A barrel sauna can be made with your own hands after carefully studying the technology of its manufacture and with a very serious approach to work. Often the dream of a bathhouse in a private house or country house seems unrealistic, since construction is a troublesome business, and you will need quite a lot of space. But it turns out that your dream can be realized by building one of the compact models of a barrel sauna.

Do-it-yourself sauna barrel

Not only is this type of bathhouse compact and easy to use, but its appearance can decorate any garden plot and bring many pleasant moments of relaxation and healing, thanks to the healing properties and aromas of natural wood.

The volume of the bathhouse is very small, so it warms up very quickly, which saves fuel or electricity if the stove heats up from it.

Despite the fact that one or several rooms of such a bathhouse are small, they perfectly accommodate all the attributes necessary for relaxation and wellness, which are also necessarily made of wood - these are comfortable benches for the steam room and dressing room, and buckets for water. There is a place for a stove with a heater and even a shower.

The best wood for a barrel sauna

In order for such a barrel sauna to be comfortable, you must pay attention to the wood from which it will be made. If almost any material can be suitable for an ordinary bathhouse, since the inside of the structure can be additionally sheathed with more suitable wood, then for a barrel you need to choose it right away.

Choosing the right wood for a bathhouse is a very serious matter.

For example, you cannot make it from coniferous trees, since they are rich in resinous components, and when heated they can actively release them, and heated resin can burn the skin.

- The only coniferous tree that is perfect for a barrel sauna is cedar. It has numerous healing properties, including aromatherapy. Cedar is also remarkable for its technical qualities - it does not deform or crack due to temperature changes, does not shrink, and is resistant to moisture and damage by microorganisms. In addition, such wood has wonderful rich textured patterns and color shades, which is very important for the aesthetic design of a bathhouse.

- An excellent option for building a barrel sauna would be oak, the strength and hardness of its structure will allow the structure to serve for many years. In addition, moisture hardens oak wood and makes it more durable. But this material is quite expensive, so it is often used only for the manufacture of individual building elements.

Oak wood has deep, rich dark shades and an excellent textured pattern. It, like cedar, has healing qualities, so it is suitable for a bath in all respects.

- Linden is a traditional material for building a bathhouse, as it can create an amazing healing and light microclimate in the room. In the bathhouse, built from linden, various diseases of the respiratory system, liver and kidneys were treated. The vapors of this tree can have a beneficial effect on the skin, rejuvenating and cleansing it.

Linden wood lends itself well to processing and does not shrink. A sauna built from linden heats up quickly and retains heat well.

The main disadvantage of a linden structure is its fragility, since low density and low resistance to fungal attack lead to rotting and damage to the wood.

- Another wood that is used to build a barrel sauna is aspen - it has many characteristics similar to linden. It has almost the same positive and negative qualities, but it tolerates moisture a little better, does not deform and cracks less.

Aspen has a lower price, so a bathhouse built from it can be called a budget option.

- Other wood is also used for such structures - alder, fir or birch, but they are not particularly suitable for building a barrel bath, so it is better to avoid using them.

Choosing wood for a round bath

Making a barrel sauna requires a careful approach to the selection of wood that will be used in construction, since there will be no additional internal lining.

It is strictly forbidden to use coniferous wood for construction, which contains a lot of resin, which, when heated, can burn the skin and negatively affect the respiratory system.

The only exception is cedar wood. Such a board for a barrel bath will be one of the best options, because it has a healing effect on the body due to the content of essential oils and other components. In addition, cedar wood does not crack or change shape when heated, and is resistant to high humidity and bacterial attacks. And the beautiful textured surface gives the room a special aesthetics and charm.

Oak wood is very good for making bath-barrels, as it is characterized by great strength, durability and hardness. And under the influence of moisture, oak becomes even stronger. However, oak boards are quite expensive, so they are used more often for making furniture in a bathhouse than for building walls.

The appearance of oak wood is very attractive - a deep dark shade combined with a beautiful texture. All these indicators, combined with the healing properties of oak, make it very suitable for baths.

However, most often the assembly of a barrel bath is made from linden. It gives the room a pleasant aroma and a special healing atmosphere. Linden has substances that can cure diseases of the respiratory tract, kidneys and liver, tidy up the skin, rejuvenate and cleanse it.

It is noteworthy that linden accumulates heat well. In addition, it does not shrink much and is easy to process. Read also: “Which barrel sauna is best for home and garden.”

However, due to the low density of wood, linden is very susceptible to fungal diseases and rot, so such a bathhouse will last less than one made from harder types of wood.

Aspen wood is also suitable for building a barrel sauna. In terms of its characteristics, it is similar to linden, however, when properly prepared, it is not subject to cracking, deformation and is not so susceptible to moisture, but, on the contrary, becomes stronger over time.

This wood is the cheapest of all the options presented, that is, it belongs to the economy class.

Although birch, alder or fir are often used for the construction of traditional baths, they are not suitable for barrel baths for a number of reasons.

Cedar

A cedar barrel sauna is the best option for durable and safe use. Although it is a real luxury in terms of price, cedar does not have any of the above negative properties of wood materials. It is unique and versatile, and is completely worth the investment.

Convenient to work with, has a wide range of colors and textures, retains its inherent special aroma for a long time, which actively exudes during use, and is absolutely resistant to rotting, temperature changes and humid environments. Externally, this material retains its noble tone and characteristic relief over many years of service.

What types of barrel baths are there?

Depending on preferences and functional purpose, barrel baths can be divided into three large groups:

- Finnish sauna

with dry steam and high temperature. It is preferable that next to the steam room in such a bath there is a font or a wooden bucket with cold water. - Russian steam room

with wet thick steam and brooms. Such a bathhouse includes two rooms - the washing room itself and the steam room. - Japanese

traditional barrel bath - ofuro. This is a kind of large wooden bathtub, which is constantly heated by a stove built into it.

Video description

Watch in the following video how the floors in a barrel sauna are installed:

Advice! Ventilation openings in the body, doors, windows, as well as thermometers and smart climate control technologies that independently regulate temperature and humidity conditions depending on the specified settings help improve the comfort of staying in the bathhouse.

Drainage system

The very round shape of the barrel-shaped bath facilitates the rapid collection and removal of water to the outside. It improves the accumulation of water at one point by giving the body of the structure a slight angle of inclination at the installation stage. For effective drainage, a hole of about 50 mm in diameter is made at the lowest point, and a pipe or hose is connected to it from the outside. Next, it discharges the flow to a receiver - a septic tank, drainage or a specially equipped pit.

Stove

There are two options for installing a wood-burning stove - with a firebox inside and outside. The first is traditional, the second is safer and allows you to get rid of burning, smoke, ash and other unpleasant aspects of its operation. An alternative to them is an electric heater, which deprives the user of many hassles and worries. However, in conditions of lack of electricity, it will not work, for example, in the case of a mobile bathhouse when going outdoors.

Russian bath

The use of a Russian bath includes two stages, therefore, it consists of the following premises:

- Steam room - in it, thick wet steam is formed by splashing water or herbal infusions onto heated stones.

- Washing room - here, after preliminary steaming and massage with brooms, they take a shower, washing off sweat and stuck leaves, and gradually cooling down.

During installation, barrel baths of this type are provided with a slight slope so that water can drain from the drainage system installed in the floor and not stagnate.

In this case, the stove for a barrel bath is installed between the rooms so that the mesh with the heater goes towards the steam room, and the heating tank is located in the washing room.

At the same time, the firebox itself is also located in the washing room, behind a protective screen. Since there is not much space in a barrel sauna, the stove must be compact. It is imperative to install heat-resistant panels on the walls around it to protect the wood from fire.

Nuances of arrangement

The internal arrangement of the sauna-barrel is determined by the needs and capabilities of its owner. If the bathhouse is planned to be used only in the warm season, insulation will not be required. Otherwise, it is necessary to insulate the walls with basalt wool, and in the lower part it is better to use penoplex that is not afraid of moisture.

In addition to the shelves in the steam room, it is necessary to make benches and a table in the dressing room. If there is a rest room, it is also better to equip it with wooden furniture that is not afraid of moisture.

The surfaces of walls and furniture can be impregnated with linseed oil or special compositions for baths.

It is imperative to equip the oven with protective guards to prevent burns.

For relaxation in the summer, a canopy-veranda is equipped at the entrance. To do this, the roof and wall boards are released above the entrance end wall.

Dry steam room

You can set up a steam room with dry light steam in one room, providing a container of water at the outlet into which you can plunge. If there is no river or swimming pool nearby, you will have to build a plunge pool, since it is necessary to cool down and rinse off.

This Finnish sauna from a barrel is much easier to build with your own hands than a full-fledged large-sized structure. It should be practically airtight, without cracks or crevices. No drainage hole is required. True, you need to provide a ventilation valve under the ceiling or in the floor with a special valve, which can be opened if necessary.

In such a barrel bath there are only beds that can be made wide - it will be quite comfortable to sit on them, as well as a stove with a heater. If desired, you can drop essential oil or herbal infusion onto the hot stones for therapeutic purposes.

The barrel-shaped sauna can be located both vertically and horizontally. In the latter version, there is much more space inside.

Where is the best place to install

Deciding on how to install a barrel sauna on a site begins with choosing a location for it. The main feature of the finished design is its light weight and small size. Therefore, it can be installed either permanently or with the possibility of transportation on a trailer. In the latter case, you can take a mobile bathhouse with you on a nature vacation. Naturally, the technical side of the issue depends on the capabilities of the user’s car and his needs. As a rule, the length of the structure reaches from 2 to 6 meters with a height of about 2 m, and it weighs from several hundred kilograms to two tons.

When installing a permanent bathhouse on a site, it is necessary, first of all, to be guided by the following regulatory construction requirements for distance:

- To the border of the territory - at least 1 meter.

- To a residential building - from 3 meters or more.

- To a stream, river, lake, well - at least 12 meters.

At the same time, the finished structure, even if it is often transferred to a trailer for road trips, should not simply stand on the surface of the ground. A base of boards, timber and concrete must be built under it.

Ofuro

This type of bathhouse is quite new for Russia. This is a traditional Japanese bathhouse in the form of a heated barrel. It is very easy to use and place.

The ofuro bathhouse does not have a roof, however, it can be used regardless of the time of year.

The ofuro is placed on a wooden platform, and inside the barrel there are wooden seats and a stove covered with a partition to prevent burns.

According to Japanese philosophy, in such a bath a person’s emotional and physical health is restored, he comes into harmony with himself and the world around him (read: “Japanese bath - types and features”).

As a rule, ofuro has an ellipsoidal shape, which allows the stove to be placed in the safest way for humans. Alternatively, heating pipes can be installed inside the barrel, and the stove itself can be moved outside the bathhouse.

However, such a design will require more time and resources to heat up and maintain temperature.

The duration of procedures in the Ofuro bath is usually 10-20 minutes. After such a bath, the skin should be rubbed with a hard glove, performing a massage similar to Russian brooms.

Video description

Watch in this video what the preparation of boards and the process of making a barrel sauna looks like:

The side walls are made of boards with pre-sawed grooves of two types - along the edge (a rounded tongue-and-groove type for attaching wall boards to each other) and a shelf (at the point of contact with the round wall). With their help, they are attached both to each other and to round ends and partitions. This ensures reliable adhesion of all elements of the structure.

Recommendation! The strength of the barrel-shaped bath is ensured by the use of tightening metal strips or cables on the outside. To securely fix them, it is better to use clamps with adjustable tightening. Subsequently, when the material begins to shrink, they can be tightened, thereby preventing a decrease in the rigidity of the structure and the formation of gaps between the boards.

Insulation and moisture insulation

Properly assembled walls of a barrel-shaped structure using the tongue-and-groove technology eliminate the presence of any gaps. Inside, the heated air remains for a very long time - especially with a high power stove and a wall thickness of at least 40-50 mm. For this reason, there is no need to specially insulate the bathhouse for operation even in cold weather.

The only possible way to insulate a steam room is to line the interior with clapboard. All other methods, especially with the use of artificial heat-insulating materials, can lead to the accumulation of dampness in the wall material and, as a consequence, the development of rotting processes and a significant reduction in service life.

The bathhouse also does not require special moisture insulation. It is enough to treat all parts with a special antiseptic impregnation and properly arrange a water drainage system, ensuring a slight slope of the structure itself.

Arrangement inside and outside

A considerable part of the work in deciding how to assemble a barrel sauna, after installation of the main structure, comes down to internal and external arrangement on the following points:

- Application of protective compounds, painting.

- Formation of a drainage system.

- Creating a wooden floor sheathing for better drainage and ease of use.

- Installation of windows and doors.

- Installation of a stove, shower and other bath accessories.

- Wiring and installation of electrical equipment.

- Arrangement of a ventilation system, monitoring and control devices for climate conditions.

- Installation of benches and other necessary furniture.

Preliminary work with bath material

Even if you know how to make a barrel sauna with your own hands, you still need to prepare the material for work in advance.

If you have the skills and equipment to process wood yourself, bath boards should be purchased with parameters of 90-95 mm width and 45-50 mm thickness.

Otherwise, you should provide the master with drawings of the barrel bath indicating the dimensions, according to which he will prepare the required amount of material, which will be perfectly fitted and processed.

It is worth noting that the number of boards directly depends on the size of the barrel bath. To calculate this indicator, you should draw a drawing to scale, calculating the circumference and dividing it by the width of one board. The length of the boards affects the size of the future room. As a rule, round baths occupy from 2.5 to 6 meters, depending on the type and layout of the building.

In addition, you need to prepare the wood for the back and front walls with the doorway. The stands for the barrel are made of durable wooden beams, machined to the desired shape according to the drawings. To ensure the strength of the entire structure, the walls will need to be tightened with iron strips that resemble hoops on barrels.

The fitting of window frames and door panels must be done as carefully as possible to ensure the tightness of the structure. The benches and floor inside the barrel bath are also made of wood, so they will need to be trimmed and sanded.

To ensure thermal insulation of the furnace, you should purchase a special material, such as mineralite. Since the bathhouse must breathe and be ventilated, it is provided with a special window.

Even before making a round bathhouse, you need to decide on the type of chimney, as well as the material from which it will be made.

In the case of a Russian bath, before construction you need to prepare pipes for drainage, tanks for heating water, as well as trays if you decide to equip a shower.

Depending on the type of future roof, material for it is prepared. You can use soft roofing material laid directly on top of the barrel ceiling. A more complex gable roof will require the installation of rigid supports.

All elements will be fastened with stainless steel screws or nails.

In some cases, in barrel baths, a small veranda is installed in front of the entrance, which will also require building materials.

Size, shape, layout - project

Before starting all work, it is necessary to decide what size, shape and internal structure the future structure will have. It is best to do this on paper, indicating all the important features. Therefore, from a design point of view, let’s consider what a do-it-yourself barrel sauna made from boards should look like - how to make drawings, diagrams, carry out the layout and set the dimensions.

The dimensions of the building primarily depend on the number of internal compartments and their purpose. There are the following three main layout options:

- Steam room only. Length 2-3 meters. There is no waiting room or locker room inside. The recreation area can be located nearby under a canopy or directly under the bath canopy.

- Steam room + sink. Length 3-4 meters. Inside there are two compartments - like in a full-fledged Russian bathhouse. There is also no locker room or leisure room.

- Steam room + washing room + dressing room. Maximum dimensions – up to 6 meters. Full bath with three compartments. You can steam in it, wash, and relax.

The height and width of a barrel-shaped bath are determined based on a combination of ergonomics and compactness. As a rule, their values range from 2.2 to 2.5 meters in external dimensions. In this case, the shape, important architectural features, indicating the dimensions, are clearly depicted on paper before the start of construction. In the future, this helps not to forget important design nuances and quickly navigate the features of the structure at each stage of construction.

Good to know! The stove in a Russian-type barrel-shaped bathhouse must be installed in such a way that the hot water container and the firebox door are located in the washing room, and the heater is in the steam compartment.

Discharge of wastewater from the bathhouse

Since a large amount of dirty water will form in a bathhouse with a washing room, it must be properly drained. If you use the bathhouse infrequently, you can get by with a hole in the floor. However, this method is not suitable for intensive use of a barrel bath, since excess moisture under the structure will lead to the appearance of fungus, rotting and damage to the floor, and an unpleasant odor.

Therefore, initially the bathhouse is installed at a slope towards the drainage hole connected to the pipe through which the waste goes into the drainage pit. This pipe should be carefully insulated so that in winter it does not crack and the water in it does not freeze.

For ease of movement in a round bathhouse, a grid-like flooring is arranged on the floor. Through the cracks in such a lattice, water will flow freely towards the low tide, and the boards will be able to dry well, and the structure will take on a finished look.

Main design elements

The barrel sauna consists of the following main parts:

- The base is in the form of stands.

- Round end walls - similar to the lid and bottom of a barrel.

- Side walls are made of boards laid longitudinally using a tongue-and-groove system.

- Iron external wall ties are similar to barrel hoops.

- Elements of external and internal furnishings - heat and moisture insulation, cladding, finishing, stove, drainage system.

Let's look at the features of each part in more detail.

Base

What to place the sauna barrel on is the most important aspect on which the efficiency and durability of its operation will depend. Therefore, the site is initially thoroughly prepared in accordance with the following principles:

- The area should be flat or with a slight slope - this will ensure better water flow from under the bathhouse.

- If the bathhouse is being built in a flat area, it is necessary to construct a drainage system for drainage.

- The soil under the base must be sufficiently hard and stable so that the structure does not sag or tilt during operation.

- If the structure is heavy or the ground surface is insufficiently dense, the site is concreted, or paved or paved with tiles.

The base itself is made in the form of log-crossbars connected into a single frame with a round profile - along the cross-section of which the bottom of the barrel bath will fit. In this case, the material used is thick edged boards - from 5 cm thick and about 18-20 cm wide from rot-resistant wood species, for example, larch.

The distance between the crossbars is no more than 1.5 meters, and their total number is determined by the total length of the bathhouse. The structure is made so that the bottom of the bathhouse rises about 30 cm above the ground. All elements of the base are secured to each other with self-tapping screws, screws, and corners. After assembly, the structure must be impregnated with antiseptic agents.

Walls

The barrel bath has two types of walls - end and side. The production of each variety has its own nuances. The rear and front ends have the following features:

- They have the ideal shape of a circle or oval, as well as a rounded rectangle - depending on the project plan.

- Equipped with holes for inserting windows and doors.

- If there is more than one section inside the bathhouse, you will need partitions of a similar shape and size with door openings - according to the number of rooms.

- Initially, a square is knocked together from the boards, from which the wall is then cut into the desired shape using a jigsaw using a jigsaw.

- Along the contour of window and door openings, bars are installed to strengthen the structure.

Step-by-step construction instructions

After the procurement of materials is completed, the wood must be treated with protective antiseptic impregnations, dried thoroughly, after which the assembly of the structure can begin.

Laying the foundation

Before you make a barrel sauna, you need to lay the beams for the base, which will bear the entire load of supporting the building above the surface.

The base beams are laid as follows:

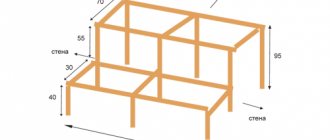

- Prepare the required number of beams 3.5-4 cm thick and 30-35 cm wide - from 2 to 4 pieces, depending on the length of the building. In them, according to the drawings, recesses are cut into which the boards of the lower part of the barrel for the bath will be laid and secured.

- Next, the beams are placed at equal distances from each other, positioned in such a way that the first supports the wall with the doorway, and the last is under the back wall.

- At the end, all laid beams should be fastened into a single rigid frame so that during installation and operation of the bath they cannot move to the sides.

Working with front and back walls

At the next stage, they begin to manufacture the bottoms of the future barrel, that is, its front and rear walls. They should be smooth and even, without cracks or defects. They need to be marked for windows and doorways. Depending on the location of the openings, bars will be fixed to the walls, along which the boards of the sides of the barrel itself will be sewn. These bars are fixed across the structure.

First of all, they assemble a frame from bars and sew a board onto it to get a square. Having calculated its middle, a circle is drawn on the surface and a circle is cut out along the contour. Both walls are marked in the same way.

Next, in each circle, markings are made for one or two windows and a doorway, after which holes are cut out. If necessary, the resulting holes are reinforced with bars.

Marking boards for the side walls of the bathhouse

Further actions will be related to the preparation and marking of boards for the side walls of the barrel bath. In those places where the front and rear panels will be adjacent to the sheathing, you need to cut special grooves that match the width of the boards in the walls and reach 8-10 mm in depth. The so-called bottoms will be inserted into these recesses.

And if the bathhouse consists of two adjacent rooms, in the place of the partition between them, grooves must also be provided in the cladding boards to secure the wall.

Window and door frames

Since windows and doors must close absolutely hermetically and not let air out of the steam room, not everyone can cope with this task on their own. Therefore, it is recommended to place an order for ready-made windows and glass doors, which will be produced in compliance with all standards.

This way, you will receive high-quality products so that you can create an optimal microclimate inside the barrel bath and get the maximum benefit from the process.

How to assemble a barrel sauna

The assembly of a round bathhouse begins with the installation of support beams on a prepared site, located slightly at a slope, to which communications for drainage are connected. They will subsequently be connected to the low tide from inside the bathhouse.

In each of the cut out recesses of the base, a center is marked to which the first bath board is attached.

Next, the remaining boards are sequentially secured on each side until the base arc is filled. In this case, you should pay attention to ensure that the grooves located on the boards form a single contour. Thus, the floor of the building will be sheathed.

The next step is to fix the front and rear walls of the bathhouse in the grooves. They should stand firmly and not require additional support. At this stage, it is already possible to determine the shape of the future building.

After installing the walls and internal partition, they move on to covering the sidewalls. All subsequent boards are fixed directly to the walls. They are laid out and fixed parallel on both sides of the barrel.

When the fastening of the boards is completed, the entire structure must be secured with metal tape. Such rims can be installed in several places from two to four. Holes are made at both ends of the tapes and, after inserting bolts and nuts into them, they are tightened, tightening the ends.

After this, you can install windows and doors.

At the last stage of construction, the roof should be arranged. It can be made of flexible tiles or soft sheet metal laid directly on top of the barrel on a waterproofing substrate. As an option, you can install a gable roof covered with corrugated sheets or metal tiles.

If you install benches outside the building on both sides of the front door, you will get an impromptu veranda.

Manufacturing of end walls

As mentioned above, a barrel-sauna is made with your own hands from two (minimum) round edge elements connected by profiled cladding boards. Therefore, construction begins with the assembly of the ends of the barrel using panel technology.

Place 2 support beams on a flat area and begin assembling the rear blank wall in the following sequence:

- Place the blanks selected for the back wall on the beams.

- Attach connecting jumpers from 4 x 10 cm boards to the resulting shield using self-tapping screws - 2 pcs. on every connection.

- Carefully measure the center of the structure and nail a long strip to it. Having marked the required value of the radius of the circle on it, drill a hole at the indicated point and secure the pencil.

- Rotating the bar on the nail, draw a circle line on all workpieces, including power jumpers.

- Using a jigsaw, cut off the protruding edges of the lumber, keeping the blade straight along the line. The first wall is ready.

Advice. It is not necessary to tie the blanks into a shield with two long jumpers. Place 4 crossbars shorter and closer to the edge - the product will look more aesthetically pleasing.

When assembling, the groove of each subsequent beam is put on the ridge of the previous one, as builders of log houses do. This connection method prevents precipitation from entering the joint. Fit the boards tightly; if necessary, use clamps and wedging.

The front wall is made in the same way, only the door frame serves as the base. Twist it with self-tapping screws from the beams, having previously secured it to the stands with clamps and aligned the diagonals with a tape measure. To trace the circle, nail a temporary board to the box with the center on it.

After sawing off the excess, sand the ends of both pieces and install the door. It would not hurt to additionally secure the outer boards of the wall with long furniture screws screwed into the adjacent board bars. How to make the round walls of a barrel-sauna, watch the video:

Interior work in a round bath

It is advisable to coat all wooden elements inside the bath structure, both walls and floors, as well as furniture, with linseed oil so that the wood is less susceptible to moisture.

The already completed bathhouse building needs to be filled with the necessary furniture and functional details:

- A recess is made in the floor for connection with pipes for draining water.

- Plank flooring is laid on the floor for ease of movement - it must be removable.

- There are shelves on the sides.

- The surfaces near the stove - floor, ceiling and walls - are sheathed with a layer of thermal insulation.

- Install the stove and chimney. At the point of contact with the ceiling, the pipe is covered with thermal insulation.

- Connect a tank for heating water if the design provides for its installation separately from the chimney.

- Water supply pipes are installed - if possible and necessary.

- If a shower is installed, a tray and associated plumbing equipment are installed.

- Set up a table if space allows.

- Lay the wiring with waterproofing and connect it to the electrical network.

- A font is placed near the bathhouse for rinsing after staying in the steam room.

If you want to steam not only in summer, but also in winter, you should think about how to insulate the barrel sauna from the outside so that the heat does not leave it too quickly. In addition, insulation will allow you to save on fuel for heating the bath in the winter. However, when carrying out such a procedure, it is necessary to comply with all standards and lay layers of vapor and waterproofing materials.

Note that the process of building a barrel bath is not as simple as it might seem. Therefore, if you are not confident in your skills, but want the bathhouse to be of high quality and comfortable, it is better to order the production of a barrel bathhouse from construction companies. After delivery and installation of the structure on your site, you will only need to connect the communications system. And then you can light the stove and use the steam room.

Base

Base for a barrel sauna

There is, as a rule, no need for a foundation. It is enough to prepare a flat area and place a special base on it, which will serve as a reliable support for the structure of a round shape.

The following can be used as such a platform:

- completely concreted or asphalted area;

- concreted area with paving slabs laid on the screed;

- an ordinary well-compacted soil surface with a wooden board laid on it;

In addition, an old reinforced concrete slab of suitable size can be used to prepare a level area.

Reinforced concrete slab as a platform

When assembling the support base, try to adhere to the following recommendations:

- To equip it, a high-quality edged board with a thickness of at least 5 cm must be used, pre-treated with a special impregnation or any other composition that protects the wood from rotting.

- The distance between the transverse support boards should be no more than 1.5 meters, and their total number should be selected based on the size of the bathhouse.

- During the assembly process, a rounded recess is made on the crossbar boards, exactly repeating the contours of the structure installed on them (when preparing the recess, be sure to ensure that the unselected part of the board is at least 10 cm on each side).

- To give the structure additional rigidity when assembling the structure, you should use metal blanks installed in corner joints and at the joints of individual base elements.

Advantages and disadvantages

The main advantage of such a structure is environmental friendliness, since it is made of natural wood, which does not harm the environment or human health. High-quality species are selected for construction, which are characterized by a long service life, strength and reliability. In addition, wood is not capable of heating up to such a state that it burns the skin, and this is a big plus.

Adaptability is another advantage of the barrel, because it can be installed not only outside, but even inside. Such buildings are equipped not only with wood-burning stoves, but also an electric heater can be installed inside. Today you can find a huge number of bathhouse designs for every taste with the most non-standard sizes, so everyone has the opportunity to choose what they personally like.

The barrel will last a long time if it is properly maintained and looked after, which will be discussed below. Having a sauna in winter will be an excellent solution, because the procedures improve health, relieve stress and improve tone.

It is worth noting the ease of assembly of the structure if you want to do it yourself. The presence of unique hinged components made from a semicircular profile ensures ease of installation. Perhaps this is one of the main advantages that distinguishes a barrel from a regular bathhouse. The low weight of the components allows you to work manually without any equipment. The structure can be installed on a stable surface, the area can be filled with concrete, or the soil can be compacted.

If we talk about ready-made design options, manufacturers pay a lot of attention to details. You can assemble a ready-made kit yourself within one day, then start decorating it, both inside and outside. Many buildings have heated floors, which increases comfort. The structure is also equipped with benches and may have a small pool inside and a seating area with a table.

Briefly about the main thing

The barrel-shaped sauna is light, mobile, compact and at the same time ergonomic, economical and original in appearance. There are three main types of it:

- Traditional - Russian, with a steam room and a washing room.

- Finnish - only with a steam room.

- Japanese - in the form of a vertically installed barrel without a roof.

The best materials for their manufacture are linden, cedar and aspen. When used correctly, they provide a healthy microclimate and do not rot or deform. When choosing a location for installation, you need to proceed not only from personal preferences, but also take into account the regulatory requirements of SNiP - 1 meter to the border, 3 meters to the house, 12 meters to the water source.

A barrel sauna consists of a base, end and side walls, partitions, iron ties and furnishing elements - stove, furniture, drainage, windows, door trim and trim. The installation of all elements has its own characteristics. You can do it yourself, but it is better to entrust it to specialists.

Beautiful examples

One of the advantages of a barrel sauna is undoubtedly its original appearance. He can't help but attract attention. Many people, having heard that their friends have such a bathhouse, want to visit it and try its steam in person.

The interior of the barrel bathhouse also looks very original from the inside. Most of the furniture is made of wood. The spherical wooden room promotes additional relaxation. Psychologically, it is comfortable, a person feels protected. In cross-section, it looks like a “sandwich” of several rooms: locker rooms, dressing room, steam room. And if the bathhouse is made of medicinal wood, then it also becomes a home clinic, which improves not only immunity, but also mood.

But over time, even such an exclusive can become boring. Many owners begin to decorate the building, and the bathhouse turns into a space shuttle or submarine or other buildings that have a cylindrical shape. Some people make a bathhouse that looks like a fairytale hut, but with an elongated oval shape. The use of glass on a large part of the facade will give the building a touch of high-tech or industrial style. Such a bathhouse, of course, will not be suitable as a winter option, but in the summer it will always delight the eye with its original appearance.

Other owners begin to emphasize the shape of the barrel or additionally adapt it to the structure of the house (leaving the necessary “gap” of 6 meters), equip it with a roof and veranda, and adapt it to a pool or water container. (If initially these architectural elements were not included in the bathhouse package).

With proper care, a barrel sauna will last for decades. Main:

- Do not forget to ventilate the steam room, and other rooms, for at least 4-5 hours, preferably after each use and if the sauna has not been heated for a long time.

- Do additional “drying” of the bath. It is necessary to run the oven at full power within one to two hours and keep the doors and windows open.

- Treat the structure with protective agents at least once a year.

- If a wood-burning stove is installed, it is advisable to use non-coniferous wood for heating. Firewood must be dry.

The water tank must be at least half full

This is very important when burning. After use, it is advisable to remove the remaining water from the tank. Check and clean the chimney regularly. Make sure that the water in the drain does not stagnate or freeze. In the autumn, the hoops that tighten the bathhouse frame should be loosened

It is during the cold season that wood tends to expand slightly due to the surrounding moisture. In summer, the reverse process occurs, the wood dries out, and the hoops need to be tightened.

Assembly order

Dimensions of a large barrel sauna

Assembly of the sauna body begins with the installation of partitions fixed to the crossbars of the base. When arranging them, one should not forget about special openings designed for installing door and window blocks, as well as treating the wood material with a special protective impregnation.

Assembly

Then, several boards of the required length are laid on the ready-made oval base, connected to each other using the “tenon and groove” method. Upon completion of the preparation of a part of the circle sufficient to fix the end partitions, the latter are installed in place and securely fastened. After this, you can safely continue forming a circle from the boards supported by the partitions.

Interior

The required rigidity of the barrel bath structure is ensured through the use of tightening metal hoops. For reliable adhesion of the enclosing hoops, special iron clamps are used, with the help of which subsequently (after the wood has dried) it will be possible to tighten the structure, preventing the formation of cracks.

Interior arrangement

As for the exterior decoration of the building, its function can be performed by a traditional soft roof mounted on the upper sector of the bathhouse. When arranging it, this part of the barrel is first covered with waterproofing material (polyethylene film, for example), and then covered with roofing felt or bitumen shingles.