Before moving on to choosing an interior door leaf, you need to install the frame. Properly selected materials and correct installation significantly affect the performance characteristics of the door block. The box is a structural element that is the basis of the entire structure, so you cannot save on it. In addition, this may not be necessary due to slight fluctuations in prices for different types of products.

Massive emerald-colored door frame in a contemporary interior

In most cases, the part is already included in the door structure. This ensures unity of stylistic design and color scheme.

Height and width of the doorway

The most important characteristic.

Door sizes are selected to match the doorways. The generally accepted heights for a doorway are 2100 mm and 2400 mm. But the width varies from 700 mm to 1900 mm. Single-leaf (single-leaf) doors are installed in openings with a width of 700 mm to 1200 mm, and double-leaf (double-leaf) doors are installed in wider openings. There are also one and a half doors - these are doors with two leaves of different widths. The dimensions of arched doors are designed for openings of the same standards. The dimensions of interior doors are always indicated on the product packaging. The dimensions of the door frame should be approximately 30 mm smaller than the opening in both width and height. This is the gap necessary for the correct installation of the door - its fastening (wedging) in the opening, filling the seam with foam, sound and heat insulating materials, and carrying out adjustment work.

- 1 of 3

On the picture:

Half-leaf doors are installed in cases where one leaf is not enough for free passage, and the use of two leaves at once is inconvenient.

Basic structural elements

Interior doors are made of solid wood, MDF, plastic, glass, metal or a combination thereof. The canvas can be panel-based, filled with solid or porous materials, finished with decorative cladding or drawstring, that is, consisting entirely of stacked slats. The doors can open to the left or to the right (determined by the hand that opens the door towards itself).

Main structural elements of internal doors:

- box - a frame installed in the opening and rigidly fixed;

- leaf - the movable part of the door hung on hinges;

- overlap - a narthex, or quarter, serves to tightly adjoin the sash to the frame;

- lining - bars in frame doors located along the perimeter of the leaf;

- threshold - the protruding lower part of the box;

- extensions, platbands - decorative details for masking cracks and decorating the opening.

The moisture resistance of interior doors is average, since operating conditions are more gentle than those of entrance doors. If direct water ingress is possible (for example, in a bathtub or shower), it is recommended to install more moisture-resistant plastic doors.

Main parameters of the door block

Most manufacturers, when mass producing doors, frames, and trims, are guided by the standards accepted in a given country. They are reflected in GOSTs (GOST 6629-88) and building codes and regulations (SNiP). The standard is suitable for houses that are built based on these standards. But they are more of a general recommendation.

Drawing and sketch of the door frame

The problem of non-standard openings often arises during the reconstruction of old houses, especially with high ceiling heights, for example, in “Stalin” buildings. It will be necessary to either adjust the opening to the standards, or also order the doors individually.

Door marking according to GOST 475-2016

With all the variety of types, a unified designation system makes it possible to standardize products according to a number of basic characteristics. In accordance with the standard, all doors are classified:

- by purpose - for external H, internal, interior M and for bathrooms C;

- according to the opening method - swing left or right Rl and Rp, swing K, sliding R, folding S;

- by the number of canvases - single- or double-field, 1 and 2, respectively;

- according to the presence of glazing - solid G or glazed O;

- by type of threshold - without threshold PrB, with threshold Pr, with descending threshold Po.

All design features are reflected in the markings. For internal doors of residential and administrative buildings, symbols are used (from left to right):

- appointment;

- opening method;

- opening height, dm;

- opening width, dm;

- performance characteristics;

- design features;

- GOST number;

- Additional Information.

For example, a hinged interior block, single floor with right opening, for openings 21x9 dm, glazed without threshold, strength class MD1 will be designated as

DM 1 Rp 21x9 O PrB MD1 GOST 475-2016.

Door blocks for interior rooms and for bathrooms belong to the strength class Md1-Md3. This means that the blocks must withstand the standard static load in the plane and perpendicular to the canvas, as well as impacts with a soft and hard body of a certain force specified in GOST. The resistance to heat transfer and air permeation for interior doors is not regulated.

Opening for sliding built-in door

Sliding partitions have an attractive appearance. They can be used not only as an interior door. If you connect several doors into a single system, then with their help you can even separate one large room, making it two rooms isolated from each other.

But for the most part, a sliding door is installed in a doorway. For a door with a width of 60 to 90 cm, it is made single-leaf. If the canvas reaches 120 cm and higher, the design will be double-leaf. Moreover, each of them can be either different sizes, or completely symmetrical to the other.

There are no special GOST requirements for sliding systems. There is a general category that organizes the principles of system structure. It also displays opening standards for certain door leaf sizes.

The classification is based on design features:

- In compartment doors, a straight leaf moves along guides and moves along the wall. Smooth movement is ensured by rollers mounted on the canvas;

- The book-shaped design has two or three panels. When opening, they slide and fold;

- In the “Accordion” model, several narrow slats are connected to each other by hinges. When opened, they slide along a guide and assemble, as in the musical instrument from which they get their name;

- There are designs in which, when the door is opened, the sash moves into a special cassette.

Preference can be given to any option, but everything will depend on what opening is available. You should always leave a reserve, even if it is calculated for a 60-centimeter door. Therefore, before choosing the type of construction, it is necessary to accurately measure the existing opening. Sometimes you may be disappointed and instead of the desired “Accordion” or “Book” you will have to install a single-leaf model.

But sliding doors are also divided according to the method of moving the leaf. There are overhead models that move along a guide parallel to the wall, on one of its sides. There are also designs that are called built-in. There the canvas goes inside the cassette built into the wall.

Opening for overhead structure

In order to correctly measure the opening, you need to know in advance what kind of structure will be installed in it. Thus, if there is an overhead single-leaf door with standard dimensions of 600 × 2000 mm, then the opening should have the following dimensions - 680 × 2020 mm. It is necessary to leave technological gaps of 80 mm in width and 20 mm in height.

Please note that it is recommended to install the overhead structure only on a concrete or brick wall. Moreover, the length of the guide rail should be exactly twice the width of the door leaf. In our case it will be 1200 mm.

Opening for built-in model

The built-in sliding door cassette is installed inside a wall made of any material. These can be brick or wooden partitions. Walls made of foam concrete and even plasterboard structures. Moreover, there is no need for additional strengthening.

The width of the opening for a door with standard dimensions of 600×2000 mm should be 1350 mm. The width of a regular sash is double, and the technological gap is already 150 mm. The height of the opening should be 2100 mm. There is also an increased gap here, since the guide and rollers will have to be hidden. And also the door frame.

When the installation work is completed, all gaps are filled with construction foam. Then the partitions are installed. You can cover everything with plasterboard, and also cover the cassette with ordinary brick. Usually in this case it is laid on the edge when laying. This saves free space in the room and the opening does not look heavy. The work is completed with finishing touches.

Most manufacturers have launched the production of built-in sliding doors, in which the cassette is adapted to the size of the door opening from 60 to 100 cm. The kit includes a ready-made pencil case and a guide mechanism, on which a carriage with rollers is already installed. All that remains is to mount everything in the opening and hang the door leaf.

The width of the doorway directly depends on the design of the door block. But in any case, for a door 60 cm wide, it is necessary to add technological gaps. And their size is selected based on which model is installed in the opening: hinged or sliding.

Why are standard dimensions needed?

Despite the fact that many residential owners are skeptical about the Soviet standardization system, considering it hopelessly outdated, the presence of standard door sizes greatly simplifies life for both manufacturers or installers, and consumers themselves. Among the main advantages of standard sizes are the following:

- Considering that almost all modern door manufacturing plants have switched to automated production lines, the increased speed of manufacturing standard elements with minimal labor costs significantly reduces costs. As a result, the door that goes on retail sale becomes more accessible to the common consumer.

- If the door leaf or any element of the frame is damaged, the owner can make a replacement as soon as possible, since standard products are presented at every retail outlet in our country. If the product has individual dimensions, this is much more difficult to do.

- Most of our compatriots live in standard panel houses with standard dimensions. Considering that when developing GOST standards, engineers relied on this type of housing, carefully calculating every little detail, standardized dimensions of doorways filled with standardized elements will allow the resident to comfortably use the space they own.

Rice. 5. Appearance of typical designs

It should be taken into account that the presence of a wide range of products on the market makes it possible not to pay attention to the standard dimensions of those consumers who want to give their premises an element of uniqueness. So, in order to install an exclusive door, it is not at all necessary to create an opening of non-standard sizes, since you can simply choose an exclusive and bright design of the door leaf itself.

What should be the opening for installing an interior door?

If you do not want to overpay 20-50 percent for non-standard interior doors, then you need to decide on the doorway in advance.

You need to start from the doors you like, the variety of which can satisfy even the most fastidious taste. Basically, doors are produced in standard sizes: 2 meters high and 60, 70, and 80 cm wide.

Less common is a standard with a width of 40, 55 and 90 cm and a height of 1.9 meters. The thickness of the door frames can vary in the range of 1.5-4 cm.

Loading …

Depending on the room, standard door sizes may be used.

This is how they usually put it:

- in the bathroom and toilet, the height of the opening is usually from 1.9 to 2 meters, width 55-60 cm, depth 5-7 cm.

- in the kitchen height 2 meters, width 70 cm, depth 7 cm.

- in the bedroom or living room, the height of the doorway will be 2 meters, width 80 cm and depth from 7 cm to 20 cm.

- if the door to the bedroom has double doors, then only the width will change: it will be either 2*60 cm, or 40+80 cm.

After plastering and leveling the walls, the depth of the doorway will increase accordingly.

These dimensions of doorways are very difficult to overestimate. After all, if you did not take them into account in your calculations, you may encounter a problem when your door frame does not fit into the opening. And not every opening can be enlarged; sometimes this is impossible due to the specific layout or design of the wall. If this is a load-bearing wall, then you will also face a number of difficulties.

Please note: Handles for interior doors: how to choose and install

Even a simple plasterboard wall is not easy to reduce due to the transfer of metal profiles. In this case, you will have to overpay for non-standard sizes of the interior door.

There is also the opposite situation, when the doorway is much larger than the door. Here you will also overpay specialists when installing the door, for narrowing the opening.

An unpleasant situation may arise when, as a result of reduction, the platband cannot close the hole in the doorway. In this case, you will need to seal up the uncovered sections of the wall, glue wallpaper or lay tiles. It’s good if the room hasn’t been glued up yet, but if it has been, then everything will have to be re-glued.

Therefore, even at the project stage, you need to decide on the size of the doorways, then you won’t have to overpay for non-standard doors or redo the opening.

What you need to know to calculate a doorway:

- height and width of the proposed door

- door frame thickness

- box width

- width of platbands

- the box will be with or without a threshold.

Suppose you need a door measuring 2 by 0.8 meters and 2.5 cm thick. To calculate the dimensions of the doorway, you need to add the dimensions of the frame to the dimensions of the door, plus an installation gap of 1 to 2 cm on each side.

Calculation of the width of the doorway

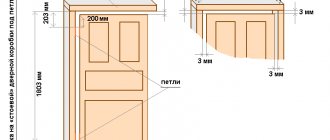

Figure y shows a diagram of a doorway with a door and dimensions. Using these data, we can easily obtain the opening width of 800+30+30+10+10+4+2=886 mm or 88.6 cm.

You can find out the width of the frame on the website of the manufacturer of the doors you like.

Calculation of the height of the doorway

Similarly, we can calculate the height of the doorway. We look at the data in the picture:

- with a threshold of 2000+30+30+10+5+3=2078 mm. or 2 meters and 7.8 cm..

- without threshold 2000+30+10+5+3=2048 mm. or 2 meters and 4.8 cm..

Calculation of doorway thickness

Please note that the most common thickness is 7.5 cm and therefore many manufacturers adhere to this particular size. Please note: Sliding glass doors: features of choice

Please note: Sliding glass doors: features of choice

If the wall is thicker or thinner than the box, then you will need to install an extension or cut the box lengthwise, respectively. Without these operations, you will not be able to install trim on the door and everything will look much worse.

Naturally, these operations will lead to an increase in the cost of installing an interior door. Which, by the way, you can install yourself.

Using our recommendations, you can make an opening under the door, which subsequently will not lead to a significant increase in the cost of installing an interior door.

What nuances should be taken into account when choosing a box?

When you intend to purchase a door frame, experts recommend paying attention to the following features:

- Material.

Each raw material has its own advantages and disadvantages. At the same time, experts are unanimous on one thing: you should not choose a frame made of fiberboard, since it is not strong enough to hold the leaf and will certainly bend under the weight of the door during installation work. An excellent alternative is wood or MDF.

- Resistance to physical impact.

Polypropylene coated MDF is easily scratched during installation, so do not remove the protective film until the installation process is complete.

- Opening dimensions.

When your home is undergoing a major renovation, we recommend that you take measurements of the doorway after finishing the walls and laying the flooring are completed, since as a result of covering the surfaces, their parameters can change significantly. Consider the location of the electrical wiring in order to order trims in advance that will cover protruding wires.

- Opening doors.

Consider which direction the canvas opens, since the holes for the hinges in the finished product must correspond to your request. If they are on the left, then the door is left, if on the right, it is right. In the case of a double door, you should pay attention to the position of the handle: on the left hand is the right door, on the right is the left one. However, the described principle does not work for European doors, the sides of which should be determined exactly the opposite.

The frame is an indispensable component of the door block. If you find it difficult to choose a design, experienced store consultants will help you choose the appropriate option. However, the choice of palette and quality always remains with the buyer.

How to calculate values for an opening using measurements

The opening does not always comply with GOST or another standard. Then you have to measure them. Each parameter has its own scheme.

The height is measured from the lowest point on the floor (if there is a baseboard, it must be taken into account) to the highest. The opening can be uneven, then measurements begin in the narrowing area and go to the casing;

Width is measured based on height

It is important to note that the measurement is not taken from the top, but exactly in the middle - the height is divided in half and measured from the center point of the right casing to the center point of the left. Again, if the opening is uneven, the narrowing is also fixed;

The depth is measured from above and below and in the center, the maximum value is found and then based only on it.

Width measurement (from middle to height)Source i.ytimg.com

see also

- Ceiling in a bathhouse made of timber

- Houses made of laminated timber

- Expolesstroy timber houses

- Chicken coop made of timber 100 by 150

Timber house demand- Residential trailers made of timber for living

- Brand of concrete for the foundation of a bathhouse made of timber

- Where to start building a house from timber on your site

- The bottom of the frame wall is how to attach it to the bottom beam with wood grouse nails

- Finishing with basement siding of houses made of timber

How to properly install a stove in a timber sauna

How to calculate correctly

The optimal parameters of the door leaf must be calculated in advance. There is an easy way to take your own measurements. To do this, take the door width, then add the box thickness, multiplied by two. To the resulting calculations you need to add another 4 cm (parameters for gaps for installation and seams). When the height is calculated, the box thickness must be additionally added to it.

In the absence of a threshold, the thickness is added once, and in its presence - twice. But there are situations when you need to select a box that needs to be mounted in a previously used opening.

In this case, there is a certain action plan:

- eliminate unnecessary elements at measurement points. You need to remove not only the previous box, but also the trim.

- Tidy up the main wall. It is necessary to remove uneven surfaces. Then you need to measure the dimensions at the largest and smallest places. Any indicator must be recorded.

- Measure the dimensions at least at two different points in the opening, especially if it is corner.

- Determine whether the opening requires adjustment, for example, when it warps or is too narrow.

- Test the hardness of the cleaned surfaces. If necessary, they need to be strengthened.

Cleaning the end surfaces of the opening does not always go smoothly, especially if the opening has been used previously.

You can find out the height of the doorway with the threshold (in other words, with the lower bar, which is also a part of the frame) using the following formula: add two thicknesses of the frame to the height of the door leaf, then add a gap for installation of 13 mm for free operation of the door from above, as well as 5 mm of space for operating the door from below.

Calculation of the height of a doorway without a lower frame beam (without a threshold) is carried out according to a different scheme: the height of the leaf and the thickness of the frame are summed up, 1 cm of indentation from the finished floor is added to them for free operation of the door, 3 mm of indentation on top and 10 mm for the installation seam are added.

The wall is carefully examined and it is decided where it is safest to install the door. You should equally carefully examine the slopes on the sides to find out what their geometry is. It is possible that they may be curved or create other difficulties.

It will not be possible to take measurements with just a tape measure; you will have to use a building level, or, in extreme cases, a laser builder. Measurements are taken on the opening side from bottom to top.

Recommended door dimensions for different rooms

In apartments of old standard buildings, almost all door blocks are installed in compliance with the standards of past times:

- entrance - 200x90 cm;

- interior - 200x80 cm;

- in bathrooms and utility rooms - 200x60 or 200x70 cm.

It is believed that doors of this size provide comfort and safety in the home. In Stalinist apartments built in the pre-Khrushchev era, the doors are much higher and wider. In those days, they did not yet strive to save space, so houses were built with high ceilings and spacious rooms. Doorways reached a height of 2.4 m, a width of 1 m or even 1.4 m (in a double-leaf version).

Taller doors not only look better, but are also more convenient. In Europe, the standard canvas height is 2.1 m.

But if the ceilings are low - up to 2.7 m - then the design must correspond to the general concept so as not to look alien. If the ceiling height is high - 2.8-3 m - it is better to install doors at least 2.1-2.2 m. By the way, some manufacturers offer such options, and their price is no higher than ordinary two-meter blocks.

You can visually increase the height of the opening and make the door look grand with the help of door portals or wide trims. Even a standard canvas without any special decorations will look more respectable.

Modern open-plan apartments often have no partitions at all and, accordingly, no openings for doors. Each owner is free to resolve issues of space delimitation in his own way, which many use with great pleasure.

When choosing an interior door, it is recommended to take into account not only the dimensions and design, but also the soundproofing qualities. If silence in the room is a priority, you can opt for models with a drop-down threshold. The device is also sold separately, so you need to buy it and take it to a workshop for installation.

Moisture resistance is important for plumbing blocks. For the kitchen and nursery - practicality, the possibility of wet cleaning.

How to sheathe with plasterboard?

If, instead of a classic concrete opening with a box installed in it, you want to make a wall with a plasterboard arch, then you have chosen a simpler path. Sheathing with plasterboard is one of the most effective solutions, despite the ease of implementation.

From plasterboard you can create unusual fantasy structures that are absolutely safe for the overall stability of the entire building. Openings with plasterboard lining can have tables, columns or even a bar counter.

In any case, the plating is performed as follows:

- To begin with, all measurements are taken from the opening: width, height, wall thickness.

- Next, the parts are cut out from plasterboard. For rectangular cladding, simply cut out the strips, but for arched cladding, they need to be slightly cut with metal scissors, wetted and given the desired shape. After drying the part in a bent form, you will be able to make the necessary element.

- To glue drywall parts, use ordinary putty. After the elements are attached, the joints must be additionally puttied and leveled using aluminum or plastic profiles.

- Afterwards it is necessary to prime the entire surface. After complete drying, you need to carefully putty the uneven places and rub them until smooth.

Opening direction

To choose a convenient option for opening the door, you need to draw a floor plan with the arrangement of furniture and the location of switches for lamps. The door handle should be next to the switch so that upon entering the room you can immediately turn on the light.

If in public buildings, for reasons of fire safety, the door must open outward, then in residential buildings there are no strict requirements with the exception of entrance doors. They, as a rule, also open outwards.

Due to the small area of the premises, bathrooms, bathrooms, dressing rooms and storage rooms can also open towards the exit. But if the size of the room allows, you can install doors that open inward.

In bedrooms and children's rooms, open canvas should not clutter up the space. Therefore, the opening is usually located in the corner, and the door, when opened, describes approximately 1/4 of a circle.

If the living room area is large, the opening can be located anywhere, including in the middle of the wall. Doors are used not only single-leaf swing doors, but also double-leaf, sliding or accordion-type folding doors. They will not take up much space, and they are more convenient to open than a wide swing structure.

Using Radio Devices

Attention! Radio devices can only be those manufactured under the ZONT brand.

These are radio thermometers, radio leakage sensors, radio motion sensors and radio key fobs. They can be used with a thermostat only if the ZONT ML-489 Radio Module is connected to Input 2 of the thermostat (not included in the delivery package and must be purchased separately).

Registration of radio devices is carried out from the personal account of the Internet service, setting up the Radio device

Radio module ML-489 Thermostat ZONT

Pink wire Input No2:

Black wire

“-” of the main power Red wire “+” of the main power

Registration of radio thermometers, radio leakage and motion sensors:

Open the housing of the sensor to be registered and find the registration mode enable button on the board.

In the Internet service settings, click the “Add devices” button. From this moment on, the time allocated for sensor registration will begin. Registration is available in 3 minutes.

Press and hold the button on the board of the registered sensor until the LED lights up.

The registered sensor should appear in the radio menu.

Registration of radio key fobs:

In the Internet service settings, click the “Add devices” button. From this moment on, the time allotted for registering a new key fob will begin. Registration is available in 3 minutes.

Simultaneously press and hold down both buttons to turn on and off the security mode (image of an open and closed lock). Successful registration is indicated by a short-term (~ 1 second) lighting of the LED on the key fob body.

Registered radio key fobs should appear in the radio device menu.

Wood frame: everything you need to know

There are many benefits to timber frame building, from factory standards achievable to fast build times, and so it's no surprise that timber framing is no longer a niche building system choice for those looking to build their own home.

In fact, according to a 2022 market report, the number of timber frame self-builds (including SIPs) was almost equal to masonry builds.

This shift may be partly due to homeowners prioritizing energy efficiency in their specifications. Highly insulated SIPs are becoming increasingly popular among self-builders looking to create airtight and efficient homes, with some even achieving Passivhaus accreditation.

This beginner's guide to timber frame building explains what it is, how you choose the right system and supplier, what's typically included in the price, and how those costs stack up against masonry.

If you're looking to extend with timber framing, check out our guide to timber framing extensions.

Explaining the structure of a wooden frame

At its most basic, wood frame structure features walls made up of wood studs secured in place (usually) with OSB or plywood. Strength and rigidity is provided by a board that, when nailed to a stud, makes a very rigid box known as an exposed panel - the panel is “closed” after the insulation is introduced.

James and Claudia Gray's timber frame house is a fitting addition to a site steeped in military history (Photo: Simon Maxwell)

The exterior of the frame is wrapped in a waterproof barrier, which is then wrapped around the outer wall elements, which can be assembled from earth (brick or stone) or suspended from wood frame walls - as is the case with wood cladding or tile.

In terms of buildability, a timber frame tends to work best with simpler shaped structures This can reduce the wall width by up to 150mm, which adds a surprising amount of internal floor space.

Mike and Jill Tate chose timber frame construction for their traditional building in the Lake District (photo credit: Jeremy Phillips)

In the UK, timber frame houses are typically built in a factory and then quickly assembled on site. Factory prefabricated is by far the most popular route chosen by the builders themselves, as manufacturers must work with strict quality control methods, ensuring the correct material specifications are used and high quality is achieved degree of dimensional accuracy.

( MORE : Step-by-step guide to building a timber frame and beam house)

Should a timber frame system be selected and opened or closed?

Exposed panels are manufactured ready to accommodate external joinery (doors and windows) and delivered to site along with flooring members and roof trusses. Once framing is complete, work can begin on both the interior and exterior of the home.

Enclosed panels are supplied to the site with insulation already installed at the factory. External cladding, windows and doors can be fixed, as can electrical and plumbing. Alternatively, a service gap can be added for those who are unsure about their electrical and plumbing plans.

Enclosed panels are often offered by German prefabricated suppliers and can result in very fast assembly. Due to the weight of the panels, a crane is required for assembly.

Timber frame panels can be delivered to the site "open" or "closed".

SIP construction is sometimes referred to as timber-free frame construction. The strength of the panels comes from bonding the insulation within the inner and outer skins of the slab to create a very rigid, highly insulated shell .

The factory produces these panels, leaving holes into which doors and windows will be placed later, and then ships them to the site, where, along with the floor elements and rafters, the house's superstructure is erected in a few days .

The roof is covered with a waterproof coating and once the framing is complete, work can begin both inside and outside the house.

It's very fast and you can work on wet roads.

Remember

- Any structure below the finished grade must be constructed using masonry or concrete. However, floors above this level can be built using timber frames

- . Ensuring that the building below is built to the correct dimensions and tolerances is key to ensuring that when the timber frame arrives on site for installation it will fit

. Timber framing was used to build this modern family home overlooking the Firth of Forth (Photo: David Barbour)

How much does a timber frame cost?

The framing, associated design work, delivery and on-site assembly are paid for by timber frame companies as a package, which provides a certain level of cost.

From a cost perspective, open panel systems remain the cheapest to produce, but as demands for lower U-values and better airtightness levels increase, cost differentials narrow.

Mike and Linda Bray's timber frame, available for self-build in Hampshire, demonstrates how this construction method can be used to create a stunning modern home (Photo: Martin Gardner)

SIP and closed panel options typically cost around 10–15% more per frame, but offer better performance and less time on site to compensate.

Keep in mind that the timber frame element of a home rarely accounts for more than 30% of the overall budget, so the additional cost could drop to 3-5% of the total build, not much different from what you might spend on a more luxurious kitchen or lighting scheme for the whole house.

Perhaps more interesting to the builders themselves is how a timber frame stacks up compared to traditional masonry structures. In terms of cost, there is no clear winner. The cost of masonry tends to rise and fall depending on market conditions - in contrast, prices for wood frame structures tend to be significantly less.

How can I find a timber supplier?

There are a large number of companies producing timber frames for the UK self catering market.

The most common way of working is for the company to design, build and erect the superstructure, but there are variations in how much superstructure is supplied. The services provided by timber framing companies can range from providing just the superstructure to a complete package. This creates difficulties when comparing companies.

Andrew and Tony Lees built a stunning Cotswold stone house in Wiltshire using a timber frame from Potton (Photo courtesy of Simon Maxwell).

Tips for finding the right supplier. Association

- Ask three or four companies to provide quotes for your project . They will need your drawings (ideally plans/sections/elements at a scale of at least 1:100) as well as the most detailed specification possible.

- When you compare manufacturer offers, make sure the two offers have comparable specifications . Some manufacturers offer a free price comparison service; if they do, it's worth using. Don't automatically reject the most expensive quote - the company may have quoted for a higher specification or for more assembly items.

- Once you've narrowed your choice down to two manufacturers, arrange to meet them at their factory where you can travel. their quote in detail

- Ask if they have any cost-cutting suggestions, as fairly small changes to plans can often mean significant cost savings

- When you're at the factory, request a tour and see, touch and feel the different materials they plan to use. Ask about timelines, too. Please expect a 10-12 week lead time for structural shells from the time you place your order.

- Base plates, moisture-proof profiles and clamps

- Structural Exterior/Interior Wall Panels and Waterproof Membrane

- Floor beams and floor coverings (not finishing)

- Whole roof elements, usually supplied as prefabricated trusses

What is included in the delivery of wooden frames?

Basic packaging can usually consist of the following items:

Merula Frankel collaborated with German packaging company Baufritz to create her timber frame house in Hampshire (photo credit: B/Baufritz)

Items that are unlikely to be included unless the entire building contract is handed over to the timber framing company:

- External cladding

- Roofing materials: felt, lath, tiles, etc.

- Insulation

- Floor screed

- Chimneys

- Glazing (although more and more are coming with glazing)

- Heating, plumbing and electrical

- Plaster

- Kitchen units, built-in furniture for bedrooms and plumbing fixtures

- Finishing, cladding and finishing of walls and floors

- Garage Doors

Many packing companies will not manage the foundation, drainage and landscaping.

You should carefully look at the specification offered by each company and check that you are comparing like with like.

Why choose wooden frame?

- The timber frame is suitable for those hoping to take on the role of project manager as the superstructure is built by a single company

- The frame is factory designed, meaning the walls and floors are perfectly square

- This means there is also less room for "human error" during construction

- Allows you to increase the speed of construction

- Prefabricated houses can achieve high U-values with comparatively thinner wall profiles

- A large number of timber frame suppliers are accustomed to working with self-builders

5 Ways to Build a Better Timber Frame Structure

Self-builders Sandy and Melvin chose timber frame construction for their dream home in Surrey (Photo credit: Darren Cheung)

Because timber framing is a lightweight structure, there are elements when agreeing the specification with your architect that need to be taken into account to ensure you are as satisfied as possible when you live into finished property.

- Avoid squeaky floors . Floor beams must be designed with a serviceability index (a measure of beam performance) of at least 1.2. This results in a stiffer floor that flexes or sags less than a floor rated at SI 1.0. For a squeak-free floor, glue to the joist with a 6mm bead of D4 glue, glue the tongue and groove, use screws (generally 2.5 times the thickness of the floor), apply D4 glue to the exposed edges of the decking to seal it and leave 10- millimeter expansion gap around the perimeter of the floor.

- Soundproofed walls and floors . Think about airflow and impact noise and how you can design for it. You can exceed the minimum soundproofing requirements set out in building regulations.

- Safe fastenings . Timber frame framing walls are usually located on 600mm centres, which can sometimes make it difficult to attach heavier items to the wall as there are limits to the weight that plasterboard can support. If you can, think ahead. Have a carpenter/builder set the nuts in the appropriate positions before installing the drywall to ensure a secure fit.

- Avoid overheating . Homeowners typically want to increase the amount of glazing in their homes, which can increase solar gain but lead to overheating. A wooden frame will offer less thermal mass, so your designer will have to consider how to prevent overheating. Installing salt beams, blinds or a retractable awning can be a useful design option to keep your timber frame cozy all year round.

- Ensure adequate ventilation . Frame construction by its nature provides a very good level of airtightness. The expression "slim and well-ventilated" is exactly what you are aiming for here. Enabling the MVHR system is a good idea.

,

Box sizes

The consumer is offered different sizes of door frames, depending on the location of their installation. Dimensions are maintained according to the standard. It differs for manufacturers from different countries. The most common standard door frame size for interior doors from a domestic manufacturer coincides with products from Finland, Italy and a number of other European countries.

The standard size is:

- sash width – 55, 60, 70, 80 and 90 cm;

- sash height – 190, 200 and 210 cm;

- box thickness – from 2 to 7.5 cm.

This thickness of the interior door frame was determined for good reason. The size variation is due to different wall parameters.

The optimal depth for the door frame of an interior door is 7.5 cm. The frame is suitable for walls made of plasterboard or brick. For thick partitions made of other materials, boxes 10 cm wide are produced. There are imported boxes with a depth of up to 20.5 cm.

The total height and width of the door frame of the interior door is determined taking into account the size of the leaf. The thickness of the pan is added to the dimensions of the canvas. It will be clearer with an example. Let's take a canvas 60*200 cm and a frame 7.5 cm thick. As a result of the calculations, the total width of the door with the frame will be 67.5 cm, and the height will be 207.5 cm.

The size table will help you determine the dimensions of the interior door frame.

Double doors

In apartments, double-leaf door blocks are often installed. The dimensions of a door with 2 leaves are slightly larger than single-leaf products. The minimum width of such a structure is 80 cm. It includes two doors measuring 40 cm each. The opening for this door is 90 cm in size. The maximum width of a double-leaf product is 180 cm. The opening for such a door model should be 190 cm. As for the height of the double-leaf block, it is standard. Such door models are excellent for openings of atypical sizes.

Standard dimensions of interior door frames: width, height and thickness

The GOST standard strictly defines the dimensions that a door frame must comply with. Dimensions may vary depending on the functional purpose of the room for which the interior door is selected.

- The width of a standard interior door frame for living rooms is 80 cm. At the same time, the standard thickness of such a doorway into which the frame is inserted is from 7 to 20 cm (depending on the type of material from which the house is built).

- The width of the door frame of an interior door for a bathroom is 60 cm. At the same time, the standard height of the doorway is from 190 to 200 cm.

- The standard width of a modern interior door for a kitchen is 70 cm, and the thickness of the doorway in this case is 7 cm. The height of the opening into which the door frame is inserted is also standard and is 200 cm.

Purpose of the additional element

Door frame extension strip

The additional element is a strip that is used to expand the timber of the used frame for the opening.

Types of additional elements

It is used to cover a section of the wall that is not hidden by the frame beam. The width of the required extension is calculated by measuring the thickness of the wall in the door opening, and the width of the frame beam is subtracted from the resulting value.

The standard width of an interior door frame is 7 centimeters. If the wall is thicker, additional installation is required. An exception is the use of “L” shaped trims.

L-shaped platband

Tip: When purchasing doors, you need to take into account the largest size of the wall thickness at the opening. Otherwise, the box will be smaller than the width of the wall. In this case, the platband will not fit tightly on the wall and frame.

If such a defect occurs, you need to use alabaster or gypsum mortar to cover the gap.

The width of the extension is equal to or greater than the part of the wall to be covered. For example, if the wall width is 12 centimeters, and the boxes are 8, an addition of at least 4 is required.

Features of the selection

Before installing the strips on the door frame, you should familiarize yourself with the advantages of installing them:

- High speed of installation of an expanded door block.

- There are no “wet” finishing processes that are unfavorable for wood.

- Long period between regular repairs.

- Aesthetics, which ensures the integrity and beautiful appearance of the door structure.

- Low price of planks.

Installation diagram of the additional element

The three components of the extender-extension, assembled into a single whole, resemble the letter P; it can be attached:

- Straight to the door frame.

- To the wall, where the opening is installed.

- On a mounting beam placed between the extensions and the vertical planes of the opening.

If there is no special mechanical load on the extensions, only liquid nails can be used to fix them into a specially made recess. But more often galvanized self-tapping screws are used for installation.

Installation of the extension

Tip: If the fixation is performed from the front side, it is necessary to hide the fastener heads with mastics or plugs matched to the tone of the box.

Types of additions

To furnish your home, you can purchase the following doors:

- With boxes in which a groove was pre-selected on the outside for proper alignment with the extensions.

To do this, you can use chipboard or wooden planks one centimeter thick. The width of the panel strips is measured with a box mounted into the opening, which will be the basis of the structure. In this case, the element is nailed on the back side of the opening with galvanized small nails in increments of 20 to 35 centimeters. You can insert the strips into the recess and then fix them in the opening of the box with glue.

- Without groove with box beam. In this case you can:

- choose a groove using a machine with a special straight cutter yourself;

- attach the extensions to the box beam through pre-drilled screws from the end of the element;

Attaching extensions to timber

Tip: To attach additional strips to the frame, the diameter of the through holes along the entire length is not the same. First, the drill is taken with a diameter equal to the screw head, then according to the size of its barrel.

- additional elements are installed on bars screwed to the wall with self-tapping screws. The first of them is located 200 millimeters from the floor, and then in increments of 60 centimeters;

- the extensions with the box “sit” inside the base of plywood or plasterboard;

- a box beam without a groove is connected to the slats by installing a rail, which runs from the outside of the opening along the alignment line;

- a lath or plank made of plywood is attached around the perimeter not in a continuous strip, but in separate sections.

The timber and trim strips are nailed to the rail. In this case, the central axis of the rail and the connection line must coincide or have a slight offset.

Design of the opening box

After assembly, the outer line of the extensions is flush with the opening. Excess up to one millimeter is trimmed off with a plane, and then everything is closed with cash.

Dimensions of openings in the wall

Knowing the standard dimensions of interior doors manufactured by manufacturers along with the frame, you can easily calculate the necessary parameters of the doorway when constructing walls and interior partitions in the house.

To get the width of the wall opening, you need to add up the width of the door leaf (for example, 800 mm), double the width of the frame for an interior door (for example, 30 mm), and two installation gaps of 15 mm each. In this case, the width of the opening is 800+30*2+15*2=890 mm.

The height of the opening is calculated in the same way. It is equal to the height of the door leaf (2000 mm) + the width of the frame (30 mm) + the installation gap (15 mm) + the gap between the door leaf and the floor base for air exchange (5 mm) = 2050 mm. If necessary, the air gap can be made up to 10 mm. And if liquefied gas is used in a residential building, then the gap is made at least 15-20 mm. This is necessary for good air ventilation.

If interior doors are selected to fit ready-made openings in the walls, their parameters are calculated in accordance with current standards. For example, if the opening is 900 mm wide, an 800 mm door leaf will fit. That is, the calculations are performed in reverse: the width of the opening in the wall (900 mm) – 2 installation gaps (15 mm each) – 2 door frame widths (30 mm each) = 810 mm. The extra 10 mm is covered with platbands.

General parameters and markings

When choosing a door design, keep in mind that the standards are conditional. That is, each manufacturer can independently determine the volumes. The purchased box can only protrude 3cm from the wall. (including installed platbands). The usual width is 90cm, but not all brands have it. However, for offices and old houses, 90cm. doesn't fit. For each place you need a clear measurement.

If the box has no threshold, it is U-shaped. They can be combined with canvases of any height and trimmed if necessary. If the design has a threshold, then more careful measurements are needed in order to accurately match the panels and the opening. Also, boxes can be arched, when the top bar is curved. To measure them, it is better to invite measurers who will make the arch. For ease of subsequent repairs, the structure is framed with telescopic platbands.

The product is marked according to GOST 6629 88 standards. All interior doors are designated as follows:

- The letter “P” means a panel, and the letter “D” means a team;

- By type of canvas: reinforced fully filled letter “U”, letter “K” swinging with glass, glazed letter “O”;

- The designation “DM” means the width and height for interior doors together with the frame;

- Auxiliary designations: float “N”, threshold “P”, on the left side “L”.

Arched doorways

One of the options for a non-standard entrance to a room or kitchen is an arch. This is a rounded entrance at the top, without a door frame or door leaf itself. It is made from the following materials:

GKL - plasterboard sheets with a thickness of 9.5 mm, 6.5 mm. They bend and install well. Using this material, not only standard arches are created, but also in various styles. Fiberboard - wood fiber boards. They have sufficient flexibility, their advantages and disadvantages. Plywood - rarely used. Wood - working with it to create an arch is labor-intensive

This material is used for rooms where the emphasis is on natural wood of valuable species.

An arched passage is chosen for several reasons:

visual increase in ceiling height; expansion of space due to the lack of a door structure; brightening the room (if the room is dark, the arch is made with lighting from spotlights or LED strip); interesting appearance that attracts attention.

Arches are created both rounded at the top, having a large width and standard height, and narrowed, oriental style, which have minimal dimensions in width, but normal height.

Curly doors: how to measure

Naturally, it is much more difficult with figured doors. After all, creativity is not always reflected in size. In some apartments and houses you can see interior doors with a rounded top. In other words, when opened, the opening looks like an arched entrance.

There are also two ways here: one is easier, the other is more difficult. If the size is standard, then a fixed structure should be ordered for the vault, which will complement the doors when closed. In this case, the upper part should be made of the same material as the doors themselves. The second option is more difficult - to make a figured canvas that will open completely

And here it is important to perform all the calculations correctly.

It must be said that in some houses there are absolutely amazing designs of original works, in which even the forms differ from the generally accepted standard. Such doors are calculated and manufactured only individually.

Algorithm for measuring the size of a doorway

The measurement process itself is no less important. Experts assure that it is precisely in this work that mistakes are most often made, and, accordingly, subsequent calculations will be incorrect. In order for the door frame in a residential or public space for interior doors to be measured correctly, and the dimensions to allow correct calculations to be made, the following sequence of actions must be followed:

- First, the height changes from the floor itself to the top of the opening. If you are sure that it is not level, measurements should be taken in the middle;

- The width is measured from the middle of the left to the middle of the right casing;

- The depth can only be known by taking comprehensive measurements: at the top, middle and bottom to find the widest value.

Standard table for calculating doorways:

| Width, cm | Height, cm | Type of room | Standard indicators |

| 62 — 65 | 195 — 197 | bathroom | 55*190 |

| 67 – 70 | 195 — 197 | Bathroom | 60*190 |

| 67 – 70 | 195 — 197 | Room | 60*190 |

If a person lives in an apartment or house with a standard layout, then the indicators of his measurements will be identical to those indicated in the table.

How to choose a door frame

Usually, to perfectly fit the box to the opening, select a product that differs from the opening in dimensions by 3-4 cm smaller. Domestic manufacturers work according to approved construction SNIPs and do not produce boxes wider than 90 cm. Foreign-made products have excellent sizes; when purchasing them, you should first “try on” their dimensions to the existing opening.

If you are not sure about the height of the opening or could not find a model that exactly fits your dimensions, then you can take a U-shaped model. Vertical posts can be trimmed to height if necessary. Frames with thresholds must be selected exactly according to the specific size of the opening and door. The choice of door frame is often made according to the size of the opening in the wall. To do this, it must be measured correctly. Height and width dimensions are measured at three points: two extreme points and the middle one. The lesser of the received data is accepted.

The thickness and diagonals of the opening are also additionally measured. The diagonals should be as close as possible to their face value. The big difference in them indicates that the opening is “blocked” to the side; its angles are far from 90 degrees. The opening will need to be corrected before installing the box to ensure the durability of the interior unit.

How many components are needed for the opening?

When installing the door block, you will definitely need components. The aluminum door frame goes on sale with mounting plates, a seal, and a set of corners.

When purchasing a door frame for an interior door, a design is selected taking into account the installation location. Frames with a threshold are placed in the bathroom, at the entrance, or, if the height of the opening requires (3 blanks are required for one door). The U-shaped box is mounted in ordinary interior partitions (for one door you need 2.5 pieces).

The number of platbands is calculated according to the need for framing. On one side you need two and a half strips 2 m long. To cover both sides, buy 5 platbands.

If the door frame is narrow, the projections of a thick wall are hidden with extensions. The number of boards is calculated based on the size of the protrusion.

You will need hinges from the fittings. For a light sash, 2 elements are enough, and for a heavy sash you can put 3 pieces. Overhead or hidden hinges are placed on the door frame without a quarter. By design they are one-piece.

A lock and a peephole are installed on the front door. Although, the last element is optional. Any door is equipped with two handles, and a latch is attached to the interior door leaf.

Assortment of door designs

The market is developing because everyone wants to create their own interior and complement it with unique details

The manufacturer takes into account the requirements and needs of people, and every year more and more different designs appear, having a unique shape, size, material, differing from other models in some important detail. All this has a positive effect on the emergence of new standards.

Material:

- Glass;

- PVC (high-quality plastic);

- Wood of different species;

- Fiberboard;

- Metal;

- chipboard;

- MDF (dense laminated wood panels).

Interior doors are different Source dekormyhome.ru

But the whole point is not even in the variety of materials, but in the design of door structures. Everything is done in such a way as to simplify the task of using the doors as much as possible - they open and close conveniently, the hinges are made not to creak. The fittings create a clear and expressive ensemble, and the variety of different styles allows you to use both fittings and door leaves to tie into one style, no matter what it is.

The dimensions of doorways continue to matter, as more and more universal models are being created that fit different openings.

About the sizes of interior doors in the video:

What is included in the door frame kit

The standard installation kit consists of:

- platbands (telescopic, which have a “tenon”-groove type of fastening and pressed ones, for the installation of which nails or adhesive are actively used);

- additions (if the depth of the opening requires it);

- fittings (mortise and overhead);

- seal.

Brown solid pine door with an extension in a modern hallway interior

Calculating the non-standard size of the metal entrance door frame

Calculation of the dimensions of a non-standard box begins with measurements. To carry them out, the old structure is completely dismantled to gain access to the opening. The degree of curvature of the walls is checked by the level. Small deviations are compensated by technical gaps, significant defects are eliminated with cement mortar. In several sections (in the corners and in the center) from the base of the wall, the height, width and depth of the opening are measured. For each parameter, the average value is taken as the basis. Separate measurements are taken along two diagonals. The difference in values shows how much the opening is tilted to the side and deviates from perpendicularity.

When forming the dimensions of the box, installation and technical clearances are taken into account. They will allow you to correctly install the door block and ensure smooth movement of the door in the future. The opening should be larger than the box on each side. Gaps are left in the narrowest places.

The height and width of the door block is calculated according to the dimensions of the future door, added to them is the size of the door frame profile and plus a gap of 3–5 mm on each side of the leaf.

What other dimensions need to be taken into account during installation?

The general appearance of the structure, including the metal entrance door, depends on compliance with simple rules.

- The mounting hole for the box should be about 10 cm wider than the tray. In extreme cases, it can be narrowed. This is much easier than expanding, and after installing the platbands nothing will be noticeable.

- The adjoining of the opening space to an adjacent wall is prohibited. The distance must be at least 10 cm.

- Voids under the platbands are formed when the depth of the hole does not match the thickness of the slab and when the wall is uneven. The latter must be corrected before installation work begins.

- The thickness of the platband is no more than 0.8 cm, so the distance from the wall to the floor covering should not be greater.

Knowing the standard sizes of interior door systems greatly simplifies their selection and installation. It is important not to make mistakes in taking measurements and selecting a product, otherwise it is difficult to calculate how much additional money will be spent on correcting errors.