Types of furnaces by materials

The structures are made of brick and metal. Both materials have pros and cons.

Brick

Brick steam room stoves are a traditional solution. Many owners of private baths are now more inclined towards factory-made products - it’s easier and faster. But professional stove makers recommend not to deviate from traditions.

Such structures are massive. Weight can reach a ton or more. A full-fledged unit of this type cannot be placed in a small steam room. But mini-structures, although they are less powerful, are quite accessible to owners of small buildings.

Advantages of brick options:

- good and long-lasting heat transfer – a heated structure can transfer heat for up to 8 hours;

- high degree of fire safety - you can steam in the bathhouse without fear for your health and life;

- soft heat - a brick stove for a small steam room perfectly warms the room and users, but the high temperature does not cause discomfort;

- possibility of heating a large area;

- Excellent decorative effect - design variations are endless.

- the need to construct a foundation is a consequence of considerable weight; small stoves do not need a powerful base;

- the need for a highly qualified stove maker - the technology for laying stoves is much more complex than conventional masonry;

- stove buildings eat up bath space; but there are options designed for vertical laying - the usable area is preserved;

- thermal inertia - such units melt within several hours; therefore, you need to prepare for bath procedures in advance;

- considerable cost – professional services are expensive; but, if you put it in with your own hands, the monetary disadvantage will turn into a temporary one - you can save money, but spend a lot of time.

Metal

Those for whom brick sauna stoves are not suitable can choose from a variety of metal variations. Such structures are divided into cast iron and steel.

Figure 3. Stylish cast iron heating design

- high heat transfer;

- anti-corrosion effect;

- no problems during long periods of downtime;

- a huge selection of models - powerful and beautiful.

- heavy weight; in this case, a foundation may also be required; the base does not have to be as strong as in the case of masonry, but the presence of a pedestal is recommended;

- poor amenability to processing - if there is a need to modify the unit, without certain tools it will be problematic or impossible to do this;

- intolerance to sudden temperature fluctuations;

- considerable cost.

Now about the features of steel models.

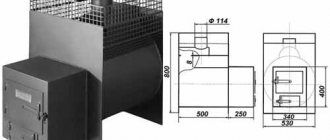

Figure 4. Homemade steel model for a bathhouse

- ease of installation;

- no need for a foundation;

- the possibility of producing handicraft options;

- fast heating;

- simplicity of the firebox;

- space saving;

- availability;

- a large number of factory models.

- shorter service life than cast iron modifications;

- relatively fast cooling;

- low degree of fire safety;

- low power; one medium unit is enough to heat a small steam room, but for heating large saunas it is recommended to install several stoves;

- poor protection against thermal shock - shielding is required to protect against the negative effects of infrared rays.

Among steel models, products made of chrome steel are very popular. Their main advantage is that the burning of oxygen in the steam room is minimized.

The simplest version of a metal structure is a potbelly stove. If you have the funds and/or the desire to build a better unit, it is better to ignore the potbelly stove. But with a modest budget and lack of qualifications, this is an excellent option.

Which stove is best for a private bath? The answer depends on capabilities and needs. The brick option will be preferable if there is no need for prompt kindling. The metal solution is suitable for those who do not want to deal with the hassle of construction or want to quickly prepare a steam room.

Advice! When choosing a stove, you need to evaluate and analyze a large number of parameters. Only in this way will the use of the bathhouse bring the greatest benefit and pleasure.

Furnaces with heat exchanger

A stove for a home bath with a water heat exchanger is a solution for buildings that do not have a hot water supply system or the ability to heat water using electricity. The purpose of the heat exchanger is to heat the water and “transfer” it to the hydraulic tank and/or radiators. It’s very convenient - both the sauna and the water are heated. Everything is rational, the efficiency of the heating design is maximum.

Figure 5. Operating principle of a furnace heat exchanger

The task of the element is to heat not only the water in the shower. Circulating through the pipes, the water simultaneously heats the room - additionally the main room or the dressing room, if the design features allow this.

There are two formats of heat exchangers:

- external is the chimney element; in this case, the pipe is surrounded by a sealed module;

- internal - an element mounted into the side of the stove or located at the bottom of the unit.

Regardless of the format of the furnace with a metal water tank, the heat exchangers are filled with liquid - ordinary water or antifreeze. The operating diagram of the heating element is simple - the heated liquid circulates through the pipes and tank, giving off heat to the room or acting as an independent useful component. Circulation occurs either naturally or through a pump.

Figure 6. Model with hydraulic tank

Recommendation! Experienced stove makers advise making a structure with pipes no more than three meters long. A large length significantly reduces the efficiency of the heat exchanger. This indicator is quite enough to equip a bathhouse with an autonomous water and heat supply system.

Stoves with open and closed heaters

Without a heater, the stove loses functionality and simply turns into a place for regular washing. Stones best accumulate and release heat, so the sauna stoves of our distant ancestors were equipped with a container with stones. There are two stove formats - with an open and closed heater.

Structures with exposed stones

Such stoves take up little space and heat the room quickly. After a maximum of an hour and a half (usually faster), the stones heat up to 300 degrees. This temperature is enough to envelop the steam room in a pleasant hot steam.

During operation, such stoves are maintained in a “bath” state by periodically adding water to the stones. For owners of small-sized steam rooms, this is an excellent option.

Structures with closed stones

Since the elements responsible for steam generation are hidden from users, this is reflected in a number of advantages of the option:

- the steam room does not heat up very quickly, but evenly - staying in such a room is more comfortable;

- the culminating temperature of the stones is 500 degrees; this is almost twice as high as in the opposite case;

- heat transfer from heated stones is very long - up to 4 hours; if you plan to stay in the steam room for a long time, one kindling is enough to maintain an acceptable temperature throughout the entire procedure;

- Despite the higher temperature, there is no overheating of the room.

Difficulties with covering the firebox

In the design, the second tier of the stove and the pipe rest on a bandage of fireclay and red brick. But due to the incomplete lining of the first tier, it was no longer possible to come up with an effective solution. It was possible to leave gaps between the fireclay bricks - that is, not to cover with mortar the edges of the bricks that hang inside the firebox on the sides and on top, where the red brick rests on them. It is the edges of the fireclay that will begin to deteriorate more significantly, and it was necessary to ensure their low mobility - approximately 1% of the size. There is an option to put fireclay on the cladding and asbestos fabric. The fireclay lid should also not be suspended from metal. Covering a firebox is a complex task that requires careful thought.

Exposed stones in the heater create another problem: they will need to be heated until the soot burns out.

The idea of quickly heating a room is good for a summer residence, but for permanent residence another factor is much more important - the heat capacity of the stove device.

Furnace power

For each bath, the stove power must be individual. The main mistake is the desire to choose a design that is too powerful. But choosing a “weak” unit will not lead to anything good.

Figure 9. Oven with optimal power

Excess power means hot air and stones that cannot heat up. Being cold, the stones have no meaning for the steam room. Otherwise, the heating equipment will not last long - in an effort to heat the room to an acceptable temperature, the stove will wear out.

The required power of the unit is determined based on the volume of the steam room. The calculations are not very complicated. To find out the parameters that are suitable for a particular situation, you need to:

- find out the product of the dimensions of the room (height, width, length);

- find out the area of non-insulated areas of the steam room;

- add these areas and multiply the resulting number by a factor of 1.2;

- add up the volume of the room and the total area of open areas;

- multiply the result by 1.5 if the room has a glass door.

The final number will demonstrate the working volume of the room. The furnace power is directly determined based on the dependence: per 1 m 3 - 1 kW .

Type of heating oil

According to the type of fuel, heating structures are divided into:

Wood burning

This option is primarily for those whose bathhouse is located in an autonomous area, cut off from the power supply mains. Power outages are also a reason to think about a stove that is independent of the mains.

- firewood is fuel that you can stock up on without any problems; store-bought logs are relatively inexpensive, and if the site is located in a forest area, the fuel will be completely free;

- financial savings on connecting to the central power grid;

- the pleasant atmosphere created by burning logs;

- wide variety of models.

- longer heating time compared to options running on other fuels;

- the need for regular tossing of logs;

- the need for regular cleaning of the ash chamber.

Electrical

This is the most common option. The main disadvantage is dependence on the main power supply. Or relative high cost if electricity is “produced” autonomously. In addition, using an electric generator is not very convenient.

A secondary disadvantage is the lack of atmosphere inherent in wood heating. If the aesthetic component is not of great importance, this minus can be omitted.

- accessibility – there are models of different price categories;

- prompt and uniform heating of the room;

- a fairly high degree of fire safety;

- small sizes;

- no need for connecting pipes, cleaning chimney channels and other manipulations inherent in other options.

Gas

The fuel used is gas (cylinder or mains). The equipment includes a fuse and a thermostat.

On a note! Gas ovens are dangerous. It is recommended to purchase them at branded retail outlets. It is mandatory to check the technical passport - the heating unit must meet all necessary standards. By purchasing a stove externally, the buyer runs the risk of installing a low-quality product that could lead to trouble.

Advantages of gas equipment:

- financial savings;

- quick heating of the steam room;

- no need to monitor the condition of the fuel (which is important, for example, for wood-burning sauna stoves);

- small sizes; in other options there is a firebox and an ash pan that take up space; here these elements are not present - gas equipment can be installed even in a modest-sized steam room;

- possibility of comfortable temperature regulation.

- danger - you need to constantly monitor the technical condition of both the stove itself and the cylinders (if there is a cylinder version);

- the need to connect to the main gas pipeline or regularly purchase cylinders.

Combined

Such modifications are designed for two types of fuel. One of the popular combined options is a device that runs on wood and gas. Unlike a gas unit, it has a firebox for logs. At the same time, it is possible to connect to gas equipment.

The best universal heaters for a Russian bath

Universal stoves can run on both natural gas and wood. All you need to do to change the fuel type is to install or remove the injector. This is done in a matter of minutes. In fact, this is the most convenient option to use. If you just need to wash in the bathhouse, without sitting there over long conversations and drinking tea, just install a gas nozzle - and in a couple of tens of minutes the bathhouse is ready. But if you are planning a get-together, and the issue of aesthetics comes first, remove the burner and heat the stove with wood. Now you can admire the open flame and the indescribable smell of firewood. In this category you will find heater stoves exclusively from Russian manufacturers.

Additional criteria for choosing a sauna stove

Listed above are the main criteria that should be relied upon when choosing a design. In addition, one can proceed from other considerations.

Steam source

The most common (traditional) source of steam is heated stones to which water is supplied. But sometimes the amount of natural steam is not enough. Those who strive to create a real hot “fog” in the steam room are recommended to purchase and install a stove with a steam generator. With the help of the latter, you can be guaranteed to provide the room with an acceptable amount of “water” - light and dry.

Firebox location

According to this criterion, heating structures in the bathhouse are classified into ordinary and with an extended firebox. The latter option makes it possible to heat the steam room from the adjacent room. This makes bath procedures even safer and the bath atmosphere more comfortable.

Distinctive characteristics of the stove

Sauna stoves come in two types: with an open heater and a closed one. In the latter there is no direct access to the stones, since they are located in the chimneys. It is possible to achieve a comfortable temperature in the steam room if you have a brick stove with a closed heater. This type of construction is only necessary in a Russian bathhouse, since it places special demands on temperature and humidity, as well as steam quality. In such a room, at an air temperature of 60 degrees, the humidity should reach 50%. It is under these conditions that a special steam arises - light, transparent, saturated with tiny droplets of water.

A brick oven does not overheat the air, accumulating heat within itself, and the stones in a closed space are “washed” by the flame. Fire raises their temperature to 800–900 degrees. If you splash water on such stones, it instantly heats up to 100 degrees and turns into the necessary steam.

The steam door in such a furnace is installed above the level of the cobblestones and kept closed during combustion, otherwise the entire room will immediately fill with smoke. They open it before entering the steam room, which needs to be heated to a temperature of 50–60 degrees. To completely heat such a stove, it takes 3–4 hours, which increases fuel consumption.

For 6–8 hours, the stove does not require additional kindling, and you can take bath procedures the whole evening. This is convenient when there are many people who want to take a steam bath, and there may not be enough space for everyone at the same time.

Flaws

Since in a waste oil stove there is a partition between the stones and the fire, it will take more time to warm them up properly than in open-type models. This will lead to increased waste on fuel, which will be consumed much faster.

Owners who love the most aesthetic appearance may be disappointed when choosing stoves for a Russian bath, since such units are often built taking into account technical characteristics, and not external beauty, but this point is extremely individual.

The steam room will take much longer to warm up, which will delay the start of the procedure; in some situations, this drawback will cause inconvenience.

Choosing a stove

The heater is the main element of the bathhouse. And her choice must be approached with full responsibility. Brick stoves are called inertia stoves because they take a long time to heat up and then cool down. Metal products can heat up in half an hour and during the same period they will have time to overheat the steam room, which will be very difficult to be in.

Brick version

When choosing a heater, you need to determine for yourself the optimal time that you want to spend on lighting the stove.

A brick stove for a Russian bath with a closed heater comes in several varieties (depending on how the smoke leaves the stove):

If the chimney pipe is inserted directly into the firebox or heater, then this design is called direct-flow. It has low efficiency, since the heat is simply released into the atmosphere. The advantage of a direct-flow furnace is its ease of construction and maintenance.

In a stove with a smoke circulation system (channel), gases moving through vertical or horizontal channels give off heat to the heater. The disadvantage of such designs is that chimneys must be cleaned regularly so that the draft does not disappear. The walls of the chimney inside must be smooth, because soot will linger on any unevenness. With such forced smoke circulation, the heating of the furnace is uneven, which leads to the formation of cracks.

The bell-type stove is considered perfect: only the potbelly stove surpasses it in terms of speed of kindling. When building it, you do not need to calculate the height of the chimney pipe for good draft. In such a furnace, any fuel (even wet) is effectively burned to ash, which is very economical. At the same time, not only the room is heated, but also water (up to 170 liters) and stones.

This design is also called dome because the smoke, leaving the firebox, enters the bell (like an inverted glass over the firebox) and, giving off heat to the roof of the furnace, is cooled. A new portion of hot smoke displaces cool stove gases down and into the chimney. The cap itself can be made of any shape. The main thing is that there is a pipe to exhaust cold air. This type of heater is very easy to light even after a long break in use.

The difference between channel and bell-type stoves is that in the first design the smoke is drawn out, and in the second it is pushed out. Consequently, the smoke does not move as quickly, which is why the efficiency increases to 94%.

However, the dome stove also has its disadvantages. Only the upper part of the heater heats up well, and for maximum heating of the steam room, the heat needs to come from below. This drawback is eliminated by the design of two caps. If such a furnace is overheated, then the gases stop flowing under the dome: they immediately strive to escape into the chimney. Therefore, experience is required in regulating the air entering the firebox.

Metal stove: advantages and disadvantages

Such stoves with smoke circulation are rare; they are usually direct-flow. In fact, it is a box with a grate inside, separating the ash pan from the firebox. The metal can be different: either steel or cast iron alloy.

Brick heaters take longer to cool down, but take longer to warm up. Steel fireboxes heat up very quickly and cool down instantly. Therefore, cast iron is considered the golden mean, and its use for the manufacture of stoves is not only practical, but also profitable. Such a stove will last for 20–30 years.

Alloys have different properties

| Options | Characteristics | |

| Stainless steel is considered the best. | Steel, which has excellent resistance to corrosion and oxidation, contains approximately 17–19% chromium and 8–13% nickel. | Stainless steel is not afraid of external influences, but it also has a weak point in the design - these are seams that tear. |

| Cast iron. | It is a durable material, has excellent thermal conductivity: it heats up quickly and retains heat for a long time. | But if water gets on it in a hot state, then the cast iron becomes brittle. It is also very sensitive to mechanical shock. |

It is better to use metal stoves in small rooms. They do not require a foundation at the site of operation, and their installation is reduced to the removal of the chimney to the street. Metal conducts heat remarkably well, but practically does not accumulate it, which is why many people install combined stoves. The ability of a metal stove to retain heat is increased with the help of an internal lining (lining the inside of the heater with fireclay or simply refractory bricks), as well as an external lining with brick.

In addition, it is possible to have a screen and lining at the same time, which increases the combustion time. So if you need to warm up the steam room in half an hour, the lining will be unnecessary. But it has one advantage: it extends the service life of the furnace, because its body is subjected to lower temperature loads. Most often, the combined option is used when installing a cast-iron stove, which is covered with a brick screen to protect it from cracking in case of accidental exposure to cold water.

A metal stove warms up a steam room much faster than a brick structure. Within an hour the air temperature in it can be 100 degrees. However, experts say that this has nothing to do with a true bathhouse, since the walls continue to remain cold. A sauna stove must first heat the walls of the sauna, and only then the air in it. That's why even a metal stove needs to be heated within three hours. Brick cladding significantly increases the duration of heat transfer.

When choosing a stove for a bath, the desired heating time of the steam room, the quality of the steam, the duration of the procedures, and the area of the room are important.

Designs of sauna stoves: general points and differences for different types

So what is a stove? This is a fire built inside a container. But combustion is an oxidation reaction of fuel, therefore, it cannot occur without oxygen. Therefore, we will call a furnace that container through which, at least temporarily, with the dampers open, flowing air moves.

Traction

This movement is called "traction" and it occurs when there are inlet and outlet openings.

Of course, such a definition suffers from incompleteness, because it does not apply to electric heaters. In them, heating occurs due to the passage of current through a material with high resistance. This releases heat.

But let's return to furnaces, where heat is released due to a chemical reaction. The art of the stove maker is to skillfully vary the amount of incoming air and the amount of firewood in the stack, in order to achieve their uniform burning and maximum complete combustion .

What happens if the combustion is still ongoing, but the air is blocked? Instead of carbon dioxide, a dangerous monoxide will begin to form - carbon . But why block the pipe if it is so dangerous? — The draft is shut off so as not to let the stove cool down when the wood burns out, because heat flies into the chimney along with the air.

So, we know about the role of air. Let's look at a diagram of the simplest draft furnace. What must be present in it? Three things:

- inlet (air vent or firebox door);

- firebox (aka firebox);

- outlet (chimney).

The first division of stoves can be carried out according to the presence or absence of a blower : without it they are called “stoves with a blind hearth”. In this case, air is supplied through the open firebox door. Here's what both look like in cross-section:

Kamenka

Now let’s ask ourselves: what do all sauna stoves have , but the stoves that heat houses are missing? Of course, this is a heater . All sauna stoves, even electric ones, have a container in which the stones are stored. The stones themselves are used as batteries - they accumulate heat. This is necessary so that the high temperature in the steam room lasts longer. Their other function is to create light steam , but in this capacity they are needed only in a Russian bath.

There are two classifications of heaters according to different criteria: one takes into account contact with fire in the firebox, the second - contact with air.

If there are gaps between the firebox and the heater through which the flames lick the stones, then this is a flow-through heater .

If the barrier is blind, then the heater is called blind .

When the container with stones is inside the stove, it is a closed heater .

And if the stones are in sight - open .

In this regard, furnaces are classified as follows:

We build a stove with our own hands

Of course, you can buy a factory-made stove with a closed heater at an affordable price and of good quality, but for many true connoisseurs of the Russian bath it is important to make it yourself. Homemade stoves are made from red brick or sheet steel (pipes).

Laying a brick heater always starts from the base. The foundation is installed 50 cm below ground level. It is raised to floor level using a mortar of cement and sand in a ratio of 1:3 (hereinafter clay-sand mortar is used). After a day or two, the base of the stove needs to be protected from the effects of temperature changes by placing roofing felt on it. The first row of bricks is laid on it, and another piece of insulation is placed on top of it. This way, condensation will not penetrate into the brickwork, which means it will not destroy the stove.

Useful video

Not just diagrams, but also a description of the advantages and disadvantages of vertical and horizontal structures (not necessarily made of pipes). Plus interesting life hacks.

Even more diagrams, even more explanations about them. However, the main concern of the author of the video is that you get a stove for a real Russian bath. So sauna lovers don’t have to watch it).

+++

We hope that you have received some kind of holistic understanding of what a sauna stove is. Other things can only be learned from practice and experiment. Good luck to you!

What are the advantages of a closed heater?

Since the stones are closed, the active transfer of heat to the steam room is significantly reduced, this in turn results in several useful properties:

- the steam room space warms up slowly but evenly, which creates more comfortable conditions for steaming;

- the stones are heated to an equally high temperature (400-500 o C) and hold it for a long time;

- for the same reason, the steam room does not overheat.

Stones heated to a high temperature, after applying water to them, produce a large amount of steam. Water, falling on hot stones, turns into finely dispersed steam, which in turn overheats in a confined space and comes out through the open door in a ready-made state. This kind of steam is called moderately dry and hot or light .

A closed heater retains the temperature of the stones for a long time and can keep it high for up to 3-4 hours. This is convenient if you make a lot of visits to the steam room or steam in a large group

In general, it cannot be said that one type of stove is better than another . Each carries its own qualities and characteristics . Of course, for more professional and high-quality steam, a stove with a closed heater with a brick lining is suitable, but we must not forget about those who like higher temperatures.