Vesuvius producing furnaces, heat chambers, burners, and industrial complexes since 2004, and judging by the range of products, the experience and practice may be older. The catalog of sauna stoves consists of two impressive sets of steel and cast iron products. In partnership with the Litcom company, the products took part in specialized exhibitions in Moscow, which tells us about a certain level of the manufacturer.

At the moment, new models of stoves are appearing and this indicates what is happening further, the development process. There are materials online where customers complain about the product and even show a “video of cutting” a stove, criticizing the stated indicators. Subjectively, there is an incorrect interpretation of the characteristics of the product elements, in some cases, use under incorrect installation or conditions. However, no matter how much confidence the appearance and name of the manufacturer may inspire, you should always be convinced of the claimed qualities with your own eyes.

Video: Which stove to choose for a steam room

Vesuvius stove range

Actually, there are two model ranges: steel and cast iron stoves. The first includes 7 items:

- "Optimum";

- "Scythian";

- "Typhoon";

- "Rusich";

- "Lava";

- "Russian steam";

- "Premium".

The entire model range covers a wide range of steam room sizes - from a volume of 6 m3 to 40 m3. The characteristics of each series will be discussed in more detail below, but now we will present a list of names of cast iron sauna stoves:

- "Legend";

- "Hurricane".

Here the range of steam rooms is a little narrower: from 8 to 30 m3, as is the number of modifications. The fact is that cast iron products are significantly more expensive than steel products, which is why the demand for them is less. Which does not at all mean that the quality of the products is poor; at the moment, reviews of the Vesuvius brand are overwhelmingly good.

How to light a stove?

For complete kindling you need a “seed”. The stove is heated with the help of 4 narrow small logs, shavings/chips and paper (preferably newspaper - it flares up better). Kindling algorithm:

- Place a couple of logs parallel to each other on the grate; the distance between them is 10-15 cm;

- place crumpled paper between the firewood and sprinkle it with shavings or wood chips;

- Place two more logs diagonally on the bottom logs;

- Set the paper on fire on one or more sides.

It is not always possible to light wood the first time. This requires a certain skill. Liquid fuel must not be used as an aid. In extreme cases, dry alcohol can be used. But if the firewood is dry, then problems with kindling are minimal.

As soon as the flame flares up, you need to close the firebox door and then partially close the ash damper. After this, you can be guided by the sound - if there is a characteristic hum from the firebox, everything has been done correctly. If the sound is weak or absent, you will have to melt it again.

This is just the beginning - a wood stove needs regular refilling of logs. This also needs to be done wisely.

We suggest you familiarize yourself with: Chimney size for a brick stove

Overview of steel furnaces

The model range opens with the “Optimum” series, which is designed for heating a small steam room with a volume of 6 to 14 m3 and includes 2 modifications. The difference between them is that one stove is fired directly from the steam room, and the second from the adjacent room. The length of the remote firebox is 25 cm. The design of the heaters can be seen in the figure:

Despite its small dimensions (650 x 560 x 490), the Vesuvius “Optimum” stove is quite massive - 53 kg. The reason is the thickness of the metal from which the combustion chamber is welded; the diagram shows that it is 5 mm. In addition, a metal partition is installed inside the firebox, which prevents the direct passage of combustion products into the chimney. This increases the heat transfer of the chamber, which is surrounded on all sides by a ventilated open heater.

The rest of the design is classic; a grate is built into the bottom of the firebox, and under it there is a drawer for the ash pan. With its help, the combustion air supply is controlled. These Vesuvius bath stoves are equipped only with a blind loading door and are considered a budget option.

Owner reviews

As often happens, some owners speak positively about the product, and some speak negatively. The video below shows how a dissatisfied customer saws apart a new Vesuvius-16 Skif stove to prove that the steel thickness is less than stated in the instruction manual.

Apparently, adjustments have been made to the description of the stoves, here are the latest excerpts from the manufacturer’s website:

“When designing the Skif sauna stove, the designers of our plant found a unique and at the same time simple solution to create a sauna stove with high efficiency. Sauna stoves of the Skif model range are made of special structural steel. The thickness of the main elements of the firebox reaches 12 mm.”

It is stated in black and white that the thickness of the main elements of the firebox reaches 12 mm, but it is not entirely clear what is meant by “main elements”. We can assume that we are talking about the arch of the firebox.

Personally, after watching the video, what bothered us was not that the thickness of the steel was less than stated, but that some of the seams were not welded. This suggests that in the production of Vesuvius stoves there are problems with quality control (alas, this is typical for many domestic manufacturers).

Series "Skif"

The difference from “Optimum” here is expressed in the configuration of the partition, which forces the flue gases to transfer heat more efficiently, bending around it. In addition, the upper and rear walls of the combustion chamber are reinforced; the metal thickness there reaches 8 mm. At the same time, as planned by the designers, the side walls “lost weight” to 4 mm. By the way, stainless steel is not used in the manufacture of Vesuvius stoves, hence the reasonable price of the products. The structure of the Skif furnace is shown in the diagram:

From the diagram it is noticeable that the structure of the ash pan and heater remained the same: respectively, a drawer and a cylindrical mesh for holding stones. The series includes 5 lines of stoves, each of which is designed for a specific steam room size, ranging from 6 m3 to a volume of 40 m3.

Bath heaters Vesuvius "Skif" cover the widest range of thermal powers, the series includes the largest number of stoves - 36.

Wood-burning stoves "Skif" are equipped with an expanded package of options. This includes a hanging tank for heating water with a capacity of 30 liters, heat-resistant and panoramic glass instead of a blank loading door. Thanks to the combustion chamber pushed forward, it is possible to heat it both directly from the steam room and while in an adjacent room.

Installation features

Installation diagram

The brand recommends involving specialists in the installation of equipment. If the owners have the skills or tools, self-installation is allowed. The process goes like this:

- Laying a red brick base to a height of 6 mm or a fireproof foundation made of 20 cm thick material.

- Removing the product from the wooden wall by 50 cm.

- Wall covering with metal sheet. In this case, the distance is reduced to 38 cm.

- Making a half-brick superstructure with preliminary cutting of the wire frame of the furnace.

The walls can be covered with slab apothecary bricks.

The manufacturer's instructions note the specifics of installation of a particular modification of the stove.

Legend Series

Installation work involves assembling the chimney taking into account the location of the rafters and load-bearing beams:

- Installation of ceiling trim in section. A hole 130 mm in diameter is made along the axis of the chimney with an angle of inclination along the corner of the roof.

- Fixation on the outlet pipe of a single-circuit, starting pipe or tank with sealing of the gap.

- Installation of further elements - tap through the boards with a mallet or hammer.

- Installing the throttle valve and putting the chimney on it. Passing the starting sandwich through the hole and organizing the support clamp.

- Laying heat-resistant heat-insulating material - basalt wool, mineral wool.

- Further assembly of the chimney using sandwich elements along the condensate line.

- Place a cone clamp on the chimney and tighten it further.

- Installation of the last sandwich and covering it with an umbrella-head.

After checking the strength, tightness of connections and draft, a test fire is carried out.

Sauna stoves

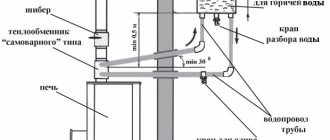

The equipment is located in the steam room, and the tank is located in the sink. For convenience, a samovar-type heat exchanger is used to heat the water. This increases the efficiency of the device and eliminates heat dissipation through the pipe.

Fireplace installation

The units are installed in rooms with good air flow. The optimal height of smoke channels is 600 cm. The pedestal is made of non-combustible materials. To remove ash, a flood zone is created from a sheet of metal 40 cm in front of the firebox and 10 cm on each side. The distance from the fireplace to the ceiling is from 1.2 m.

The Vesuvius line of stoves provides high-quality heating of the bath, is efficient and economical. The manufacturer produces cast iron models designed for long service life.

Typhoon Series

Under this name, 9 units are produced, adapted for heating rooms from 6 to 30 m3. The design of the Typhoon's fuel chamber and gas duct system does not shine with originality and almost completely replicates the Skif model. The difference lies in the shape of the heater, which has turned from cylindrical to rectangular. The heater is ventilated and also open on all sides.

The manufacturer declares that some elements of the stove that are most exposed to fire are made of 12 mm thick carbon structural steel. True, he does not indicate what these elements are. Otherwise, the metal remained the same - 4 mm on the side walls, 8 mm on the back and top. All stoves have a firebox with an external channel. The extension size is standard, 25 cm.

If we talk about options, the Vesuvius “Typhoon” stove boasts 2 types of viewing glasses:

- heat-resistant, built into a standard fuel door.

- panoramic, with dimensions 41 x 41 cm.

In modifications with sight glasses, it is possible to regulate the air supply to the firebox using a special damper. There is also an option to install a hanging tank for heating water.

Recommendations for use

The manufacturer of equipment for Vesuvius steam rooms prescribes recommendations for operating the device in the instructions for the models. You should familiarize yourself with them in advance and strictly follow them. This affects the service life of the device and the company’s warranty obligations. When working with company equipment, it is prohibited:

- Use peat, coke, gaseous and liquid materials as fuel. This does not comply with fire safety regulations. The combustion temperature may exceed that for which the device is designed.

- Firewood must not exceed the permissible dimensions of the firebox.

- Do not use the device if the tank is not filled with water.

- Install in residential areas for heating.

- The chimney can only be closed when the fire has completely gone out.

- Do not burn soot from the smoke duct.

- Make changes to the original design of the furnace.

Important! To prevent the destruction of cast iron, you should familiarize yourself with the rules for laying stones. You can water the stones for steam generation at a minimum interval of 5 minutes

If these simple requirements are met, the company undertakes to eliminate all defects during the entire warranty period or replace the device free of charge.

The quality of Vesuvius stoves depends on the model and compliance with operating rules. Skif class models are a budget option. They require careful handling and periodic maintenance. Cast iron stoves “Legend” are highly resistant to temperature changes. Let's consider the reviews.

I have a stove installed - a Vesuvius Legend fireplace made of cast iron. It's been standing for three years now. There were no changes in it during use. Once a year I paint the grille to prevent rust. Heat for a long time. There are no other complaints.

Kravtsov Ilya, 30 years old, Kamyshin.

I bought a Skif stove. It burned out after a year and a half of operation in two places.

Bondarenko Roman, 30 years old Nizhny Novgorod.

Vesuvius "Skif" 28. They provide a two-year guarantee. In the third year, three walls burned through. You can't lay it with bricks. The walls are warped by the waves. The far support burned out. The unit is only suitable for waste.

Problems with holes forming in the stove body may be due to improper placement of stones. A dense, mosaic distribution of stones without ventilation leads to the formation of holes in the walls of the body. The second cause of the problem is frequent watering of stones with water in order to create a steam cloud. The interval between watering should be five minutes. Otherwise, frequent changes in temperature and humidity lead to the destruction of the cast iron material.

How long the stove will last depends on the installation. Incorrect installation can reduce the service life of the system several times.

Series “Rusich”, “Lava”

These 2 series include 24 and 27 modifications, respectively, installed in steam rooms from 6 to 30 m3. The internal working part again remained unchanged, as did the thickness of the metal walls. But the rectangular or cylindrical heater here is open only at the top; on the sides it is fenced with a convection casing with grooves made for the passage of air.

“Rusich” or “Lava” is well suited for those people who cannot tolerate the direct heat emanating from the stove in the form of infrared radiation. The barrier in its path is the convection casing, and the heater is ventilated through it.

In fact, all furnaces have the same body (“Rusich” is rectangular, “Lava” is round). A variety of modifications is achieved through various configuration options, which include:

- an external channel for the firebox from the adjacent room;

- fireproof and panoramic glass.

According to company representatives, purchasing and installing a stove from one of these series will provide the fastest heating of the steam room, while the temperature of the heater can reach 350 °C. So the presence of an outer casing in the design is very useful here.

Recommendations for selection

To choose the optimal fireplace stove model, it is important to determine the following parameters:

- volume of heated room;

- installation location;

- functional load;

- heating mode.

So, for small premises (country houses, country buildings) with non-permanent residence, and, accordingly, periodic load of the fireplace, the basic version PK-01(270) for wall mounting or PK-01(220) for corner installation is sufficient.

If the fireplace will also be used for cooking, the PK-01(220) series is excluded due to the absence of a hob. The choice will fall on models PK-01(205) or PK-01(270) with a hob.

The PK-01(270) series is particularly reliable and is recommended for heavy loads and intensive use, therefore suitable for permanent homes.

The presence of partitions in the room prevents heat exchange. In this case, for heating efficiency, it is worth taking a closer look at models with an electric fan and a water circuit.

“Russian Steam” and “Premium” series

The somewhat elongated round shape of the Russian Steam heaters is due to changes in the internal structure. Here, directly above the combustion chamber and the secondary flue, there is an additional completely closed heater, which removes heat from the hot flue gases.

Thanks to this, its maximum temperature can reach 400 °C. Outside there is a second heater bounded by a powerful cylindrical mesh, which surrounds the firebox body on all sides. To fill the internal cavity with stones, a separate opening is provided in the upper part of the furnace.

The line includes only 5 modifications, providing heat to rooms with a volume of 14 to 30 m3. The package includes the same accessories as in previous series. They also became the basis for the development of premium-class stoves “Elite”.

This means that the Vesuvius “Skif” sauna stove was taken and the outside was decorated with decorative stone (talcomagnesite or green coil). For another modification, the basis was the “Russian Steam” unit; in total, under the name “Elite” there are 5 heaters for steam room volumes of 12-30 m3.

"Vesuvius" with open or closed heater: the choice is yours

Since the structure for laying stones is located outside, it should be understood that it is unable to provide steam with the humidity that the very concept of “Russian bath” in its classical interpretation implies. If you are a fan of a real Russian steam room, with its inherent humidity and high temperature, then consider purchasing models that have a closed heater. If you love the specifics of the Russian bathhouse, but you are still attracted by the appearance of an open heater, the appearance of the stones laid in it, then you will have to acquire additional devices and fixtures, examples of which we will describe below.

According to experts, in an open-type heater there are no conditions for the stones to heat up to a temperature level that would make the steam really light. If the furnace power is high enough, it provides good heating of the stones. However, since the stones are open, they quickly release their heat into the steam room. This state of affairs makes the bathhouse more similar not to a Russian, but to a Finnish dry-air sauna.

It is easy to pour water onto stones placed in an open heater, but the resulting steam turns out to be “heavy”. To provide the couple with the desired “lightness,” bath professionals lay tubes between the stones that go deep into the stone mass, and through them water or herbal infusions are supplied. Since the temperature of the stones located near the firebox is much higher, the steam they produce is drier. Rising through the layer of stones laid on top, the steam is additionally dried and becomes finely dispersed, i.e. it turns into that “light” steam that is typical for a Russian bath.

However, this improvement of the heater using tubes is far from ideal: a heated stove does not allow you to calmly strain water into the tubes laid for this purpose, and there is a high risk of getting burned by the escaping clouds of steam. The matter is complicated by the fact that initially the tubes are laid purely intuitively. If the laying result is unsatisfactory, the stones have to be re-laid in order to move the tubes inserted into their mass. Thus, this improvement can only result in additional hassle for those who like to steam.

In our opinion, stove models with a closed heater are the most suitable option for steam rooms, called Russian. However, greater convenience of their use is achieved provided that the open part of the heater can be closed and covered, which ensures regulation of heat transfer and heating of the stones themselves.

Cast iron stoves

Structurally, these units are almost identical to their steel “brothers”. A similar combustion chamber with an ash drawer, a two-pass smoke circulation and the presence of an open-type heater fenced with a mesh. The difference is that the firebox is a 12 mm thick cast iron with external ribs. They perform 2 functions: they give rigidity to the body and provide intense heat transfer.

The Vesuvius cast iron stove is produced in two names - “Legend” and “Hurricane”. Accordingly, modifications 11 and 3 are intended to serve steam rooms with a volume of 8–30 m3. The design is as varied as that of steel heaters - different types of glass, a remote tunnel and a tank for heating water for washing.