Official website of the exclusive importer and distributor of METALOTERM chimneys in Russia

The only fireproof chimney pipes in the world are produced by the Dutch company Schiedel Metaloterm BV under the METALOTERM brand.

METALOTERM chimneys

Why do we have the right to proudly declare that Metalotherm chimneys are the right chimneys? EVERYONE needs to know this!

Buying a METALOTERM chimney is cheaper than not buying!

Metalotherm pipes (METALOTERM) are professional chimneys developed by ONTOP (Netherlands). This company has been well known to specialists for more than 50 years as a world leader in the production of ultra-reliable chimneys for marine shipbuilding, for equipment operating in difficult climatic and technological conditions (offshore oil and gas platforms and drilling sites, industrial facilities, mobile and stationary generator stations). Since 01.01.2020, Ontop BV has been part of the Schiedel Metaloterm BV group

All innovative technologies developed for industrial chimneys have been introduced into the production of smoke ducts for private housing construction .

| Go to the full catalog of chimneys | ||||

| Chimney sandwich | Metal chimneys | Corrugated pipes | Coaxial chimneys | Industrial pipes |

We all think about our safety and security. , METALOTERM chimney pipes equal . Real security is now available not only to owners of factories and ships :)!

What is important to remember when choosing

Not only its operational characteristics (for example, draft), but also the date of repair depend on which chimney system for a bathhouse you choose. The Schiedel company, being an expert in the development and production of modern chimney systems with 70 years of experience, advises to approach the choice comprehensively. To minimize all risks and troubles, it is convenient to evaluate options according to the following criteria:

- Durability of the design . The factor that ensures long-term trouble-free operation of the chimney is a material that can withstand heat and the destructive effects of condensate for a long time.

- Safety . The manufacturability of the chimney plays a primary role. And it consists of careful installation, precise geometry, and choice of thermal insulation. For a steel chimney system, the grade of steel and the quality (reliability) of the seams are important. Violation of installation technology often leads, for example, to the appearance of backdraft and smoke in the room.

Fireproof passage through the ceiling Source elmin.ru

- Availability . The opportunity to save money is a nice thing, but you need to understand that the cost depends on the quality of the raw materials and the manufacturing method. A budget price is a sign of artisanal technologies and cheap materials. Saving when purchasing leads to problems during operation, additional expenses and a reduction in service life.

- Installation features . They depend on the material and the method of exiting the pipe. Sometimes you need to think about strengthening the foundation.

- Subtleties of service . They are influenced by the pipe configuration, cross-sectional size, and the quality of the material inside the pipe.

Types of chimney pipes

Stove pipes and chimneys can be divided into several large groups depending on the material they are made of. So they can be made using brickwork, from metal pipes of various types, as well as from multilayer materials.

In addition, stove chimneys may differ in the way they are installed:

- Wall chimneys are mounted directly into the thickness of the walls of the building, external or internal. In this case, stoves and fireplaces can also be installed directly in the walls of buildings.

- Suspended chimneys are mounted on the external walls of buildings.

- There are also main chimneys. Such structures are mounted separately, next to the stove.

Criteria for choosing a chimney: configuration and diameter

The pipe is selected based on the volume of the steam room, that is, after the general layout and dimensions of the steam room become known. The main selection criteria are the pipe configuration and its diameter. The configuration is determined by the following parameters:

- The method of connecting the pipe to a sauna stove (to a fireplace, boiler) . For example, for a metal wood stove, there are usually two options: from behind (side) or from above. You will need an adapter for fixation. Our Permeter chimney system has three installation methods: floor, wall, mounted (on the firebox).

Installation of the pipe from above Source koffkindom.ru

- The method of bringing the pipe to the street . Output through the wall is limited to one hole. This solution will be technologically simpler, but less efficient in operation. A vertical (through the roof) chimney can boast better characteristics, but it is more difficult to install, since its path runs through at least one ceiling and roof. An additional plus is that you can install a “samovar” type water tank on the vertical chimney.

The productivity of the furnace is selected taking into account the volume of the steam room (1 kW of furnace power per 1 cubic meter of steam room). Consequently, the calculation of the diameter depends on the size of the room. According to the rules, for 1 kW of power (for a wood-burning stove) there must be at least 8 cm² of pipe cross-sectional area.

Knowing the minimum required cross-sectional area, you can use the formula for the area of a circle from the school course to calculate the diameter. The resulting value must be rounded up; in any case, the diameter should not be less than the outlet from the furnace to which the pipe is selected. There is an alternative way: the diameter can be selected according to the finished diagram; for this it is enough to know the power.

Methods for removing the pipe Source banipechi.by

Requirements for chimneys for stoves with a long-burning system

Chimney long-burning furnace requirements

The smoke removal system of long-burning units is considered a fire hazardous facility and is subject to state fire safety requirements. The design of such systems must comply with GOST R 51032.97. The technological parameters of boiler units and their auxiliary devices are specified in SNiP 41.01/2003.

The rules include the following requirements:

- The height of the pipe must be at least 500 cm from the boiler or, more precisely, its grate;

- the structure placed on a flat roof structure must rise above it at a distance of at least 100 cm;

- installation of the structure on pitched roofs is limited to a height of 50 cm, provided that it is located at a distance of up to 150 cm from the ridge;

- when located in the range of 150-300 cm to the ridge, the chimney is installed level or slightly below the roof ridge;

- when installed at a distance of more than 300 cm from the roof edge, the pipe is installed at an angle of no more than 10 degrees between the upper cut of the pipe and the roof ridge;

- For systems made of ceramic blocks, the arrangement of horizontal sections is prohibited; such a structure must have an exclusively vertical arrangement.

Specifics of choosing a chimney material for a bathhouse

The material for the chimney is selected taking into account the type of stove. In private baths, two types of wood-burning stoves are common:

- Brick . It is equipped with a chimney made of brick, metal or asbestos cement.

- Metal . It is best to remove smoke from it through a steel pipe with a layer of insulation (sandwich). Sometimes there are options made from asbestos cement; you can choose ceramics or glass.

It is better to discard asbestos immediately, since it has a porous structure and is not suitable for use in extreme conditions. On such a surface, the formation and accumulation of condensate increases, which, together with heating, leads to the destruction of the pipe. To reduce the risks of using asbestos cement pipes, it is thermally insulated and lined with bricks.

A chimney for a bathhouse is made of materials that are resistant to fire and conduct heat well. Often there are combined options, for example, a steel pipe lined with brick, or ceramics inside a metal shell.

External chimney made of stainless steel Source metall-sg.ru

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

Materials are used with different frequencies for the following reasons:

- Asbestos cement . Fiber-reinforced concrete does not corrode, but due to its porosity, it successfully accumulates condensate. It is chosen because of its low price, but it also comes with problems such as cracking, health hazards, and fire hazards. There are installation restrictions: the pipe cannot be mounted at an angle, and it is impossible to install an inspection.

- Brick . It is aesthetically pleasing, gives off heat for a long time, and lasts a long time. However, brick is used less and less because of its high cost: a foundation is needed for it, and the material must be fireproof. The disadvantages include difficulties in finding an experienced mason, installation time, and operating features of square masonry (the traction is unstable, soot accumulates quickly).

- Made of black metal . An affordable option with good heat conductivity and significant disadvantages. The significant weight of the pipe makes installation difficult and sometimes requires the construction of a foundation. Rapid heating is dangerous for surrounding materials; a particular danger is rust, which quickly (sometimes within a couple of years) leads to through corrosion.

The weight of a brick chimney can reach a ton. Source wixstatic.com

A chimney in a bathhouse is in many ways similar to the design for a wood-burning fireplace - both are designed for periodic increases in temperature. However, it also has its own specifics. Since they prefer to use wood for the interior decoration of bathhouses, the chimney requires special reliability and high safety. The design of the pipe does not play any role, but its compact location becomes important. Systems made of steel and ceramics most fully meet all requirements.

Steel chimney

Metal pipes for removing combustion products have been used for a long time and willingly, and most modern baths are equipped with just such a design. The popularity is due to the following advantages of the product:

- Resistance to external factors . Steel does not deform during operation under the influence of temperature and atmospheric processes. The smooth inner surface resists corrosion processes well, as it prevents condensation from accumulating excessively, and soot settles slowly

- Safety . This is achieved by sealing the seams. Individual elements are welded or connected through socket joints, using sealant and clamps.

Steel chimney in a Finnish sauna Source finnsauna.fi

- Simple and quick installation . This is possible due to the light weight of the pipe. If the stove is made of steel, then you do not need a strong foundation.

- Long guaranteed service life . For example, the Permeter chimney system manufactured by our company has a 10-year warranty, subject to installation technology and careful operation.

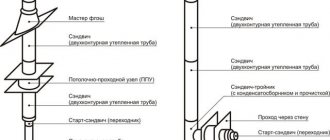

There are three types of smoke ducts; the first is single-walled. These are simple designs consisting of stacked parts of different diameters. They have an attractive price, and their feature, strong heating, can be used to produce hot water if you hang a tank. And yet, despite the benefits, heating cannot be considered a plus, so they strive to neutralize it.

The only way to do this is to use the second type - sandwich systems. They look like double-walled pipes with a heat-insulating layer of non-flammable fiber. Technical basalt fiber (it can be heated up to 600°C) or kaolin wool (its limit reaches 1200°C) is usually used as an insulation layer.

Exiting a sandwich pipe through the roof Source zhk-akvapolis.rf

Long-burning wood stoves for home use: pros and cons

Long-burning boiler design

A characteristic feature of such heating devices is the slow combustion of solid fuel. In fact, it smolders in the combustion chamber, and the volatile substances released from the fuel burn. This process is made possible by regulating the volume of air entering the combustion chamber. It is divided into 2 working compartments and is completely sealed. The volume of the combustion space is quite impressive, allowing you to add fuel that ensures the operation of the boiler from several hours to several days. The duration of work on 1 tab occurs due to the specifics of the combustion process. Due to the lack of oxygen, the fuel burns very slowly, while capturing new underlying layers.

The advantages of long-burning boilers include:

- Compactness and light weight lead to savings on the purchase and installation of the unit;

- the ability to regulate the intensity of fuel combustion;

- high level of efficiency for solid fuel boilers, efficiency 85 – 90%;

- modern design, due to which the unit is harmoniously integrated into any room;

- multifunctionality - the ability to work on two heating circuits - heating and hot water supply and be used for cooking when installed in a hob design;

- reliable structural components ensure long service life of the unit, many of which have a service life of at least 50 years;

- relatively low price;

- easy operation, since the unit is able to operate for a long time on 1 load of fuel.

However, like all boiler units, this type of boiler also has its disadvantages:

- The need for regular chimney cleaning;

- high requirements for wood moisture content;

- difficulty in setting oven modes;

- low level of automation, due to the inability to instantly stop the combustion process.

Video description

What you need to know when choosing a sandwich chimney in the following video:

Ceramic chimney

For stainless steel chimneys, an important factor for flawless operation is high-quality thermal insulation between the sandwich layers. If a stainless steel pipe does not suit you, you can consider an alternative - a ceramic chimney with the following advantages:

- Ceramics is a material that has increased strength and is insensitive to intense heat (up to 1000°C).

Construction of a ceramic pipe Source stroiremdoma.ru

- Energy efficiency . Ceramics accumulate heat well and release it slowly. This property is especially valuable in a bathhouse, but it will also be useful in a residential building, where it will allow you to warm up, for example, an attic.

- Versatility . A ceramic pipe is connected to any stoves, fireplaces or boilers, regardless of the type of fuel.

- Durability . Ceramics are not afraid of temperature changes and chemical corrosion; soot is almost not retained on smooth internal surfaces (which also means high fire safety). Maintenance of such pipes will be minimal.

The downside is the high cost - such a design can hardly be called budget; Besides this, there are other disadvantages:

- Complex (sometimes poorly thought out) installation ; some manufacturers do not guarantee reliable operation.

Installation of ceramic pipes Source sckovcheg.ru

Stainless steel - why are chimneys made of it?

Improvements in technology have made it possible to create new materials that have given impetus to the development of the industry. For this reason, choosing stainless steel for the chimney shell became as logical a decision as giving it a round shape.

But thin-walled stainless steel did not immediately begin to be used for chimneys. The development of metallurgy has made it possible to improve the characteristics of steel and give it the necessary properties. In the case of steel chimneys, the main requirement is heat resistance.

Flue gases heat up to 800–1000 °C. A steel chimney can withstand high temperatures, but it is also a good heat conductor. And since a hot pipe can cause a serious burn, they decided to cover it with a protective heat-insulating layer.

But the thermal insulation layer also requires protection from atmospheric and other external influences. Therefore, they began to make a metal casing on top of the insulation, but not from heat-resistant steel, but from less ordinary steel, which does not need to withstand extremely high temperatures.

Video description

About brick, ceramic and steel chimneys in the following video:

- Pipes are quite fragile , so they need a casing for protection. Often the consumer is offered a product without a box and insulation, which leads to additional costs.

- The quality of ceramics varies , making some ceramic chimneys vulnerable to damp environments and acidic condensation.

Most of the shortcomings are neutralized in the UNI ceramic chimney.

Schiedel specialists have developed a system designed for all types of heating devices. The chimney has the following advantages:

- Safety . UNI is a system with a minimum level of heating of the external surface. All elements of the system meet fire safety requirements, which is confirmed by the VNIIPO EMERCOM of Russia.

Features of the UNI chimney Source heatsystems.ru

- Quality . The UNI system is manufactured in accordance with all European and Russian requirements and internal standards. All ceramics for the Schiedel UNI system are produced in Germany, at the Schiedel plant.

- Equipment . The system is equipped with a decorative URATOP shell made of fiber concrete or a stone shell (made of expanded clay concrete blocks) with a front panel made of mineral fiber.

- Life time . All main components: ceramic pipe, insulation, stone shell have a guaranteed service life of 50 years.

The UNI ceramic chimney has been successfully sold in European countries since 1985, as evidenced by the title of sales leader; It has been sold on the Russian market since 2009. The system is used in low-rise and cottage construction, and it can be used both during the construction of new buildings and during reconstruction.

Method of fixing the ceramic system Source samstroy.com

External chimney along the facade of the building: advantages

An external chimney is a chimney whose main area is located on the street. Only a small horizontal section of pipe remains in the house, connected to the heating device. In the vast majority of cases, this method of organizing a smoke route is resorted to when the smoke channel was not provided at the beginning of the construction of the house. In order to avoid labor-intensive and costly processes of reconstruction and adaptation of internal structures to the smoke route, the pipe is simply brought outside.

Advantages of an external chimney:

- easy installation

- simple design

- higher fire safety

- no possibility of smoke and carbon monoxide entering the room

- good traction with the ability to adjust it

- saving useful living space

- the possibility of installing a smoke exhaust route at any stage of building a house, or after its completion

Disadvantages of an external chimney:

- hypothermia of the chimney in winter and difficulty in lighting the fireplace

- low draft in the cold season

- supercooling of flue gases, which provokes the formation of condensation on the internal walls of the pipe

- constant risks of damage to the chimney structure by snow and wind

- violation of the appearance of the building facade

- heat losses

- the need to use expensive fasteners due to the large loads placed on the smoke duct in bad weather

Briefly about the main thing

A high-quality chimney for a bathhouse is a significant contribution to the comfort and safety of your holiday. When choosing a chimney system, they are guided by the size of the bathhouse and the power of the stove; this helps determine its working diameter and configuration.

Brick, asbestos cement, ceramics and various types of metal are used as materials for the construction of a chimney. Stainless steel construction is most often used as it has the most attractive combination of properties. The use of ceramic systems, as they are the most durable, looks promising. The Schiedel company manufactures and sells steel and ceramic chimneys in full factory readiness. Thanks to the use of modern technologies, all of them are designed for long-term stable operation, taking into account the safety and quality requirements of modern housing construction.

Additionally,

the exhibition of houses “Low-Rise Country” expresses its sincere gratitude to the specialists for their assistance in creating the material.Schiedel is an expert in smoke extraction - a manufacturer and supplier of chimney, stove and ventilation solutions.

For more information, visit schiedel.com

Ratings 0

Read later

Fire safety technology

Installation rules are determined by SNiP 2 04 05-91U, NAPB A 01 001-2004, DBN B 2.5-20-200. According to them, the room under the heating unit must have an individual hose for removing combustion products, a separate ventilation system, and a sufficient level of natural and artificial lighting. The firebox must be located at a certain distance from walls and passages. It is important to make the floors fireproof; it is better if the supply of coal or firewood does not exceed the volume designed for one shift.

Only masters can take into account all these and many other points. Therefore, it is better to entrust the connection of a solid fuel boiler to the chimney and commissioning of the heating system to specialists. And in addition to this advice, we attach several more interesting thematic videos: