- Label information

- Elements of smoke exhaust systems

- Types of installation

To prevent carbon monoxide from accumulating in the steam room, it is necessary to consider smoke removal for the bath complex during the construction stage. Correctly selected and installed chimneys determine the level of comfort in the steam room even more than the structure itself. In this article we will tell you which pipe is best for a stove chimney in a bathhouse and what to look for when choosing materials and installation method.

Which one to choose - main criteria

First, let's identify important indicators that you should pay attention to in order to avoid surprises in the future:

- The affordability of the price consists of the cost of raw materials and manufacturing method. Savings shorten service life, and artisanal, outdated production technologies create maintenance problems in the future.

- Possibility of replacing chimney elements without significant expenses. Thus, the modular type is easy to assemble, replace, and adapt to different architectural features of buildings.

- The ease of installation of a smoke exhaust structure depends on the material and method of pipe outlet. In some cases, additional construction of a reinforced foundation is necessary.

- The ease of maintenance of the chimney depends on the internal surface and cross-sectional design. The fewer obstacles the flue gases encounter on their path, the less soot will settle in the “dead zones.”

- Durability depends on the ability to withstand negative influences for a long time: condensation and high temperatures.

- The safety of the chimney is determined primarily by the production technology: the accuracy of the product geometry and the reliability of the seams. As well as the choice of steel and thermal insulation material and pipe installation. If installed incorrectly, problems such as back draft and smoke in the room often arise. Some varieties pose a health hazard because they release toxic substances when heated and are easily destroyed at high temperatures.

Types of chimneys in a bathhouse depending on the material

Let's analyze the advantages and disadvantages of the most well-known options.

Asbestos cement pipe

Asbestos cement is fiber reinforced concrete. Popular due to its prevalence, low price and ease of installation. Although it does not corrode, it has a porous structure and accumulates condensation. This further leads to the formation of cracks and fire hazards.

Let's note other disadvantages:

- It is possible to mount the product only at a right angle; it will not be possible to do it at an angle.

- At temperatures above 300°, asbestos becomes brittle, cracks may occur, and chemical compounds hazardous to health are formed.

- Rough pipe walls accumulate soot, which is highly flammable. Absorbs condensation, accumulating an unpleasant odor.

- The small bore diameter increases the resistance to the smoke flow, which weakens the draft.

- Impossibility of placing an inspection hole.

Black metal chimney

This is an affordable product that will cost you approximately 80% less than using masonry. There are such nuances:

- Large mass. This complicates the installation process and also makes it necessary to build a foundation.

- They conduct heat very well and heat up quickly. This is dangerous if there are substances nearby that tend to ignite quickly. It is especially worth taking care of insulation if the duct passes through the attic, ceilings and roof.

- Moist smoke, high temperature, snow and rain outside, and cyclical operation of the heating device reduce the service life. Rust forms very quickly; within a year, through corrosion damages the chimney and leads to a fire hazard.

- The absence of an inspection hole makes it difficult to remove soot.

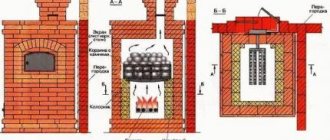

Brick chimney

A common solution for organizing smoke removal. The time it takes to manufacture a furnace duct by professional masons is determined by the complexity of arranging smoke exhaust structures with cleaning hatches and hogs. Due to the high mass of the product, it is necessary to build a foundation. The rectangular cross-section makes it difficult for a uniform flow of flue gases, which is noticeable in windy weather due to a drop in draft. The very rough surface of the pipe leads to the rapid accumulation of soot. Combustion products must be cleaned regularly to prevent fire.

Advantages:

- Due to the high heat capacity of the brick (880 J/kg), C gives off heat for a long time.

- Beautiful appearance.

- Long service life.

- The external environment, including wind, does not cause significant damage.

But there are also disadvantages:

- Expensive. The standard stainless steel model will cost less (see price list), but will perform the same functions.

- Duration of installation - each layer must dry before applying the next.

- If you took recycled or low-quality, cheap material, then rapid destruction may begin under the influence of changes in temperature and humidity.

- Traction is disrupted: it goes in the opposite direction or stops. This is explained by the presence of swirls in the square masonry.

Over time, gaps form in such a smoke exhaust system and carbon monoxide leaks. In conditions of condensate accumulation, such a chimney does not last very long, and it can also become damp and moldy. Therefore, it is better to sleeve it to improve performance. This operation consists of placing a stainless steel product in a rectangular section of the smoke exhaust duct.

Ceramic chimneys

Ceramics is a very durable material that can withstand high temperatures and has a number of significant advantages:

- It is energy efficient, retains heat for a long time and cools slowly, which allows you to warm up the nearest wall or attic space.

- It is universal, does not depend on the type of fuel of the stoves and can be connected to fireplaces, stoves or boilers of any type.

- Ceramics do not deteriorate under the influence of temperature changes up to 1000°.

- Durable.

- It is fireproof, since the inside of the pipe is smooth - soot will not accumulate on it.

With all the pros, there are also cons:

- High cost of construction compared to others.

- These chimneys are susceptible to corrosion due to exposure to aggressive environments.

- Difficult installation: Due to the heavy weight, additional mounting parts and foundation are required. Installation is difficult in an already constructed house.

- Special restrictions during installation: turns and bends of the channel are allowed as a last resort. At the same time, manufacturers often do not include turning elements in their warehouse program. And those that exist do not guarantee the reliability of the system. Moreover, some manufacturers recommend passing such areas with a stainless steel sandwich.

- Fragility: If you do not install a casing for protection, exposure to strong winds or mechanical damage will lead to cracking of the pipe. Very often, the consumer is offered not an independent product, but a ceramic sleeve, which must be covered with additional structures such as a box and insulation. All this requires additional costs.

- Another important detail of ceramic chimneys: they are made from various materials. It can be clay or volcanic pumice. Each of them behaves differently in a humid environment, hence the resistance to acid condensation will differ.

- Low maintainability: the tee is the most vulnerable part; if any element fails, replacement inside the shaft is impossible or extremely difficult.

- Installation plans are often not fully thought out. It will be very difficult for a non-professional to perform it correctly. And installation by craftsmen is expensive.

- The option made of ceramic blocks has a number of difficulties in joining and filling voids with mortar. This raises difficulties with controlling the filling of seams and the tightness of the system.

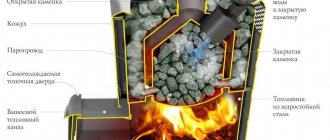

Stainless steel chimney

Our production

Single wall chimneys

Double wall chimneys

Mounting elements

Most bath complexes - home or commercial - use this option. This is due to excellent resistance to atmospheric conditions, condensation virtually does not accumulate, and the installation will last for many years. The appearance fits well with any bathhouse exterior; the shiny surface is pleasing to the eye.

Single-wall chimneys are the simplest in design and consist of assembled elements from 80 to 300 mm in diameter, from which a chimney of any complexity is assembled. The socket system made of stainless steel makes it possible to achieve tightness at the joints, the absence of excessive soot sedimentation and ease of installation.

Double-wall pipes have a second name - sandwich. This is a modern method that involves double rings of different diameters, between which lies a layer of insulation made of non-flammable fiber. Technical basalt fiber (up to 600°) and kaolin wool (up to 1200°) are recommended for use.

Advantages:

- Simplified installation: the weight of the product is light, there is no need to build a powerful foundation if the stove is also made of steel. It is not necessary to start installation right away; you can leave it for the last stage of construction work. Even a person who does not specialize in this can install the structure.

- Durability: No cracking, no deformation, stable corrosion resistance. The guaranteed service life is at least 10 years, and with proper installation and careful operation – more.

- Ease of maintenance: the inside of the pipe is smooth, so soot does not actually accumulate on the walls. Cleaning should be carried out for preventive purposes no more than once every six months.

- Safety due to sealed seams. These are places where individual elements are welded and connected.

Where do unscrupulous manufacturers save money?

In conditions of handicraft production, it is impossible to achieve precise geometry of products, tightness of joints and a high service life of chimney systems. This is due to manufacturers saving on materials and the lack of an automated production line.

Cheap steel chimneys are obtained by using:

- Thin sheet steel less than 0.5 mm with a small chromium content of less than 13%. It quickly loses its properties, deforms and collapses under the influence of high temperatures. Perforation corrosion occurs in less than a year.

- Construction mineral wool (up to 300°) instead of technical wool (up to 600°). The insulation is stuffed by hand and crumbles over time. The pipe heats up unevenly and becomes deformed.

- Old equipment for rolling sheets. In this case, the exact geometry of the products is not ensured.

- Welding occurs with an overlap or a mechanical connection in a lock; the high temperature causes the seam to separate.

- Zigging method for connecting parts. Soot accumulates at the joints, making cleaning difficult.

Organization of passage through the roof

The most critical stage of installation is the passage through the roof. After all, cutting a hole in the roof of the steam room can disrupt the hydro- and thermal insulation of the roofing pie, resulting in leaks and destruction of the rafters of the building. Following these recommendations will help you make the right passage through the roof:

- The hole on the roof must be designed in such a way that the distance between its walls and the pipe is about 10-13 cm.

- Make a wooden box on the roof in the place where you plan to install the chimney.

- Fill the entire space that separates the chimney from the inner duct with non-combustible material. In this case, stone wool is suitable.

- Press the waterproofing layer with sheathing bars.

For proper waterproofing, small cracks in the roof can be sealed with silicone-based sealant. Larger cracks can be sealed by installing a special element - a passage, which is located at the point of exit through the roof.

Chimney passage through the roof

The roof passage is an apron-cap, which consists of a steel base and a rubber tip.

The passage is put on the pipe and securely fixed to the roof. Too much effort when shrinking the apron onto the pipe is not required; it can break the tightness of the connection and cause a roof leak.

Types of smoke exhaust structures

We provide a summary table in which we briefly summarized the options discussed above.

| Type | Type of heating device |

| Asbestos | A gas boiler |

| Made of black metal | Heating and sauna stoves |

| Brick | Fireplace and heating stove |

| Ceramic | Solid fuel boiler, heating stove or fireplace |

| Stainless steel | Fireplace, solid fuel or gas boiler, heating and sauna stove. |

Choosing the right chimney for a bath

Let's consider the points that should be key when choosing a product.

Label information

Wanting to save money, manufacturers use steel of insufficient thickness that is not intended for use in the required conditions.

The consumer must have an address where he can contact regarding the quality of pipes. If a manufacturer avoids disclosing the steel grade, does not provide fire safety certificates, and does not indicate its contact information, then the product is most likely of low quality.

Composition and grade of steel

To reduce the cost of production, in most cases, steel with an 11% chromium content AISI 409 is used. When exposed to rain, snow and condensation, the material quickly becomes unusable due to through corrosion within a year.

Ferrum's high-quality products are made from heat-resistant AISI 430 stainless steel with a mirror surface. This brand has a low carbon content and a high chromium content of 17%, which ensures its resistance to high temperatures and durability.

Connection Features

To produce pipes from sheet steel, lock joints or lap welding are often used. The seam joint is the most vulnerable place for corrosion. Argon arc spot or seam welding destroys the steel structure by burning out alloying elements. When exposed to high temperatures, the seam opens.

The thinnest, but at the same time the most durable connection is obtained using laser welding, which guarantees the following advantages:

- High production speed of 5 mm/sec.

- The combination of a large seam depth with its small width.

- High-quality welding even in hard-to-reach parts of the product.

- No geometry violations even for the smallest structural elements. The size of temperature deformations is 3-5 times less than with arc welding.

- Uniformity of the seam in composition with the main part. This protects the welded joint from corrosion.

- The strength of the joints is 260 percent higher than after the burner.

How to choose the type and method of filling a chimney insulation for a bathhouse

Pipe production in a garage does not provide the proper level of product control. Manual stuffing with materials insufficient in heat resistance (building basalt fiber) in the future leads to the insulation rolling down with the formation of air pockets. All this interferes with normal operation.

The Ferrum automatic insulation filling line allows you to produce products with verified alignment and adherence to accuracy standards for weight and size.

The use of technical basalt wool, which can withstand temperatures of 600°, provides the required level of heat resistance of the system and its durability; the thermal insulation does not crumble over time and retains its original density.

Package

Many pipe manufacturers do not care about product packaging, delivering damaged goods to consumers. Products without packaging may become deformed during transportation, which leads to dents, scratches, and moisture penetration into the thermal insulation layer of the chimney.

Packaging in Ferrum shipping corrugated cardboard preserves the appearance of the product without scratches and protects the thermal insulation from exposure to the external environment.

Video description

This video contains complete information about AVT chimneys, which are a product of such joint production:

Among similar products, it is worth noting the products of such joint ventures as:

- Shidel;

- Wolfshäuer;

- Ecoosmosis;

- Hymen.

Due to the fact that insulating elements and external blocks are produced locally and do not require transport and customs costs, the cost of chimneys of these brands is lower than that of completely European ones. But if you prefer completely imported products, then they are represented on our market by the following companies:

- Tona (Germany);

- Marshal (Czech Republic);

- Effe 2 (Italy).

Popular device circuits

When choosing steel, metal thickness and insulation, we recommend focusing on the type of fuel you plan to use. The height depends on the power of the heating device and the diameter of the heating device.

For sauna stoves operating on solid fuel, we recommend using steel with a thickness of 0.8 mm.

To assemble a smoke exhaust system of any complexity, Ferrum has provided a bell-shaped design for assembling the structure. It consists of a hermetically sealed connection of two elements into one due to mounting extensions at the ends. The sockets are produced by cold forming of high-quality low-carbon steel while maintaining the plasticity of the materials during manufacturing. The alternative crimping technology does not provide a tight seal and leads to the accumulation of soot at the joints and creates difficulties during cleaning.

Elements of smoke exhaust systems

Required parts during assembly: boiler adapter, single-wall meter chimney, damper, start sandwich, sandwich pipes, polyurethane foam, roof trim and cap, as well as clamps.

The sandwich is the main element of the system for removing flue gases in straight sections. It consists of two pipes nested inside each other, between which thermal insulation is placed. This design has the following advantages:

- extremely low amount of condensation;

- soot practically does not accumulate;

- higher fireproof properties compared to single-wall chimneys.

This option is not connected directly from the furnace, as this could cause the pipe to burn out.

The boiler adapter is the starting pipe component of the future chimney. It is necessary for condensate assembly, as it reorients the turn during installation.

The gate blocks the flow of flue gases if necessary, representing a valve with holes to prevent combustion. The start sandwich is an intermediate element in the transition from single-wall to double-wall construction.

A ceiling-passage assembly (CPU) with mineralite is a mandatory element when maintaining fire safety at the point of passage through roof and ceiling slabs. PPU contains fireproof insulation material, an air layer and an area for placing an additional layer of thermal insulation.

The groove on the roof insulates the chimney from rain and snow. The increased rigidity of Ferrum structures will protect during snow melting, preventing leaks.

Clamps are used to fix the chimney relative to the installation plane. Steel fasteners are needed to position the system so that it does not rest on the stove or fireplace.

The role of the tee in the smoke exhaust system is to change the direction of the smoke channel, drain condensate downwards using a condensate drain and facilitate maintenance. Ferrum tees have sealed joints obtained through laser welding and the use of cold metal drawing. There are designs at 90° and 135°.

When assembling a chimney for a bathhouse, we suggest focusing on the Ferrum assembly diagram.

You can make a more accurate selection in the Constructor section, which in real time allows you to completely assemble the device taking into account the size of your bathhouse.

Briefly about the main thing

The main questions when choosing a pipe for a bathhouse are which one is better, safer, more practical, cheaper, more durable. Each owner has his own requirements, so their choice may vary. First you need to decide where the chimney will be installed - inside or outside, and then select it based on the material it is made of. The most practical and durable option is ceramics, but it is also the most expensive. The cheapest pipe is made of ferrous metal, but it is susceptible to corrosion. The optimal solution is a modular chimney made from a sandwich pipe. Regardless of the type of pipe chosen, it is necessary to calculate its diameter and length and select component materials for installation and insulation.

Source

Assembly Features

There are two methods for collecting smoke exhaust system elements. They differ in the placement of the lower and upper parts.

For single-wall chimneys, when assembled “by condensate”, the upper end is inserted into the lower end. For sandwich-insulated structures, this rule applies to internal assembly. The outer part is collected “by smoke”.

Ignoring the formation of moisture leads to disastrous consequences. Condensate, mixing with soot, forms acids that corrode the surface of the pipe.

Types of installation

Installation can take place on brackets through the wall or straight through the roof.

In the first case, the entire system is carried into the wall, and then rises, adjacent to the bathhouse, but without passing through it. This looks more aesthetically pleasing, and has the following advantages:

- the free space of the steam room is not used;

- there is no risk of getting burned on steel or stone;

- less chance of fire;

- It’s easier - you don’t have to make a hole through the entire attic.

- cases of smoke are easier to detect, as well as to track the general condition.

But at the same time:

- heat loss increases, since steam actually immediately enters the outside;

- the installation itself is more difficult due to the need to comply with the dimensions of the connection between the hole in the wall and the parts of the product;

- The heating of the pipe is greater due to the fact that the gases escape in the horizontal direction. With this arrangement, the resistance of the flue gases when moving through the channel increases;

- In terms of the number of elements, this option is 10% more expensive than the usual one.

When installing smoke exhaust systems in a straight line through the roof, the chimney is located straight, without bends, it departs from the boiler and goes upward, where it crosses the ceiling and exits on the back side of the roof. Advantages of such a connection:

- Stable draft due to the location of the chimney closer to the roof ridge.

- The condensate container is kept warm, so its cleaning pocket is dry and clean. This extends the service life.

- Cold bridges do not form in the walls, and thermal insulation is not compromised.

- The stability of the smoke exhaust duct is higher due to the fastenings to the roof. The fasteners themselves can be chosen cheaper than for the option on the facade.

- The aesthetics of the structure are not spoiled by side smoke outlets.

- Only a small part of the structure is located outside, which deteriorates over time from snow and rain. You can inspect and clean most of it without leaving the building.

- You can use non-insulated parts of the chimney that are located inside the bathhouse.

- This option is easier and 10% cheaper to install than when outputting through a wall.

- Flue gases go up, there is no obstacle to their exit. Heating is less than with a horizontal connection, since the resistance to smoke flow is minimal.

However, there are also weaknesses:

- The probability of “missing” the occurrence of a fire is higher, since smoke occurs in the ceilings that are located in the attic and on the roof, and they are simply not visible until the fire appears.

- Heat loss through the roof. Tightness is restored when waterproofing is installed before coating.

- Reduction of usable area, since according to safety requirements there should be nothing around the stove pipe for a bath.

- Increased costs for changing the roof and ceiling of the steam room, in particular, after finishing the final finishing.

- If the integrity of the smoke exhaust structure is damaged, the bathhouse begins to smoke.

- Condensation leaks and accumulated soot spoil the appearance of the roof.

- Burns from heated parts are possible in emergency situations.

When deciding on the installation method, the following nuances must be taken into account:

- dimensions of the building - if it is very small, then it is logical to make an external structure;

- the steam room is built from scratch or in an old room - in the first case, you can immediately think about the issue of insulation;

- Do you need to heat adjacent rooms?

How to avoid problems

Even if the chimney installation is carried out correctly and it is operated according to all the rules, problems may arise, the most important of which is clogging of the pipe.

Along with the smoke, soot, soot, and grains of ash come out through it. Some of them gradually settle on the inner surface of the pipe, reducing its diameter and reducing draft.

If this is not dealt with, then over time the heat transfer of the stove will decrease, the load on the chimney will increase, which can lead to its premature wear. In addition, the resulting thick layer of soot can ignite and cause a fire.

You can identify a clogged pipe by the following signs:

- Smoke color. When the chimney is working normally, it is transparent, but if dark clouds appear, it’s time to clean the chimney.

- Flame color. His tongue should be light orange rather than bright red.

Rules for installing a sandwich chimney

Here are the general rules for self-installation:

- The chimney is installed less than 1.5 m from the ridge of a nearby building. In cases where it is higher than the roof level, additional installation clamps must be used.

- The elevation of the smoke exhaust structure above the flat roof must be at least 0.5 m.

- The total length of the gas exhaust system is at least 5 m. If this is not possible, then evacuation pumps are used to remove flue gases.

- The minimum permissible distance to the ceiling covering in a wooden bathhouse is 0.38 m.

The answer to the question of what type of chimney pipe should be for a stove in a bathhouse is a stainless steel set. To select high-quality elements for flue gas removal, check the grade of steel with a chromium content of more than 13%, the thickness of the products (optimally 0.8 mm), and the best welds in terms of tightness and durability - after laser welding. The recommended socket connection system is cold formed. Ferrum products meet all these criteria.

Bottom line

Despite the fact that a chimney for a bathhouse made of stainless steel is a more advanced design, the brick analogue does not lose its relevance to this day (also find out how to make a chimney for a bathhouse with your own hands in a country house). Which modification to choose should be based on existing circumstances and individual wishes. You can get more detailed information by watching the video in this article.

Did you like the article? Subscribe to our Yandex.Zen channel