All builders know that reinforcement of a strip foundation is a necessary stage in the construction of buildings, thanks to which it is possible to achieve the necessary characteristics of strength, reliability, resistance to external influences, and significantly extend the service life. The tandem of concrete and metal guarantees the best properties that neither of these materials can provide separately.

Strip foundations are most popular in individual construction of residential buildings, as they are relatively inexpensive, involve low consumption of materials, and quick and simple construction. But without strengthening the foundation, a structure of this type will not have the necessary properties and will not last long. Therefore, hardening must be done; all work can be done with your own hands.

Requirements for fittings

To understand what reinforcement is needed for a strip foundation, it is necessary to perform calculations and consider the main types of material. To perform the work, mechanically strengthened, hot-rolled, heat-treated construction reinforcement is used. The class is selected according to maximum loads, taking into account tensile characteristics, ductility, weldability, corrosion resistance, ability to withstand temperature changes, etc.

The main brands of rods: hot-rolled rod (A), cold-deformed wire (BP), very strong rope (K). For the foundation frames, rods of the A400 (AIII) yield strength class with a crescent-shaped herringbone pattern are selected.

Proper reinforcement involves the use of the following types of rods:

- Workers - for laying around the perimeter

- Transverse vertical

- Transverse horizontal (clamps)

- Additional - usually a binding wire is used instead

To understand which fittings are best to use, you need to remember some rules. To strengthen the base of one- and two-story buildings and light structures, rods with a diameter of 10-24 millimeters are suitable. The strength characteristics of thicker (and much more expensive) reinforcement are unlikely to be used.

The rods must be corrugated, as they provide excellent adhesion to the concrete mortar; their thickness must clearly correspond to the values specified in the documents. Smooth rods are cheaper, but they will not allow you to create a reliable and durable reinforced frame. They can only be used in transverse connections where the load is not very large.

When creating a strip foundation frame on homogeneous soil, you can choose a material with a diameter of 10-14 millimeters; on heterogeneous soil, 16-24 is better. If the side of the building is more than 3 meters, the working reinforcement of the monolithic foundation is made from rods of at least 12 millimeters, but not more than 40.

The technology requires that horizontal clamps in diameter should not be less than a quarter of the working rods - usually 6 millimeters. Vertical rods for low-damage foundations of 80 centimeters or less should be at least 6 millimeters in cross-section. Having thought everything through, you can determine what diameter of rods is needed for different types of work.

About the need for strengthening

To what extent is it necessary to strengthen a concrete mass with steel wire? After all, concrete has fairly high strength characteristics. Indeed, concrete has increased resistance to compressive loads, but requires reinforcement against the destructive effects of tensile forces.

The greatest likelihood of stretching is on the surface of the base, this is where the reinforcement should be placed

This feature of concrete can be compensated for by laying steel rods at two levels of the base. This solution increases the strength characteristics of the array, allowing it to maintain integrity under the influence of bending loads, torques and tensile forces.

The concrete base is additionally reinforced with auxiliary rods located in a vertical plane. Vertical elements provide fixation of the rods of the upper and lower levels of the load-bearing frame.

Reinforcement requirements

Before reinforcing, you need to decide what size the frame will be, make a drawing, draw a diagram of all the work and structures. The geometric dimensions of the foundation must be such that the location of the reinforcement is free. The concrete layer completely covers the frame, protecting it from external influences and corrosion.

The minimum distances between the rods must be sufficient for effective joining and compliance with all technology rules. Only high-quality fittings are used in the work, in accordance with SNiP 3.03.01. Bending of rods is performed using special devices. The bending radius corresponds to the diameter and physical parameters of the rods.

Video of manual machine for bending reinforcement

And another useful video:

Video on how to bend reinforcement using a homemade machine

Pouring concrete onto the frame

We have just figured out how to reinforce the foundation, now we will look at how to pour concrete correctly so as not to damage the integrity and increase the strength of the structure. The first step is to make a good base. To do this, pour 5 centimeters of broken brick or cinder block under the first strapping belt. Next, fill it with liquid solution so that it penetrates well into all the cracks and ensures maximum strength of the sole.

Important: you cannot fill the foundation and plinth in “waves,” especially at the junction of the reinforcement - the crack will go along this line. If you need to perform the operation in 2 times, then it is better to make the “break” in the middle of the foundation. For example, if its height is 150 centimeters, then at the level of 75 cm you can take a break. Next, you need to fill everything with a monolithic layer, and that’s the only way.

The metal is poured at least 8-10 centimeters so that it is not near the edge, otherwise the foundation will fall apart under an average load. This will not affect the overall strength, but the base will lose its appearance - the edges will crumble.

Calculation of size, quantity and diameter of reinforcement

It is important to immediately know how much reinforcement is needed to make the reinforcement cage reliable and durable. Knowing the dimensions of the building, you can carefully calculate everything.

Standard frame configuration for small houses:

- Bottom and top row of belt

- 3-4 rods for each row

- The current distance between the rods is about 10 centimeters. The distance from the rods to the edges of the base should be at least 5 centimeters.

- The belts are connected with clamps or sections of rods in increments of 5-30 centimeters.

So, if you need to build a building with an area of 150 square meters, the perimeter of the external walls is 50 meters. To calculate the amount of reinforcement, you need to take everything into account: 2 belts of a longitudinal row of 3 rods each equals 6 rods, multiplied by 50 meters, that gives 300 meters of main rods. If the lintels are laid in increments of 30 centimeters, the result is 167 pieces per 50 meters. The length of the transverse lintels is 30 centimeters (167x0.3=100.2 meters), vertical - 60 (167x0.6=200.4 meters).

It turns out that to the question of how much reinforcement is needed to strengthen a house with an area of 150 square meters with a wall perimeter of 50 meters, the answer is: 300 meters of thick corrugated rods and 300.6 thinner rods. Plus 10-15% for stock and docking.

Assembly Rules

The parameters of the frame for the strip foundation have been determined, you can proceed to the installation processes. First of all, you need to cut the reinforcement into elements along the length. It is clear with vertical and transverse ones. In our example it would be:

- vertical 90 cm;

- transverse 40 cm.

The quantity is calculated taking into account the total length of the trenches. For example, the length of the trenches dug under the walls is 100 m; this figure must be divided by the step of laying the reinforcement. If it is 20 cm, then 100/0.2 = 500 pieces of both types.

As for longitudinal rods, the length of one rod is taken as a basis. It is equal to 11.7 m, taking into account the knitting overlap, a value of 10 m is used. Therefore, in one row of longitudinal rods: 100/10 = 10 pieces. In the case of 5 rows with a pitch of 20 cm, plus two gratings, it turns out that what is required to assemble the frame is: 10x5x2 = 100 pieces of reinforcing rods 10 m long.

Rules for reinforcing strip foundations

- Working rods must comply with at least class A400.

- Welding is not used to connect rods due to the likelihood of weakening the cross-section of the element.

- The frame is tied at the corners, not welded.

- It is better not to use smooth reinforcement even for clamps.

- The layer of external protective concrete should be at least 4 centimeters, which will guarantee effective protection against rust.

- In the longitudinal direction, the rods in the frame are connected with an overlap equal to at least 25 centimeters and at least 20 diameters of the rods.

- The standards require that when metal rods are frequently placed, the aggregate in the concrete solution is not very large and does not get stuck between the rods.

- How to properly lay reinforcement in a trench - this can be done in two ways: create a frame outside the foundation or directly in the trench. The reinforcement methods are almost equivalent, but you will have to hire someone to work in the trench, while constructing the frame separately on site can be done independently.

- Knitting is carried out with a special crochet hook or knitting machine.

- Many people wonder what kind of wire is used for knitting - the answer is simple: soft thin wire of not a very high level of strength. It needs to be pulled well; a strong knot is obtained in 2-3 turns of the hook.

- The overlap (the distance from the edge of the rod to the knitting point) should be at least 5 centimeters.

- All wire connections should be as tight as possible, with no free space between the clamps and the frame, and no element should move.

Connection methods

You can assemble the reinforcement into a single frame using two methods:

- welding;

- knitting

If plastic fittings are used, then there is no question of any welding. However, metal reinforcement is also rarely welded, since the welding points become weak points of the structure, they can withstand less load and are more susceptible to corrosion. Welding ensures that the rods adhere too tightly, eliminating even the slightest play. This design is less susceptible to deformation and cannot be used when working on moving soils. Moreover, you can only weld those fittings that have the letter C in their markings.

It is much more practical to use knitting with wire. It is folded in half, the free end is threaded into the resulting loop with a hook, and then twisted so that the connected rods cannot move freely. Simple, cheap, reliable, but long - an experienced builder will be able to make up to 20 connections per minute, and a beginner - no more than 5-6.

You can simplify the knitting process by using a special knitting gun. It is leaned against the intersection of the steel rods, the trigger is pulled, and the connection is complete. Up to 40-50 such operations can be performed per minute. The downside is the high price of the equipment and the need to use expensive wire.

Finally, we note that when purchasing, in addition to the diameter, class and surface type, you should pay attention to whether the product has the appropriate documentation (first of all, this is a certificate of conformity). The final touch - visual inspection

If you notice traces of rust, scratches and other mechanical damage on the fittings, then it is better to refuse the purchase and find really high-quality products - without exaggeration, they will support the entire house.

How to knit reinforcement mesh yourself

The following step-by-step instructions will give you the opportunity to learn how to properly make a frame and provide the foundation with the necessary properties. The easiest way is to knit ready-made reinforcement for a strip foundation on the ground. Straight sections of the mesh are created outside the structure, but the corners are knitted after the frame is lowered into the trench.

- First you need to cut pieces of rods. It is better to start knitting with the shortest section of the foundation in order to gain a little experience. You need to cut to a minimum, trying to use the entire length of the working rods. If we take as an example a strip foundation 40 centimeters wide and 120 centimeters high, then the indicators are as follows.

- The metal is poured on all sides with a layer of concrete at least 5 centimeters thick. The net dimensions of the frame in height are a maximum of 110 centimeters, width – 30. For knitting, add 2 centimeters on both sides for an overlap. It turns out that the blanks for horizontal jumpers should be about 34 centimeters long, and vertical ones - about 144 centimeters. This is for high foundations, but usually a base with a height of about 80 centimeters is used.

- 2 rods are placed on a flat surface, horizontal spacers are knitted at a distance of 20 cm from the ends on both extreme sides: the wire is folded in half, pushed under the fastening point and tightened by twisting the hook.

- At a distance of about 50 centimeters, all the horizontal struts are fastened in turn, the structure is put aside, another one of the same is made - these are the lower and upper frames that need to be tied together: adapt stops for both meshes between the rods and 2 struts vertically at the ends, attach the remaining pieces. The same should be done with all straight sections of the structure.

- Then, pads with a height of at least 5 centimeters are laid at the bottom of the trench, side supports and a mesh are installed correctly. Now you need to knit every corner and joint, creating a single frame. The overlap of the ends of the rods must be equal to at least 50 times the diameter of the rods.

- Next, the lower turn is tied, the vertical posts are attached, and the upper frame is attached to them. Then, on all surfaces of the formwork, you need to check the distances, indentations, and overlaps at the joints so that everything is done correctly and clearly.

- Connecting rods along the length usually does not cause problems, but fastening the frame parts in the corners must be done in accordance with established standards. There are two ways: between two perpendicular structures or at the point where a wall adjoins another.

Corner knitting technologies:

1) Rigid with a foot - at the end of each rod, knit a foot at a right angle with a length of at least 35 diameters of the rod, connect the bent part to the perpendicular section. This is how the outer rods of the wall frame are attached to the outer rods of the other, while the inner ones are also welded to the outer ones.

2) G-clamps - instead of a clamp, take a clamp with a length of at least 50 reinforcement diameters, one side is attached to the frame of one wall, the other is attached perpendicular. The outer rods are connected to the inner ones, the pitch of the clamps is ¾ of the height of the wall.

3) U-clamps - for one corner you need to install two U-shaped clamps with a length of at least 50 reinforcement diameters, each welded to one perpendicular rod and two parallel ones.

Junctions are created using similar fastening methods.

Do-it-yourself formwork installation

A properly made frame for the foundation will not only save a lot of money on the purchase of concrete, but also significantly simplify the reinforcement process. If you already have it, you can skip this stage and go straight to the reinforcement; if you don’t, then consider the step-by-step instructions.

STEP 1: selection of material. With a small foundation height, choosing a material is quite easy: plywood, wood, OSB boards, fiberboard. The main requirement is the strength of the material. For high foundations (from 150 cm) only metal is used, since the pressure of the concrete will be significant and the wood may fail.

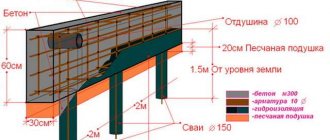

STEP 2 : preparing the base. Let's say we have a trench that meets the standards, now we need to compact the base. Pour a 150 mm layer of sand, fill it with water, then 4-5 centimeters of concrete to level the surface. Do not forget about communications, they must be done at the stage of formwork and reinforcement of the foundation of the house; you must not forget about the embedded pipes in the right places, otherwise you will have to work with a hammer for a long time and break the solidity of the foundation.

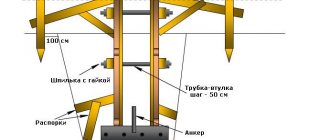

STEP 3 : having a construction project, we install pegs along the perimeter of the trench exactly to the width of the future foundation, they will hold the bottom of the formwork, we place spacers at least 70% of the height of the structure (the spacer itself is 2 times the height of the foundation). It wouldn’t hurt to make 3-4 control slats for the width of the foundation, which can be used to measure width deviations.

Expert advice: you need to drive the nails from the inside of the formwork into the spacers and pegs, so that later you can remove everything without any problems. Otherwise, you will have to break the wooden beams or saw off the hats, since the protruding nails are concreted. If the foundation is 150 cm or higher, it is recommended to tie the formwork together with wire in a checkerboard pattern every 1 m.

The formwork should be as rigid as possible, the gaps between structural elements no more than 0.3 cm, so that when pouring the foundation, the liquid mixture does not leak out, otherwise the strength of the foundation will decrease in arithmetic progression.

It must withstand heavy loads and retain its shape after pouring cement; this is the only way to make a monolithic foundation for a house that will last for decades.

Important: the inside of the formwork must be lubricated with technical oil or other petroleum products (working off will do) so that it can more easily peel off from the concrete after it has hardened. You can use it many times.

Photos of strip foundation formwork

Formwork with spacers

Wooden formwork

Correct formwork

Panel formwork

Knitting reinforcement using a special device - a knitting machine

To create this tool, you need to take several boards 20 millimeters thick, cut 4 boards along the length of the reinforcement, connect two at a distance equal to the pitch of the vertical posts, creating 2 identical templates. Next, two vertical supports are made with a height equal to the height of the reinforcement mesh. The supports are constructed with side corner stops; it is better to choose a flat area for work.

The device is used as follows: the legs of the stops are installed on two knocked down boards, the two upper boards are placed on the top shelf of the stops and fixed. That's it, the reinforcement mesh layout is ready, now you can quickly knit it. It is enough to place the vertical reinforcement struts in the marked places, fixing them with nails, install the rods on each steel lintel, doing this on all sides of the frame. Next, take a hook and wire - that’s it, you can knit. Such a device is relevant where it is planned to create many similar mesh sections.

Video on how to knit reinforcement using a device

Stages of work

- Drawing up a project that will take into account all the soil features based on geological research. Depending on them, it is worth deciding on the type of foundation, its depth, and making calculations about upcoming expenses .

- Site preparation - removing the fertile layer and marking the future foundation. All distances are measured with a tape measure, pegs are driven into the ground at a distance of approximately 30 cm from each other, they must be installed at the corners. A cord or thick threads are stretched between them. Please ensure that the corners are strictly rectangular, especially if you are going to build a house made of timber .

- After the trench has been dug, you should go to its bottom lay a sand cushion approximately 10 - 15 cm thick for soil compaction. Most often, sand is moistened with water for maximum shrinkage, this is enough, but on some soils it is sometimes necessary to use geotextiles to prevent groundwater from penetrating and having a destructive effect on the foundation.

- The next stage is the assembly of formwork from wooden panels , the height is adjusted according to the level, all cracks are covered with film or other material.

- The most important point is the installation of fittings . Depending on the correct knitting and location of the steel rods, the rigidity and strength of the foundation will depend.

- Pouring concrete mixture into the resulting structure . Now all that remains is to wait for complete drying and hardening, which occurs within 3 to 5 days and depends on the weather.

As you can see, almost all stages are not difficult to complete, except for reinforcement, which requires certain knowledge and skills. It is important to remember that openings should be provided for various communications .

Step reinforcement

If the construction site has large differences in height, then the foundation is poured with steps , which are reinforced according to a certain pattern:

- The reinforcement of the step is extended by 1 meter from the ledge .

- Rods 2 meters long should be placed in the upper part , its middle should be at the center of the ledge.

- Horizontal rods should be laid one and a half meters apart from each other .

Corner reinforcement

A lot of mistakes are made when reinforcing corners, but in no case should they be allowed, because this place experiences multidirectional loads , and incorrect laying of reinforcing rods will lead to the fact that the foundation will not be a monolithic structure, but a set of separate parts, cracks will appear , the concrete will delaminate.

Usually simple crossing , without additional vertical and horizontal reinforcements, which does not ensure the strength of the entire foundation.

To prevent this from happening, additional reinforcements should be used in the form of U-shaped or L-shaped rods; they are used at the joints of the reinforcement.

There are many schemes for their location. Transverse rods are laid twice as often as in the middle .

Additionally, vertical rods are laid. If it is necessary to reinforce an obtuse angle, then several L-shaped rods should be used , located in a certain way. The structure is reinforced with additional cross members.

Connection methods

There are two ways to connect steel rods to each other.

Welding is a quick and easy process, but it has a number of disadvantages:

- Due to high temperature, the properties of the metal change.

- In order for the welding units to be strong, a highly qualified welder is required .

- Welding increases the rigidity of the structure , thereby increasing the likelihood of violating its integrity when pouring concrete.

Knitting is the most effective method , although it takes more time. Knitting is done with wire using pliers and a special hook.

How to knit reinforced mesh in a trench

Working in a trench is more difficult, so you need to plan everything ahead of time. Special devices or ordinary stones are placed at the bottom of the trench at a height of at least 5 centimeters in increments of the width of the mesh. The stones are laid out with longitudinal rods, and horizontal struts are tied. Until the rods are in the desired position, a second person holds their ends.

The reinforcement is knitted with a step between spacers of 50 cm wide. We install the pegs and begin to knit the monolithic structure. This is done on all straight sections. Parts of the frame should not touch the formwork; they should be at a distance of several centimeters from the formwork.

Then the corners are knitted using one of several existing methods. It is imperative to maintain the length of the overlaps, with the installation of vertical rods. Rods are often used here with a larger diameter, increasing the strength of the material. Upon completion of the binding, the concrete solution is poured in one go, covered with polyethylene, and during the drying process, it is periodically watered with water by spraying.

Installation diagram

Reinforcement of a strip foundation is usually done using a metal reinforcement frame assembled by welding or tied with special soft steel wire.

The working rods are installed in a horizontal position in such a way that in cross-section they form a rectangle with sides 10 cm smaller than the width and height of the concrete strip.

This ratio ensures the depth of immersion of the rods in concrete, at which the load-bearing capacity is sufficiently high, but the material is reliably protected from corrosion. Vertical reinforcement serves to fix the load-bearing rods in the desired position during pouring and hardening of concrete.

Both of these processes cause significant loads, so the quality of the reinforcement depends on the strength of the connection.

Photo of the drawing:

Welding fittings for reinforcement

In most joints, it is better to use knitting instead of welding - the finished structure will be more durable. Welding is possible only if you have a machine and extensive experience, exclusively on straight sections.

In order for the foundation to be truly reliable, it is also necessary to take care of the correct execution of the excavation work under the tape, arranging several layers of materials (not only for the base and top of the foundation, but also for filling).

Practical advice

In places where there is no heavy load, you can select reinforcement in favor of bars of smaller diameter. If strength does not suffer from this, but it is possible to reduce the cost of work, this option is allowed. Deciding what diameter of reinforcement to use in your work should take into account two parameters: ensuring sufficient strength and the cost of work, choosing the optimal price-quality ratio. In some places, the use of thick reinforcement is simply not relevant, but purchasing more expensive material will significantly increase the cost of the entire construction.

The layout of the frame in the formwork must be level. Before laying the structure, it is necessary to carefully check all dimensions to exclude distortions, deformations, and non-compliance with parameters.

Video reinforcement of shallow monolithic strip foundations

And another video:

Basic rules of reinforcement

From a strength point of view, the optimal way would be to place the reinforcement cage externally.

But in practice this is impossible for a number of reasons, the main ones being:

- The metal's tendency to corrode.

- It is impossible to install the frame on long or submerged blocks.

- The surface must be flat and ready for the attachment of other building elements.

For these and other reasons, internal reinforcement is used, which protects the metal from corrosion and solves a number of other issues. The disadvantage is the need to perform many actions necessary only to fix the reinforcement in a stationary state until the solution hardens.

This means excessive consumption of material, irrational labor investments, and waste of time. But there are no other reinforcement options; the technique used has been tested for many decades and has shown its reliability and effectiveness.