The lifespan of any furnace depends on how you use it. It is especially important to fire the stove according to the rules. Many people think that this is easy to do: throw in some wood, light it with paper, and that’s enough. But in practice, improper kindling can not only shorten the life of the structure, but also provoke a fire hazard.

In this article, I will tell you not only how to properly light a stove, but also what problems you may encounter when lighting and how to fix them.

General recommendations

Loading and lighting the stove correctly is not just a sign of the homeowner's skill with the fireplace. In case of efficient kindling, the efficiency of the stove will be maximum.

Before lighting wood or charcoal, factors to consider include:

- furnace structure;

- its location;

- what and how much fuel is used for kindling;

- experience in handling the firebox.

How to light a stove with wood:

The first thing you need to do is clean the cast-iron grate (grate), designed for free access of air under the fuel, and also remove all the ash from the ash pan. This is required to ensure that air flows equally evenly to all fuel. If you plan to heat the stove with wood, then they must be dry, of the same size, 8-10 cm in diameter.

Good to know: the combustion temperature of different types of wood in a stove is in Celsius.

The best firewood is birch and oak. With their help you can quickly heat a room. It is necessary to fill the internal cavity of the stove with firewood, taking into account that there should be a distance of at least 20 cm between the top of the firewood and the ceiling of the firebox. It is necessary to lay all the firewood at one time, so as not to constantly open the firebox, adding fuel and thereby cooling the fireplace.

In order for the firewood to ignite, you need to set fire to a splinter, paper or birch bark, placing it all under the fuel. The use of gasoline or similar flammable substances is strictly prohibited, so as not to deform the firebox.

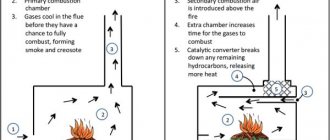

Operating principle of long-burning furnaces

The operating principle of long-burning furnaces is fundamentally different from the functioning of a conventional heating device. The operation of a long-burning stove is based on the spread of fire from top to bottom. The fuel is ignited at the top thanks to the use of an air supply pipe. When burning, gases are sucked out through the chimney. The air supply is controlled by a damper: the combustion process is transformed into smoldering. This functionality allows for heat dissipation for many hours and even days.

The processes in the furnace are carried out as follows:

- drying of fuel (energy carrier);

- pyrolysis (decomposition); prerequisites - lack of oxygen, temperature about 450ºC;

- combustion of volatile (light) fractions with parallel carbonization (saturation with carbon dioxide) of the fuel;

- decomposition of solid fuel fractions and their transition to a volatile state;

- oxidation reaction (production of hydrogen and carbon monoxide) at a temperature of 400ºC.

The result of oxidation (reduction) is the release of a large amount of heat. Mandatory condition: the temperature should not fall below 250 ºC. Otherwise, hydrogen and carbon monoxide will escape. No heat will be transferred.

Fuel types

For kindling, the type of fuel for which the stove is intended is recommended. When choosing or independently building a fireplace, you need to take this factor into account. It is better to make a device that can be melted in different ways.

The most high-calorie type of fuel is anthracite coal. When it burns, 7200 Kcal is released. For comparison, hard coal is up to 7000, brown coal is 4000-4500. Firewood produces the smallest amount of heat, only 3000 Kcal/kg. But they are absolutely environmentally friendly. It is worth considering that well-dried firewood produces more heat - up to 4500 Kcal/kg, raw firewood - half as much.

How to light the stove:

When lighting with coal, you need to take into account that coal powder burns just as long as large pieces of coal. Therefore, you need to add it gradually, 1-2 packets at a time.

As already noted, firewood remains the most environmentally friendly fuel, despite the development of modern technologies for the production of fuel for stoves. The demand for wood-burning hearths continues to this day. Therefore, information on how to properly heat a stove with wood is still relevant .

Construction of a long-burning furnace

The oven is designed as follows:

- combustion chamber (fuel tank), which has two compartments: one for burning fuel, the other for burning combustion products. The latter is made in the form of a dome;

- chimneys (optimal diameter within 80 - 150 mm), through which combustion products are removed;

- some models are equipped with an air convection system or a water heat exchanger;

- slabs may be included in the design; ovens, etc.

It is better to heat the stove with wet rather than damp wood...

Yes, that's true, but it's a joke. It is better, of course, to heat the stove with dry wood. Let's take a closer look at what dry, wet, wet and damp firewood is...

Wet firewood

Freshly cut firewood is considered damp. The relative humidity of such firewood is 50-100%. In such firewood, not only the intercellular space is filled with moisture. The pores through which moisture is delivered to the foliage - “channels”, “tracheids”, whatever you want to call them) - are also filled with moisture.

Damp firewood will not give the required temperature, if at all it burns and does not smolder. The fact is that for rapid evaporation of moisture in firewood, a significant temperature is needed. If you put a raw log in a hot firebox, it may even increase the intensity of the chemical processes of oxidation - combustion. After all, water begins to burn at high temperatures. But this is a topic for a separate article.

So, damp firewood will not provide the required temperature for ignition - there will be problems with melting it. Even if you melt such an armful, the moisture from the firewood will not go anywhere, but will fill the stove channels and can form an air lock. A combination of factors - low temperature of burning gases (in wet wood) and air humidity in the stove - will cause problems with draft.

Wet firewood

We accept firewood dried outside as conditionally dry, its relative humidity is 20-30%. But such firewood is quite hygroscopic. They can both quickly gain moisture and quickly release it.

Firewood with a relative humidity of 30% or more can be called wet, although it may appear dry. The fact is that moisture in the tracheid canals of wood evaporates faster than intracellular moisture. Therefore, firewood with a moisture content of up to 30% is conditionally dry firewood. This is the moisture content of firewood that is normal for outdoor drying.

Firewood that has been exposed to rain or soaked in anything is wet firewood. But this does not mean that they are raw. Firewood exposed to rain, if it was not damp, is still better than raw firewood, even if it appears dry. Well, something like this…

Now about dry firewood.

Checking traction

If the flame of a lit match or splinter deviates towards the exit of the flue gases, everything is in order with the draft. Otherwise, it will have to be stabilized, otherwise it will not be possible to light a fireplace without smoke. Natural draft depends on many factors, including the strength and direction of the wind, atmospheric pressure, humidity and others. But we can influence only one of them - the difference in temperature outside and inside the chimney.

If the room where the fireplace is located is warmer than outside, problems usually do not arise. There is already a temperature difference. Otherwise, we recommend using one of the following tips:

- Use a hair dryer. To do this, you need to cut a plywood panel that will completely cover the firebox opening, and make a hole in it the same size as the hair dryer nozzle. A stream of hot air will quickly warm up the firebox and remove the so-called air lock from the chimney.

- Open the chimney inspection hatch and burn several bundles of newspaper in it. You can also heat the chimney through the firebox. You need to bring the torch as close as possible to the outlet pipe.

- Place a burning candle in the firebox, close the firebox door and open the vent slightly. Warming up will take about half an hour.

One of the conditions for stable draft is normal supply ventilation. The room where the fireplace stove is installed should not be tightly sealed.

Stages of the combustion process

The heat entering the room appears as a result of the combustion of wood. It is important to organize the combustion process in such a way as to achieve maximum efficiency and safety at each stage. Combustion does not occur instantly. This is a fairly long period that can be divided into two stages.

Ignition

The wood is placed in the combustion chamber and set on fire. First, the wood is heated or pyrolyzed, during which flammable or pyrolysis gas is released. Gradually it ignites, heating the fuel material even more.

Combustion

The temperature of firewood heated by burning pyrolysis gases increases to the combustion level. The entire bookmark ignites and burns evenly.

You need to know that without a sufficient supply of oxygen, pyrolysis gases burn out very quickly and exit through the chimney. In order for the combustion to be long and uniform, it is necessary to maintain an optimal temperature in the firebox, ensure the supply of oxygen, and ensure that the pyrolysis gas burns out completely.

Top burning kindling

There is an alternative way of stacking firewood to light a fireplace, in which combustion occurs from top to bottom. The stacking begins with the thickest logs, wood chips are placed on top, then birch bark and paper. With this method, the firebox can be filled approximately 2/3 full. Even if the stove is cold and the draft is uncertain, the paper, which is located almost at the very outlet pipe, will warm up the chimney.

A prerequisite for starting kindling is that the ash pan must be tightly closed so that combustion air flows through the open opening of the fuel channel. When the draft stabilizes, you can open the blower and lock the glass door. After the bookmark burns out, a new portion of firewood is loaded. The fireplace stove is already warm enough. Therefore, if the room also becomes warm, it can be switched to long-burning mode.

To clearly demonstrate how to properly light a fireplace without smoke with an alternative stacking of firewood, we recorded a video that shows in detail all the nuances of this method. You can ask any questions you are interested in in the comments to the video by subscribing to our channel on YouTubeFornaksFilm

How to light the top logs

- After the firewood has already been placed in the firebox, you need to remove one log.

- Then, in the resulting area, create a hill of dry wood chips.

- Next, just set it on fire.

- Then, the fire ignites the top logs, and then the rest of the firewood in the firebox.

How to quickly light a stove if the wood is not completely dry

Of course, it is best to prepare firewood for the winter starting in the summer so that it has time to dry out. to significantly reduce the time spent chopping wood . So, the combustion process will not be problematic. But if it already happens that the firewood was prepared late and did not dry out completely, you need to have a stock of dried wood chips. There is one trick that will help you light wet wood . The bottom line is that ignition should not start from the bottom of the firebox, but, on the contrary. It won’t take much effort to light the top logs, and they will already warm up and ignite the rest of the logs. Now that it is already clear how to quickly light a stove with raw wood , you need to decide on the issue of maintaining the fire.

How to quickly dry firewood

If you did not take care of the preparation of logs in advance, and you need to heat the constructed structure right now, then you can get out of the situation:

- The raw material is sawn and split to the size needed for your system.

- We stack the finished dies next to or above the heating structure so that air easily circulates between them (a well or a thin layer).

- Please remember that the drying material may ignite! Therefore, safety precautions must be observed. Direct contact with very hot parts of the heating device must not be allowed. A tree can catch fire even at a distance from infrared radiation!

- Such actions will allow you to quickly solve the ignition problem.

- Logs, without direct contact with precipitation, dry in wet autumn and severe frosts. The conclusion from this is to store logs indoors.

- Soft woods such as pine, spruce, aspen, and poplar are most suitable for ignition. It must be kept in mind that they burn very poorly when wet. But they are easier to dry than oak, ash or birch.

Principles and rules of kindling

The rules for lighting a stove have been passed down from generation to generation. Over the centuries, the technology has been refined, and today it has reached perfection. Many stove operating procedures form the basis for servicing modern heating equipment, such as pellet boilers

Preparatory work

Before lighting the stove for the first time after completion of construction work, you will need to wait until the solution has completely dried. The first stage is an external inspection, paying attention to the following points:

- Corresponding thickness of seams;

- correct execution of brick ligation;

- compliance with vertical angles;

- ensuring the accuracy of tile installation.

In this case, deviations are allowed: for masonry without cladding - up to 5.0 mm, and up to 2.0 mm when facing with tiles, vertical - no more than 2.0 mm per 1.0 m height.

Next, check the density of the masonry. Typically, a material with a high emission of black smoke is used for this. A trial fire is carried out for several days in a row with a normal load of firewood. When the furnace is operating, not only the uniformity of heating along the outer walls is determined, but also the uniformity of cooling. Next, the structure is checked for cracks and, if found, they are promptly repaired.

Stacking firewood

Before laying firewood, clean the ash chamber to allow the blast air to flow without resistance through the ash pan to the flame. The stove is lit only with dry wood.

After cleaning the stove from any remaining ash, they begin to place logs in the firebox. This is done in two ways: • a hut with a cone for a large combustion space; • in parallel, maintaining clearances of 8 to 10 cm.

Firewood is placed in the center of the firebox or closer to the door until approximately 2/3 of the firebox is filled. The top of the combustion space must remain free at least 18–25 cm. Firewood should not be stacked against the back wall.

Methods of igniting a flame

Next, push the view to the desired level and push the blower door a little. The paper is lit with matches in front of a pile of firewood. After igniting the wood, close the combustion door. When burning evenly, cover the view. The combustion process is adjusted by opening/closing the viewer and the blower.

The firebox door must always be closed. Open it only if you need to stir the coals with a poker or add firewood.

Combustion control:

- White flames and noise in the smoke ducts indicate a high draft; it is reduced by using the blower door.

- A red flame with dark smoke from the chimney indicates low draft and you need to open the vent slightly.

- The yellow color of the flame characterizes the normal process of fuel combustion.

Nuances of choosing fuel

A home stove is actually a universal heating device, since it can operate on different types of fuel: wood, coal, peat. In modern conditions, fuel manufacturers offer new types, so-called Euro-firewood, and various options for pressed briquettes.

The traditional fuel for the stove is birch, which has a high lower calorific value. Its logs burn out completely, do not shoot or spark. The only drawback of birch is that if it is placed in a firebox higher than normal, a strong fire can lead to a fire.

In terms of calorific value, the best fuel is oak, which burns for a long time and produces a lot of heat. Its net calorific value is almost 20% higher than that of birch. But since the price of oak is also much higher, before choosing, you need to make a simple calculation of what will be more profitable for heating in a given climatic region.

Oak firewood

Pine and spruce firewood have a heat transfer even lower than that of birch and oak. For the heating season, they are purchased 20-30% more. The presence of resin in the logs not only causes a strong crackling sound, they also shoot and can throw pieces of ash onto the floor; if it is wooden, a fire may occur. Therefore, when using this type of firewood, it is recommended to place a metal sheet in front of the stove.

Aspen and alder firewood are highly valued because in addition to providing heat, they clean the chimney of soot, which is why they are rightfully considered “royal” firewood.

Euro firewood performed well when firing a Russian stove, with a complete combustion process and low ash yield. Their price remains high, equal to the cost of coal, but their calorific value is approximately the same.

Nuances of ignition

To light the stove, you can use dry alcohol in tablets or coarse table salt. Two or three handfuls of it are enough to ignite the wood.

To avoid facing the same problem the next day, you need to chop several logs as small as possible and dry them on the stove after heating the stove.

A few armfuls, enough for a day or two, can be stored in the room. By constantly renewing your fuel supply, you can temporarily get rid of the problem of damp firewood. Do not neglect the correct placement of the woodpile. In severe frosts, this will help the wood get rid of moisture faster.

However, it is not advisable to constantly use such fuel. When raw wood burns, steam is generated, which passes through the stove channels and settles on them. Drops of moisture mix with soot and gradually contribute to the destruction of the chimney. Using dry wood as fuel for the stove will help avoid this.

Reloading

Long-burning solid fuel devices are designed in such a way that one fill lasts for a long time. With regular wood-burning stoves, one serving doesn't last long. At best, not 6-8 hours. Therefore, to maintain the operating mode, it is necessary to re-bookmark. It is performed when the wood is almost burnt out, but a bluish light flame remains.

In the process of laying a new portion, two important conditions are met. First, carbon monoxide must not be allowed to enter the room. Secondly, you need to keep the temperature high, which will make re-kindling much easier. Therefore, they do everything as quickly as possible. They begin by carefully raking the smoldering remains of firewood and coals into the center of the chamber. So that they are in the middle of the new bookmark. Then everything is done the same way as the first time.

Necessary accessories

You need to prepare for the first kindling in your life. There are a few seemingly insignificant things that should be on hand when you start lighting a fireplace in your home:

- Poker . It needs to reach the back wall and the far corners of the firebox, then it will be comfortable for her to work.

- Scoop . It should be light, non-flammable, and fit across the width of the ash drawer door. When choosing, pay attention to metal scoops: they meet all the requirements.

- Canvas mittens . The fire door handle, poker and scoop can become very hot. Canvas mittens will protect your skin from burns and are comfortable to work in. Cloth vachegs, for example, are significantly inferior to them in terms of comfort. They are convenient for holding a thick crowbar, but not a poker.

How to heat “problem” stoves

These, for example, include heating devices that have not been used for a long time. In addition, in winter it is more difficult to flood any stove appliance. First, let's figure out how to heat a bathhouse or house with wood after a long break.

Step-by-step instruction

- We inspect the equipment to make sure it is in good working order.

- We warm up the chimney. To do this, set the maximum thrust, open the views and the blower door. Roll a tube out of cardboard or paper. We introduce it into the cleaning window and set it on fire. We warm up the pipe until a characteristic hum appears.

- We close the cleaning window and put flammable material into the chamber: sawdust, paper scraps. We set fire until they burn out, and once again check the quality of the chimney exhaust.

After this, you can light the stove. In cold weather, burning the warming material is added to the actions described above. To do this, approximately half of the usual amount of fuel is put into the chamber. It is burned at maximum draft until coals are formed. After this, full loading is carried out with kindling and entry into operating mode.

Installation of long-burning stoves

Correct installation of a long-burning stove is associated with its correct operation and compliance with fire safety requirements. To install the stove correctly, the following rules must be observed:

- the distance to any flammable and combustible materials should not be less than 1 m;

- the location of the heating device should be as close as possible to the stationary chimney;

- the free space in front of the firebox must be more than 1.25 m;

Which firewood is better?

Heating a stove to heat a home or bathhouse with wood is the most economically efficient way. However, different types of wood produce different efficiency indicators. The duration of burning of logs depends on the density of the tree, therefore, the denser its structure, the longer the logs will burn and the more thermal energy they will release into the room. This is important to consider when choosing firewood.

Which tree species is the hottest?

Of course, oak is an ideal fuel in terms of efficiency, but this type of wood is very expensive and heating a stove with oak wood is an unforgivable luxury. That's why

In the middle zone and northern regions of the Russian Federation, it is most acceptable to use birch. Wood of this type optimally combines price and quality. In the southern regions, it is better to use white acacia to fire stoves.

At the same time, in order to heat buildings as efficiently as possible, you need to carefully prepare for the heating process.

Installation of long-burning stoves

Before installation, you should select a set of pipes for the chimney. There are two main types of installation: external and vertical.

With vertical installation, the sections are mounted inside the building, and the outlet is carried out through the roof. The pipe is aggregated into an existing brick channel. With the external method, the chimney is led along the outside of the building. Output to the street is carried out via a side outlet. In this option, the chimney must be insulated.

The installation of a long-burning stove in a wooden house should be carried out when the main door and window openings are equipped, i.e. after a clear understanding of the direction of cold air flows in the room. If the stove must heat several rooms, then an air duct system must be designed.

In order to properly heat a long-burning stove, it is necessary to take care of the fuel storage location. It is necessary to plan the working space in front of the heating device and think over ways to supply fuel.

Preparation and storage of firewood

When preparing firewood, use trees growing in dry places; they contain less moisture, therefore, they will burn with greater heat transfer. If there are no dry stands, then the fallen logs must be thoroughly dried. The best period of time for harvesting wood for fuel is November-December.

You should not leave cut trees for a long time; if possible, cut them into several parts. The logs that are intended for heating the stove should be of medium size - 8-10 cm in diameter, the length depends on the dimensions of the combustion chamber.

After cutting the logs, it is better to split them and stack them in a special well-ventilated room, without excess moisture, protected from rain or snow. Therefore, you cannot store firewood in the cellar; it is better to store it in a shed or under a shed with good ventilation.

One of the effective ways of laying logs is in criss-cross cells:

The editors of the site santehnikportal.ru recommend drying firewood before using it for 2-3 years. During this period, most of the moisture will evaporate from them, leaving only about 10-15%. Well-dried and split logs are easy to ignite; they burn with great heat transfer, without forming condensation on the constituent units of the stove structure and chimney.

Liquid fuel designs

When considering various design options, it is worth remembering about a long-burning furnace that runs on technical oils. The stove operates by burning oil vapor. The burning time is comparable to solid fuel designs and ranges from 12 to 20 hours per refill. It is economically profitable to use such units where there is a large volume of mining. The disadvantages include the need for frequent cleaning of chimneys, or the need to pre-clean the oil.

How to light the stove after a long break?

In early spring, when you arrive at your dacha, you will have to light the stove to warm up. But after a long period of inactivity, it is worth lighting a fire in it so as not to damage either the heating structure itself or the residential building.

First of all, check the stove outside and inside for the presence of:

- chips;

- cracks;

- foreign objects;

- small animals and birds;

- soot deposits.

The presence of these inclusions can become a serious obstacle to the normal operation of the device.

Fill cracks and chips with mortar and get rid of foreign objects. To clear the chimney duct of soot accumulation, use a special metal ball on a long rope. The ball can be equipped with a wire brush, then lower it down the chimney and lift it up, repeating these manipulations several times, shaking off the soot after each rise.

Be sure to check for draft if the stove has not been fired for a long time. Light the wood by fully opening all the doors, then close them, adjusting the degree of exhaust. Lay two logs parallel to each other at a short distance, then place the other two on top of them, placing them perpendicular to the first row. Place paper inside and set it on fire.

After a long period of inactivity, do not heat the oven at full power at once. The first combustion should not exceed half an hour; after 4 hours, the kindling can be repeated, increasing the combustion time.

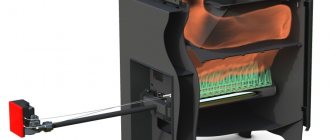

Comparison of long-burning stoves

It does not matter of fundamental importance whether a long-burning stove is installed in the house or a factory-made one. Any device must meet a number of mandatory requirements. The following is fundamental:

- fire safety of the structure;

- The burning time of a long-burning stove should be at least 5-7 hours.

A comparison of long-burning furnaces shows that the design must contain afterburning channels (nozzles) that ensure smoldering of the fuel. The location of the channels is not important. They can be at the bottom, in the middle or at the top of the firebox. Some manufacturers hide the location of the jets.

The next comparison parameter is the volume of the firebox and the dimensions of the firebox door. The larger they are, the greater the amount of fuel that fits into one stash. It is important to have glass in the door. It's always nice to look at the fire.

It is worth considering the availability of design solutions that extend the service life and increase the efficiency of long-burning stoves (for example, a flame arrester protecting the chimney).

Features of the furnace fire in the black sauna

Lighting a stove the black way is sometimes practiced today when heating a bathhouse, since this method produces more efficiency than the “white” method, and less fuel is consumed.

Combustion products in such devices do not exit through the chimney, but through the windows and door. A large amount of soot settles on the walls, acting as an adsorbent.

The procedure for firing a black stove in a bathhouse:

- Open the windows and door to bring in fresh air and support the combustion process.

- Fold the firewood into a “house” by placing paper under it and set it on fire.

- Before adding wood for the second time, generously spray the walls and shelves with water.

- Gradually add firewood, finishing the fire when crimson light appears above the stones.

- Wait until the last portion of wood burns out and remove the coals.

- Ventilate the room by opening the windows and door.

- Rinse doors and shelves with cold water.

- Splash a tub of water on the heater and close the doors.

Now you can enjoy all the delights of a steam room, melted in black!

What is a fireplace stove?

The appearance of fireplace stoves on the heating appliance market has become a real boon for summer residents and owners of temporary residences. Previously, they had to choose between fast warm-up and high efficiency. An open fireplace, which in a few minutes turns the glacier into a comfortable room for living, is very voracious. Firing with wood requires a lot of attention: if you miss the time of the next bookmark, the fire will go out and the room will cool down as quickly as it warmed up. The efficiency of most modern stoves exceeds 50%, and the intensity of fuel combustion in them is well regulated. But the fast warm-up mode can not be configured on all models.

The fireplace stove is a hybrid heating unit that does not have these disadvantages. The intense combustion of the first bookmark allows you to quickly deliver a large amount of heat into the room. After additional loading, the fireplace stove can be switched to a long-burning mode, maintaining heat release at a level that compensates for heat loss.

The main differences in the design of this unit from a traditional fireplace:

- glass door equipped with a locking mechanism that ensures a tight fit;

- flame breaker - a metal plate that changes the direction of movement of exhaust gases, that is, it organizes smoke circulation.

The main difference from a traditional chimney stove is its lighter weight, which does not require installation on a foundation. At the same time, the design of the fireplace stove retains the blower door and smoke channel damper. Many models are equipped with functions for supplying secondary and tertiary air and self-cleaning glass.

How to properly heat a stove with coal?

The peculiarity of coal as a heating fuel is that it begins to gasify at a temperature much higher than that of wood, and when heated to less than 800-900 degrees, the combustion process is sluggish. But, if coal is quickly heated to 900-1000 degrees, it will produce a high temperature. In this case, the coal exerts a large thermal stress on the stove.

Since the heat capacity of the furnace is limited and the thermal voltage is greater, coal is loaded less frequently, and the number of fireboxes can be increased up to 4 times a day. But not every design is suitable for using this type of fuel.

The Russian stove is not at all suitable for burning coal. Great care should be taken when using this fuel to heat Swedish, Dutch and other duct structures by three or more turns. At the same time, the oven in a Swedish stove when fired with coal will not work efficiently.

It is not so important how to heat the stove with coal, but what type of fuel is best to use:

- Young geological fossil lignite coal, which retains its woody structure, is not suitable for firing furnaces: it immediately turns into dust, completely clogging the grate.

- Anthracite generates a lot of heat, rapidly but briefly gasifies and is difficult to ignite. It can be used to heat cast iron and heat-resistant steel devices, sometimes bell-type structures and ducts by no more than 2 turns with a fireclay firebox.

- Brown coal can be used to heat any stove except a Russian one, but it is a very unenvironmentally friendly fuel. In addition, brown fuel cannot be stored in large quantities (more than 10-15 kg): it spontaneously ignites.

- Ordinary coal is suitable for firing cast iron stoves and brick stoves with fireclay fireboxes. Coal from individual deposits can be used to heat brick kilns without fireclay and with fireclay, but in a layer of 12-18 cm.

Attention! To light a stove using a corner, it is better to use a special lighter that produces a strong flame that immediately warms up the load to 1000-1100 degrees.

Fuel cakes can be made from coal dust mixed with water, but they are a strong allergen and carcinogen and can spontaneously combust.

Test firing of the stove after construction

After laying, the stove is dried naturally for 2-3 days. Next, the process of forced drying begins, which involves heating the firebox for 1 hour not at full power. Test ignition is carried out using a small amount of dry firewood from thinly chopped logs, wood chips and shavings. The oven is heated 2 times a day, the forced drying process lasts 3-6 days, depending on the size of the structure and the complexity of the brickwork.

A trial firebox after construction allows you to check the quality of the stove maker’s work and identify possible design flaws. If the forced drying work is done correctly, this will give strength to the clay composition, but the elasticity of the masonry will be preserved.

Types of coal and their characteristics

Coal is a natural fuel. It consists of flammable carbons and various impurities that do not burn. The quality and classification of raw materials depends on the ratio of such substances. The age of the fossil also affects the grade of fuel.

Several types of coal are used to light stoves - brown, anthracite, lingite or stone. Each fuel group has its own characteristics and features of use for stoves.

Brown coal

Due to its low carbon content, large amount of water and volatile compounds, brown coal has a low heat of combustion. Therefore, it is classified as a low category fuel. The color of this still “young” geological deposit is brown.

Brown coal consists of 30-40 percent moisture. A significant proportion is occupied by volatile substances, and the carbons necessary for combustion can range from 50 to 70 percent. When stored outdoors, the density of raw materials is significantly reduced. This occurs as a result of water evaporation. Prolonged exposure to the open air leads to the transformation of the fossil into powder.

What does brown coal look like?

Brown coal is used quite rarely for heating stoves. It is mainly used in subsidiary farms. The use of such raw materials for the firebox leads to excessive clogging of the chimney pipe with soot. When burning, a pungent odor and smoke are released, and after burning, quite a lot of ash is formed.

Lingit

This fuel is classified as a type of brown coal. Lingite is considered the “youngest” fossil. In some countries it is not classified as coal due to its too loose structure. It contains up to 45 percent water and the same amount of sulfur. This fuel has a brown tint. Often the name “black lingite” refers to subbituminous coal.

The use of such fuel is completely limited, since its combustion characteristics are somewhat lower than those of brown coal.

Coal

This type of raw material is best suited for furnace devices. Its deposits are located deeper and are formed under high temperature and pressure. The nitrogen content in such raw materials depends on its type and can reach 95 percent. Thanks to this, coal has good physical and chemical properties and is a fairly valuable fuel.

The raw material contains a low level of moisture - up to 32 percent and a lot of flammable substances. The specific heat of its combustion is 5.5 kcal/kg. The color of coal can be black or dark gray.

Anthracite

Anthracite is found deepest in the ground. In color it resembles coal, but only with a more pronounced metallic sheen. The main qualities of such fuel are high density up to 1700 kg/m3 and a significant thermal combustion rate of 9 kcal/kg.

There are quite a lot of volatile substances in anthracite, so it does not ignite easily, but due to the large amount of carbon, up to 97 percent burns well. The special value of such fuel is its smokeless combustion.

The advantage of anthracite is smokeless combustion

The type of fuel affects not only the productivity of the heating process, but also the operating time of the stove. The average service life of heating devices powered by coal is seven years. If used correctly, the operating period may increase slightly. The manufacturer of furnace equipment always indicates what type of raw material the furnace is intended for.

Ways to speed up kindling with wet wood

Damp wood can be made to burn better.

There are a couple of time-tested methods to speed up the process:

- Take regular coarse salt and sprinkle it on the firewood. You can use salt before kindling and during the heating process. It absorbs moisture, making it easier to light wet wood.

- Use an ax to cut off the top layer - the bark and a little more. Finely chop and later use as a torch. The inside of the wood is much drier and it will be easier to light it. Chop the peeled log lengthwise as finely as possible.

- Make lighter fluid. Mix alcohol and laundry soap in a 1 to 1 ratio and use at the beginning of the process.

To speed up the kindling, you can sprinkle salt on wet firewood.

Causes of smoke

Sometimes, even when the stove is properly lit, smoke may form. The reason may be poor quality coal. But most often the following factors influence smoke:

- the appearance of cracks in brickwork;

- presence of blockages in the chimney and stove channels;

- destruction of the internal part of the heating device.

The appearance of smoke may be due to blockages in the chimney and stove channels.

When igniting in a very cool firebox, smoke may also be released in the entire stove system. Soot often forms when two stoves are directly connected to one chimney. To avoid smoke, a smoke damper is installed.

Preparing the firebox

The algorithm for preparing fireboxes is the same for all solid fuel heating devices:

- We take out everything that can be taken out: the “armor”, the grate, the ash drawer.

- We inspect the surfaces for cracks, burns and contamination.

- We make sure that the smoke damper, the secondary air supply damper, the hinges and locks of the glass door are working, and we check the tightness of the latter.

- We clean all accessible surfaces using a scraper and brush, and remove the ash.

Most manufacturers of metal stoves and fireplace stoves recommend calling service specialists to inspect the stove and chimney before the start of the heating season.

Tips for lighting a sauna stove

And a little about how to heat a wood-burning sauna. In general, the process is no different from that described above, but there are some features. Before ignition, in addition to the mandatory serviceability check of the equipment, the presence of water in the boiler is checked. It is strictly forbidden to light the stove without it. The valve is opened before lighting.

After the flame has flared up, close the ash door and move the valve onto the boiler. At the same time, the exit to the chimney is closed. When the water in the container has boiled, the logs have burned and become red coals, the stones have become hot, the temperature in the steam room has risen, you can begin the bath procedures. Preliminarily open the valves and close the doors of the firebox and blower.

Learning to use wood heating appliances is not that difficult. It is important to always remember their potential dangers. Never use flammable liquids for ignition. This leads to a fire. The floor near the firebox is always finished with non-combustible materials, and the fuel is stored so that there is no risk of ignition. The chimney valve closes completely only after all the carbon monoxide has escaped. This is determined by the color of the flame. The blue shades are leaving them.

Chimney cleaning before the start of the heating season by specialists

The chimney cleaning service is available in: heating industry specialists will carry out a full range of measures for servicing the chimney:

- Inspect the internal contour of the chimney for the presence/absence of dirt, debris, soot build-up and condensation. Cleaning the internal circuit from any detected contaminants using special devices.

- Inspection of the external contour of the chimney for the presence/absence of damage, cracks, depressurization, inspection of the condition of joints and fastenings, insulation. Eliminate any detected defects and damage promptly.

- Lighting up the heating device, checking the draft level, the quality of the flue gas output, comprehensive testing of the performance and safety of heating and smoke exhaust equipment.

- Drawing up a certificate of work performed and providing warranty obligations.

Attention! If you clean the smoke duct yourself, it is recommended to follow fire and technical safety measures, as well as use specialized devices - a brush, a cable with a load, and others.

Safety regulations

The main hazards when using furnaces are carbon monoxide and fire. For safety reasons, follow a few rules:

- inspect the stove before lighting for traces of soot;

- do not use flammable liquids for ignition;

- finish heating 2 hours before bedtime;

- Use fuel that is suitable for this type of stove.

In conclusion, we note that brick stoves are heated to the maximum, and metal stoves - in small portions to avoid warping of the body.

Efficiency of long-burning furnaces

The nature and method of heat removal depends on the design. The housing of the heating unit can be equipped with a protective screen. This device prevents the ignition of materials located nearby and significantly improves heat transfer. The result is excellent performance indicators. Thus, a long-burning pyrolysis potbelly stove has an efficiency of 90%.

In some cases, the installation of a long-burning stove at home involves a water pipe, which is directly connected to the liquid heating circuit of the house. When installing a long-burning stove, it is necessary to take into account that when it comes into contact with cold liquid, the body will inevitably cool down. Such contact negatively affects the pyrolysis process occurring inside.

To avoid heat loss, it is necessary to increase the performance of the heating element (which is technically difficult to achieve), or to place the water jacket at some distance from the body.

Reviews

Lyubov, 60 years old, Taganrog

“In the 90s there was no gas. You wake up early in the morning, it’s cold, you add firewood. Annual maintenance gets boring. In the summer, you gather your strength and rake out soot all day. Once you’ve done everything, it’s time to take up the woodpile. At first it didn’t work, but then I got used to it. Now there is gas in the house, but I remember those times with warmth. Life felt different then.”

Konstantin, 45 years old, Moscow

“I bought a dacha. The house is small. The most important thing is that it is heated with a Russian stove. The owner sold it at a discount only because he didn’t know what to do with the beautiful stove. It's already 20 years old and hasn't been cleaned in that long. So I started smoking. But I'm glad."

Nowadays it seems that everything is mechanized, civilization is everywhere, and every problem can be solved by video. But as soon as you leave the city, you plunge into a world of tilting houses with black chimneys. You need to know how to use old structures. To get the maximum effect from a solid fuel stove, learn how to operate it - heat it correctly and manage the kindling process.