If the wall turns out to be wider than the door frame for the front door or the door to the room, then use additional inserts. Before installing such products, it is worth deciding on their dimensions. Then the installation of the extensions will be easier and of better quality. To find out the dimensions of the extensions for interior doors, it is not necessary to call a specialist. You can do this work yourself and save money. But you need to know a number of rules and follow the instructions. It is also useful to understand what kind of door frames there are for interior doors: the sizes of telescopes and products with straight sides.

What types of extensions are there: types according to materials and design

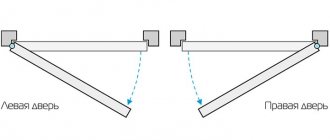

Manufacturers produce various additional elements for interior doors. Products can be divided into two groups according to design features: completely flat and telescopic. Inserts with smooth edges are a board that is butt-joined to the door frame with self-tapping screws. They come in different sizes. Can be equipped with decorative edge. Processing one of the ends of the additional strip prevents displacement of the casing. Such additions are not particularly convenient to install. You have to think about closing the outer parts of the screws, making sure that the strip does not split. Fastening is also possible using glue. Telescopic extensions have special grooves for alignment with the door frame. Therefore, they are more convenient and easier to install. You just need to drive the protrusion into the groove and tap. Also, this type of extension allows you to install a telescopic casing.

They make additional parts for interior doors from various materials. According to this parameter, they are divided into wooden, PVC and MDF. Wood planks are usually made from real wood. The most commonly used wood is oak, beech, pine, and ash.

A wide range of additional boards makes it easy to choose the appropriate type of additional board for your existing door block. If the door leaf is wooden, then the trims should also be chosen from the same material. If the door leaf is made of PVC, plastic extensions would look logical.

The nuances of installing extensions without a groove

Extensions without a machined edge are more difficult to install, since the master must take into account a number of important nuances when installing products of this category:

- It is necessary to carefully measure the installation depth from the box to the nearest adjacent plane.

- It is recommended to install such products on a frame made of bars or galvanized profile elements.

- The extensions should not be attached to liquid nails or polyurethane foam, since the slightest temperature difference can cause the elements to bend and form a visible joint.

- When installing extensions from natural boards, provided that the thickness of the wall requires the installation of several boards in width, it is recommended to refine them to a perfectly smooth plane after fastening them to a static position.

Before installing such additions, it is also recommended to arrange mechanical fastenings of the boards to the frame elements at least every 400 - 500 mm along the entire length, which will reduce the risk of their deformation even during long-term use.

Table of standard door frame sizes

The dimensions of the door frame extension vary widely. And it’s difficult to say unequivocally what size bars there are. The standard width of the trim is 10 cm. The thickness usually does not exceed 3 cm. As for the length, it may vary. Extensions with lengths of 200 and 220 cm are standardly produced. These parameters are regulated by GOST 475-2016. The table below will help you understand what sizes of extensions for interior doors there are.

| Wall width in cm | Extension width in cm | Extension thickness in cm | Extension length in cm |

| 9-16,5 | 10-20 | 1,5-2,5 | 200-220 |

| 21,5-26,5 | 20 | 2,5 | 200-220 |

| 7,5-9 | 10 | 1,5 | 200-220 |

| 16,5-21,5 | 15 | 2,5 | 200-220 |

At the request of the client, the extensions are made in other required sizes. This is true for door blocks with non-standard parameters.

Types of framing

We have figured out what a door accessory is, now let’s find out what types it comes in.

Products are divided according to the following parameters:

- Type of construction;

- The material from which they are made.

Diagram of the telescopic structure

Construction type

There are two types of product design:

- Telescopic door extensions - the name of these models speaks for itself. Their main feature is the ability to adjust the width to the depth of the opening. This possibility is realized due to deep grooves and tongues of individual structural elements - panels and platbands. As a result, you can install extensions on a wide doorway or a narrow one without resorting to trimming;

- Edged - have a fixed width, which is slightly larger than the width of the opening. Therefore, before installation, the excess part of the panels is cut off.

Wood panels are the most durable and durable

Material

As for the material, the following types of products can most often be found on sale:

- Solid wood door panels are the most expensive, but have some disadvantages, such as the possibility of deformation and cracks, especially if low-quality wood was used. The surface of the panels can be covered with veneer of expensive types of wood, as well as varnish, impregnation or paint.

The advantages include the possibility of restoration, which increases their durability;

MDF is a pressed board made from wood chips

- Made from MDF, they are a cheaper option for additions, but visually they are not inferior to their wooden counterparts. Let us remember that MDF is a pressed board made from wood chips, denser and more uniform than chipboard. The surface of such panels can be veneered or laminated, i.e. covered with PVC film.

MDF products reliably imitate wood

MDF is a less moisture-resistant material than solid wood. In addition, such panels are practically impossible to restore. But they do not crack and have a more stable shape, and their price is usually lower than their wooden counterparts.

As you can see, all types of products have their pros and cons. Therefore, you must decide which of the above options you prefer.

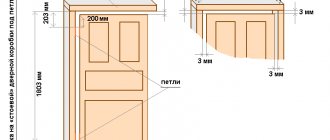

Rules for determining the width and length of an additional element for a door frame

It is important to understand how to correctly determine the dimensions of additional boards for an interior door. The width of the extensions directly depends on the thickness of the doorway and the design of the door block. To calculate the width of the additional board, you need to measure the thickness of the doorway wall and subtract the width of the existing door frame from the resulting value. The width of the insert should match the result obtained or be slightly larger.

For example, the width of the wall is 27 cm. The width of the door frame is 7.5 cm. This means that an extension is required, the minimum width of which will be 19.5 cm. You can take an extension strip of 20 cm and then saw off the excess. You can also take two additional 10 cm strips and connect them in width, and then remove all excess.

To calculate the length of door trims, you should measure the length of the side components of the door frame. The resulting value will indicate what size bar is required. As a rule, the length of decorative strips corresponds to the standard parameters of the door leaf.

The main thing is not to make mistakes in the calculations. If you buy an extension that is smaller than what is needed for the interior door, then a lot of problems will arise. Therefore, you should carefully consider determining the size of the extensions. It is recommended to measure the thickness of the passage wall, width and height of the door frame several times.

When determining the width and length of additional strips, it is important to consider the following rules:

- The width of the remaining doorway for covering with a decorative strip is measured from the door frame to the edge of the wall.

- The dimensions of the extensions should be determined taking into account the maximum values obtained during the measurement of several places.

- The side and top panels must be measured separately and at several points. This is due to the unevenness of the surface.

How to choose

For people who are far from construction and finishing work, the process of choosing accessories in a store or on an Internet site may seem complicated. Therefore, we will give some useful recommendations to make this difficult choice easier.

When purchasing, pay special attention to ensure that the overall appearance of the doorway looks harmonious as a result of the work. This is the main task, so the selected decorative details must match the color and material of the door. In addition, the patterns and texture of the materials must be identical.

We recommend that you familiarize yourself with the standard door frame sizes at this link.

It should be noted that there are no special differences when choosing extensions for metal and wooden interior doors: the principle is the same. The main difference is in the installation, since the metal door frame does not have a groove, so you will have to use joining parts.

Pay attention to the cost of materials. You should not save on additional costs by buying a laminate model if the door itself is made of expensive solid wood. The result will be a clear discrepancy, disharmony, and the overall appearance of the door structure will be reduced in price.

It is possible that you will find the standard dimensions of doorways, which you will learn about here, useful.

Before going to a hardware store or placing an order on the appropriate website, be sure to carefully take measurements and set the exact parameters of the doorway. If the wall where the door is installed is up to 8 cm wide, then you can do without additional additions; the frame and the canvas itself will be quite enough. But if the wall is thicker, even by 5 cm, it makes sense to think about additions.

The best option is to purchase accessories in one store and at the same time that you purchase the door block itself. In this case, you will be able to select decorative details that exactly match the pattern and texture of the door material.

You will probably be interested in learning more about overhead door bolts.

How is the thickness of the trim for interior doors calculated?

The thickness of the additional strip should not exceed the dimensions of the door frame groove. On average, this parameter is 1-6 cm. Standard extensions in factories are made taking into account the dimensions of the partition. If the width of the wall does not exceed 9 cm, then the thickness of the insert is 1.5 cm, and if this parameter varies between 9-16.5 cm, then an additional thickness of 1.5 or 2.5 cm will be required. For walls with a width of 16, 5-26.5 cm, a decorative strip 2.5 cm thick is needed. This parameter should not exceed 3 cm. The thickness of the trim for non-standard door blocks is determined individually. For typical interior door structures, additional strips 1.5 cm thick are sufficient. For entrance doors, this parameter is higher and amounts to 1.5-2.5 cm.

Why do you need extra?

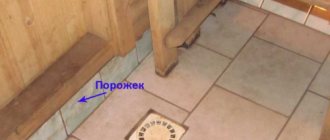

Additions are required to install a door frame that does not match the dimensions of the opening. The thickness of the wall can be 5–10 or 15 cm greater than that of the box. By installing additional slats, this difference can be easily compensated. Simple structures are easy to build yourself.

The main purpose of the addition is to create an aesthetic appearance for an interior or entrance door. Elements are selected to match the tone of the canvas, baseboard, wallpaper or contrasting shade. The main thing is to choose the right type of extensions and calculate the width.

Installing the product helps solve a number of problems:

- strengthens the opening and ensures structural strength;

- facilitates door maintenance and eliminates additional finishing of slopes;

- creates additional insulation of entrance structures;

- strengthens the box and eliminates distortions, preventing movement during operation.

Today, manufacturers offer decorative additions that give the space a complete look. Factory-made products are distinguished by their original design and finishing. Often additional slats are complemented with carvings and inserts.

What to do if the dimensions of the extensions do not correspond to the interior door

There are often situations when it turns out that purchased telescopic extensions or completely flat products are smaller or larger than the open section of the passage. Most often, this problem is faced by those who have interior doors, doorways with non-standard dimensions, who do not know which extension is best to buy, as well as those who made gross mistakes when calculating the size of regular or telescopic extensions. In any case, the question arises: what to do, how to carry out the installation? You can order new additional trims. Or you can bring them to the required size and get out of the situation without unnecessary financial expenses.

If the boards are too wide, then they are carefully reduced. To do this, use a hacksaw or saw. On the front side you need to make a groove for attaching the platbands. Difficulties in adjusting the size may arise with telescopic extensions. After all, such parts have grooves on both sides. Such boards are divided into pieces lengthwise with a saw. The spikes are removed from the platbands and attached to the smooth edge of the plank using nails.

If the thickness of the doorway wall is very large and the purchased additions cannot cover it, then several such elements are used for finishing. They are combined with each other using adhesive or furniture clips. Telescopic extensions are connected with pre-prepared thin strips. They are inserted into the recess of the two ends.

In general, the work of bringing the dimensions of telescopic extensions or planks with straight sides to the desired value is not accompanied by difficulties. Therefore, any home master can do it himself. All you need is the necessary tools and some free time.

Subtleties of choosing a good board

It is advisable to buy such fittings immediately, together with the door frame, because after installing the door frame it will be difficult to guess the shade of the frame.

Selection of planks by size

The telescopic extension for the interior door and a similar design for the front door differ only in thickness and material of manufacture. We’ll talk about the material a little later, but now we’ll look at the different sizes of telescopic extensions.

The thickness of the telescopic extension for interior doors starts from 10 mm.

Since the structure is equipped with an end groove, its thickness cannot be less than 10 mm. Although in fairness it should be noted that there are planks in which the main body of the extension has a thickness of about 7 mm, but in such planks there are overlays along the edges that form a groove.

The thickness of the extensions on interior doors ranges from 10 to 14 mm. They can also be used for entrance doors, but still, if conditions permit, then for entrance doorways it is better to take planks thicker than 15 - 25 mm.

It is advisable to take thicker additional telescopic strips for openings for entrance doors.

In the windows of hardware stores you can now find telescopic additional strips with a width of 90 mm to 400 mm. But the most popular sizes are 90 mm, 130 mm and 170 mm.

The most common telescopic structures have sizes of 90, 130 and 170 mm.

If you need a non-standard, very wide additional strip, you can order it from any workshop specializing in the manufacture of doors or furniture assembly. But you can go the other way and assemble such an array from several planks.

If the smooth joining of straight strips is quite problematic, then telescopic structures are easily joined using thin connecting strips; in the diagram below this structural element is indicated as a “fixing element”.

Assembling a wide extension from several telescopic bars will not be difficult.

As for the length, the dimensions of the telescopic bars vary from 2150 mm to 2500 mm. For narrow interior doors, for example, in services, it is advisable to take long slats, they create less waste.

By the way, stores often have substandard additional trim strips, for example, scratched or chipped, such strips are significantly cheaper. If you have the right color, you can save money by taking 2 normal strips for the side panels and 1 substandard one for the top crossbar, because you still have to cut it and the damaged part will be cut out.

Standard configuration of structures with telescopic extensions.

What are the accessories made of?

In general, additional planks are made from MDF, natural wood, chipboard, plastic and metal. But telescopic structures are only made of wood, MDF and chipboard.

- Natural wood – it makes sense to take natural wood extensions only for a similar door leaf. If you have a hollow door leaf with a laminated coating, then the dissonance between the wooden paneling and the laminate will be very noticeable;

If you are going to make a telescopic extension with your own hands, then the best material for this will be natural wood.

- MDF - this material is now perhaps the most popular in the manufacture of add-ons. MDF is not afraid of moisture, is quite resistant to mechanical damage and has an acceptable cost. Plus, under wooden doors you can use MDF covered with natural veneer, which will be much cheaper than buying wooden panels;

Veneered MDF is visually no different from natural wood.

- Chipboard - this option can be safely called budget. Extension strips made of laminated chipboard are the cheapest of the telescopic structures, but that’s where their advantages end. Chipboard is afraid of moisture, plus thin strips in the grooves break easily, so if there is an alternative, it is better to refuse installing chipboard.

MDF is the optimal material for telescopic extensions.

Material of manufacture

The door should not only be beautiful, but also resistant to mechanical damage and weather conditions. The same requirements apply to additional door elements. The material for their manufacture is selected based on operating conditions.

Tree. Solid wood panels have high strength and durability. Natural material is high-quality and expensive, allowing you to create unique design solutions thanks to the many options for wood species, shapes and processing methods.

Plastic. PVC panels are structurally similar to lining. Ideal for metal-plastic doors and windows. Their main advantage is moisture resistance, which allows them to be used in bathrooms or outdoors.

Chipboard and fibreboard. Woodworking derivatives, cheap and available

However, they should be used with caution, avoiding rapid deterioration due to excess moisture and fragility.

MDF. Additional elements made from laminated MDF boards are widely used due to the variety of colors and textures, wear and moisture resistance, and relatively low cost.

Metal. It is logical to add an extension made of the same material to the metal entrance door. But such solutions are implemented quite rarely, mainly in non-residential premises

Some useful tips

- Installing extensions on polyurethane foam is the simplest and cheapest way, while the strength of the installation does not suffer at all from the absence of nails or screws. More complex installation options were necessary before spray foam was so common. Installation, which requires drilling holes and using fasteners, is not a cheap process. In addition to the extra installation costs, there is a risk of damaging the strip during drilling, in which case you will have to purchase additional material.

- If a small gap has formed at the junction of the vertical and horizontal planks, you should not try to fasten the trim elements with nails: this can cause the plank to split. When the polyurethane foam expands, this gap will disappear on its own. To be sure of the quality of the work done, you can drive a wedge between the plank and the opening.

- It is not necessary to install the extensions completely assembled. The U-shaped structure does not have a rigid base and will warp. All defects will still have to be eliminated on site, and the installation process will take much more time and effort.

If you need outdoor floodlights, then on the page https://ledin.kz/ru/catalog/prozektora today every modern consumer has the opportunity to get acquainted with one of the most practical, reliable and attractive solutions.

Preparation for installation

Preparation of the opening depends on its condition. If the slopes are plastered and the plaster is in good condition, the preparatory stage consists of removing dust and dirt and treating with an antiseptic primer. If the plaster is cracked in places, it is worth repairing cracks and chips and leveling the surface.

Tools and materials

To install you will need the following:

- additions, pieces of MDF, long-length chipboard scraps, plastic;

- saw or jigsaw;

- plane, hammer, knife;

- level, tape measure and pencil;

- fasteners - galvanized self-tapping screws, usually nails and glue - “liquid nails” are better;

- polyurethane foam.

Installation of elements does not pose a danger to others and the performer himself. However, it is recommended to wear gloves and an apron to protect your clothing and skin.

Installation of telescopic extension strips

It is advisable to install a telescopic extension if the frame and platbands have a tongue-and-groove fastening. If you have a stationary circular saw and the appropriate skills, you can cut the tenon yourself.

Installation of finished structural elements is carried out without any particular difficulties. The planks are installed one by one in place. By adjusting the tenon-groove seating depth, the product is aligned along the plane of the wall and the joint line with the frame. Then we protect it from spacers in the standard way - with spacers or construction tape, moisten the dust-free surface of the opening with water, and fill the space with sealant.

Kinds

The planks are produced industrially in the form of monolithic panels of different widths, which allows you to select the extension to suit any conditions. If necessary, they are joined using several strips.

Standard extension without edge. Slats with a width of 70–250 mm do not have an end covering and are directly connected to the door frame and platband. Made from MDF, fiberboard, laminate or plywood.

Standard with edge. It differs from the previous version by the presence of a film coating or veneer at the end. The coating gives a decorative look and protects from moisture. Used for interior doors in bathrooms or kitchens.

Telescopic. The additional element for doors looks like lining with a longitudinal tongue-and-groove joint at the edges. It is assembled into a monolithic structure of the required size and is used for large wall widths with the possibility of precise adjustment within 10–20 mm. Installation does not require additional fastenings.

Combined. A unified design consisting of a door strip, often of a telescopic type, and a platband, made in a single design solution. The panel has an angular profile and immediately forms a portal, closing the wall near the door and the remaining gap. Installation of such models requires minimal costs.