In order for the tree to work as fully as possible to create favorable conditions for living in the house, you need to correctly select the sizes of logs for the structural elements of the house: external and internal load-bearing walls, floors, ceilings and roofing.

The dimensions of the logs influence many indicators of the finished house building, but most of all its heat-insulating characteristics, the final price of construction and the external appearance of the building. Having chosen the diameter of the round timber, you need to be prepared for the fact that in fact the supplier may supply the cross-section of the products by 2-3 cm smaller.

Design features of a log bathhouse

Wooden bathhouses were traditionally installed on the Russian bathhouse grounds. And now they build either from ordinary chopped (sanded) logs, or from rounded ones, laid in rows (crowns) in a log house for a bathhouse. A simple Russian bathhouse, which can still often be found in rural areas, consists of a dressing room and a steam room-soap room. The stove here is usually placed in the log house of the bathhouse - steam room, and the dressing room is heated with heat through the adjacent wall or when the door to the steam room is opened.

A more comfortable Russian bathhouse is usually built in such a way that several people can use it at the same time. In this case, the log house of such a family bath consists of a steam room with an area of 6-9 m2 for steaming and washing, a dressing room with an area of 4-6 m2 (undressing rooms) and a vestibule-hall. The space is used more efficiently when the doors from the steam room and the dressing room open into the vestibule. In addition, thanks to this, all three rooms can be heated with one stove.

Rounded logs - GOST, regulations and standards

Please note that there is no single regulatory document regulating the production and characteristics of rounded logs. Neither in Russia, nor anywhere else at all.

Self-respecting manufacturers develop their own standards - StP (StO) - the standard of an enterprise (organization), which contains all the information about the dimensions and deviations, quality and storage conditions of the material.

However, there are a number of state standards (GOST) that regulate certain aspects of the production and storage of rounded logs:

GOST standards for rounded logs

And a number of international standards (ISO) and European standards (EN):

ISO for rounded logs

Characteristics of rounded logs according to GOST 9463-88

Miracle Kamenka

To reduce heat and steam loss, the door to the steam room is equipped with a high threshold and a low frame. Along a blank wall there are wooden shelves (in 2-3 tiers), the length of the shelves is 160-200 cm. A stove-heater (it not only heats the room and heats the water, but also provides dry steam for the steam room), heated with wood, is usually installed in corner by the door.

A real Russian bath requires approximately equal values of temperature and humidity - approximately 65 to 65. This combination is optimal both for the Russian broom - it does not dry out, and for humans - humid air is considered a less aggressive environment than hot dry air. The secret of a real Russian stove-heater is that its heat is directed not outside, but inside. Thanks to this, the stones inside the furnace (rubble, boulders, pebbles, granite, but not marble, limestone or flint) are heated to 700-800 degrees. When hot stones come into contact with water, very fine and light steam is released, almost immediately rising to the ceiling of the bathhouse. We can say that the stove-heater was an ancient analogue of modern air humidifiers and heat guns.

Wood type

Pine is most widely used in construction due to its optimal price-quality ratio. The distinctive features of pine rounding are its beautiful structure, strength, relatively low thermal conductivity, resistance to external influences and affordable price. Arkhangelsk pine stands out because it practically does not crack.

Spruce can be considered an analogue of pine. It has fewer knots and is easier to process.

As for cedar, its spread is hampered by its high price.

The same judgment is true for larch. Which is the most suitable raw material for the production of rounded logs. Larch is resistant to temperature changes and moisture, has high density and strength. However, the cost of a rounded larch log is twice the price of a similar pine log. Such characteristics of larch logs have led to the fact that it is used as the main one when forming the lower crown of a log house.

Recommended height of the log bath

The height of the log house for a bathhouse, as a rule, is chosen to be minimal, since the larger the volume of the bathhouse, especially the steam room, the more heat, that is, fuel, is required to warm the interior of the log house bathhouse to the desired temperature. The main platform or bench (shelves) is made above the top row of stones in the stove, which is located approximately 1 m from the floor. If the ceiling is 1.1 m higher than the highest bench, then a person can sit on this bench and use a broom in complete comfort. Thus, the height of a medium-sized family bath is at least 2.1 m.

How to choose the best one

The desire to buy a huge log house for a bathhouse is understandable; you want everything at the same time: a large steam room, a washing room with a shower, a room for family or friendly gatherings, a place to relax on the second floor... The list goes on and on. But then the oven intervenes.

How long does it take to warm up the steam room to operating temperature? How much fuel is needed to heat rooms? Practical owners begin to count and limit themselves in their desires and settle on a standard log house width of 3 or 4 meters.

Next, a puzzle is solved with the location of the main blocks: steam room, washing room, locker room, rest area.

Where to place it?

The ideal place to build a bathhouse is a gently sloping bank of a river, lake, or pond, protected from the wind by trees. If the bathhouse is part of a system of outbuildings, the distance between it and other buildings for fire safety reasons should be at least 20 m. In residential buildings and summer cottages located outside densely populated areas, the bathhouse can be built under the same roof as the main building. It is also necessary to provide for the possibility of draining contaminated water, so it is better to locate the bathhouse in an elevated place - the possibility of minimal deepening of the sewer tray.

In ancient times, a settler who came to live in a new place began the development of the site by building a bathhouse, in which the family lived the entire time necessary to build the house. A city dweller who is developing a garden plot can now do the same: build a temporary building - a bathhouse and live in it until the construction of the house is completed.

Information on the purpose of the calculator

Online calculator for rounded logs

designed to calculate the quantity and volume of logs for a house, bathhouse and other buildings, taking into account gables and internal partitions. Additionally, calculations are made of the usable area of the room, the number of crowns, the diameter and number of wooden dowels, as well as shrinkage and load on the foundation.

When filling out the data, pay attention to the additional information with the Additional information sign

From time immemorial, log houses have been famous for their good quality, high heat capacity and environmental friendliness. With the increase in the volume of individual construction, with the advent of aerated concrete, foam plastic and other modern materials, interest in wood has not diminished at all. Even today, in the age of innovation and new technologies, many land owners continue to build wooden cottages and summer houses, preferring rounded logs.

What is a rounded log?

The material for rounded logs is usually coniferous wood. In terms of the ratio of cost and consumer qualities, pine is considered the best. When rounding, the top layer (sapwood) is cut off and the core remains, impregnated with resin and having a characteristic pine aroma.

By removing the sapwood on the log, the number of cracks decreases, which significantly increases the thermal insulation of the material. After rolling on end-cutting machines, the wood is impregnated with special mixtures that provide protection from the external environment. Despite multi-stage processing, the surface of the wood retains its magnificent pattern, which gives the appearance of the structure variety and elegance.

Advantages of buildings made of rounded logs

Rounded logs are a good alternative to sanded logs or sawn timber. They are not only not inferior to these types of building materials in terms of quality and durability, but also have a number of undeniable advantages:

- Due to the even and smooth surface of the log, a new house does not require decorative finishing.

- The logs have neat grooves made on special machines, so during construction they can be tightly joined at the corners of the structure.

- The installation and construction time of a house can be significantly accelerated by calculating and preparing a complete building constructor in advance.

- Houses made from rounded logs have an attractive appearance and can be built in different architectural styles - from the “European” version to the traditional Russian hut.

In the hands of a skilled craftsman, wood seems to acquire a soul and delights home owners with a pleasant shine, aroma and unique design. Cottages made from rounded logs can provide comfort; they are easier to breathe in compared to the stone frames of city apartments, and the ability of wood to accumulate heat in summer and retain it in winter makes it possible to build such buildings in areas with any type of climate.

The following is a complete list of calculations performed with a brief description of each item. If you haven't found the answer to your question, you can contact us via feedback.

Layout

A bathhouse usually consists of 3 parts: a steam room (optimal size 1.8 x 2 m), a washing room and a dressing room (dressing room).

The recommended ratio of room areas in such a bathhouse is 1:1, 5:2. With this layout, the locker room is used as a rest room and therefore has a large area. In the more common version, the bathhouse does not have a separate room for washing and consists of a steam room, a locker room and sometimes a vestibule. The area of the steam room in such a bath is determined by the type of stove used, its dimensions and construction capabilities.

The dimensions of the steam room vary from 1.8 x 2 m when using a 2.5 x 3 continuous metal stove for heating when installing a periodic brick stove.

Dimensions of rounded logs

During the logging process, logs are sorted before being processed. A trunk with the correct parameters allows you to obtain lumber with the specified dimensions.

Standard log sizes:

- diameter (section) of a rounded log . This parameter is of greatest importance, since it directly determines the thermal conductivity and reliability of the walls.

The diameter of the log varies between 160-320 mm. The most popular in private construction is a rounded log with a diameter of 240 mm.

Section (diameter) of a rounded log (180, 200, 220, 240, 260 mm)

What diameter of log is needed for year-round use?

The choice of diameter when building a house is determined by its purpose and location:

| Log diameter | Purpose | Location |

| 160-180 mm | Cottage, bathhouse, outbuilding | Southern regions |

| 200 mm | Summer house, cottage, bathhouse, outbuilding, gazebo, garage | european part of Russia |

| 220 mm | Seasonal house, cottage, guest house, bathhouse, gazebo | european part of Russia |

| 240-260 mm | Houses of permanent residence with insulation. Recommended for one-story houses with an area of more than 250 square meters, two-story houses and houses with an attic | Western Siberia |

| 280-320 mm | Year-round houses with attic insulation. Designed for one-story houses with an area of more than 250 square meters, two-story houses and houses with an attic. | Western Siberia |

- working height of a rounded log . This indicator determines how many crowns should be laid to achieve a given wall height. The working height is calculated by measuring the distance from the top point of the log section to the top of the groove. The type of groove also affects the working height. For example, the working height of a rounded log with a diameter of 240 mm is 208 mm. (if there is a lunar groove) and 190 mm (if there is a Finnish groove).

- length of rounded log . Standard length – 6.m.p. or a multiple of 1.m.p. By special order it is possible to produce logs with a maximum length of up to 12 m. However, this will significantly affect the cost of the product, because There will be a significant amount of waste during the production process. This is due to the significant difference in trunk diameter over a tree length of 12 m.

- groove width . With an equal log diameter (for example, 220 mm), the Finnish groove will be wider (140 mm) than the lunar groove (110 mm). There is also an extended lunar groove (20 mm wider).

Standard groove width for rounded logs

- compensation cut . The presence of a cut allows you to reduce internal stress in the log and prevent the appearance of a large number of gaps (cracks). The cutting depth (15-20 mm) is determined by the diameter of the log. In practice, it is a controversial decision, with many arguments for and against.

Unloading cut (compensation) on a rounded log

- cubic capacity of rounded log . As a rule, lumber is sold in cubic meters. The volume of the log, depending on the type of profile (groove), diameter and length of the log, is given in the table.

How to calculate the cubic capacity of a rounded log mathematically?

- calculate the cross-sectional area of the log;

- multiply the resulting value by the length of the log;

- round to the nearest whole number.

FUNDAMENTAL question

The bathhouse is built on a special foundation made of stone or concrete.

By design, foundations are divided into strip foundations - in the form of continuous walls and columnar foundations - in the form of separate support pillars. The depth of foundations depends on the depth of the soil layers taken as the natural foundation. In clayey and loamy soils, which have the property of swelling when freezing, the base of the foundation is placed below the soil freezing level by 10-25 cm. In non-heaving soils, which include sandy and gravelly soils, the foundation depth does not depend on the freezing depth and is no less than 0.5 m from the planning mark. For internal walls it is less than for external ones, but not less than 0.5 m from the ground level.

Strip foundations are made from irregularly shaped natural rubble stone with cement mortar or from rubble concrete and concrete (a cement mortar of 1:3 composition (1 part cement and 3 parts sand) is used to level the top.

It is advisable to dry the leveled and smoothed cement mortar, and put waterproofing on top of it on mastic from two layers of roofing felt or roofing felt (roofing felt on tar, and roofing felt on bitumen mastic). The thickness of the strip foundation depends on the size and design of the bathhouse and can vary from 250 to 500 mm.

Columnar foundations are usually made for wooden baths with light loads in the form of individual stone or brick pillars measuring 380 x 380 mm. The pillars are placed at all corners of the structure and at the junction of the internal walls with the external ones. For large baths, intermediate ones are installed between the main pillars so that the distance between adjacent ones does not exceed 2 m.

Production of rounded logs

The unique properties of rounded logs are acquired during its production process, which consists of the following stages:

- sorting of raw materials (saw logs) by diameter;

- processing in a rounding machine. After the milling stage, the top layer will be removed from the log, and only the core part will remain, which is the strongest and has the least shrinkage. Also, during processing, the difference in log diameters at the bottom and at the top will be minimized. According to the standard, it cannot exceed 4 mm;

- log sorting. Allows you to sort workpieces according to specified sizes;

- drying: natural or forced;

- formation of a compensation cut. Note that not all logs have a cut, and it is often done according to the buyer’s order;

- open.

The log goes on sale having a standard length. But many homeowners prefer not to bother with adjusting the logs to length, but order a house kit for their home. A house kit made from rounded logs is a ready-made kit for assembling a house. It resembles a construction set that contains a set of parts (logs) prepared in length in accordance with the provided house design, with the corresponding marking of each element. A significant advantage of using a house kit is the presence of seats (bowls), which make joining of logs quick and tight;

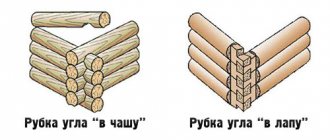

- bowling – involves cutting the seats (bowls) necessary for laying crowns from logs. Like a profiled beam, two types of seats are cut out in a rounded log:

– transverse bowls; Material prepared for the website www.moydomik.net

– diagonal bowls;

– longitudinal grooves. The curvature of the grooves is somewhat different from the curvature of the log. This is necessary in order to lay heat-insulating material at the junction of the logs. If the dimensions of the grooves coincide, then there is a high probability that after shrinkage the log will touch the bottom only with the central point, and not with the entire surface of the groove. This will lead to the fact that the junction of the logs will have to be caulked;

- trimming. End processing;

- antiseptic treatment. It is performed over the entire area of the log, including longitudinal grooves and bowls. Allows you to ensure biological inertness of the log and preserve its properties during storage, transportation and installation. Only water-based antiseptics are used. This solution does not clog the micropores of the wood, and it continues to dry;

- transportation to the construction site. Manufacturers often take on this function, as they can ensure the unloading and proper storage of logs on site. After all, a log house is built from 4 to 6 months, depending on its size and complexity of the project. During this period, it is necessary to organize proper storage of the material;

- storage;

- package.

Log walls for a bathhouse

The log walls of a bathhouse are built in the same way as for a hut. The walls of log houses are based on log houses made of processed round logs, laid in rows (crowns). A groove is cut out from the bottom side of each log, with which the log is placed on the round surface of the previous log (hump) with a layer of tow made of flax and hemp tow or moss 1 cm thick. The lower crown of the logs is isolated from the strip foundation with a layer of roofing material.

The log house of the bathhouse can also be made from timber. The beams are connected on round tenons (dowels) with a diameter of 25 mm and a length of 100 mm. At least 2 spikes are placed on each beam. Corners and connections with internal walls are assembled into a tongue or groove. The free length of walls in timber buildings should not be more than 6.5 m; for longer lengths (to avoid bulging of timber from the plane of the wall), vertical compression is applied.

Tow is laid between the beams. After installing the walls of the log house, the grooves are caulked. The final caulking of the seams of log and timber walls is carried out a year and a half after the construction of the bathhouse, when the walls have finally settled.

Which height do you prefer?

Centuries of experience have shown that the universal ceiling height in a bathhouse is 2.2 m. This means that when choosing a log house you should not listen to the manufacturer’s reasoning that small dimensions will help save heat. Please note that:

- floor joists cut between the second and third crown (0.35 cm of total height is lost);

- the attic floor is installed in the penultimate crown (minus 0.16 m);

- the thickness of the floorboard is from 3 to 5 cm, and the lining on the ceiling is about 2 cm;

- The shrinkage of the building is usually 1 cm from each crown (minus another 0.15 m).

Attention! Taking these design features into account, it turns out that the bathhouse frame needs to be selected with a height of 2.9-3.0 m.

Floors in the bathhouse

Floors in the bathhouse are made of two types - solid or suspended.

Hard floors are made of concrete poured over a gravel base, sloping towards a drain hole through which water is carried through a pipe into a drainage hole. The joint between the floor and the walls of the log house is sealed with a concrete plinth for moisture resistance. To protect feet, the floor is covered with plank flooring installed on rubber pads, thus ensuring quick drying after use. The flooring should consist of several sections, which allows them to be taken out of the bathhouse and washed.

The suspended floor is laid from edged or tongue-and-groove boards 25-37 mm thick over wooden joists using waterproofing. The logs are laid on brick pillars with a cross section of 250 x 250 mm, installed on a sand or concrete base. If the bathhouse is placed on a strip foundation, the floor is made of edged boards and they are secured to the joists with a gap of 5-7 mm so that water flows freely from them. The underlying layer under the floor is covered with concrete or compacted with clay with a slope towards the drain hole.

Floors can be earthen, clay, concrete or tiled - the main thing is to ensure the outflow of water from the bathhouse.

In the steam room, the floors are either wooden (coating it with varnish is strictly prohibited; nothing in the steam room should be varnished.) or tiled. And they do not require any insulation, otherwise moisture, slowly seeping under the floor boards, will accumulate there, which will lead to the process of rotting, an odor will appear... Since at the bottom of the steam room there is the highest humidity and low temperature, the wooden floor does not dry. Therefore, it is still better to lay tiled or similar tiles on the floor. Well, in order not to get burned on the tiled floor when you steam, wooden “ladders” or gratings are laid on it. A tiled floor and wooden “ladders” will, of course, cost a little more than just a wooden floor, but replacing a rotten floor in 3-4 years will cost even more.

To maintain heat, the floor in the steam room should be 15 centimeters higher than the washing room floor. And the level of the washing room floor is 3 centimeters below the level of the locker room. It is absolutely unacceptable for a bathhouse to have a floor made of any synthetic materials, such as linoleum, since in the hot atmosphere of the bathhouse they will emit harmful gases.

View of the profile (groove) of a rounded log

The profile or longitudinal groove is selected along the entire length of the rounded log and is designed to ensure a tighter fit of the logs along the length during installation.

Lunar groove

The lunar profile is a longitudinal cut of a semicircular shape. It has become more widespread due to the simplicity of the device.

Lunar groove of rounded log

Characteristics of rounded logs with lunar profile

Marking, diameter, working height, groove width, volume m.cub.

Finnish groove

It has a more complex tongue-and-groove installation system. It has so-called shoulders - cuts that increase the thermal insulation properties of the joint. The Finnish groove allows you to reduce damage from cracks to a minimum. At the same time, the use of a Finnish groove allows you to abandon the procedure of caulking log walls.

Finnish groove of rounded logs

Characteristics of rounded logs with Finnish profile

Marking, diameter, working height, groove width, volume m.cub.

Note. According to the thermal calculation data, a log with a Finnish profile with a diameter of 220 mm. Thermal insulation is equivalent to a log with a lunar profile with a diameter of 280 mm.

Wastewater disposal

When building a bathhouse, it is best to divert water outside the bathhouse and the farther the better, but at least 2-3 m.

It is best to discharge water into a centralized or local (local) sewer network. In its absence, water can be diverted to a ravine or other place, while observing sanitary supervision standards. For water drainage, it is best to use cast iron, asbestos-cement, ceramic and concrete pipes. It is possible to use modern PVC-based materials. It is not recommended to use wooden pipes (boxes) or steel pipes, they quickly rot, and steel pipes are destroyed by rusting.

Drain pipes with a diameter of at least 50 mm are assembled into a ladder box made of steel or concrete with a pipe raised 19 cm from the bottom. An inclined metal plate is installed in the ladder, not reaching the bottom by 5-6 cm, and is hermetically fastened to the wall from the sides and top. The top of the ladder is covered with a grille-lid with holes. This creates a water seal that prevents odors from rotten water and cold air from entering the bathhouse. To prevent water from freezing in the drain, it must be removed after washing. The joints between the pipes are covered with cement mortar.

Advice from Ivanovich

Our expert, an experienced builder and a seasoned bathhouse regular, Yuri Ivanovich, reveals secrets that are worth listening to.

- Don't overpay for the foundation. This construction is quite light; traditional monolithic pillars and a good sand bed 40 cm deep are quite sufficient.

- Do not settle for a ceiling height of 180 cm. Such a bathhouse is not cozy and cramped. The minimum ceiling height should be 210 cm. It is better to order a log house one or two crowns higher.

- Do not cover the roof with roofing felt; use durable, modern material right away.

- Cut out openings for windows and doors after the frame shrinks, after a year. And it will be easier to move whole logs for felling. If you really need it, cut a passage three or four logs high.

A bathhouse furnished with your own hands is an excellent proof of the owner’s wealth and a cozy place to relax. After completing the troublesome construction, you can rest peacefully for years, relaxing your soul and body.

Ceiling

The ceiling of the bathhouse is made of planed boards, tightly fitted to each other. To preserve heat, steam and thermal insulation is installed on top of the boards. The easiest way to make a vapor barrier is to apply a 1.5-2 cm thick coating of clay on top of the boards. For insulation, use mineral wool or backfill with wood chips moistened with a cement solution in a ratio of 8:1, 15-17 cm thick. A lime-coated layer is placed on top of the insulating backfill. sand screed or backfill with sand (earth) at least 20 cm thick. The thermal regime of the steam room largely depends on the quality of the ceiling insulation.

How to calculate volumes of materials

For those who decide to build a log house, it is important to correctly calculate the required amount of building materials. Since logs are characterized by a cylindrical shape, calculations must be made based on this parameter. You cannot calculate the volume by simply multiplying the thickness of the walls by the height. To do it yourself correctly, use a special cubical of rounded logs.

The simplest calculation is carried out using the formula = P*R2*N, where

P

= 3.14;

R2

is the radius of the rounded log squared;

H

is the length of the rounded log.

We multiply the result obtained by the number of logs needed to build a house or bathhouse. Do not forget to add 7%, which is allocated for the shrinkage of the log house. To facilitate the calculation, the results for different log diameters are presented in a table of log cubic capacity.

Doors

Doors are made on dowels from thick tongue-and-groove boards or from boards with selected quarters. The door dimensions should be 5 mm less than the distance between the side folds (quarters). If the doors fit tightly into the quarters of the frame, then, swelling from water and steam, they may jam. In the steam room and washing room, their width should not exceed 70-75 cm. The height of the doors, as a rule, is 160-170 cm. It is recommended to make the threshold high - 25-30 cm from the floor. This is somewhat inconvenient, but it retains heat better, especially at floor level.

Physical properties of rounded logs

- thermal conductivity. The table shows a comparison of the thermal conductivity of a log and a brick wall at different freezing temperatures.

- soundproofing . Thanks to the structure of the wood, the log does not transmit sound well, which allows you to avoid the penetration of external sounds and enjoy silence in a log house;

- strength . Caused by the presence of resin in coniferous wood and larch;

- dimensional stability . Achieved through the use of high-quality equipment. Material prepared for the website www.moydomik.net

Choosing a foundation for a bath

When choosing which foundation is best for a bathhouse, you need to consider three factors:

- weight and size characteristics of the structure;

- geological conditions on the site - presence of a slope, type of soil and its bearing capacity, freezing depth and groundwater level;

- budget allocated for construction.

In most cases, the best option would be a strip foundation for a bathhouse. The different depths of the strip foundation allow you to build in any soil conditions - on stable soil it is rational to construct a shallow strip (deepened by 30-80 cm), in heaving soil - deep strips (the support base is 20-30 cm below the depth of soil freezing).

However, the arrangement of a buried foundation is accompanied by serious costs for materials, and in order to save money, it is better to give preference to screw or columnar foundations.

The screw foundation for a log bathhouse consists of steel piles tied with a grillage, the blades of which open the surface layer of soil and rest on solid deep soil. The advantages of this option are low cost, quick installation time (installing a foundation for a bathhouse takes 2-3 days) and reliability.

Shallow strip foundation for a bathhouse

A good analogue for the construction of light buildings (log house, frame panels - area from 3x3 to 6x6 m) is a bathhouse on a columnar foundation. To install a log bathhouse on poles, the soil on the site must not be prone to horizontal shifts, otherwise there is a high risk of the supports overturning. The pillars can be monolithic (concreted asbestos pipes) or prefabricated (from FBS blocks).

In complex soils - mobile, heaving and low-density - a foundation slab is needed. This is a monolithic structure made of reinforced concrete 30-50 cm thick, the dimensions of which correspond to the area of the building. The slab is a reliable and durable foundation for a frame bathhouse or log house, but its cost is higher than other analogues.

A simple foundation for a bathhouse, suitable for light frame buildings measuring 3x3 and 3x4 m - a base made of car tires. It is possible to erect a building on such a foundation in stable soil that is not prone to heaving. A bathhouse without a foundation can only be built on rocky soils.

Collection of characteristics and calculation of the foundation

Before building a foundation for a bathhouse with your own hands, you need to calculate the foundation and find out whether it will withstand the building in specific soil conditions. You need to determine the type of soil on the site (sandy, clayey, sandy loam) and, using standard tables, find out the value of its resistance per 1 cm2.

Next, you need to calculate the loads that will be transmitted by the foundation to the soil. Load calculations are performed using the following algorithm:

- Calculation of the mass of a building - the weight of the roof, floors and walls is separately calculated and summed up by multiplying their area by the specific weight of the building material (tabular data).

- Calculation of snow loads - multiply the roof area by the weight of m2 of snow cover in your region.

- Calculation of operational loads (furniture, stove, wall cladding) - multiply the area of the basement floor by the average load of 100 kg.

- Calculation of total loads - we summarize the obtained data and add a safety margin by multiplying the amount by 1.2.

It remains to determine the supporting area of the foundation, multiplying its perimeter by its width, and calculate the load per 1 cm2 of soil.

For example: the standard width of the tape for log walls is 30 cm, for a bathhouse with an area of 6 × 6 m (perimeter 24 m) its supporting area will be 240 * 30 = 7200 cm2, for a 3 × 3 building - 3600 cm2, for a bathhouse 3 ×4 - 4200 cm2, and so on. Now you need to divide the total loads by the supporting area and compare the resulting value with the resistance of 1 cm2 of soil; if the result exceeds the bearing capacity, you will need to increase the area where the foundation rests on the ground by adding the width of the tape or the diameter of the pillars.

Board, timber, log

Introduction to lumber

- Everyone knows what a board is, especially since most of us see such a profile every day (or structures made from it), but not everyone realizes that its price depends on the type and assortment. We will not talk about the assortment now, but we will point out the three most common types - these are edged, unedged and one-sided edged boards, which can have different widths and thicknesses and can be made from. There is also the so-called croaker obapole or slab - these are boards that are not completely sawn and on one side there is usually the upper part of the trunk along with the bark.

Note. It should be noted that often a board of 100×50 mm or, for example, 120×50 mm is perceived as timber, but such a profile in any case remains a board.

- The instructions call a beam a trimmed profile with a cross section of at least 100 mm; thinner profiles belong to the category of bars, and those less than 30 mm belong to the category of slats. Such lumber can be either solid wood or glued together from lamellas (boards or plywood) - its performance qualities, such as strength and water repellency, largely depend on this. In addition, it can have a different profile, since it is usually used for the construction of walls and partitions.

- A tree trunk, if it is long enough, can be divided into three parts - the lower one is the butt, the middle one is the drug, and the upper one is either the top or the third, but any of these parts has a larger section at the bottom and tapers at the top. In addition, the circumference of the trunk is far from ideal, therefore, if you calculate how many cubes of logs are needed for a 10x10 house, the answer may turn out different each time. A completely different matter is a rounded log, where after processing the trunk on a special machine, an almost perfect round timber is obtained, where the circumference along the entire length is maintained down to a millimeter.

Making calculations

Note. As we have already said, sawn materials with right angles (timber, timber, slats or boards) are much easier to calculate, since when laid they occupy almost the entire space. But how much a cube of a log is will be accompanied by some explanations.

| Cross section of the board in mm | Number of pieces per m 3 with a board length of 6 m | The volume of each board is 6 m in m 3 |

| 25x100 | 66,6 | 0,015 |

| 25x120 | 55,5 | 0,018 |

| 25x150 | 44,4 | 0,022 |

| 25x200 | 33,3 | 0,03 |

| 40x100 | 41,6 | 0,024 |

| 40x120 | 34,7 | 0,0288 |

| 40x150 | 27,7 | 0,036 |

| 40x200 | 20,8 | 0,048 |

| 50x50 | 66,6 | 0,015 |

| 50x100 | 33,3 | 0,03 |

| 50x120 | 27,7 | 0,036 |

| 50x150 | 22,2 | 0,045 |

| 50x200 | 16,6 | 0,06 |

| 50x250 | 13,3 | 0,075 |

Edged board calculation table

| Cross section of timber in mm | Number of pieces per m 3 with a beam length of 6 m | The volume of each board is 6 m in m 3 |

| 75x150 | 14,8 | |

| 100x100 | 16,6 | 0,06 |

| 100x150 | 11,1 | 0,09 |

| 100x200 | 8,3 | 0,12 |

| 150x150 | 7,4 | 0,135 |

| 150x200 | 5,5 | 0,18 |

| 150x300 | 3,7 | 0,27 |

| 200x200 | 4,1 | 0,24 |

Calculation table for solid timber

Table - how many cubes are in a rounded log

In fact, everything turns out to be much simpler than it looks at first glance, and the very first step is to calculate the volume of one log using the formula πr 2 *H. As everyone knows, the number π has a value of 3.14, r is the radius of the object being counted, and H is its length.

For example, let’s calculate the volume of the thickest rounded log with a cross section of 320 mm, but since we are interested in cubic capacity, we will carry out calculations in meters, which means that our diameter will be 320 mm = 0.32 m, and the radius will be 0.32 /2=0.16m. Now we count 3.14 * 0.16 2 * 6 = 0.482304 m 3 . Consequently, in one studied object we obtained a volume of 0.482304 m 3.

You can also calculate construction timber in the same way, but there you will not be able to get accurate calculations for the reasons that we have already mentioned above - narrowing of the trunk and blurred cross-section.

But here we can make allowances for the fact that the butt (lower) part of the trunk is used for construction, and there the narrowing is least noticeable, so here calculations can be done with the smallest allowances.

Undeniable advantages and annoying disadvantages of frame baths

Frame bathhouse covered with a block house

The frame bathhouse pampers its adherents with beauty and comfort. For a dacha, it is impeccable: neat, attractive and ergonomic. In addition, she demonstrates a colossal number of undeniable advantages.

- Long service life. Thanks to innovative technology and modern raw materials, the bathhouse is durable. In addition, it does not require frequent repair work.

- Wear resistance. A cozy steam room, built using modern frame technology, is generously treated with special substances that make it resistant to the harmful effects of negative environmental factors. Namely: it is not afraid of the action of chemical, biological, climatic, thermal factors. And it is not afraid of mechanical factors (within reason), since it is built using the strongest materials - the same OSB boards or plywood.

- Environmental friendliness. The bathhouse is not capable of harming people's health, as it is constructed from environmentally friendly raw materials that have passed the strictest testing by experts.

- Aesthetics. Frame steam rooms look avant-garde, solid and noble.

- Comfortable. Structures built using modern frame technology are easy to use and easy to maintain.

- Economical. The cost of a frame structure varies within reasonable limits. Well, at least it won’t leave the owner of the steam room “without pants” (although depending on how you look at it, it’s inconvenient to wash while dressed). The construction will cost approximately $80 per square meter.

- Lightning speed of construction. Construction of the structure lasts from two weeks to a month.

- Possibility of finishing work. The surface of the bathhouse can be combined with any facing raw material, allowing you to make your wildest dreams come true. Do you want to have a magical house, like in fairy tales? Maybe you dream of a mansion? Perhaps you are dreaming of a hut on chicken legs? Although, maybe you want to have a super innovative building? No problem! For a frame bath, “all outfits” are good.

- There is no bad weather. And even if there is, the frame bath doesn’t care. Construction can be carried out at any time of the year.

- Heat capacity. The steam room heats up very quickly, so you won’t have to wait long for the optimal temperature to be reached.

- Non-shrinkability. The design does not shrink, which is simply wonderful. After all, you don’t need to wait a lot of time to do the exterior and interior decoration.

So-so. A worthy competitor, to say the least. Maybe she has no flaws? The advantages are painfully good. How? Yes, of course.

- Expensive. How so? Construction is inexpensive. That's how it is. But facing work will cost a pretty penny. In addition, a capricious steam room requires high-quality insulation, which is also not cheap, alas.

- High thermal conductivity. Yes, undoubtedly, the baths warm up in a short time, but, unfortunately, they are not able to retain heat for a long time.

- Possible harm. What is it? It was said that the frame structure is safe. This is true. The structure, which is usually built from wood, cannot harm human health. But thermal insulation material, especially if the owner has saved on it, can release toxic substances under the influence of high temperature and humidity (take the same polystyrene foam).

That's all. The frame bathhouse has no more negative aspects. In principle, if you want, you can read reviews from the owners of such objects and make sure that the design deserves attention.

Converting the calculated number of logs from pieces to cubes

If you decide to build a log house, then in order not to delay construction due to a lack of materials, you should decide in advance on the size of the hut and determine how much timber it will require. Calculating, for example, the number of logs needed for walls is not so difficult. Let it be a house 6 by 6 meters at the base and 3 m high. The dimensions were chosen for convenience, because logs on sale are 6 m long. The diameter of their cross-section ranges from 18 cm to 30 cm, maybe more. The most popular of them is 24 cm.

Exactly one pillar is laid along one wall, and along the height of the wall - 3 m: 0.24 m = 12.5 or as many as 13 pieces. The house in this example has all equal sides, which means that in total you will have to buy 13 x 4 = 52 pillars. The price of timber is set in cubic meters. Therefore, “pieces” should be translated into “cubes”.

This can be done as follows. A rounded log has the same cross-sectional diameter throughout its entire length. Cylinder volume formula:

V = 3.14xr 2 x L,

where V is the desired value, 3.14 is a constant number, r is the cross-sectional radius of the log, L is its length. In this case, it turns out that the volume of one trunk will be equal to:

V 1 = 3.14 x (0.24: 2) 2 x 6 = 3.14 x 0.0144 x 6 = 0.271 m 3.

It has already been determined that the construction of the walls of a wooden hut measuring 6 x 6 meters requires 52 logs. Then in cubes you will need:

V 0 = V 1 x 52 = 0.271 m 3 x 52 = 14.092 m 3.

An example of the calculation is given practically for a well house; the presence of windows and doors was not taken into account.

The dimensions of all openings must be taken into account during calculations.

Just for clarity, we took such lengths of the sides that it would not be necessary to saw the board to size.

Return to contents

Budget for the construction of a bathhouse

What should those who simply do not have enough money for a log of sufficient diameter do? There are several simple and painless ways out of this situation. The first is to reduce the size of the project by removing unnecessary areas from it, and also optimize the space to the maximum. This way you can build a warm sauna from a log of the required diameter, which can be used all year round.

The second way out is to use modern technologies. Be sure to seal the joints between logs with special sealants. If we look at the question from this side, then no one has canceled the laying of insulation under the internal lining, especially since in the steam room this will have to be done anyway.

Features of using the columnar type

This type of foundation for a bathhouse consists of vertical supports, evenly spaced along the perimeter of the structure, resting on dense layers of soil, the lower part of which is below the depth of soil freezing. The columnar support is the easiest type of bathhouse base to manufacture and, moreover, the least expensive.

This type of foundation will fulfill the tasks assigned to it when it is installed on dense, hard soils that are not prone to seasonal movements, heaving, and located on hills. It is not recommended to use the columnar type as a base for baths made from thick wooden logs due to their significant weight. Also in this case, it will be necessary to make a separate foundation for the stove in the bathhouse.

The materials for the supports of such a foundation can be concrete blocks, bricks, asbestos pipes filled with concrete and reinforced with reinforcement, and even rubble stone.

Such structures are perfect for building frame-type baths or from light wooden beams.

The process of building a columnar base is as follows:

- The marking of the territory is carried out in the manner described above. However, it is additionally necessary to mark around the perimeter the places where the supports will be laid.

The gaps between the supports are 1.5 - 2.5 m. Moreover, at the joints of the bathhouse frame, supports are erected in any case, regardless of the distance to neighboring pillars. - If bricks or concrete blocks are used to construct supports, holes are dug below the freezing depth of the soil, but not less than 1.5 m deep. If asbestos pipes are used, it is necessary to make a hole of the required depth using a garden drill.

- Geotextiles are laid at the bottom of the pit and a sand cushion is constructed. The sand is thoroughly compacted.

- The supports are laid out from the selected material. For this purpose, sand-cement mortar is used using cement grades M300 - M500.

- After 2 - 3 days, after the initial crystallization of the solution, the pillars are carefully waterproofed using tar or rolled materials, for example, roofing felt. After this, the holes in which the supports are located are filled with soil and compacted well every 10 - 15 cm in depth.

- After 3 weeks, a grillage made of wooden beams is mounted on the finished columnar foundation using fastening bolts with a diameter of 12-16 mm or anchors. The frame can be installed on the grillage immediately after its manufacture.

Attention! When laying supports, you need to carefully control their height and depth using a hydraulic level. It must be the same for all elements, otherwise there is a high risk of the frame being skewed during construction.