A bathhouse, first of all, is water, without which you cannot wash and which after washing must be somehow disposed of, drained, without flooding the entire surrounding area. This means that we need an effective drainage system, a drain for the bathhouse, which on a “bath day” will allow it to function for at least half a day and provide washing for even a large family.

View this publication on Instagram

Publication from Wooden houses and baths from KELO (@artkelo)

What type of sewage system to choose for a bathhouse

In private buildings and country cottages, central drainage in the form of a centralized sewer network is not often found. Perhaps in cottage villages, with development according to some kind of pre-approved (general) plan. Basically, all types of drainage of water used in the household are limited to a septic tank (factory-made or home-made), a more open version of it - a drain well or even a pit where the water goes thanks to loose soil - the latter option assumes a very low groundwater level and soft, almost frost-free water. , winter.

Criteria for choosing a sewer system

When choosing the optimal sewage system for a bathhouse for a particular area, we are guided by the following points:

- the absorbency of the soil in the area where the bathhouse is being built, the tendency for this soil to swell, the characteristics of its flowability;

- how far is the natural water intake located and how deep does the groundwater lie;

- intensity of use of the bathhouse and the associated possible volume of drainage;

- the difference in the height difference between the location of the bathhouse and the point of discharge into the well;

- budget.

Arrangement of a drain well or reservoir

To properly arrange a drain well, its location and operating principle must be figured out already at the bathhouse design stage. The main task in such a design is to correlate the location of the steam room and washing compartment with the well itself and with the slope of the drainage pipe through which the used water will drain.

For families who use the bathhouse only on weekends and in which the number of family members is 3-4 people, and the volume of the drainage pit may be small. So that the drain water had to be pumped out every 4-6 months. And taking into account the fact that during the washing process, detergents that are aggressive to the environment are used (no matter how they are positioned in advertising regarding safety), drainage wells for bathhouses must be as airtight as possible in the sense of the penetration of used water into the soil surrounding the well.

To do this, the walls of such tanks are concreted or waterproofed from the ground in some other way.

Drain well

Drain wells are considered to be reservoirs (pits) completely isolated from the environment. That is, the used water does not go anywhere, settles with solid fractions settling to the bottom, and only after some time is removed (pumped) out of the well.

They are made by digging a hole with earth-moving equipment; waterproofing is ensured by lowering concrete ends into the hole with a sealed bottom on the bottom and sealing the joints between the rings.

Drainage well

A drain option, but without a sealed bottom. Instead, a sand cushion is made at the lowest level, on top of which fine gravel is poured. It is installed in soils that do not have loamy and clay layers, which allows wastewater to undergo deep filtration. If there are such layers, then the drainage well on them serves as a storage well.

Such wells are constructed after assessing the absorption properties of the soil and its throughput per unit of time. the assessment is made after test drilling on the site selected for construction.

Pit under the steam room

If the bathhouse will be used exclusively in the summer (or during the period when the air temperature is in the range of +4⁰С and above), a simple pit located directly under the floor of the steam room can serve as a storage and disposal tank for drain water under the steam room.

Absorption pit

It is a hole dug in the ground in advance, even before the construction of the bathhouse, filled with at least 60% filter material (sand, crushed stone, ceramic or brick chips). Used only for columnar foundations. In winter, in the middle zone and to the north, operation is impossible - the pit freezes and will not absorb and filter drain water. Frequent use of a bathhouse with a steam room, in which such a pit serves as a container for draining water, is also not allowed, since it will not have time to absorb water.

Autonomous sewerage system with settling well

If it is impossible to connect the bathhouse to a centralized sewer system, the best and environmentally friendly option would be to create settling wells - single- or double-circuit.

In the first case, the inlet pipe-tee is located above the same drain (outlet) pipe-tee. In a double-circuit settling well, which ensures even greater purity of settled water, a bypass hole is made between the second and first chambers. Water purification occurs under the influence of gravity, due to which suspension and solid particles of dirty water gradually sink to the bottom and form sludge. And already in it, under the influence of anaerobic bacteria, the decomposition of harmful components into simple non-toxic compounds occurs, which are cleaned from the bottom of such wells at a certain frequency.

Video description

Characteristics

There are many options for round baths, each of which has its own characteristics, ranging from size to internal arrangement. Thus, after going through all the possible options, you can choose your “ideal” barrel sauna.

Dimensions

The smallest bathhouse, located horizontally, is 2 meters long. Its design implies the presence of 1-2 rooms. You can undress here at the entrance if the bathhouse has a porch with a canopy. The weight of such a building is about 1.5 tons.

The largest barrels reach a little over 6 meters. There can already be up to 3 rooms: a dressing room (with a well-thought-out resting place, a table, clothes hangers, benches), a wash room (with a shower or water containers), a steam room (with comfortable benches and loungers); or in the case of a sauna, the washing room can become a relaxation room. On average, the length of each room will be 1-2 meters.

Classic round baths can be of the following sizes - up to 2, 3, 4, 5, 6 meters in length, about 2 meters in diameter (1.95 m is the internal diameter). Quad and oval baths may have slightly different parameters: 4x4, 3x6. Almost any bathhouse can accommodate comfortable sun loungers with a width of 500 mm.

In two-meter baths there is only one room. In the three- to four-meter ones there are already two – a small locker room and a steam room. The largest ones have space for three rooms.

The classic shape of a barrel bath is a circle, or rather a cylinder, located horizontally.

Less common are oval, square or rectangle shapes with rounded corners. In addition, there are options for baths with a semicircular top and rectangular bottom.

The entrance to both oval and quad baths can be from the front or the side. The entrance can be framed by a canopy or equipped with a gazebo. And the barrel sauna can be additionally enclosed in the frame of a gable roof.

Double-rounded baths have a rectangular outline. Vertical barrel baths are most often round-shaped buildings, less often oval or rectangular with rounded corners.

Materials

The main performance characteristics of a bathhouse depend on the materials from which it is made. The bathhouse is built from wood, or rather, specially processed profiled timber with a moongroove or tongue-and-groove fastening. The following types of wood are usually used for construction:

- Oak is a very high-quality material that becomes even stronger when exposed to water. It has excellent properties and can serve for many years. It has a beautiful structure, but is very expensive.

- Linden is an excellent material for a bathhouse. Known for its medicinal properties. Unfortunately, poorly treated wood of this species is easily susceptible to rotting and other negative effects.

- Aspen is an analogue of linden. With its help you can also create a favorable microclimate. But unlike linden, it is more resistant to harmful effects.

- Larch is a material that does not rot, and therefore will last a very long time. True, the price for round timber of this breed is quite high.

- Cedar is the only conifer that is highly recommended as a building material. It can also be used to create a healing microclimate. It has a beautiful unique structure. It has one drawback - it is quite expensive.

- Spruce, pine and other conifers are not recommended as building materials for baths. This is due to the fact that when exposed to high temperatures, wood is capable of releasing resins, which can cause burns. However, this effect only occurs from temperatures exceeding 100 degrees. Moreover, if such wood has undergone good chamber drying, then this process is minimal.

- Alder and birch are not suitable for building a barrel sauna, as they get very hot.

In addition to wooden elements, you will need ties, which are made from iron tape (strip), or steel hoops. Of course, metal corners, screws and other fasteners will be needed.

Wastewater disposal method

Let's look at specific cases of wastewater disposal methods depending on the type of soil under the bathhouse, how high the groundwater level is, and how the water used for cleaning is removed.

Pit under the bathhouse

The simplest and most cost-effective option for draining the water used in the bathhouse during washing. It does not involve the creation of complex engineering structures and expensive materials. It is a rectangular or circular hole dug in advance, even before the construction of the bathhouse, directly under the washing compartment and/or steam room. At the bottom of which chalk filter material (sand) is poured, and the layer above is made of larger bulk fractions (crushed stone).

It is permissible to install a pit under the bathhouse if the foundation of the bathhouse is columnar, which presupposes the presence of effective and constant natural ventilation under the floor, and the depth of groundwater is sufficient for the soil filter in such a pit to cope with purifying water from detergents dissolved in it

Drain well

It is located somewhat away from the bathhouse being built, water is drained by a pipe laid from the drainage point in the floor and inclined towards the drain well at an angle of at least 2⁰. This is desired in order to:

- the water flowed by gravity into the settling well;

- the water did not freeze in the pipe at subzero temperatures, thereby blocking the self-flow.

These two conditions require a very low sump location. That is, the deeper the hole into which such a well with a sealed bottom is installed, and the lower the receiving hole is located in it, where the water drain pipe from the bathhouse is inserted, the more efficient and reliable the drain will be.

Emptying a well can be done in two ways:

- pumping out excess water using a sewage disposal machine, with the subsequent removal of such water to treatment sites by public or private enterprises;

- adding biological reagents to the drained water, which completely neutralize harmful substances dissolved in the water. In this case, such water can be brought through a low-lying special pipe into the soil at a depth and distance, where the natural purification cycle will be completed in such water.

Note:

| The denser the surrounding buildings and the higher the groundwater level, the stricter the requirements for water discharged into the ground after biological treatment - up to a complete ban on such discharge. |

Filtration well

A well that does not have a sealed bottom and is filled in its lower levels with filtering natural materials. Drain water in filtration wells is filtered and purified naturally through loose soils with different fraction sizes, after which it naturally goes into the soil, dissolving in the environment. Or, in the case of dense soil “pillows” in the form of clay, it settles on such a natural dense bottom and, processed by beneficial bacteria (originally present in such wells or introduced artificially in the form of biological products), is extracted from there and used for household needs.

Ground filtration

You can count on filtering drain water from a bathhouse with soil only if:

- the bathhouse is not used in winter or if the freezing point is below the groundwater level;

- The drain water has time to pass through all layers of soil filtration before it reaches the groundwater level.

The particle size of filter fractions increases from bottom to top. That is, at the very bottom of the filtration well there should be the smallest particles of filtration substances. Usually it is clean, without clay impurities, fine river sand.

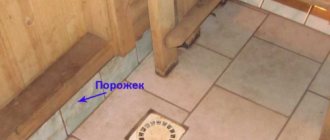

Construction of a pouring floor

When installing a drain, it is not necessary for the floors to be warm. This means that they do not require laying a thermal insulation layer inside the structure. Installation of flooring boards consists of fastening them around the perimeter using additional cranial bars. The created structure can, if necessary, be easily dismantled and taken outside for ventilation and drying, which will extend its service life.

Lags

Before you start laying the logs with your own hands, you need to prepare a place for them. Be sure to put a double layer of waterproofing

Particular attention should be paid to the installation technology: these elements must be installed strictly horizontally with a slight slope towards the waste water collection site. The slope is made by cutting down the logs, gradually reducing their height by 2-3 mm in the direction of the wastewater collection point

Ultimately, the required floor slope should be obtained, which should not exceed 10°.

When laying floorboards on leaking floors, there is no need to use fasteners. To properly carry out this work, it is necessary to take into account a number of important points, which are determined by the specifics of pouring floors:

- It is unacceptable to begin laying boards of a leaking floor until a water receiver has been installed.

- The flooring used simultaneously serves as a waterproofing material for the bottom floor of the bathhouse.

- When laying boards, it is imperative to maintain a gap size, which should be at least 5 mm. This will be enough so that water can naturally drain down even if the flooring swells significantly.

- It is mandatory to wrap the support posts for the logs with a double layer of waterproofing.

Support posts

For the manufacture of lag support columns, 250 x 250 mm bricks are used. These supporting elements are installed on a sand or concrete pad, maintaining a step of 0.8-1 m between them. Upon completion of installation, they must be plastered, and the ground between them covered with roofing material.

If everything is done correctly, then the distance between the lowest point of the surface of the leaking floor and the roofing felt laid below will be at least 300 mm. This requirement can be met due to the logs, which are laid on support posts.

Preparing for drainage installation

Draining used water from the bathhouse, if it is not associated with the use of a pit, is carried out in two stages: first along the internal part of the drainage system, passing directly under the bathhouse, then along the outer section of the pipe. To do this, the method of laying the pipe must be planned at the stage of creating the bathhouse project - with reconnaissance of the properties of the soil around the proposed construction of the facility, calculation of the cross-section of the pipes, their type and the depth of the wells.

Design of the internal part of the drainage system

The design of the internal part of the drainage system is directly related to the type of water collection device. Which, in turn, depends on the design of the floor, which can be:

- torrential - with a lag structure. The installation of such a floor is possible only in a region with a warm climate and with soil consisting of light loose particles (light pebbles, sand of all types, shell rock, etc.). In the plank flooring of such a floor there are small gaps through which water rolls directly into soil for a bathhouse installed on columnar supports or a pile foundation. In regions with winters, when the temperature drops below zero degrees Celsius, the construction of such a bathhouse is impractical.

- Leaking. The floor is made of boards resting on logs, and the logs, in turn, rest on the lower rims of a wooden frame or on the supports of a load-bearing foundation. The floor is slightly inclined to one side or funnel-shaped, with the lowest point usually in the center of the room, where the drain is installed. This design is optimal for baths on a columnar or slab foundation.

- Not leaking. It is built on a strip foundation. It is a concrete poured structure with a slope towards one of the walls or in the form of a flat funnel towards the center of the floor. In the first case, to drain water out along the wall, a drain gutter is made, through which the water flows into the drain; in the second, such a drain is mounted directly into the thickness of the concrete screed.

In addition, preliminary calculations of water consumption for each person are immediately made and, in accordance with this, the diameter of the drain pipes, on which the throughput of the drain system depends.

In any case, the pipe connecting the internal part of the drainage system with the external one must have a slight slope, at least 2 degrees, so that water flows by gravity and it is impossible for it to stagnate in any area where it flows outward.

Design of external drainage area

The external section of the drainage system is a direct continuation of the internal one, and is arranged according to the same physical principles: an inclination to the drainage point of at least 2 degrees, pipes of the same cross-section as inside (or at least not smaller). The cross-section of the pipes, associated with their throughput, is selected according to the following criteria:

If the number of people visiting the bathhouse at a time for about 12 hours does not exceed 5 people, then a pipe with a cross-section of 7 cm is sufficient. If there are more than five or among these five there are especially “zealous” lovers of steaming, then it is better to choose a drain pipe with a diameter of 11 cm .

| You can control the angle of inclination of drain pipes without measuring the degrees of inclination, but by taking into account the difference in levels of each subsequent section of laid pipes. For optimal flow, a difference in levels of 2 cm per meter is sufficient, with a lowering of that part of the pipeline that is closer to the well/septic tank/sewer. |

Video on the topic of planning sewerage in a bathhouse

Wet valves

If you choose a water seal for a bathhouse based on the efficiency of locking, then the best option would be a hydraulic circuit with a curved U-elbow, or an annular chamber with a concentric partition.

Eternal knee

A water seal in the form of an elbow requires a free space of at least 150 mm in height for pipes with a diameter of 50 mm and an overhang of 250-300 mm for a full drain with a cross-section of 100 mm. Therefore, knee bellows are used primarily for bathhouse projects on stilts or columnar foundations. To reliably lock the pipe, the height of the water column must be at least one and a half diameters of the channel.

The main advantage of a water seal is its simplicity of design; it is quite possible to make such a siphon for a bathhouse with your own hands from parts of sewer fittings and pipes. It turns out not as beautiful as industrially made drains, but for a bathhouse it is more important that the structure is easy to repair and simple to maintain. The knee can be easily cleaned, either with a brush or with specialized attachments, rotating brushes and even chemicals such as “Mole”.

This type of drain can work in a properly constructed bathhouse for a couple of decades, until someone uses a cable to punch a hole in the plastic elbow of the water seal.

Flat water seal

For a bathhouse installed on a strip foundation, it is best to use a trap water seal. Its height usually does not exceed 10-12 cm, so the drain box can be safely mounted into the floor screed, and no additional fastenings are required for connection to the sewer.

For example, the “CENTER AQUAPA” model consists of two halves. In the bottom part of the water seal there is an annular cavity with water, which, after installing the top cover, will be divided by a partition. The result is the same bellows, but with a gate height of only 15-20 mm. The drain body is simply put on the receiving hole of the compensating adapter of the sewer pipe of 110 mm.

Important! In this case, the use of a sliding adapter is a prerequisite so that the water seal box is not torn off the pipe due to the expansion of plastic from hot water in the bathhouse.

The box-shaped design turned out to be quite reliable and easy to maintain; the only drawbacks include a small level of water in the water seal. In summer, the water in the drain evaporates, and, accordingly, odors from the septic tank will break into the bathhouse within a couple of days. Whereas in the bellows elbow the water seal will last 3-4 days.

In winter, in a country bathhouse, the drain drain may freeze, but this does not affect its operation in any way. There is little water left, so the risk of damage is minimal. A water seal with an elbow can actually be crushed by frozen water.

Float device for organizing a drain in a bathhouse

Structurally, the water seal with a float is very similar to the previous version of the water seal. The only difference is that in the ladder version, the outlet hole is blocked by raising the water level, and in the float version, the same window is blocked with a foam liner.

Float valves very tightly and reliably block the drain passage even with a minimum amount of liquid. In practice, the drain in the bathhouse can be reliably blocked within 10-15 days from the date of the last visit to the steam room. Among the disadvantages, one can note the sensitivity of the water seal to contamination. After soapy water, the float must be washed with clean boiling water.

Step-by-step guide to creating a bathhouse drain with your own hands

About 90% of Russia's territory is located in a climate zone where in winter the temperature is guaranteed to drop below minus five degrees. Therefore, the drainage system for drainage water will most likely be connected to a sump well, less often to a drainage well with the ability to filter drainage water through a ground bed, as well as to septic tanks or, if there is a developed municipal infrastructure, to connect the drainage system to a stationary sewerage system.

Therefore, there is no point in considering pits under the washing compartment or steam room in this case: such a bathhouse cannot be used in winter due to freezing of the soil and the inability to absorb water into its lower layers, which are below the freezing point or groundwater level.

So, a sump well, a septic tank or a sewer. What steps should be taken step by step to ensure that the bathhouse drains correctly?

Installation of the internal part of the drainage system

- Trenches are dug with a depth of 40 to 60 cm for laying drain pipes, with a slope of 2 cm for each linear meter. The bottom of the trenches is covered with sand, the sand is compacted while maintaining the required degree of slope.

- A drain system is installed with all the necessary adapters in the form of corners, tees, etc., with sealing of joints, if this is included in the technological minimum according to the instructions.

- A sewer riser is installed, secured to the wall with special clamps, if the bathhouse has a toilet. In addition, the riser is either equipped with a ventilation well with an outlet above the roof, or it is cut off above the level of the toilet cistern and a check valve is installed on the cut-off part.

Installation of a closed septic tank

A septic tank for collecting wastewater can be either homemade, made from scrap materials (even car tires placed flat on top of each other), or produced at a specialized enterprise. With a ventilation “trunk”, a hole for connecting a drain pipe, a shaft for the corrugation of a sewage disposal machine. Moreover, if the wastewater drained into it does not exceed a volume of 300 liters at a time, and 700 liters per week, then it is quite possible to settle on a septic tank made from tires.

The height and base area of the septic tank depend on the type of soil on which it is placed. Sandy ones have the greatest absorption capacity - 100 l / m2 / day. On mixed soils, this capacity usually does not exceed 50 l/m2/day, on loamy soils - no more than 20 l/m2/day.

The procedure for installing a septic tank is as follows:

- A trench is dug from the exit point of the bathhouse drain pipe to the selected location for the septic tank, maintaining the required slope along the entire length of the route.

- After excavating the soil, in an area of 3 x 3 m, they dig a 2 x 2 shaft with a depth of 2.5 - 3 meters, into which tires from heavy trucks (6-8 pieces) are lowered flat sequentially. A hole is cut in one of the top ones for the entrance of the drain pipe.

- The finished septic tank is closed with a plastic or metal lid with a ventilation pipe inserted into it.

- They check the ability of the soil under the septic tank to absorb water, for which up to 100 liters of water are poured inside through a pipe and the time of its absorption into the soil is determined, after which the lid of the septic tank and the surrounding area are covered with the excavated soil.

Installation of a drain well

The most convenient material for a drain well is reinforced concrete rings. They are produced in different diameters and fit perfectly together, for which purpose grooves and protrusions are provided at the ends, ideally matching one another. In addition, they can be equipped with matching bottoms and covers with standard plumbing hatches.

For natural water flow, it is better to place the well under the septic tank in a low area - this way you will have to remove less soil. In addition, there must be a place for the access of a special vehicle that will pump out the accumulated excess drain water. To construct a well, a 2 x 2 m shaft is dug, with a calculated depth.

Precast concrete rings are an expensive thing, so many limit themselves to homemade devices. For example, they use used and even broken bricks to line the walls of a well. In such cases, a sand cushion is poured onto the bottom, compacted, and then a concrete mixture based on cement-500 is poured in, and after the concrete has hardened, finishing of the walls with bricks begins. It is better to use a mixture of clay and sand as a binding solution. After such walls have dried, they are treated with bitumen mastic. As a cover, they either take ready-made reinforced concrete for a well shaft, or cast it from concrete with the formwork placed so that the cover overlaps by 30 cm in length, width or diameter. The filling is made in two layers, with reinforcing rods between them. Such a self-cast slab is also treated with bitumen mastic, and before backfilling with soil it is also covered with polyethylene 200 microns thick.

Installation of a ground filtration system

If there is no low-lying area near the bathhouse that will ensure self-flow of water, then you have to dig a deeper hole for the septic tank. But in any case, it is better to place it as close as possible to the place where the drain pipe exits the bathhouse - this provides a greater guarantee of non-clogging.

A trench 80-110 cm deep is dug at the place where the septic tank is dug. The specific depth of laying the pipe is selected taking into account the level of freezing of the ground.

Drainage pipes are being laid. To make them, holes are drilled in pipes using 8, 10 and 12 mm drills. In this case, the pipeline to the septic tank is divided into three conditionally equal parts, and as you move away from the bathhouse, the diameter of the holes in each of these parts is reduced.

The pipes are laid on geotextiles, which, in turn, are laid on a crushed stone bed. At the end of the pipe, a branch is strengthened with an angle of 90⁰ to the pipe, onto the end of which a protective valve with holes is put on. The pipe is also wrapped in geotextile, and after checking its functionality, it is first filled with 10 cm of crushed stone, and then with ordinary soil.

Tips for use

Drainage pipes require regular cleaning using plumbing fixtures or cleaning products.

The waste container is regularly checked to ensure it is full and emptied in a timely manner. Particular attention to filling is needed in the fall and spring, during periods when the soil is saturated with water and it does not leave the septic tank so intensively. And every 12-15 years it is necessary to completely replace the sand and gravel cushion in the trenches simultaneously with the lower layer of earth underneath them. Polyethylene pipes, whose service life reaches 50 years, do not need to be replaced.

Tips for using water drainage from a bathhouse

If the conditions of slope and evenness of laid drainage pipes are met, there are no problems with their operation. Or they can be solved in the following ways:

- Dirt in the drain. Usually this is hair or remains from some kind of bath procedures (washcloths, broom leaves, etc.) and is simply cleaned: a floor board designed in advance for this purpose is raised, under which the drain passes, the drain is removed and cleaned. Pipes are cleaned mechanically - with a brush on a thick wire (reinforcing rod).

- Pipe freezing in winter. Such a nuisance occurs when the pipe is not tilted enough or when a “wave” forms on the pipe, as well as when it becomes clogged. In these cases, you need to start defrosting the system as soon as it is detected - otherwise ice, which has an expansion coefficient greater than water, will rupture the pipe. This can be done by running boiling water from Esmarch’s mug into the pipe with the drain removed, calculating that for every 5 cm of ice plug you need at least 5 liters of boiling water. However, steam generators cope even more effectively with ice plugs in drains. You just need to make sure that the superheated steam does not overly soften the polyethylene or polyvinyl chloride pipes.

Drainage system in the washing room

If the floor is not torrential (and in 99% of bathhouses in Russia with its cold winters it is just like that), but leaking, then the main internal part of the drainage system is a drain with a drain pipe. In a leaky floor with special slots for drains, prefabricated gutters are made between the joists from bent galvanized iron 0.5-0.8 mm thick. And in a monolithic, hermetically sealed one, with an inclination towards one of the walls, gutters are installed, which drain water to a ladder, from which there is already an exit to the external sewer pipe. The second option for a non-leaking floor is in the form of a funnel with a gentle slope towards the center of the room. In this case, the drain ladder is mounted directly in the concrete screed, in a place previously provided for this.

When deciding whether a drain is needed in a steam room, they proceed from the capacity of the bathhouse. If it is heated more than once a week and a total of 5 people wash in it, then it is better to install a drain similar to the drain in the washing room and in the steam room.

Horizontal filter pad method

This method is only suitable for a seasonal bathhouse, in which water consumption is so low that there is simply no point in making a sump. It consists of the following: at a distance of 2-3 meters from the foundation of the bathhouse, a trench is dug long and 1 m deep, with a width of no more than 50 cm.

Drainage material (crushed stone, broken brick, expanded clay or slag from coal combustion) is placed at the bottom of the trench and covered with a small layer of sand. Afterwards, a drain pipe diverted from the bathhouse is laid at the bottom. The pit will be designed for a small volume of waste, no more than 100 liters. Therefore, you should think carefully before choosing this option.

Pit against sewer

When deciding what is best to install on the site - a cesspool for a bathhouse or a stationary septic tank (which is a variant of an autonomous sewerage system) take into account the following

Advantages and disadvantages

these devices:

- service life - for septic tanks it is many times longer;

- environmental Safety;

- practicality, ease of use;

- volume of devices (septic tanks have a whole “model range” that best suits the different needs of consumers).

Septic tanks have only one drawback - high price. But the cesspool has many more disadvantages. This includes silting, the need for regular cleaning, and the inevitable release of harmful substances into the soil, which are not all “fertilizers.”

Reviews

Most reviews from barrel sauna owners are positive. But there are also negative ones. Owners of such designs praise them primarily for their original design, as well as ease of assembly, mobility, and quick warm-up. Many note that this design is intended for temporary use only during the warm season. Although there are those who used them in winter.

We suggest you read: How to use a spray foam gun

There are a lot of records of bathhouse owners who recently purchased them, in contrast to those who have used them for at least 3-4 years. Positive reviews are often so “sweet” that one involuntarily doubts their reality and non-commercial component. Therefore, negative comments are especially valuable. Those who are against and criticize barrel baths - that is, probably real buyers - note the following:

- Over time, the boards dry out, and then pulling and installing them becomes problematic. Although in many ways this indicates the initially poor quality of the building materials - they were not properly dried.

- In winter, baths do not warm up as quickly and cool down just as quickly. It feels cold from below when there is still steam above. There is no opportunity to sit for a long time in the steam room.

- The need to monitor drainage, especially when used in cold weather. The drain pipe may burst, and this will lead to poor drainage, stagnation of water and the occurrence of rot.

- The appearance of mold and mildew even with proper care - regular ventilation and cleaning.

- Many users of summer baths are confused by the thickness of the walls. The boards that are used are quite thin - only 4-5 cm.

- Expensive - for the same amount you can build an ordinary frame or foam block temporary bathhouse, which will be more spacious.

Choice of material: metal or plastic

In order to save money, very often a septic tank in a country house is made from barrels that previously served another function. For example, they could be used to store grain, sand, cement and other bulk substances. The container can be metal or plastic, the main thing is its tightness.

If the question of purchasing a barrel still arises, then it is better to give preference to plastic. And that's why:

- wider range on the market;

- resistance to corrosion and aggressive effects of wastewater;

- absolute tightness over a long service life;

- installation without the use of lifting equipment due to its low weight.

To be completely objective, it should be clarified that the last point is only partly an advantage. The small mass of plastic makes it necessary to attach the container to a concrete base to level out the buoyant effect of groundwater. In this regard, a septic tank made of iron barrels is considered more preferable, since it does not require anchoring.

Any barrel that meets the tightness requirements can be suitable for a sewer sump.

Metal barrels - temporary wastewater collection system

When arranging a septic tank from iron containers, it is necessary to dig a pit of suitable dimensions and be sure to concrete its bottom. Then prepare two barrels and drill holes on their sides. You will insert the outlet of the drainage pipe and the inlet of the overflow pipe into them. Remember - the pipe product coming from the house is always inserted into the first barrel with a certain slope. Due to this, wastewater will flow by gravity into the septic tank without any problems.

Important pro tips to follow when installing a sewer system made of metal barrels:

- the second metal container should be installed in the pit slightly lower than the first;

- use barrels with a volume of at least 200 liters;

- high-quality insulation of the septic tank on all sides is mandatory (there is no need to lay heat-insulating material only at the bottom of the pit);

- The tanks are backfilled with soil; the top of the septic tank is covered with roofing felt and lids made of wood or iron (do not forget to make a hole in the coating through which wastewater will be periodically pumped out of the tanks).

Construction of a sewer system from metal barrels

If you want to increase the volume of the structure in question, it is possible to install several barrels on top of each other and weld them together. In addition, additional iron jumpers can be mounted. They will provide more reliable fastening of the barrels. All joints between barrels should be thoroughly waterproofed. For this, hot bitumen is most often used.

Let's say it right away. No matter how you set up a system of iron barrels, after 3-4 years the metal tanks will have to be replaced. They will begin to rot and rust under the influence of aggressive wastewater.