The traditional material for building a bathhouse is wood. And this is no coincidence; the benefits of bath procedures are most fully manifested in a log steam room, in which a special microclimate is created, filled with the healing aromas of natural wood. But on the other hand, high humidity and extreme temperatures characteristic of a steam room do not have the best effect on wood, which quickly deteriorates in such conditions. Treating the bath with oil will help prevent destructive processes. In this regard, in the article we will focus on two main points: what are the best oils and impregnations to use in a steam room, as well as how to properly treat the internal surfaces of a bath with oil compositions.

The need for bath treatment

As noted above, a bathhouse is a room with special conditions in which high temperatures and humidity are constantly present. Wood is characterized by high hygroscopicity, that is, it strongly absorbs moisture.

In a steam room, the tree becomes an ideal environment for the development of pathogenic processes. Microorganisms appear in it, insects settle, mold and mildew form. As a result, the tree can completely turn black and turn into dust.

Once the process has begun, it is very difficult to stop, especially when it comes to a fully functioning steam room. To prevent the occurrence of such manifestations, it is necessary to protect all internal parts of the bathhouse frame in advance at the construction and finishing stage by treating them with special compounds.

There are many products for interior treatment of a wooden house and bathhouse. This review is dedicated specifically to oils, so we will only consider oil formulations.

Impregnation: the difference between a bathhouse and a sauna

We would call this question archivally important. Because it is the temperature that determines the evaporation of substances that impregnate the top layer of wood.

And it is precisely the temperature that distinguishes a Russian bathhouse from a Finnish one . Therefore, let's agree that the compositions that we consider absolutely suitable for a Russian bath with its temperature not exceeding 60 degrees during the entire steaming period should not be recommended to sauna owners, where the temperature sometimes rises not only to the recommended 90, but also to 100-110 degrees (we simply do not consider higher).

The second, less important parameter is humidity. In a sauna it is low (5-15%), in a Russian sauna it is high (50%). In principle, a less humid sauna spoils the wood less, so you can actually do without impregnation at all, but the Finns rule here, and they believe that impregnation should be done at least for beauty and cleanliness.

The humidity of a Russian bath should be considered an argument in favor of water-repellent impregnations.

What oils are suitable for baths

Oil is a traditional bath treatment product.

In earlier times, when there was not such a variety of means for protecting wood, steam rooms were covered with expensive oils of anise, rose, and lavender. These compositions not only protected the log walls from moisture and rot, but also filled the room with a special natural aroma. Inexpensive hemp and linseed oils and wax were also used for processing, which have not lost their relevance today.

All oil compositions used in the steam room can be divided into two large groups:

- For treating walls and ceilings.

- For impregnation of benches and other surfaces in direct contact with the skin.

General requirements for oils for steam room processing

- Oil impregnation should provide reliable protection to the wood, and at the same time should not deprive it of its ability to breathe.

- An important condition is the environmental friendliness of the oil composition. Therefore, to cover the bath room you need to choose natural products. Synthetic impregnations contain chemical components that, when exposed to high temperatures, form harmful volatile compounds that are released into the atmosphere. In a small confined space, harmful substances are especially dangerous and can cause serious poisoning.

- For a bath, it is necessary to use moisture-resistant impregnations that are well absorbed into the wood structure, protecting it from moisture.

Products for treating walls and ceilings

When choosing a wood preservative to cover the internal surfaces of the steam room, in addition to the special conditions of the bath room, it is necessary to take into account the type of building material.

Usually these are logs or clapboards. For floors, walls and ceilings made of these materials, you can use non-toxic acrylic-based varnishes, which do not emit any odor at high temperatures, natural oils and waxes, as well as special impregnations for saunas. Acrylic varnishes form a protective film that can withstand temperature changes and exposure to water and steam. The varnishes contain antiseptics, so the surfaces do not require additional antiseptic treatment. Natura Teknos acrylic varnish has proven itself to be excellent, forming a translucent protective coating under which the wood grain is clearly visible.

One of the best means for internal treatment of wooden surfaces of a log bathhouse and a log house is linseed oil. This is an inexpensive natural product with antiseptic and hydrophobic properties. The oil penetrates into the deep layers of wood, providing it with reliable protection. The composition can be used both in pure form and in the form of a mixture with beeswax.

In addition to the pure product, there are various impregnations on sale based on linseed oil, which contain natural resins and pine turpentine. The most popular products are those under the brands Caparol, Tikkurila, and Remmers.

Oils for bath canopy

Particular attention should be paid to the choice of composition for impregnating the bath canopy. The canopy is in direct contact with the human body; if a poor-quality composition is used, a rash and burns may appear on the skin. Manufacturers produce special oils for shelves that do not form a film on the surface, since when heated it can cause burns. In addition, the impregnation must be of high quality and should not cause allergic reactions on the skin.

- The oil compositions Sauna Natura from the Finnish manufacturer Teknos, Supi Laudesuoja from the Tikkurila brand, and Eurotex Sauna have proven themselves better than others in this group of products.

- A good wood preservative is carnauba orange oil wax. The product contains flaxseed and orange oil. The composition turns out to be very thick and resembles mastic in appearance. It is used to cover benches and backrests in saunas.

- Another product used to treat floors is beeswax. In addition to wax, the composition includes linseed oil and gum turpentine. This impregnation is less resistant to high temperatures than carnauba wax, so the coating will have to be renewed periodically, because Over time, its protective properties weaken.

Typical impregnation features for different parts of the room

Some owners do not want to spend too much time and effort on selecting protective components. As a result, they choose one product with which they treat all parts of the room, the entire bathhouse from the inside. This can also be done, but this is far from the best solution. It is advisable to take into account that operating conditions in different parts of the bathhouse differ significantly. If you pay attention to this, then the processing will be maximally adapted to specific parameters.

Let's start analyzing all surfaces. We will try to derive optimized rules for protecting sauna impregnations in accordance with the type of zone.

Ceiling

Experts and craftsmen note an interesting point: steam and hot air rise to the ceiling, but at the same time there are not so many requirements for the surface when compared with other zones. Here we take into account the influence of high temperatures, which is typical for all areas and surfaces in the sauna. A good solution is to cover the ceiling with high-quality specialized varnish, which is produced specifically for use in bathhouses or saunas.

Walls

The largest part of the composition will be spent on protection from all the negative effects of the lining with which the walls are sheathed. Here are the two most significant factors. Be sure to take them into account:

- You cannot cover the walls with impregnations that will not allow the wood to “breathe”. This will provoke premature aging of the material, as well as its deformation.

- Varnishes and impregnating compositions must be completely safe for human health and environmentally friendly. Such products, even with extreme heating, do not emit unpleasant odors or harmful chemical compounds.

As experts with extensive experience note, it is better not to try to save money on such impregnations. If you purchase an untested product, you can provoke rapid aging and damage to the wood, which will entail large expenses in the near future.

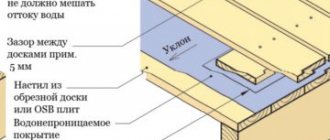

Floor

It is the floor surface that is exposed to maximum negative influences in the bathhouse. This is especially true for the steam room. Almost all the water that is used here ends up on the floor. And it is protection from water that will require maximum attention. In addition, we must not forget about powerful antibacterial protection.

Experts immediately remind us of a protective varnish coating for the floor. There are also quite a lot of requirements for it, determined by the operating conditions in the sauna. Let's look at a few of the most significant factors:

- The tree must be able to “breathe”. Therefore, a professional product that is not in the lowest price category is suitable.

- There is no need to apply several layers of varnish. There is a common misconception about the increased strength of multilayer coatings. But this is a misconception: with repeated layering, the varnish coating becomes cracked much faster. They can be invisible and small, but at the same time they will allow water to pass through and jeopardize the safety of the tree.

- The protective layer of varnish, of course, should not slip, as this can lead to injury in the sauna.

- Some varnishes are simply not designed to withstand extremely high temperatures, so they may begin to stick when heated. Of course, this option is also absolutely not suitable for a bathhouse.

Another expert tip. Already at the stage of constructing a bathhouse, it is necessary to take care of the impregnation of the logs themselves, on which the floor boards will then be laid. They are also impregnated with protective compounds to maximize the service life and preservation of the wood.

Benches, shelves

View this post on Instagram

Publication from Alexey (@drevostroy)

The shelves are the most significant part of the entire steam room. It is important that the shelf is not only comfortable, but also completely safe for health and environmentally friendly. Therefore, maximum attention is paid here to the quality of protective impregnating compounds.

Let's start with temperature. Wood itself is a poor conductor of heat. Even if you lie on a tree at an extremely high temperature, you will not get burned. But if the tree is covered with an unsuccessful protective film, it may well cause serious thermal burns when it comes into contact with the body. This is precisely why experienced craftsmen note: it is undesirable to use varnishes and paints here for processing. The best solution is to use the appropriate impregnation, adapted specifically for the bath. In most cases, such protective compounds are made on a wax basis.

Interesting point. Nowadays, the requirements for environmental cleanliness and comfort are often so high that the owners insist: the shelves in the bathhouse must be completely natural. That is, the wood is not impregnated at all. This is possible, but such an approach implies regular replacement of these elements, since they will certainly quickly deform and the tree will age quickly.

When a bathhouse or sauna is decorated very well, the interior is thought out, powerful wooden panels are used, there is a desire to preserve it all longer, to maximize its service life. And here, undoubtedly, you can’t do without impregnation.

Rules for applying oil impregnations

- Before applying impregnation, the surface is thoroughly cleaned of dust and dirt and, if necessary, the old coating is removed.

- Then the wood is sanded, dried and the dust and shavings formed as a result of sanding are removed.

- The impregnation is mixed well and applied to the surface with a short-bristled brush.

- Within 7-10 minutes after treatment, remove excess with a soft, lint-free cloth.

- The surfaces are allowed to dry and then polished.

- If necessary, repeat the treatment.

The drying time for each layer ranges from 4 to 24 hours. The exact time required for a particular product to dry is indicated in the instructions. In addition, the drying time is affected by the humidity and temperature of the room, as well as the absorbency of the wood species. In any case, it takes at least a day for the surface to dry completely.

Remember! Wood is only reliably protected from moisture when it no longer absorbs moisture.

What to soak: varieties and their purpose

You come to the store to choose a wood impregnation, and there are so many options there that your eyes widen.

In reality, you just need to distinguish between goals. A bathhouse is most often a separate building, in which, in addition to the steam room, there are other rooms . Many baths are built of wood or have wooden lining. There is wooden furniture everywhere. All this implies different purposes and compositions for them. Manufacturers of protective impregnations distinguish them as follows:

In our particular case, we are looking for something to saturate the shelves in the bathhouse with. Now let’s decide on the task: what we want to protect the shelves from. It’s tempting to protect against everything at once, but without going into details for now, let’s say that antiseptics and fire retardants do not have a beneficial effect on our health, that is, it’s not worth protecting shelves from rot and fire .

Basically, the wood of the shelves is protected from water . In addition, not only for the sake of beauty, but also as a type of antiseptic , bleaches are used which return darkening wood to its original color.

We will now consider this limited set of what can be used to cover the shelves in a bathhouse.

Impregnations, colorless and colored

Everything here is quite simple: if you add one or another color to the impregnation, which has no or little effect on the original color of the wooden surface, then the result will be a colored impregnation . Wood painted with it will differ from wood coated with regular paint in that its texture will still be visible .

Each manufacturer of color impregnations accompanies its products with a catalog of colors, from which it is easy to choose the right one. Colors for impregnation are not sold separately.

Oil

The most well-known property of oils and waxes is their hydrophobicity, that is, non-wetting by water. This is precisely what predetermined their use in the creation of water-repellent compounds for wood.

However, there is one important point: in the simplest case, a hydrophobic coating forms a film on the surface of an object, which differs in its thermal conductivity from wood. In practice, this means that the coating can burn if the air in the steam room is heated to a high temperature.

Therefore, manufacturers contrive to prepare oil for shelves in a bathhouse in such a way that the impregnation is absorbed into the wood without creating a noticeable film on the surface.

Usually bath oil has no color, but there are tinted ones too.

Bleaches

Experienced steamers are not deceived when they see light wood in the steam room - it won’t stay that way for long if you use the bathhouse regularly. However, their expectations may not be met if the owner of the steam room uses special impregnations that bleach the wood.

Strong oxidizing agents not only lighten, but also disinfect wood, destroying fungi and their spores too..

The depth of penetration of the composition also depends on the concentration of the active substance. Bleach can be in a more or less concentrated form when sold, and then, if desired, it can still be diluted with water.

Features of oil treatment

- If pure oil (usually linseed) is used, it is heated to 50-60 degrees before processing.

- The composition is applied either with a brush with natural bristles or with a cotton cloth.

- Apply the oil in a thin, even layer.

- The product is applied 5-6 times with layered sanding.

- After covering the next layer, wait for it to dry, then sand and apply the next one.

- It takes at least 2-3 weeks for a surface coated with linseed oil to completely dry.

If a mixture of oil and wax is used to process the bath, then the ingredients are taken in a 2:1 ratio to make it. To prepare the product, add heated wax to hot oil and then mix well.

The mixture is applied with a foam sponge strictly along the fibers. When the first layer has dried, remove the residue with a waffle cloth and treat the surface again.

What to cover with? And is processing necessary?

Let's start with a tricky question. The fact is that many bathhouse owners believe that the shelves in the bathhouse do not need to be treated with anything . At the same time, they easily accept the fact that wood, under the influence of heat and steam (humidity), quickly becomes dark and then collapses. It is believed that it remains environmentally friendly and this is more than enough, because the main thing is human health.

It is simply impossible not to agree with the last argument, but no one contrasts the beauty of the steam room with the health of its visitors . Now, if there was such an impregnation for shelves in a bathhouse, which at the same time was completely harmless to our bodies and increased the durability of the tree - who would refuse it?

Below we will consider in detail the compositions of various impregnations and their effects on humans. For now, let’s summarize briefly, naming the pros and cons of both choices.

Processing: pros and cons with and without it

Pros without processing:

Cons without processing

Protective impregnations for lining

First, what are they for:

Firstly: for durability; Secondly: for a pleasant aesthetic appearance.

By durability we mean long-term resistance to various physical (excess humidity and extreme temperature changes) and biological (fungus, mold, wood-eating insects, etc.) influences. By pleasant appearance, we mean the absence of dark spots and uniform color shade of the lining. And one more thing - the absence of an unpleasant odor.

Fundamentally: to treat lining in a bathhouse, it is strictly forbidden to use ordinary paints and varnishes. This is a death sentence for your health. You can only use special heat-resistant and water-repellent impregnations created for baths and saunas.

"Advice. When buying lining, you need not only to familiarize yourself with the certificate (after all, it can be sawn from trees that grew in an environmentally “dirty” zone), but also to find out WHAT it was processed during the manufacturing process. Just in case, let me remind you that the best species for a bathhouse are aspen, linden and alder.”

Useful video

This video explains the types of impregnations and their differences:

And this video clearly demonstrates how exactly the impregnation should be applied.

Finally, let’s say that impregnations do not tolerate freezing, losing their properties, so you should buy them from trusted suppliers. Otherwise, we hope that we have been sufficiently informative, and you will easily be able to choose a coating for bath shelves.

Share on social networks

There is also oil for NORT shelves, it has shown itself to be very good in use and the price is not high. The oil contains pine essential oil. Smells nice.

Interesting. pine-scented shelves

I used a very good antiseptic for my bathhouse, which was recommended to me by my neighbors, and at one time by the seller, the name of this product was “Ultan SSA” paste. This paste helped treat and protect the regiment in the bathhouse from parasites.

roof rafter extension beyond the wall size

I read the article and wondered if it was even worth covering the shelves in the bathhouse with something if it was possible to periodically replace them as they wear out. Still, I decided it was worth it. I am especially concerned about this issue in terms of antiseptics. Does anyone know if essential oils with antiseptic properties like eucalyptus or tea tree can be used for treatment? Will there be an effect?

Vika, if the funds allow you to replace the shelves, then you don’t have to worry at all