Articles

All photos from the article

Building houses from wood, continuing the centuries-old traditions of our ancestors, is no longer just fashionable, but also completely justified on an environmental principle that worries more and more people every day. In addition, in terms of comfort of living, no building made from known materials can compare with a log house or a building made of timber. If you want to know what diameter of log is needed for year-round use, then check out this article.

Having chosen a certain diameter of a round timber, be prepared for the fact that the cross-section may differ on products by up to 3-4 cm

Optimal dimensions of logs

A wooden house outperforms its concrete and stone counterparts in all the most important parameters for housing:

- The ability to easily pass steam and air, which guarantees automatic adjustment of the optimal humidity level in the rooms.

- The lowest thermal conductivity, which means the house will be warm with minimal energy costs. In summer it will be pleasantly cool.

For your information! Wood fills the atmosphere of the house with a subtle, characteristic aroma that has a beneficial effect on human health. And lumber from coniferous trees has persistent antibacterial properties, purifies the air and surfaces of structures from pathogenic flora.

Protection from winds and frost for the house ensures the correct selection of lumber for the construction of a wooden frame. Today we will discuss choosing the optimal log diameter for a log house.

To the uninitiated, this question may seem far-fetched; what could be simpler, take a rounded log with a diameter of 400 or more, build it, it will be sound and warm. However, issues of energy saving and saving one’s own finances remain relevant for the vast majority of the population of our country.

In this regard, instructions for optimizing the purchase of wood for the construction of buildings for various purposes will be useful to many.

Advice! Those who intend to build with wood with their own hands should know the recommendations of professionals in this matter. And it is better to exercise control at a construction site if you know the basics of wooden construction.

What you should pay attention to when choosing the diameter of a log

When choosing logs for a log house, pay attention to the climatic conditions of the region. In the southern regions, for the construction of seasonal housing, if it is very important to save money, you can even use a diameter of 20-22 cm. For a house with year-round living, it is advisable to use a diameter of 24-26 cm. For northern latitudes, a diameter of at least 26 cm is recommended, the average is 28-30 cm.

For the construction of a log house for a bathhouse, logs with a diameter of 22-24 cm are suitable as a minimum. But we still recommend taking at least 24 logs in diameter, with the average being around 26-28 cm. This allows you to heat the room regardless of the outside temperature and will prevent the room from freezing without warming up.

The thickness of the external walls depends on the design of the building. The building frame must withstand all loads. Another feature is the thermal conductivity of external walls. In cold weather there must be an economic balance in heating costs. The larger the diameter of the external walls, the lower the cost of heating the room.

Compliance with the region's climate

Firstly, you need to understand that two quantities play an important role in maintaining heat in a log house:

- Diameter of a rounded log.

- The width of the groove selected for assembling the structure.

The figure shows important dimensions of lumber

Important! The assembly units of a wooden frame bear the greatest heat losses (the formation of cold bridges is possible). Therefore, in addition to the ratio of the width of the groove to the thickness of the log, the tightness of the fit to the lower crown is of great importance.

The main problem of any building is heat loss during the cold months of the year.

GOST for the construction of wooden residential buildings recommends the optimal size of the groove width depending on the minimum winter temperatures characteristic of the development region:

- At an outside temperature of -20 degrees Celsius, the groove width is 130 mm or more.

- When the thermometer marks -30 (even for a short time) – the groove width is from 150 mm.

- In areas with particularly harsh winters (-40 degrees) - no less than 170 mm.

Reducing heat loss through the groove is possible by caulking these areas (in the photo, ordinary tow is replaced with jute rope)

The majority of noteworthy enterprises involved in the production of kits for construction from rounded logs have taken the groove selection rate as 0.5-0.75 times the diameter of the lumber. This means that for the regions of the first group, the optimal log frame will be about 260 mm.

Main criteria

In the field of wooden house construction, rounding is in second place after authentic manual felling. The construction of such buildings takes less time and money, since all stages of production are automated. Blanks of the same size are an ideal material for the construction of hermetic log houses.

A rounded log is easy to use, has a low price and has all the advantages of a log house. If you choose the right diameter of the building material, you can achieve high thermal efficiency.

But remember that a rounded log must be regularly treated with protective compounds, which helps combat the disadvantages of wood - rotting, cracking, and insect damage. During shrinkage, the ends are treated with water-based film-forming agents. This technology reduces internal stresses inside the tree, which are the main reason for the appearance of a large number of cracks during shrinkage.

To select the right material, the following criteria should be taken into account:

- Climate of the region.

In cold areas, thicker logs are required. - Home operating mode.

When visiting a home in the summer, the relevance of wall thickness decreases, since a reliable, but not energy-saving, building is needed. - Dimensions.

For a harmonious exterior and convenient planning, proportionality is important: a small bathhouse made of massive logs will look colorful, but the usable area will be reduced due to thick walls. Also, a large log house made from pieces of small diameter will look awkward.

Log diameters for different buildings

Secondly, you need to understand that the construction of buildings of different types will require logs of different diameters.

It all depends on:

Table of the ratio of materials compared by thermal conductivity

- Seasonality of use:

- For a winter home.

- Summer cottage or kitchen.

- Purpose of premises:

- For the bath.

- Outbuilding.

- Residential building.

- Required temperature conditions.

House

So far, everything is clear about the optimal cross-section of a log in the case of a residential building, except for those cases when neighboring log diameters are discussed, for example, 230 and 240 mm.

In principle, in both cases the following will be very close:

- Indicators of heat loss in winter.

- The ratio of the width of the inter-crown assembly groove to the diameter of the log.

And visually in a log house it will be difficult to distinguish one diameter of a rounded log from another.

Laying lumber is also very important

But the price calculated per cubic meter of wood for a 230 mm set will be significantly lower.

For clarity, we give an approximate increase in the cost of a log house of identical dimensions when switching to the closest in size (as a percentage):

- From D 200 to D 220 – 18%.

- From D 220 to D 240 – 15%.

- From D 260 to D 280 – 14%.

- From D 280 to D 300 – 14%.

- From D 300 to D 320 – 12%.

- From D 320k to D 340 – 11%.

- From D 340 to D 360 – 11%.

- From D 360 to D 380 – 10.5%.

- From D 380 to D 400 – 10.5%.

- From D 400 to D 420 – 10%.

Visual relationship between several different diameters

Note! As you can see, the difference in the cost of a set of lumber for each subsequent diameter is quite noticeable. Therefore, it is worth carefully weighing whether the price you will have to pay is balanced with the acquired benefits of greater thickness of logs.

On the other hand, a log house made from large rounded logs will be assembled from fewer crowns with the same wall height, which will result in:

- Reduces the number of butt longitudinal seams, which means it reduces heat loss through the solid surface of the walls.

- The quantity is automatically reduced:

- Corner connections.

- Wall intersection nodes.

- Reduces labor costs and the cost of installing inter-crown seams, their primary and repeated (preventive) caulking.

- Makes the exterior of a log house more impressive and solid.

To summarize, we find that lumber should be used in the construction of residential premises starting from a size of 240-260 mm or more.

For home use, which is planned only in the warm season, it is enough to take logs with a thickness of 200-220 mm. And with successful insulation, it will be quite comfortable to stay in such buildings both in autumn and spring.

For your information! The diameter of a rounded log affects not only the energy efficiency of the log house, but also its stability, strength and reliability.

Non-residential buildings

Obviously, the construction of utility and technical utility rooms will require material of a much smaller diameter:

- For a summer kitchen, lumber with a thickness of 200 mm or less is sufficient.

- Logs with a diameter below 180 mm are only suitable for non-residential buildings, such as:

- Workshops.

- Gazebos, pavilions, canopies.

- Chicken coops, barns, etc.

Which material is better to choose for a bathhouse also depends on the seasonality of use of this structure:

- Only in the summer - it is quite possible to get by with a log 180 mm thick, or even 160.

- For year-round use, you will have to spend money on lumber from 200 mm or more.

And finally, the last thing that needs to be added is that the appearance of the structure is influenced not only by the choice of the optimal diameter of the log for the log house. You should remember about the natural flow of logs during the cutting of a log house, meaning the alternation of the butt parts of the log and the tops.

It is clear that a log cannot be of the same thickness along its entire length, so the following holds:

This is a hint on how the cubic capacity of such logs is calculated

- The butt part (chopped at the root) is the thickest.

- The tip towards which the circumference of the log decreases.

The run-off of logs is especially noticeable at vertical corners, because the next log is laid with its top on the thickest part of the previous one, the next one is the opposite, etc.

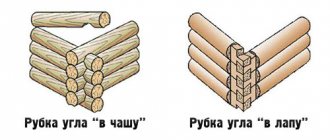

Hand-cut log houses

In production, hand-processed unrounded logs are used. (under an ax, under a scraper, under a plane and hydrobarking). When making a log house, only manual work is used - precise measurements, careful drawing, selection of the log that is suitable for a particular connection, painstaking adjustment of the logs, ideal selection of the groove and bowls, everything is done by hand.

The tools used are a devil, an adze, an axe, a plane, a level, a chainsaw, etc. It is impossible to find two identical initial logs, and therefore each product requires an individual approach.

Among the advantages of manual cutting, the following facts should be noted:

- During processing, only the bark and bast are removed; only when processing with a plane, the nearest outer annual layers of wood are slightly affected. The internal structure of the trunk is not disturbed and retains the natural geometry of the trunk and properties;

- When chopping with an adze or an ax, the top layer of wood is crushed, which reduces the possibility of moisture penetrating inside and reduces drying time. A gradual decrease in internal moisture ensures uniform settlement of the log house;

- During preparation, there is no damage to the internal structure and the original strength is maintained. Preserving the structure allows the wood to adapt faster and better to different loads;

- Removing a minimum layer and manual processing helps to obtain a product with a larger diameter in comparison with a rounded log, of almost any diameter.

- Rough processing has a peculiar appeal, confirming the natural naturalness of the wood.

But on the other hand, manual cutting has its drawbacks. Among them I would like to highlight the following facts:

- To install a log house from hand-cut logs, higher qualifications and experience are required, which affects the cost of manufacturing and installing the house.

- When constructing large houses, you can notice the slope of the trunks. This is a decrease in diameter from the butt to the apex. This is especially noticeable when building large houses with long, unjointed logs. Although for many this is, on the contrary, a plus and not a minus and emphasizes the naturalness and uniqueness of a house made from hand-cut logs.

The use of manual labor affects the cost of the building. A finished house will cost more than using a rounded version.

Conclusion

Now you know how to choose the optimal diameter of a log for permanent residence, so that you feel cozy and comfortable in your home. But I would like to remind you that the building has many places that are sources of heat loss, even if you choose a log house of the required size. These elements include door and window openings, because a lot depends on the quality of the product!

In order for the house to be warm, you need to take into account a lot of specific points at the design stage: floor, walls, ceilings, basement (if any), openings

In the video presented in this article you will find additional information on this topic.

Advantages of a large diameter.

- When using large diameter logs to cut a log house, fewer logs will be used than in a log house with a smaller diameter of the same height. As an example, let’s take a log with a diameter of 20 and 30 centimeters with a difference of 10 cm. The number of logs in a log house can differ by 50%.

- Reducing the number of connections between locks and bowls.

- The width of the groove will increase and, as a result, the thermal conductivity between them will decrease.

- Shifting the “freezing” boundary of the log due to the increase in wall thickness.

- Choosing a diameter of 240 millimeters over the years after shrinkage and shrinkage, this diameter can reduce to 220.

- Increasing the service life of the lower crowns. Sometimes, to solve this problem, the first crowns are cut from larch or a backing board is used.

Choice of number of storeys

The construction of not one, but two floors or the addition of an attic can seriously increase the total and living area of a building, as well as fit it even on a not very large plot of land. Each of these options provides its own advantages:

- Cottage. The main advantages are simple construction technology and minimal costs, as well as the absence of the need to go up to the 2nd floor, which is important when living with elderly people or small children. However, when converted to the price of 1 sq. m of total area, the construction of an attic or 2nd floor is cheaper;

- Building with an attic. An economical option to increase the area of a building with minimal costs. The disadvantage is the low quality of the attic living space, as well as the need to install attic windows;

- Two-story building. Allows you to obtain additional full-fledged living space, while requiring significant financial and time resources for this. At the same time, when calculating the price of 1 sq. m. area is second only to a building with an attic, but is noticeably more profitable than a one-story building.

When selecting a suitable project, you should consider both described stages of the selection procedure as a whole. It is this approach that will provide the customer with the maximum level of convenience and comfort at a minimum cost.

Which is better

I would still like to start by looking at wood. And not immediately by species, but for now only from the popular opinion that the best wood will be that which was harvested in winter.

It is expected that such wood will be drier than wood harvested at other times of the year. But we did a little investigation. In fact, according to wood harvesting reference books, the same conifers contain more moisture in winter than in summer. And it seems to us that the source of this myth was... the birch tree.

All sorts of light walkers and survivalists highly recommend birch as a tree for a winter fire. Because it is much drier than other breeds at this time. And by the way, they really don’t recommend conifers . Their experience also says that this wood is too wet, which means it will burn extremely poorly.

Log houses are also made of birch, of course, but only as part of a bathhouse (steam room). But for the rest, they still prefer spruce and pine (and other conifers) - and not only because they are the most abundant in Russian forests. Therefore, we advise you to be more critical of the myth of “wood harvested in winter.” You should be more interested in humidity and drying conditions .

But it’s better to install a log house in winter . And the reason for this is a fungal disease called “blue” or “blue”. Certain types of fungi change the color of the sapwood to bluish. But the matter is not limited to color - some characteristics of the tree also change, it begins to absorb more moisture, for example. However, strength does not suffer .

So, in winter, mushrooms are much less active , and if they are not encouraged, they will not grow. A log house installed in winter will avoid this disease.

Of course, treatment with an antiseptic and bleach will cause the blue discoloration to disappear. But we are talking about a bath, and the antiseptic is poisonous, so you should not use it in the steam room. Bleach... often it’s just bleach, and it erodes, so you can bleach wood in a steam room, but use it only after the smell disappears (more about bleaching here).

IMPORTANT! Antiseptics must be distinguished for internal and external work, and not be confused with each other. It is worth treating the log after laying it, and with the part that will be inaccessible in the future, do the following - they impregnate not the wood with an antiseptic, but a jute lining (for example).

What species are suitable for logs?

As already mentioned, for the most part these will be coniferous species.

These are the ones you most often find on the market and in the offers of construction companies. Of course, there is a lot of taiga in Russia, but the main reason will still be strength and resistance to rotting thanks to resins . And, of course, the straightness of the trunks is higher for conifers than for deciduous ones. All this applies not only to the cheap pine and spruce mentioned above, but also to more expensive species - larch and cedar. They may also offer you fir.

Among the deciduous trees we would name oak, birch, aspen, alder and linden. But only oak has sufficient strength and resistance to external influences. And it's very expensive.

Since we are talking about a bathhouse, where high temperature softens the coniferous resin and causes it to flow to the surface, there are two options: either partially use hardwood to build a steam room, or line the steam room made of coniferous wood with hardwood paneling .

Spruce has less resin and is lighter in color than pine. Larch and cedar are noble species. Larch is not afraid of water, it only makes it stronger.

BY THE WAY! You shouldn’t delude yourself about cedar - this is not at all the tree from which King Solomon built. Here you will find not Lebanese cedar, but Russian... cedar pine. This is what we call “cedar”.

Whom to choose? Focus on your budget. If it allows, take larch; if not, then pine will do. Although... I would like to advise you not to trust myths too much - under unfavorable conditions, larch may well rot, and under favorable conditions, linden can stand for decades.

And it is worth warning that the rounded log into which cone-shaped trunks turn can, over time, present many unpleasant surprises. Especially from the same larch. If you take an atmospheric drying log, then it often begins to wear out over time. It can curl, bend, or simply go into deep cracks.

This can only be avoided if you take trunks that have been subjected to heat treatment. It comes in two types - regular and chamber. In the first case, uniform shrinkage is achieved, but with preservation of the resin.

The second lasts much longer, and the output is wood with evaporated resin, which does not cause shrinkage, torsional deformation, bending, or cracking . All this is extremely valuable, but the price of such wood is high.

Dimensions, diameter

Before we name the dimensions of a log for a bathhouse, let's briefly go over what we know about trunks. Firstly, they tend to get thinner closer to the crown.

Consequently, the upper diameter will be less than the lower diameter of the cut. And for even laying , a cylindrical rather than a cone-shaped shape is preferable. Therefore, of the three types of processing of trunks - rounding, planing and scraping, we get the maximum level only in the first case, the minimum - in the third, and the second - something in between.

At the same time, rounding is the cheapest , since it is done on machines, while the rest involves manual labor. Manual labor costs more than machine labor. But is a rounded log ideal for use?

There is nothing wrong with the operation itself, and it produces a form that is ideal for construction.

IMPORTANT that the wood itself has no defects and is properly dried. In this case everything will be fine.

The planed version has one caveat: after all, when laying logs in a wall, you should adhere to the GOST rule, according to which 1 cm of camber is allowed for each linear meter. (Let us explain: camber is the change in diameter.)

With the scraped version there is no need to expect compliance with GOST standards for consistency. And all the flaws remain there - changes in thickness are possible in places where branches grow, and the curvature of the trunk is not eliminated.

It is clear that the first and second options are preferable, but not the third.

Now about the uniformity of the logs. There is also a rule about it:

ATTENTION! The permissible difference in the diameters of the crowns used in construction should not exceed 30 mm.

That is, it doesn’t matter whether your diameters are large or small, the main thing is that they are not very different from each other.

Otherwise, the strength of the structure will be in question.

As for the dimensions, the linear dimensions depend on the project and on the climatic conditions of the area where the bathhouse will be located. You should also take into account the seasonality of its use - thinner logs are suitable for a summer bathhouse than for an all-season one.

If the task is to make a very light summer building , you need to take material with a diameter of up to 18 cm . And it is also useful in all-season baths for creating partitions.

A more substantial summer(!) sauna can be made from logs with a diameter of 18-22 cm .

For all-season baths, diameters from 22 to 28 cm . Large numbers are applicable where we are talking about large-area objects or climatic zones with very low temperatures, where logs can be up to 36 cm in diameter (at -45 degrees that’s the best).

How many pieces do you need

There is nothing difficult in the task of calculating how many logs are needed for a bathhouse. Let's describe the solution step by step:

- We look at the plan (about layouts here, if anything) and write down the lengths of all the walls. If you use a smaller diameter for the partition, then count the partitions separately.

- Add up the lengths of the walls. The resulting figure is the total length of one conventional crown.

- Decide what diameter the logs will be.

- The height of the bathhouse is included in the project. Divide the height by the diameter of one crown. The resulting figure is the number of crowns.

- We multiply the length of the conventional crown by the number of crowns. We get the total length of all logs.

- The length of one standard rounded log is 6 meters. We divide the resulting length of all logs by the length of one log. The final figure is the amount of material to be purchased.

- Pediments are considered in a similar way.

Bathhouse made of large and huge logs

We would classify bathhouses made from large and huge logs as design projects. Because there is clearly not so much a construction need as an aesthetic preference . The owner of such a bathhouse clearly likes fabulous, epic times when heroes walked the earth