Have a nice day!

If your home is not connected to a central heating system, you will have to install an individual heat-generating device. Whatever it is: a boiler, stove, fireplace or a complex consisting of several devices at once, you will have to think through the concept of removing fuel combustion products. And in this article we will tell you how to build a chimney from a steel pipe with your own hands.

Types and designs

Chimneys are made from the following types of steel:

- Alloyed (with and without enamel coating).

- Mirror stainless steel.

- Galvanized.

Steel chimneys come in 2 models:

- Single-walled (single-pipe).

Simple rigid or flexible corrugated pipes and shaped elements for them with a thickness of one wall (0.5 - 1.5 mm) can withstand heating up to 1100⁰C. Mainly used as liners in brick chimney shafts. They can also act as an independent structural element, but in this case it will be necessary to carry out additional work on their thermal insulation and insulation.

- Double-walled (two-pipe).

So-called sandwich or coaxial chimneys consist of two pipes of different diameters and, as a rule, different levels of heat resistance, inserted into one another. The space between them is filled with fire-resistant insulating material (most often basalt mineral wool), which performs several functions:

- Insulation of the pipeline when it is placed outdoors.

- Prevents condensation.

- Ensuring a normal level of traction.

They are distinguished by a longer period of operation, as well as originality and aesthetics, which eliminates the need to cover them with a decorative casing.

Chimneys also differ according to the type of structural solution:

- The location of the chimney circuit is inside or outside the room.

Placing a chimney in a house is a more labor-intensive process, which involves laying it through the ceilings and exiting through the roof. In many ways, this concept is justified by the high heat saving coefficient and the ability to arrange the simplest and most efficient straight, strictly vertical configuration. However, this method is the most fire hazardous; in addition, the pipe eats up useful space in the rooms through which it passes.

Exiting the pipe to the street through a hole in the wall of the house and attaching it to the facade using brackets significantly reduces the fire hazard index. However, in this case, additional work will be required to insulate the circuit, and in areas with severe frosts, it becomes necessary to construct an external brick shaft as a complementary insulating casing.

- According to the angle of inclination of the contour into: upright (strictly vertical), inclined and containing horizontal sections.

The first option is considered the most effective. Slopes and horizontal planes impair traction in the circuit, so their installation must be carried out in strict accordance with building regulations.

- The shape of chimneys can be round, oval, square and rectangular.

The best is considered to be a round cross-section, which has excellent aerodynamic characteristics. Square and rectangular formats help reduce the speed of movement of the air mass inside the contour due to the formation of turbulence in the corners. In addition, it is in the corners that more soot is deposited.

Single wall pipes

This product option is traditional. In terms of price, single-wall stainless steel pipes will cost more than corrugated pipes. However, they are characterized by a longer service life. In addition, there are oval flue ducts and fittings for them. They greatly facilitate the installation of ducts in difficult areas and improve the aerodynamic properties of chimneys.

It has been proven that oval pipes are much more efficient than round ones. It takes up less space with a larger cross-sectional area. This not only simplifies installation, but improves the appearance of the structure. However, if you connect a single-wall structure to a boiler with an efficiency of more than 90%, it can quickly deteriorate. We are talking about pellet, gas and diesel units. They need to select products with good thermal insulation.

The fact is that the temperature of the exhaust gases of the considered units is low. This leads to condensation. Because of it, black streaks appear on the outer part of the channels. These designs are ideal for arranging chimneys in bathhouses since the efficiency of the boilers used in them does not exceed sixty percent.

Single-wall stainless steel pipes can also be used when installing solid fuel units. But in this case it is necessary to use thermal insulation. Otherwise, condensation cannot be avoided.

Advantages and disadvantages

Steel chimneys have many advantages:

- The smoothness of the inner walls minimizes soot settling.

- High strength characteristics and durability.

- Low weight of the structure and, as a result, no need to install a separate foundation platform.

- Aesthetics and the ability to implement any configuration solutions.

- Ease of installation and the ability to carry out installation work without the involvement of highly specialized professionals (assembly occurs according to the principle of a designer).

- Maintainability, ease of maintenance and care.

- Lowest price compared to chimneys made from other materials.

Of course, iron structures also have some disadvantages:

- Metal is prone to corrosion, so the formation of condensation in the circuit can shorten its service life.

- Long-term exposure to too high temperatures can lead to melting and burning of the pipe.

Features of operation

Metal chimneys, having a lot of undoubted advantages, require increased attention both during assembly and during operation:

- They should not be located near other utilities, such as electrical wiring or plumbing.

- Before starting installation work, the internal longitudinal seams of the pipes must be coated with a special sealant, since they are subject to temperature changes, which gradually weakens the joining edges.

- When cleaning stainless steel pipes, it is better not to use traditional metal balls with a wire “hedgehog”. Their influence deteriorates the mirror inner surface, making it difficult to drain condensate into the storage tanks. It is better to choose a brush made of synthetic materials.

Mechanical cleaning method is the most effective

Service life of a steel chimney

On average, the service life of steel smoke exhaust ducts is about 50 years. However, it should be noted that the characteristics of steel also determine the service life of the chimney:

- Galvanization is less resistant to corrosion. The formation of condensate inside a galvanized chimney inevitably reduces its “life” to 10-20 years.

- Stainless steel and especially durable alloy steel can last more than 100 years.

In addition, it is clear that the thicker the metal sheet, the longer the period of its operation.

Make it yourself or order it

It must be remembered that mistakes made during the installation process can result in the most unfavorable consequences - carbon monoxide poisoning and even fire. It is best to seek help from professionals, giving preference only to trusted companies.

However, one of the key advantages of steel chimney circuits is the ability to install it yourself. Moreover, even the pipes themselves can be made independently, which will significantly save the construction budget and select the most optimal diameter for the main line. If you have sufficient engineering and construction knowledge and skills and are ready to take responsibility for the functioning of the chimney, you can begin to independently implement the project.

Tips for choosing

When choosing a chimney duct, be guided by:

- The power of the heat generating device.

- The fuel on which it will run.

- The combustion temperature of the fuel and, accordingly, the flue gases.

- Pressure in the circuit.

- Type of firebox (with an open firebox, the heating temperature of the gases increases by 1.5 times).

- Heating mode (intensive operation of the heat generator can bring the temperature of the flue gases at the entrance to the circuit to 1000⁰C).

- The location of the chimney (inside or outside the building).

Which steel is better for a chimney?

Steel for chimney circuits must meet a number of requirements. It must be resistant to:

- High temperatures.

- Soot combustion.

- Moisture causing metal corrosion.

- Aggressive substances (acids and alkalis) formed in the pipe as a result of the chemical reaction of condensate and fuel combustion products.

Alloy steel, which contains chemical elements (chrome, copper, nickel, etc.) that improve the metal’s resistance to corrosion and destruction, has the best strength indicators.

Stainless steel is almost as strong as alloy steel, but is cheaper, so it is in greatest demand. Galvanization has an even lower cost, however, it is characterized by insufficient anti-corrosion resistance and requires careful insulation to prevent the occurrence of a sharp difference in temperature conditions, which causes the formation of condensation. In addition, galvanized steel is not heat-resistant enough, so it is used only in conjunction with gas equipment.

When choosing steel, you should be guided by the heat resistance coefficients of the material, which are set for each type of heat generator and type of fuel separately, depending on the efficiency. It can vary significantly between different brands of the same metal:

| Comparative characteristics of AISI stainless steel | |||||

| Brand | AISI 439 | AISI 304 | AISI 316 | AISI 310 | AISI 321 |

| Corrosion resistance | good | high | high | high | high |

| Working temperature | up to 600º C | up to 300º C | up to 450º C | up to 1000º C | up to 800º C |

| Gas | + | + | + | + | + |

| Wood | + | — | — | + | + |

| Coal | — | — | — | + | — |

| Liquid fuel | — | — | + | — | — |

| Peat briquettes | — | — | — | + | — |

Conclusion

The use of steel chimneys for a stove, with proper calculation and installation, will ensure efficient operation for the entire period of operation of any heating device. Good technical characteristics and high safety of this type of chimney will make you feel comfortable and safe in your home.

They have a fairly affordable price, which is very pleasing. Today, they occupy one of the first places in application in construction. The main thing when purchasing is to make sure of the quality and reliability of the purchased chimney elements. Savings must be balanced and justified, because safety and health depend on it.

Building regulations

Work on the arrangement of smoke channels must be carried out in accordance with the requirements of SNiP 2.04.05. If we are talking about gas equipment, you will have to familiarize yourself with the provisions of SNiP II-35.

Let us outline the main requirements:

- One heat generator - one chimney. Those. For each heating device (stove, fireplace, boiler) a separate smoke exhaust line must be installed.

- It is not allowed to lay a smoke exhaust duct near other utilities: electricity, water supply and gas pipelines. The distance between them must be at least 1.2 m.

- Absolute tightness of the circuit. This will not only eliminate the possibility of leakage of toxic carbon monoxide, but will also prevent the flame from escaping beyond the mine if soot accidentally ignites.

- Maximum verticality. A single slope of 30⁰ or 45⁰ is allowed with subsequent alignment of the smoke exhaust channel. If there is a need to lay a horizontal section, then its length should not exceed 1 meter.

- Mandatory installation of at least one inspection hatch.

- Thermal insulation of the channel must prevent the formation of a “dew point” (condensation) inside the pipeline.

- The height of the chimney contour is at least 5 meters, while the level of elevation of the pipe above the roof depends on the shape of the roof and the distance from the canopy.

- When venting a chimney through a façade wall, to determine its height, wind pressure zones formed by the environment (buildings, trees, terrain) should be taken into account.

Fire safety requirements for chimneys

All work must be carried out with the utmost care to ensure absolute safety of the circuit. Forbidden:

- Place connecting seams where the contour passes through the ceilings, walls and roof.

- Lay horizontal sections in the attic and arrange inspection and cleaning openings.

- Bring the chimney duct closer to building structures at a distance closer than 38 cm for wooden buildings and

Following fire safety requirements will make the chimney and your home absolutely reliable:

- When leading a pipe through a wall, a hole is cut with a minimum margin of 45 cm on each side. This hole is lined with an iron box or sandwich ring and filled with expanded clay or asbestos, and then closed with a lid made of fireproof material. This design helps prevent the wall from overheating.

- When the chimney is exhausted through the roof, a protective layer of galvanized steel and insulation is laid.

- When the chimney pipe passes close to the wall, the latter is finished with heat- and fire-resistant materials.

- The chimney should be equipped with a deflector with a fine-mesh spark arrester on top.

Traction force

The draft ensures the removal of combustion products through the chimney shaft to the outside. It is extremely important that this process be as natural as possible, which is facilitated by the correct geometry (configuration, diameter and height) and tightness of the entire smoke removal complex, as well as ensuring the flow of fresh air from the outside.

The first signals of problems with draft are difficulties with kindling, unstable behavior of the flame, its blowing out or smoke in the room. If the traction force is not working, operating the device is not safe and can lead to carbon monoxide poisoning.

The presented diagram illustrates the process of checking the draft force in a chimney:

The functioning of the draft is also influenced by weather conditions, the impact of which can be minimized by installing equipment for forced draft and a deflector at the pipe head.

Preparatory work

Diagram of an internal and external chimney made of steel pipe

Preparatory work before installing a chimney made of a metal or sandwich pipe includes: drawing up a diagram of the exhaust structure, calculating the number of elements to be connected, calculating the connection points and connections to the floors. After these conditions are met, you can proceed to the purchase of material and installation of the structure.

During the preparation process, the following conditions should be taken into account:

- The prefabricated chimney inside the room must go vertically upward. An angle of no more than 45º is allowed. When diverting horizontally, the maximum length of the pipe is no more than one meter.

- The length of the element coming from the outlet pipe of the furnace or boiler should be no more than one meter. For brick stoves, a single-walled metal pipe with a water heating tank is used as a connecting element.

- It is not allowed to join individual parts of a sandwich chimney in the area of the interfloor and attic floors, as well as in the roof structure.

- The places where the pipe passes through the interfloor and attic floors are additionally protected by a metal box or a special sandwich ring. The distance from the outer surface of the pipe to the walls of the box is at least 15–17 cm. If there is no cutting, the distance is increased to 50 cm.

- Cleanouts and ventilation holes should be located in the lower part of the chimney (from the stove pipe to the ceiling of the steam room). When exiting the interfloor ceiling, the chimney is directed vertically upward. It is permissible to install a drain if the pipe hits a load-bearing beam or other roof element.

- For roofing made of flammable materials (roofing felt, isospan, stekloizol), a deflector with a fine-mesh spark arrester is installed at the end of the smoke duct.

For preventive purposes, the chimney should be inspected once every six months. If heating equipment is used frequently, the chimney should be cleaned at least once a quarter.

Making and installing a chimney with your own hands

As we have already said, existing technologies allow you not only to install a chimney yourself, but also to make chimney pipes with your own hands. For this you will need:

- Metal suitable for the purpose.

- Metal scissors.

- Wooden or rubber mallet.

- Iron corner.

- Long strong ruler.

- “Cannon” is a machine that bends a sheet into a circle.

Stages of work:

- The metal sheet is marked and cut into strips of the required length and width.

- Then, using a mallet and an iron corner, the edges of the workpieces are bent in directions opposite to each other, first at a right angle (90⁰), then the bend angle is smoothly adjusted to 135-145⁰. Bend width – 0.7 mm.

- The workpiece is placed on the machine and, tapping with a rubber mallet, it is given the desired shape.

- The edges of the workpiece are interlocked. Place the workpiece on the machine again and flatten the seam joint with a mallet. For greater strength, the seams should be welded.

- To manufacture rotary elements, finished pipes are cut and welded at the desired angle (at least 90⁰):

- To obtain a 90⁰ turn, the pipes are cut at an angle of 45⁰.

- For a bend of 120⁰, the cut is made at an angle of 60⁰.

- For a 150⁰ turn, the pipes are cut at an angle of 75⁰.

Important. When installing, homemade pipes require mandatory insulation.

Drawing and diagrams

Before installation, it is necessary to prepare a design and diagram of the future chimney, which will help determine the required amount of material, and calculate in advance the length of the chimney as a whole and individual sections in particular.

Size calculation

- Determination of the cross-section and height of the chimney.

A pipe that is too thin will not be able to provide the required traction force, and in some cases may cause reverse draft and carbon monoxide emissions back into the room. An excessively large shaft diameter, on the contrary, leads to unreasonably high traction force, excessive fuel consumption and pointless energy losses.

The calculation is based on the power of the energy carrier. See the table:

The instructions for power plants indicate the diameter of the outlet pipe, which is taken as a basis in the first section of the circuit. Then the cross section can be changed depending on the calculated data.

Important: the more bends in the circuit, the larger the diameter of the smoke circuit.

- Determination of wall thickness:

- For gas equipment, the steel thickness is at least 0.5-0.6 mm.

- For liquid fuel installations - at least 0.8 mm.

- For solid fuel units – 1-1.5 mm.

Installation video

Watch the video in which an experienced stove maker will share his secrets with you.

https://www.youtube.com/watch?v=L4j8Bi2Ns68

Installation features

Installation of a metal chimney begins only after installation and careful fixation of the heating device. Assembly starts from the bottom, so first the element extending from the heat generator pipe is installed. Then a tee is fixed, the lower part of which acts as an inspection section and condensate drainage.

All seams are carefully treated with heat-resistant sealant, fastened with rivets and clamps, and then wrapped with aluminum tape. When joining sandwich pipes, to prevent condensation from entering the insulation, first the internal circuit is connected (the top is inserted into the bottom), then the external one. The depth of insertion of one pipe into another must be at least half the cross-section of the pipe itself.

The pipeline is fixed to the supporting elements of the house by installing brackets every 1.2 meters, a support platform, and clamps. In this case, the weight of the structure must be evenly distributed over all fastening elements. When the chimney pipe is raised above the roof by more than 1.5 meters, it must be secured with braces.

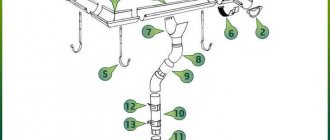

To ensure the optimal geometry of the steel chimney circuit and its maximum functionality, a variety of shaped elements are used:

- Turns.

- Adapters designed to change from one diameter (shape) to another.

- Tees and crosses that branch the circuit in different directions.

- Couplings (nipples) connecting individual sections of pipes to each other.

- Pass-through pipes and sleeves.

- Plugs, inspection modules, umbrellas, deflectors, aprons, caps, spark arresters, etc.

When a steel chimney is led out through the roof from the outside, the hole must be additionally sealed (closed) with a special sealing plug made of fire-resistant rubber or silicone.

At the end of the installation work, a test run is carried out, which allows you to check the tightness of the circuit and identify areas subject to excessive heating. Detected flaws are eliminated.

By the way, during the first start-up, an unpleasant burning smell may appear, which is a consequence of oil burning out from the surface of new pipes and crystallization of the sealant. There is no need to worry about this.

Corrugated pipes

A corrugated tube is a kind of “spring” made of iron wire, which is wrapped in foil. Moreover, the last element is attached to the main structure using a special technology. The corrugation wall is quite thin.

This gives pipelines from it the following features:

- cheapness;

- flexibility;

- low installation cost;

- Possibility of installation outside buildings;

- ability to stretch and compress;

- the possibility of refurbishment of old brick gas ducts.

This type of steel pipes also has its disadvantages. Due to the too thin wall thickness (up to 0.1 mm), the corrugation has a short service life. On average, products of this type can be used for ten years. Therefore, it is permissible to install them inside structures only in a fireproof shell. It is imperative to ensure that such pipes can be replaced.

The flexible stainless steel channel has high aerodynamic resistance. Therefore, the draft force in such chimneys is lower than in smooth-walled analogues. It is possible to create a gas duct from this material only for arranging old brick channels. It should be remembered that installation of this structure will reduce the flow area of a rectangular pipeline by approximately twenty-five percent.

It makes sense to use corrugated pipes only for arranging small sections of chimneys. For example, to connect a boiler to a flue shaft. In this case, you should abandon the use of corrugations for working with solid fuel units. Since the wall thickness of such products is small.

Frequent errors and problems during installation

Numerous errors lead to inefficiency of both the chimney duct and the heating system as a whole. However, sometimes one miscalculation is enough for the problem to become fatal without proper attention: lack of proper traction force, reverse draft effect, smoke and carbon monoxide poisoning, and sometimes fire.

- Incorrect contour structure (exceeding the permissible slope values, horizontal passages, insufficient height, too large or small cross-section).

- Pinching of a steel pipe, leading to its deformation due to the properties of the metal to expand when heated. To prevent such situations, it is necessary to provide a small gap of 1-1.5 cm when fixing the lower part (the most heated during operation) or use special flexible clamps.

- Unsuitable steel type.

- Replacement of expanded clay block in the passage unit of floors and walls with basalt insulation.

Maintenance and cleaning

Inspection and cleaning of the chimney must be performed at least 2 times a year: before the start of the heating season and at its end. An external inspection is carried out, the tightness of the housing and the quality of the traction force are checked. Metal exposed to corrosion must be systematically painted with heat-resistant paint.

So the fuel, as a rule, does not burn completely, its residues in the form of soot and soot settle on the walls of the pipes, clogging them, reducing draft and increasing the risk of fire. You can even understand the degree of contamination of the mine visually, paying attention to the color of the smoke from the chimney: white indicates that everything is normal, black indicates the smoldering of soot residues in the circuit.

For cleaning, special brushes on rigid or flexible cables are used, sometimes with a steel ball at the end.

Before cleaning, stove makers recommend burning potato peelings in the firebox. The released vapors and potato starch soften soot deposits, thereby facilitating subsequent cleaning. Aspen firewood or special chemical compounds are often used for the same purpose.

How to do the calculations

The diameter, height and wall thickness of the pipe during construction must be determined accurately. It is important not to make any mistakes. After all, the diameter of the chimney must be sufficient to exhaust the processed gas. And at the same time, the thrust should not be very large.

If this is a pipe for a boiler, the primary source when choosing is the instructions from the manufacturers. Provided that this data is not in the passport, then calculations are made taking into account the volume and height of the firebox.

The height of iron pipes is a little more difficult. The greater the height of such a pipe, the greater the thrust. And how much the pipe needs to be extended is a difficult question. When determining the distance from the stove to the tip, specially developed formulas and programs are used.

But one condition for such calculations remains the same - the chimney must be at least 50 cm higher from the roof peak, and in vertical sections its height can be at least five meters.

Video on how to calculate height

How to calculate the height of the chimney!

The wall thickness of the pipes used should be from three to five millimeters. At the exit from the stove, at least 5 or more millimeters. In the upper sections it is allowed to use a pipe of three millimeters or more.

Expert advice

- Give preference to vertical structures. Minimize the number of turns that reduce the aerodynamics of the contour.

- Choose pipes with a thicker wall, they will extend the “life” of your chimney.

- The first sections of pipes are subject to the greatest heating, which often damages the thermal insulation layer. In some cases, it is advisable to replace this area with a tank for heating water or a heater grid.

- To improve aerodynamic characteristics, every 10 meters the diameter of the pipe is reduced by 3 times.

- At the junctions of sandwich blocks, the insulation does not fit tightly enough, which leads to overheating of the circuit in these areas. The problem can be solved by installing an additional layer of insulation in these places yourself.

How to insulate

A rapidly cooling chimney causes a decrease in draft force and the formation of condensation, which leads to corrosion and gradual destruction of the pipe. The insulation works on the principle of a thermos.

And if coaxial chimneys are immediately made with insulation inside, then single-wall chimneys will have to be insulated yourself. Most often, fire-resistant basalt wool or fabric is used for this, which is wrapped around the pipe in 2-3 layers and secured with iron clamps or steel wire. Waterproofing is laid between layers of wool. The structure is topped with a stainless steel or galvanized box.