functions:

- Increases traction in adverse weather.

- Injects air that increases combustion power.

- Reduces draft in windy weather.

- Prevents heat leakage when heating the heater.

- Reduces combustion intensity, allowing you to save on fuel.

Varieties

Furnace valves available on the market today are classified according to two criteria:

- Design : retractable and rotating.

- Material – cast iron and stainless steel.

Let's look at their features in more detail.

Rotary cast iron gate Source proroofer.ru

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Design

Based on the type of design, dampers are divided into two categories:

- Retractable.

Classic model of a furnace valve. The design is a metal plate moved in a special frame in a horizontal plane. Characterized by the following performance properties:

- Easy to use.

- Ease of installation.

- Durability.

- Reliability.

Mounted exclusively in a horizontal plane. Suitable for brick and steel stoves, fireplaces.

- Rotary or throttle.

The operating element of the rotary damper is a metal plate installed in the chimney and centrally fixed to a steel pin. With its help, fastening, actuation (rotation) and adjustment of the cross-section of the chimney duct are carried out.

In order to increase or decrease, respectively, to open or close the smoke exhaust passage, it is necessary to rotate the plate around its own axis at a given angle. As a rule, the model is less reliable than the classic version discussed above.

Throttle valve for steel chimney Source cloudinary.com

The main disadvantage is the burnout of the contact connecting the plate to the fastening pin, and, as a result, disruption of the functions of the valve. It is most often installed in steel chimney systems.

Material

Based on the type of material, furnace valves are divided into two types:

- Cast iron.

Products made of cast iron are strong, reliable and durable. Their only drawback is their heavy weight. This somewhat complicates the installation procedure, and also imposes strict requirements on the base. Therefore, most often cast iron valves are installed on brick chimneys.

As a rule, sliding-type dampers are made of cast iron, but there are also rotary varieties. Their main area of application is classic stoves and fireplaces made of brick.

- Made of stainless steel.

The chimney gate valve based on a stainless steel alloy differs from the above modification in being lighter in weight. This somewhat simplifies the requirements for the strength of the base, and makes it possible to install them in steel chimney pipes of furnaces, heating or ventilation equipment.

The stainless steel gate is lightweight and durable Source prom.st

The design of a gate valve and materials for its manufacture

The main components of a typical gate valve are:

Frame. It consists of a main part and a cover (in many designs it has a stand with a yoke assembly), connected to each other with bolts. The main materials for the manufacture of body parts are carbon steel grade WCB (analogues of cast steel 20L, 25L, 30L), stainless steel (for example 20Х13, CF8, CF8M, AISI 304, AISI 310, AISI 316), gray (SCh20, SCh25) and high-strength nodular cast iron (ductile iron) grades GG-40 or GG-25.

Exclusive case materials include aluminum, bronze and AISI 904L uranium.

Typically, valve bodies are coated with a blue epoxy or powder-epoxy compound approximately 250 microns thick.

Shiber. Most often, the gate plate is made of corrosion-resistant metal alloys, which are AISI 304, AISI 310 or AISI 316 stainless steel.

Spindle. The element is responsible for moving the bolt plate, usually made of stainless steel (20X13).

Rice. 4 Materials for the manufacture of seals in SMO brand products and their varieties

Seat seals. Main materials of seat seals in gate valves:

EPDM - ethylene-propylene-diene elastomer (EPDM) is used as a sealant when transporting media with an operating temperature of + 90 °C and a maximum temperature of no more than + 125 °C.

NBR is acrylic-nitrile-butadiene rubber, it has a relatively low heat resistance with a maximum threshold of no more than + 90 ° C; when using it, the temperature of the working environment should not be higher than + 80 ° C.

Viton (FKM, FPM) is a class of synthetic fluorinated rubbers (SFK), which have a maximum temperature threshold of + 200 °C, and can be operated for a long time at a temperature of + 180 °C.

PTFE is a well-known white fluoroplastic with a soapy surface to the touch. The material has a very low coefficient of friction and the highest heat resistance among all seals at + 270 ° C. It is mainly used as an oil seal; when used in seats, fluoroplastic does not provide 100% sealing.

Nitrile (Nitril) is a synthetic butadiene-nitrile rubber (rubber), resistant to petroleum products, oils, acids and low concentration alkalis. Withstands operating temperatures up to + 90 °C.

Hypalon (CSM) is a product from DuPont that is a chlorosulfonated polyethylene elastomer (CSPE). Hypalon is a general purpose rubber with good mechanical properties and high resistance to abrasion, wear and aggressive chemicals. The maximum temperature threshold for CSPE-based rubber reaches + 120 °C.

Silicone - organosilicon silicone rubber is an elastic material that can function in the temperature range from - 60 to + 300 ° C (withstands 500 hours). The maximum operating temperature of silicone rubber with a service life of 20 years is + 120 °C. Silicone is resistant to oxidizing agents, oils and organic solvents, has a low coefficient of residual deformation, that is, it easily restores its shape. The disadvantages of organosilicon silicone rubber include its insufficiently high tensile strength compared to other elastomers.

Rice. 5 Design of gate valves according to GOST R 55020-2012

Oil seal packing. In gate valves, the gland provides a seal in the body of a moving flat plate and has an internal surface shape corresponding to an elongated rectangular gate. The following materials are used as its packing and ring gaskets:

- Dry cotton fiber, used in general purpose installations working with solid bulk materials.

- Oiled cotton fiber. It consists of woven threads impregnated with grease. Is a packing for standard shut-off valves operating under pressure.

- Cotton Fiber with PTFE is a general purpose padding made from woven Teflon-impregnated cotton fibers.

- Teflon acrylic fiber. It is a synthetic acrylic thread impregnated with Teflon using vacuum dispersion technology. It is a typical packing for valves operated under pressure in aggressive liquids (oils, oxidizers, alkalis and acids) or with suspended particles.

- Fibrous (lubricated) PTFE. Fluoroplastic fibers with a diagonal weave system can function at high speeds of gate movement in almost any aggressive environment, including those containing solid fractions.

- Heat-resistant graphite fiber is a diagonally woven thread impregnated with a lubricant made from a similar material. The packing is universal, as it can withstand not only high temperatures of vapors, gases and liquids, but also their aggressive chemical composition. Graphite is not afraid of oils, solvents, the vast majority of alkalis and acids.

- Ceramic fiber is used in gate valves that handle high temperature air or gases at low pressures.

- PTFE, nitrile and EPDM are used as rectangular gaskets.

Criterias of choice

In order to choose the right valve for a chimney pipe for specific application conditions, it is necessary to take into account the following number of parameters:

- Conditions of use . It is not recommended to equip a sauna stove with a rotary damper.

A sliding gate valve is ideal for equipping a stove in a bath Source parma.center

- Frequency of operation . For stoves used periodically or seasonally, it is better to install a pull-out valve. If you choose a throttle model, the chimney above the plate will constantly become damp, since when closed it still allows damp air to pass through, and below it a large amount of soot will accumulate during combustion.

- Type of equipment . To equip combustion product removal systems for gas heating boilers, it is recommended to use a throttle valve. Since the design ideally complies with the technical conditions, according to which the channel cross-section should not overlap by more than 40%.

In addition, when choosing a damper, you must make sure that its dimensions exactly match the cross-sectional area of the chimney channel into which it will be installed.

The dimensions of the gate must exactly match the diameter of the pipe Source parmaster.ru

Manufacturers

In addition to the products of the PromArm company discussed above, the following companies supply their products to the domestic market:

END Armaturen is a German manufacturer of high-quality gate valves made of steel and cast iron (GG-25) in closed housings, designed for pressures of 5, 6, 7, 8, 10 bar and working fluid temperatures up to 190 °C. The bidirectional products offered for sale with a U-shaped gate with diameters from 50 to 400 mm are produced with manual and lever control.

Zetkama, a well-known Polish manufacturer on the domestic market, supplies gate valves made of cast iron EN-GJL-250 with diameters from 50 to 1200 mm. The products are intended for use in pipelines transporting liquids with a 5% solids content, installations for supplying dry materials to the pulp and paper industry, and in sewerage systems with a 35% waste content. Gate valves are designed to operate at a working medium pressure of 2, 4, 7 and 10 bar and its temperature not exceeding 90 °C.

Rice. 15 Gate valve Zetkama

FAF Vana is a trademark of a Turkish manufacturer of a wide range of shut-off and control valves. FAF gate valves are produced in bodies made of ordinary or high-strength cast iron with diameters from 50 to 600 mm. All of them are designed for a working fluid pressure of 10, 16 bar and its temperature of no more than + 130 °C. Designed for use in environments containing clean and waste water, pulp, crystallized and powdery substances, and are used for transporting substances in the brewing and food industries.

CMO is a brand of a Spanish company with headquarters and production facilities in the city of Talos, founded in 1993.

The company supplies the domestic market with a very wide range of gate valves of various designs - more than 20 items with different letters. The fittings are produced from different materials with nominal diameters from 50 to 3000 mm with all types of drives. The pressure range of all products is from 0.5 to 100 bar, working media are gases, pure and with varying contents of suspended or solid liquid fractions.

Rice. 16 ABRA gate valve

ABRA is a trademark of a Chinese company, whose products are sold in Russia by Abradox. ABRA gate valves are produced with diameters from 50 to 600 mm for pressures of 4, 6, 10 and 16 bar. The product range includes several types of knife models of different sizes, the operating temperature of which depends on the type of seals used: for EPDM it ranges from - 10 to + 95 °C, for NBR this indicator is from - 10 to + 70 °C.

Tecofi is a trademark of a French company that produces the widest range of knife gate valves in the following series: standard VG, with a through knife (VGT), for dispensing hoppers (VGS), with a square knife (VGC), with a rectangular gate valve inclined at 30 degrees (VGA) ), airlock with a rectangular knife (VGM).

Tecofi gate valve body materials are regular and ductile iron, carbon steel, stainless steel, aluminum, polyvinyl chloride (PVC). Tecofi gate valves are produced with diameters from 50 to 1200 mm, their nominal pressures are 1, 2, 4, 7 and 10 bar; in special designs, the pressure characteristics can be 25 and 40 bar. The operating temperature for EPDM seals is 110 °C.

Rice. 17 Tecofi brand gate valve

Installation Features

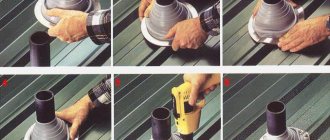

Installation of a damper on a chimney is possible in 3 main options:

- In a straight chimney above the firebox . The method is suitable for fireplaces and stoves with summer operation. The valve is located approximately 1 meter from the combustion chamber. The main advantage is accessibility and ease of maintenance.

- " Pipe to pipe ." The method involves installing a damper into the chimney duct without additional fastening devices.

- Installation in a ventilation system . Used to protect the fan motor from overheating.

Kinds

Let's look at the main types of gate valves:

- Horizontal retractable gate installation. The process consists in the fact that the plate located inside the damper moves out, due to this the cross-section of the chimney or ventilation pipes changes. This type of gate valve is used in brick chimney pipes and has a horizontal position.

2. Classic throttle or, in other words, rotary type. The process is carried out by a rotating action inside the duct. This type of gate installation has a metal body and a removable rotating disk. Therefore, with prolonged use, it may become unusable, but it can be easily replaced. You can do this procedure yourself.

3. Air damper. This type is regulating, it controls the amount of fuel (coal). Management is carried out automatically.

Video description

Video example of installing a damper in a chimney of a brick kiln:

When installing a damper in a pipe, the following series of problems and errors may arise:

- Installation of the valve in a part of the chimney duct with external thermal insulation. As a result, the mechanism will overheat and jam.

- Installation of a cast iron model in a steel pipe. Under the influence of the large weight of the damper, the chimney is deformed.

- A poorly made valve is made of thin metal. Such a product will quickly burn out or bend under heat.

- An uneven internal surface of the gate will lead to frequent jamming and poor-quality operation.

- A valve plate without a technological hole (for easy purging to avoid the accumulation of carbon monoxide in the furnace), necessary to comply with safety regulations.

- Installation of rotary models with adjustment handles that do not make it possible to control the position of the sliding plate.

Advice! To extend its service life and trouble-free operation, the damper must be cleaned regularly. The retractable plate and guides must be periodically lubricated with a special anti-corrosion compound. The rotary analogue requires cleaning through the chimney with a special brush.

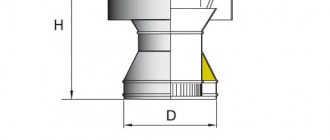

Size calculation

Even an extra gap of a few millimeters can be the cause of improper operation of the air vent.

Step-by-step steps to resolve the issue are as follows:

- First, take a tape measure to measure the size of the internal channel.

- 20-30 mm is added to the result. The result is the size of the outer frame.

- An opening for gas release is required for the finished valve.

- The position for the welding holes is also marked as accurately as possible.

Briefly about the main thing

The damper is a special damper installed in the pipe and allows you to reduce or increase the working cross-section of the chimney duct. By design, it can be retractable and rotary. Its main functions are optimizing draft, adjusting flame intensity, preventing hyperdraft, saving fuel, protecting the stove from heat loss, protecting the chimney from precipitation.

The main advantages of the damper are the ability to adjust the traction force, influence on the intensity of combustion, rationalization of fuel consumption, and heat conservation. The disadvantages are associated with difficulties during cleaning the chimney duct, operational problems due to improper installation and the need for special skills for maintenance.

Furnace dampers are divided into the following types:

- By design - retractable and rotary.

- By type of material - cast iron and stainless steel.

Each of them has its own nuances and areas of application. When choosing, you need to take into account the type of stove, heating unit or ventilation system in which it will be installed, as well as compliance with the dimensions of the smoke exhaust duct. Installation of the damper is possible in 3 options - directly above the chimney, “pipe to pipe”, in the ventilation. Installation is carried out in stages. In this case, you need to take into account the features and possible errors.

Ratings 0

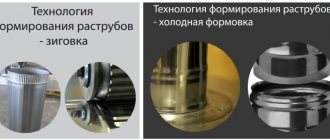

Rotary throttle

rotary butterfly valve

Rotary valves are not as widespread as the previous version. The operation is based on a rod, which is located in the center. A metal sheet is installed on it with rotation around its own axis. Due to this, the space is regulated and blocked if necessary.

This is a simple design that can be made on your own without any problems. But the moving part of the mechanism cannot boast of high reliability. Periodic replacement is required, which involves additional costs.

For installation, the socket and flange method is used. The differences lie in the fastening elements, which become relevant in each case.

Home manufacturing technology

Qualified specialists always emphasize that even a novice craftsman can make a rotary and retractable gate. After all, in order for the finished product to perfectly cope with its main task, you need to correctly take all the necessary measurements. If the finished damper fits tightly into the chimney, then over time it may jam, as it will be exposed to high temperature. And when there is a large gap between the valve and the pipe, it will be difficult to regulate the intensity of the draft during operation.

Multifunctional butterfly valve

To make this type of gate, you need to use a steel angle of 30x30 mm, as well as durable sheet steel, the thickness of which is at least 1.5 millimeters. The manufacturing process itself consists of several main stages, which must be implemented in strict sequence:

- Initially, you need to take measurements of the inside of the chimney. This is done in order to avoid mistakes during the manufacture of a frame from a corner, which is fixed with a welding machine.

- On one side of the frame, exactly in the center, you need to drill a small hole (7-8 mm in diameter). It will be useful for the rotary axis.

- A similar hole must be made on the other side of the frame.

- The plate for the damper must be cut from a steel sheet. This part must fully correspond to the internal dimensions of the manufactured frame.

- To make a guide axis, you need to take a piece of wire with a diameter of 9 mm and a length that will exceed the size of the frame itself by 7 cm. You need to cut a thread on one side of the wire (a die is best for this task).

- The finished axle is carefully threaded into the holes on the frame and secured with a nut.

- All cuts on the plate are processed with a grinding machine and inserted into the frame.

- At this stage, the master must weld the axle exactly in the center of the plate.

- All that remains is to make a comfortable handle for the guide from high-quality scrap materials.

Experts always use one piece of advice that prevents the rotary axle from loosening: you need to insert small bushings cut from an ordinary metal pipe into the holes.

Universal device

Modern gate valves include the valve itself, as well as a special guide frame. That is why, before starting work, the master must measure the internal cross-section of the pipe or brick chimney. In accordance with the available measurements, a neat rectangle is cut out of sheet steel (5 mm thick). A small longitudinal fold is made on one side, the width of which should not exceed 30 mm.

These manipulations are necessary so that the finished damper can be conveniently pulled out. Each cut must be polished, due to which the dimensions of the product are reduced by 2 mm on each side. Such actions by the technician will ensure free movement of the damper inside the chimney.

When the damper is made for a brick fireplace, the frame itself can be made of thick steel wire, the diameter of which is within 6 mm. During this procedure, the metal blank is simply bent into the shape of the letter P in strict accordance with the existing measurements.

If the chimney has a rectangular shape and is made of steel, then it is better to make the frame from a metal strip 2 mm thick and up to 35 mm wide. The prepared strip is bent lengthwise, leaving a neat gap along the thickness of the plate. Only after this can small cuts be made in two places at an angle of 45° to give the workpiece a U-shape. All gaps in the places of cuts must be butt welded.

To connect the ends of a homemade damper, you need to use two pieces of metal, which should be positioned in such a way that the damper blade can pass freely between them. At the end of all these manipulations, the master should come out with a rectangular frame with grooves for the shutter.

To make a valve in a round pipe, you need to take two identical metal sheets 2 mm thick. Round holes are cut in the center in accordance with the diameter of the chimney. The valve plate must be manufactured separately. After this, the sheets are connected to each other using a welding machine.

It is necessary to weld only three sides around the perimeter so that the holes of the finished valve on the pipe match exactly. A gap of 5 mm must be left between the top and bottom sheets. At this point, the damper manufacturing process can be considered complete, since the craftsman can only insert the valve and secure the finished product to the chimney.