Watching a burning fire is one of man’s favorite pastimes. However, in addition to purely aesthetic purposes, a burning fire can also perform a purely utilitarian task - to heat the surrounding space and other objects.

wood burning temperature

One of the most common sources of fire in country houses is ordinary firewood. Surprisingly, the burning temperature of firewood depends on the type of wood and the conditions under which it is burned. Accordingly, each of the tree species can be used for various purposes, to perform certain tasks.

Temperature threshold for combustion of wood of various species

Depending on the structure and density of wood, as well as the amount and characteristics of resins, the combustion temperature of firewood, its calorific value, and the properties of the flame depend.

If the wood is porous, it will burn very brightly and intensely, but it will not produce high combustion temperatures - the maximum value is 500 ℃. But denser wood, such as hornbeam, ash or beech, burns at a temperature of about 1000 ℃. The combustion temperature of birch (about 800 ℃), as well as oak and larch (900 ℃) is slightly lower. If we are talking about species such as spruce and pine, then they light up at approximately 620-630 ℃.

Larch

The tree is second only to oak in terms of its thermal characteristics. It’s easier to chop it, and it’s easier to light it, too. Refers to coniferous, resinous species. It does not grow in all forests, but in some places it is found quite often, and in some places it forms larch taiga.

- Fire power: 0.81de.

- Calorific value: 3062 kWh/m³.

- Combustion temperature: 865 °C.

- Burning time: long.

- Flame: smooth, has a noticeable blue tint, sparkles, and can periodically “shoot.” Smokes.

- Coals: have a long smoldering time and good heat.

- Difficulty of lighting: above average. It is somewhat easier to light larch than oak, but you still have to build a small fire before throwing the log into it.

Use of wood based on its heat capacity

When choosing a type of firewood, it is worth considering the ratio of cost and heat capacity of a particular wood. As practice shows, the best option can be considered birch firewood, which has the best balance of these indicators. If you purchase more expensive firewood, the costs will be less effective.

To heat a house with a solid fuel boiler, it is not recommended to use types of wood such as spruce, pine or fir. The fact is that in this case, the combustion temperature of the wood in the boiler will not be high enough, and a lot of soot will accumulate on the chimneys.

Firewood made from alder, aspen, linden and poplar also has low thermal efficiency due to its porous structure. In addition, sometimes during the burning process alder and some other types of firewood shoot out coals. In the case of an open furnace, such micro-explosions can lead to fires.

It is worth noting that no matter what the wood is, if it is damp, it burns worse than dry wood and does not burn completely, leaving a lot of ash.

How to simplify the choice of chimney

What is a chimney for fireplaces? This is a set of pipes, one end of which is connected to a heating device, and the other is brought outside. Its installation is a rather complex and labor-intensive process that requires certain knowledge and professionalism. Chimneys can be made of brick, stainless steel, ceramics. Each of these types has its own advantages, disadvantages, as well as installation features. Of course, in order to make the right choice, it is better to seek advice from professionals. However, in order to have some idea about the design of chimneys, we provide below a brief description of the most common types.

Heat transfer when burning wood in a stove

There is a direct relationship between the combustion temperature of wood in a stove and heat transfer - the hotter the flame, the more heat it releases into the room. The amount of thermal energy generated is influenced by various characteristics of the tree. Calculated values can be found in reference literature.

It is worth noting that all standard indicators were calculated under ideal conditions:

- the wood is well dried;

- the furnace firebox is closed;

- oxygen is supplied in clearly dosed portions to support the combustion process.

Naturally, it is impossible to create such conditions in a home oven, so less heat will be released than calculations show. Therefore, the standards will be useful only for determining the general dynamics and comparing characteristics.

Elm

Elm is often found in broad-leaved and mixed forests and can form quite large clusters. It is hard, does not chip easily, but in terms of its heat characteristics it is approximately the same as birch. Just like it, it can burn in its raw form.

- Fire power: 0.77de.

- Calorific value: 2912 kWh/m³.

- Combustion temperature: 864 °C.

- Burning time: long.

- Flame: even, smokes moderately.

- Coals: very reminiscent of birch coals - they smolder for a long time and fry well.

- Lighting difficulty: medium.

What is the combustion process

An isothermal reaction in which a certain amount of thermal energy is released is called combustion. This reaction goes through several successive stages.

In the first stage, the wood is heated by an external fire source to the ignition point. As it heats up to 120-150 ℃, the wood turns into coal, which is capable of self-ignition. Once the temperature reaches 250-350 ℃, flammable gases begin to be released - this process is called pyrolysis. At the same time, smoldering of the top layer of wood occurs, which is accompanied by white or brown smoke - these are mixed pyrolysis gases with water vapor.

At the second stage, as a result of heating, the pyrolysis gases ignite with a light yellow flame. It gradually spreads over the entire area of the wood, continuing to heat the wood.

The next stage is characterized by ignition of the wood. As a rule, for this it should warm up to 450-620 ℃. For wood to ignite, you need an external heat source that is intense enough to rapidly heat the wood and speed up the reaction.

In addition, the rate of firewood ignition is influenced by factors such as:

- craving;

- wood moisture;

- cross-section and shape of firewood, as well as their quantity in one stack;

- wood structure - loose firewood ignites faster than dense wood;

- placement of the tree relative to the air flow - horizontally or vertically.

Let's clarify some points. Since wet wood, when burning, first evaporates excess liquid, it ignites and burns much worse than dry wood. Shape also matters—ribbed and jagged logs ignite more easily and quickly than smooth, round ones.

The draft in the chimney must be sufficient to ensure the flow of oxygen and dissipate thermal energy inside the firebox to all objects located in it, but not to blow out the fire.

The fourth stage of the thermochemical reaction is a stable combustion process, which, after the outbreak of pyrolysis gases, covers all the fuel in the furnace. Combustion goes through two phases - smoldering and burning with flame.

During the smoldering process, the coal formed as a result of pyrolysis burns, while gases are released rather slowly and cannot ignite due to their low concentration. The condensation of gases as they cool produces white smoke. As wood smolders, fresh oxygen gradually penetrates, causing the reaction to further spread to the rest of the fuel. The flame occurs as a result of the combustion of pyrolysis gases, which move vertically towards the outlet.

As long as the required temperature is maintained inside the furnace, oxygen is supplied and there is unburnt fuel, the combustion process continues.

If such conditions are not maintained, then the thermochemical reaction enters the final stage - decay.

Rowan

It is often found in large quantities in forests, mainly in the form of low undergrowth, however, on the edges and clearings it can grow to significant sizes. It is often found along the banks of rivers, especially taiga ones.

Rowan wood is quite dense, comparable in weight to bird cherry. Nothing is known about the exact calorific characteristics of rowan wood. In our practice, we have repeatedly come across dry mountain ash, which burned approximately like alder, but it did not produce any special coals.

How to determine the combustion temperature in a wood-burning stove

Measuring the combustion temperature of wood in a fireplace can only be done with a pyrometer - no other measuring instruments are suitable for this.

If you do not have such a device, you can visually determine approximate indicators based on the color of the flame. Thus, a low temperature flame has a dark red color. A yellow light indicates that the temperature obtained by increasing the draft is too high, but in this case more heat is immediately evaporated through the chimney. For a stove or fireplace, the most suitable combustion temperature will be one at which the color of the flame will be yellow, such as, for example, dry birch firewood.

Modern stoves and solid fuel boilers, as well as closed fireplaces, are equipped with an air supply control system to adjust heat transfer and combustion intensity.

Video installation of a sandwich chimney with your own hands

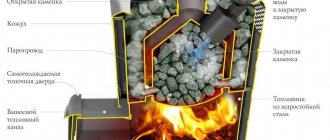

A feature of modern sauna stoves is their heating temperature, which can reach 400 degrees. An important indicator of the efficiency of the furnace is instant heating of the body and maximum heat transfer.

The entire heating process is accompanied by the release of infrared radiation, which is distributed on surfaces adjacent to the furnace. Under the influence of high temperatures, the wooden structure of the bathhouse can char or ignite.

This is why it is so important to ensure that wooden surfaces are reliably insulated from the heat of the stove. A protective screen and lining made of fire-resistant materials are suitable for this.

Heat output of wood

In addition to the value of calorific value, that is, the amount of thermal energy released during fuel combustion, there is also the concept of heat output. This is the maximum temperature in a wood-burning stove that the flame can reach when the wood is burning intensely. This indicator also completely depends on the characteristics of the wood.

In particular, if the wood has a loose and porous structure, it burns at fairly low temperatures, producing a light, high flame, and produces fairly little heat. But dense wood, although it flares up much worse, even with a weak and low flame gives a high temperature and a large amount of thermal energy.

Cedar

In mid-latitudes it is rather rare, but in more northern regions it grows everywhere. It has soft wood and cracks well. Cedar wood is good fuel for a fire.

- Fire power: 0.70de.

- Calorific value: 2645 kWh/m³.

- Combustion temperature: ~650 °C.

- Burning time: average.

- Flame: even, may spark. Smokes.

- Coals: quite hot, medium smoldering time.

- Lighting difficulty: easy.

Humidity and combustion intensity

If the wood was recently cut down, it contains from 45 to 65% moisture, depending on the time of year and the species. Such damp wood will have a low combustion temperature in the fireplace, since a large amount of energy will be spent on evaporation of water. Consequently, heat transfer from damp wood will be quite low.

There are several ways to achieve optimal temperature in the fireplace and release enough heat energy to warm up:

- Burn twice as much fuel at a time to heat your home or cook food. This approach is fraught with significant material costs and increased accumulation of soot and condensate on the walls of the chimney and in the passages.

- Raw logs are sawn, split into small logs and placed under a shed to dry. As a rule, in 1-1.5 years, firewood loses up to 20% of moisture.

- Firewood can be purchased already well dried. Although they are somewhat more expensive, their heat transfer is much greater.

It is worth noting that the wood of raw felled poplar and some other species is completely unsuitable for use as fuel. It is loose, contains a lot of water, so when burning it produces very little heat.

At the same time, raw birch firewood has a fairly high calorific value. In addition, raw logs made from hornbeam, ash and other dense wood species are suitable for use.

Weeds

Now is the time to consider alternative types of natural fuel that can be used to fuel a campfire.

Sometimes it happens that there is no dead wood near the camp, but conscience does not allow green trees to be cut (foresters do not allow them), or there is a decent distance to them. Then you have to get out with the help of herbaceous plants. As a rule, if the area is more or less wild and open, such large species of grass as:

- Sagebrush;

- Burdock;

- Thistles, thistles and others like them;

- Blooming Sally;

- Large umbelliferae: hemlock, kupir, angelica, hogweed (including the notorious giant one);

- Cane;

- Rogoz;

- Straw;

- Sunflower stems;

- Fire power: 0.1de.

- Calorific value: 378 kWh/m³.

- Combustion temperature: 800-900 °C.

- Burning time: very short.

- Flame: even, with a characteristic crackling sound. It smokes, the less dry the material, the stronger it is.

- Coals: does not actually form.

- Difficulty of lighting: extremely low, dry weeds are excellent kindling.

If the area is marshy or borders water, then the above list is supplemented by the following plants:

In rural areas, the following options are possible:

The best thing, of course, is thick, non-hollow stems (wormwood, burdock, sunflower). All this nonsense usually dries out in the fall, stands all winter, spring and the first third of summer, then - as the green herbs grow, most of last year's dry stems rot and fall off. However, you can collect a certain amount of such “wood” for a fire at any time of the year.

Dry weeds burn quickly and hotly; they actually do not form coals, because their density is very low. For a full-fledged night fire you will need ten cubic meters and a specially trained farmhand who will constantly throw this thing into the fire. It is also possible to use ingenuity: twist the grass into dense sheaves with twine. It will burn longer.

But in order to light a mini-bonfire, for example, for boiling water, weeds are quite suitable. The only thing you need is a few stones. So that you can lay out a small fireplace and not radiate heat into space in vain, thereby increasing the efficiency of the fire.

Next are the parameters of weeds as fire fuel (during the calculations, straw indicators were used as the initial parameters).

How does draft in a stove affect combustion?

If an insufficient amount of oxygen enters the furnace firebox, the intensity and temperature of wood combustion decreases, and at the same time its heat transfer decreases. Some people prefer to cover the ash in the stove to extend the burning time of one bookmark, but as a result, the fuel burns with lower efficiency.

If wood is burned in an open fireplace, then oxygen freely enters the firebox. In this case, the draft depends mainly on the characteristics of the chimney.

Under ideal conditions, the formula for a thermochemical reaction looks something like this:

C+2H2+2O2=CO2+2H2O+Q (thermal energy).

This means that when oxygen is available, hydrogen and carbon are burned, resulting in thermal energy, water vapor and carbon dioxide.

For the maximum combustion temperature of dry fuel, about 130% of the oxygen required for combustion must enter the furnace. When the inlet dampers are closed, an excess of carbon monoxide is produced due to a lack of oxygen. Such unburnt carbon evaporates into the chimney, however, the combustion temperature inside the firebox drops and the heat transfer of the fuel is reduced.

Modern solid fuel boilers are often equipped with special heat accumulators. These devices accumulate an excessive amount of thermal energy released during fuel combustion under conditions of good traction and high efficiency. This way you can save fuel.

In the case of wood-burning stoves, there are not many opportunities to save wood, since they immediately release heat into the air. The stove itself is capable of retaining only a small amount of heat, but an iron stove is not capable of this at all - excess heat from it immediately goes into the chimney.

Thus, by increasing the draft in the furnace, it is possible to achieve an increase in the intensity of fuel combustion and its heat transfer. However, in this case, heat loss increases significantly. If you ensure slow combustion of wood in the stove, then its heat transfer will be less, and the amount of carbon monoxide will be greater.

Please note that the efficiency of the heat generator directly affects the efficiency of wood burning. Thus, a solid fuel boiler boasts 80% efficiency, and a stove – only 40%, and its design and material matter.

Functions and features of operation of a chimney in a bathhouse

The main purpose of a chimney in a steam room is high-quality and controlled removal of combustion products in order to completely eliminate the accumulation of harmful carbon dioxide and the formation of burning on surfaces. The resulting draft (with air suction into the combustion chamber) maintains a stable operation of the heat generator. By manipulating the flows, the user regulates the heating value of the furnace and fuel consumption. You can heat such a sauna stove for as long as you like, and you can steam all this time.

Features of heat distribution with different methods of connecting the heater to the chimney

The stove in the bathhouse is heated inconsistently. Accordingly, the smoke channel cools down completely between sessions, so the chimney parts experience the strongest repeated thermodynamic loads. The second important factor is operating temperature. Unlike boilers and furnaces used for heating, gases heated to 700 degrees or more are removed here. Direct-flow stoves are often used in the bathhouse; due to the lack of heating shields or water jackets that remove some of the heat, the smoke turns out to be so hot. Therefore, the problem of chimney burnout (the danger of gas contamination and fire) always remains relevant. Chimneys for bathhouse stoves are made from high-quality materials. If these are factory products, they must be approved by the manufacturer for such difficult operating conditions.

A couple of phrases about calorific value

In terms of its chemical composition, wood is a rather complex material. It contains the main components - lignin and cellulose. But besides them, the tree contains:

- resins;

- proteins;

- tannins and other ingredients.

When logs burn in a stove (or simply when trees burn in a forest), these components interact with the air at a chemical level. The calorific value of wood (as well as any fuel), or thermal conductivity, is the amount of thermal energy that a unit of weight of the fuel material (in our case, 1 kg of wood) produces during combustion. Kilocalories are used to measure quantities.

The chemical composition among most tree varieties has minimal variations, which causes differences in the number of calories emitted. That is, the heat of combustion of some types of firewood can be as follows:

- for deciduous species the figure is 4460 kcal/kg;

- for coniferous species - 4560 kcal/kg;

- for mixed breeds – 4510 kcal/kg.

As you can see, the differences are minimal. At the same time, it is easy to understand that it is better to use coniferous wood for the stove due to its greater thermal conductivity. Only firewood is supplied to the market depending on volume, not weight. That is, the main criterion for choosing firewood is cubic meters. Density plays an important role here, because the higher it is, the heavier the wood.

For example, let’s take 1 cubic meter of birch logs as a starting point. Then the ratio of the volume of different rocks will look like this:

- oak logs - 0.75 cubic meters. m;

- alder logs - 1.1 cubic meters. m;

- pine logs - 1.2 cubic meters. m;

- spruce logs - 1.3 cubic meters. m;

- aspen logs - 1.5 cubic meters. m.

That is, 1 cubic meter of birch and 0.75 cubic meters. m of oak logs, 1.1 cubic meters. m of alder wood (and so on) will produce the same amount of heat. Knowing this, now, depending on how much firewood costs, you can get profitable savings for yourself.

Literature

- Gaydon A.

Spectroscopy and combustion theory. - M.: Foreign Literature Publishing House, 1950. - 308 p. - Khitrin L.N.

Physics of combustion and explosion. - M.: Moscow University Publishing House, 1957. - 452 p. - Shchelkin K. I., Troshin Y. K.

Gas dynamics of combustion. - M.: Publishing House of the USSR Academy of Sciences, 1963. - 254 p. - Lewis B., Elbe G.

Combustion, flame and explosions in gases. 2nd ed. Per. from English edited by K. I. Shchelkina and A. A. Borisova. - M.: Mir, 1968. - 592 p. - Pokhil P. F., Maltsev V. M., Zaitsev V. M.

Methods for studying combustion and detonation processes. - M.: Nauka, 1969. - 301 p. - Novozhilov B.V.

Unsteady combustion of solid rocket fuels. - M.: Nauka, 1973. - 176 p. - Lawton J., Weinberg F.

Electrical aspects of combustion. - M.: Energy, 1976. - 296 p. - Zeldovich Ya. B., Barenblatt G. I., Librovich V. B., Makhviladze G. M.

Mathematical theory of combustion and explosion. - M.: Nauka, 1980. - 479 p. - (English)

- (English)

- (English)

- (English)

- (English)

- (English)

Main settings

The main parameters showing the quality of wood are its combustion temperature and heat transfer. Both characteristics are closely related to each other, because the more intense the burning of wood in a stove, the higher the temperature, the more heat is released into the environment.

When faced with different types of wood, you will notice that some burn well and brightly, releasing noticeable heat, while others smolder sluggishly, and there is practically no heat from them. And the point here is not that some firewood can be damp, while others can be dry. This is explained by the difference between different types of wood in composition, density, structure, and, as a consequence, in combustion temperature and the amount of heat generated.

After much research, scientists were able to determine the heat output and combustion temperature of the main tree species under ideal conditions. Two factors were taken as ideal conditions:

- Almost complete absence of moisture in the wood.

- Combustion in a confined space, provided that there is only enough oxygen in it to carry out the reaction.

Some of the most valuable wood species with excellent heat transfer characteristics are oak, beech, hornbeam and larch. However, firewood from these trees is rare and costs a lot of money, so shavings, sawdust, branches and other waste from industrial production and logging are usually used as fuel.

At the same time, in order to have a complete picture of the thermal characteristics of wood, it is advisable to study the specific heat of combustion of each type of wood, as well as to have an idea of their heat transfer. Heat transfer can be measured in various quantities related to the weight and volume of the fuel.

Good to know: Fuel briquettes of the RUF brand, main characteristics

When studying the thermal characteristics of different tree species, it is worth noting that oak and birch emit much more heat when burned than, for example, alder, aspen or pine. At the same time, you should not completely rely on tabular data, because in real life it is not possible to achieve ideal conditions, so the temperature in the firebox of a wood-burning stove can be significantly lower when burning similar firewood.

The values given in various tables are ideal and are intended to show the overall picture, while the real temperature in the furnace firebox will never reach such values, and this is explained by two simple and understandable factors:

- It is impossible to achieve the maximum temperature primarily due to the fact that it is not possible to completely dry the firewood at home. For lighting fireplaces and stoves, wood with different levels of humidity is used, the one that is available.

- Another important factor that reduces the combustion temperature of wood in a fireplace or stove is the lack of oxygen. We regulate the air flow with a damper, which we often cover.

Let's look at each of the identified problems separately.

Fire safety when working with wood

Natural material easily catches fire. Any careless act can lead to an unpleasant or dangerous situation. Wood has different combustion temperatures. It depends on the breed. But they are not too big.

To maintain safety, you must do the following:

- use wet plaster;

- use fire retardant pastes;

- do cladding;

- use varnishes, enamels;

- apply fire retardant.

This will help protect yourself when working with wood.

Which wood burns better and which burns worse?

Dry wood burns best. Wood soaked in moisture also burns, but it takes considerable temperature and some time to remove and evaporate the moisture. This process is in most cases accompanied by a distinctive hissing sound. Not everyone knows that when “damp” wood burns, vinegar acid is released. This fact shows up very poorly on furnace equipment and on the overall combustion efficiency. It is highly recommended to use dry firewood, and also buy firewood in the spring so that it has time to dry before the cold weather arrives.

Dung

Dried (to the point of complete dehydration) cattle manure can also help a tourist out of woodlessness. Cow patties burn very well and take a long time, and they produce quite a bit of heat.

Unfortunately, it was not possible to find the exact parameters of dung as a fuel either in the literature or on the Internet, despite the fact that in many rural areas and agricultural countries it is a traditional method of heating. But they say that in terms of its characteristics, dung roughly corresponds to peat.

Schematic diagram

Boilers BKZ 160 are vertical water tube devices. Water circulation is natural. A drum is installed at the top of the structure, where the flows of water and steam are connected. The steam separation process takes place in remote cyclones. The units operate either with a vacuum in the firebox or under pressure.

The layout of the units is P/T-shaped or tower. The structure can use supports or be suspended. The U-shaped layout takes up much less space, while the draft devices are located at the zero level. Boilers are designed for different types of fuel, and calculations are carried out individually for the area where the boiler is located, taking into account local fuel resources.

Schematic diagram of the operation of single-drum boilers BKZ 160:

- The fuel is fed into a vertical firebox, closed on all sides by screens, the top and bottom of which are connected by pipe manifolds.

- On the front wall of the combustion chamber, burners are located on 2 tiers in the amount of 2 to 8 units, depending on the performance of the boiler.

- In screens heated by flue gases, boiler water is heated to form a steam-water mixture.

- The steam-water mixture, due to natural circulation, moves to the upper collector devices.

- Next, the steam-water mixture enters the drum and is sent through remote separators to the steam collector.

- Feed water heated in the economizer with high pressure is sent by pumps to the upper drum to replenish the volume of water that was removed from the water path by extracting superheated steam.

- Through lower cooler pipes, boiler water is lowered from the drum into the lower manifold system of the screen manifold to repeat the heating cycle.

- Steam, cleared of moisture in separators from the boiler drum, is sent to steam superheaters, of which several are installed: radiation and convection.

- After the superheaters, the steam goes for industrial extraction to a steam turbine or for technological processes.

- The boiler is equipped with a recuperative type air heater, where, due to the temperature of the flue gases, the air is heated for supply to the burner device. Usually a two-stage air heating system is installed, with temperatures up to 200 C.

- The smoke exhauster maintains a vacuum in the firebox of minus 2 mm. V. Art.

- After combustion, the flue gases are directed into the inter-tube space of the superheaters with a temperature of 1180 C, and then into the economizer with a temperature of 250 C and the air heating system with a temperature of 130 C. After which the smoke exhauster discharges the exhaust gases into the chimney.

conclusions

From all of the above, the following conclusions can be drawn: