- Standard DIN 68126

- GOST 8242-88 lining

- Linings in a cube

Lining has widely entered our everyday life.

Today it is used everywhere, it is used to cover bathhouses and residential buildings. Using lining is not only beautiful but also practical. There is a wide variety of linings on sale, both in materials and sizes. Of course, plastic lining is not suitable for a bathhouse; here you also need a certain type of wood, because here there is not only high humidity but also high temperatures. The ideal option would be to use linden lining - this is a proven material that is famous for its qualities.

But for finishing the house, for example the ceiling, plastic lining is suitable. Which has a long service life and is used very often in such places.

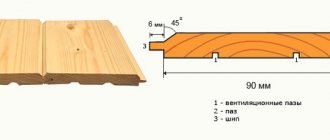

Main profile parameters according to GOST

The main parameters of the lining are regulated by GOST standards for profile parts made of wood for construction and for softwood lumber. As for the profile length, there are no strict regulations. As a rule, lining from 2 to 6 meters goes on sale. There are also no special requirements for the profile width; this parameter varies from 13 to 120 mm. Buyers, as a rule, prefer to purchase the type of profile that is convenient to transport.

The width and length of the profile are taken as a guide when it is necessary to determine the volume of products purchased. Regardless of the parameters of the lining, the installation principle of the product is identical, which is very convenient for the buyer. If repair or dismantling work is necessary, it will be very easy to find a similar profile of the required size.

On the product packaging, as a rule, the parameters are indicated in the following order: grade, thickness, width, length. The characteristics of the profile values largely depend on the type of wood from which it is made. It should also be taken into account that Russian standards do not correspond to European ones.

What to process

They try not to treat the steam room with anything. But those who would like to preserve the pristine purity of the wood and those who are not happy about the idea of making repairs in the coming years agree that in the steam room you can use impregnations based on vegetable (drying) oils to cover the lining in the steam room - linseed, for example, or paraffin, or wax or a mixture of natural oil and wax.

Silicone, for Elcon lining

The Finns will also offer acrylic varnishes for saunas - they seem to be considered safe, but here everyone decides for himself whether he needs it or not.

In other rooms, you can use any compositions to protect wood - these include impregnations, varnishes, and paints (!more about painting here), and do not forget about antiseptics. Only in the washing room it is better to take those compositions that are suitable for bathrooms.

You can read more about lining processing here.

Information about impregnated wood that has undergone industrial processing is presented here.

Use of lining depending on the length of the profile

Here are a few examples of the use of lining depending on the length of the profile:

Two-meter molded product

Profiled boards 2 meters long are often used for interior and exterior decoration of residential premises. Compact size and low specific weight facilitate the process of product delivery and installation. The type of wood, as mentioned above, plays an important role when using the material. So, for example, coniferous wood (cedar, pine, spruce, larch) have strength and good heat transfer. Therefore, 2-meter-long lining is often used for finishing saunas and baths, building facades, and attic space.

The two-meter lining made of hardwood is distinguished by the aesthetic beauty of its profile. No additional finishing or polishing of the frame is required. By their structure, deciduous trees do not contain resins, so they cannot be used in rooms with high levels of humidity. But such molded products are ideal for interior decoration.

Three-meter lining

A 3-meter long lining is considered a medium-sized molding product. The profile parameters are convenient for transportation and installation. The material cannot be used as an additional thermal insulation layer, but at the same time, a three-meter lining is capable of retaining heat in the room.

Strength and resistance to mechanical stress allows the profile to be used as a reliable finishing material - most often for the interior of premises.

Four-meter lining

The 4-meter-long lining can be used as finishing for both the interior and exterior of the building. When creating the interior of a room, lumber is most often used as wall cladding and ceiling space. The type of wood from which the 4-meter-long lining is made is of great importance.

For example, if the profile is made of linden, then its specific gravity will be small. The finished finish will not weigh down the supporting structure. Or, if we are talking about pine lining, then its positive properties include high strength and aesthetically attractive appearance. Such features allow you to create an exclusive interior in eco style in any type of space.

Six-meter lining

The largest type of profile that is actively used in construction. Most often, 6-meter-long lining is used to create an exterior or organize personal buildings (gazebos, verandas, open terraces). Linden lumber is ideal for organizing baths and saunas, and larch moldings are suitable for external cladding of building walls.

Pros and cons compared to other breeds

But in order to understand something, you need to compare it with alternative options. Since a steam room with deciduous wood, most people will call aspen an alternative to linden. So let’s look at the comparative merits of linden or aspen in a bathhouse. And one more - a little less common - comparison of linden or alder for a bathhouse - which is better?

Which is better: linden or aspen?

In another article, where the properties of linden and aspen lining were considered, we already compared the properties of these two types of wood. You can either follow the link and read the entire article, or stay here and see the table on which our conclusions are based, and, in fact, the conclusions themselves.

So here's the table:

From the columns that show the coefficients of shrinkage and swelling , that is, the change in dimensions under the influence of moistening and loss of moisture, we see that aspen is better than linden for a bathhouse. Although the difference here is not so great as to call aspen a clear favorite.

Interesting: Popular means for self-processing lining in a bathhouse

Because it darkens in the bathhouse faster than linden. Otherwise, their properties are very similar. Even if other sources give slightly different densities, they are still fairly close to each other.

Aspen darkens from water

In the store, linden will cost more than aspen, but also not by much. Therefore, go through your priorities - you will have to look for high-quality aspen wood and spend your time on it. If you are ready for this, bet on aspen, and linden will remain for those who prefer the option that is not much worse, but faster, albeit more expensive.

IMPORTANT! In a bathhouse, any(!) wood rots, only the conditions and timing vary. If you are dry after the procedures (see the section on ventilation), then linden will last longer than larch for someone who neglects drying.

And so, of course, linden is practically unable to resist rotting, unless you help it with impregnations. But this also applies to aspen. Yes, it gains hardness under the influence of water, but its resistance to rotting is low.

In general, these two species have very similar characteristics, we recommend aspen , but if you have problems with a good aspen or you just like linden, take it.

Linden or alder?

But of this pair, we prefer linden. Alder is best at the harvesting stage, because linden is often discarded during the initial drying - this is when its warping occurs. Dried linden is quite stable and does not create problems. Alder exhibits minimal warping even at the initial drying stage.

But if you are an ordinary buyer, then it is enough to check the moisture content of the purchased lumber and the presence of warping - any differences from the correct geometry, for example, bends or twists.

Otherwise, these are also two types of wood quite similar to each other. Alder is as inelastic, soft, easy to work with and not resistant to rotting as linden.

ATTENTION! Alder and linden are damaged by metal-wood contact in a humid environment. Therefore, it is advisable to protect screw fastenings from moisture, or abandon them in favor of classic carpentry joints.

If you have a choice, then from black and gray alder you should choose black, it has better technical characteristics.

What else could be the basis for choice - alder has reddish shades and looks darker than linden. If you are interested in achieving just such an effect, you can use alder wood. Linden lighter in color and yellow, but there are pinkish and reddish varieties. Linden smells nice , but the smell is weak. Alder is neutral.

As you can see, it all depends on personal preferences, and there are no significant disadvantages or advantages in either breed.

IMPORTANT! Please note that for now we are talking exclusively about wood for the steam room. If there is a desire to use any of the mentioned breeds outside of it, the chances of longevity are increased by the ability to use antiseptics.

Dependence of the price of lining on the dimensions

If you are planning to purchase lining, then keep in mind that its price depends on the dimensions of the profile. As a rule, the longer the molded product, the higher its cost. Four-meter and six-meter linings are more expensive, as they should not contain dead knots. The presence of such a defect affects the defective finish. As a rule, a long profile is used for hemming roof overhangs and in this case the wooden board must be flawless, without any flaws.

A small lining is easier to transport, and delivery, as a rule, also affects the final cost of the order. In any case, it turns out that purchasing oversized profiles is much more profitable, but, unfortunately, in some cases it is appropriate to use only a long wooden board.

Product Information

If you do the work yourself, then you will have to choose the material yourself. Therefore, carefully read the information from the sections below and use it when purchasing lining.

This is what a linden tree looks like in its natural environment

The wood itself has a fairly soft structure, which makes it easy to process. And the wide distribution of this species in our flora reduces the cost. When making linden lining, trees under 50 years old are used. Due to this, the number of knots on future boards is reduced to a minimum.

Production of linden lining

The size of the lining depending on the type of wood

The type of wood from which the lumber is made also affects the final profile size. The most popular varieties of trees from which molded products are made are larch, cedar, and Angara pine. The main parameters, grades and prices of lining in our company are presented in the table below

| Pine/spruce | larch | Linden | cedar | Angarsk pine | |

| thickness | From 12.5 mm to 13 mm | 14 mm | 14 mm | 14 mm | 14 mm |

| length | 6 meters | From 3 to 4 meters | From 1 to 3 meters | 2 to 3 meters | From 2.4 to 4 meters |

| Width | From 96 mm to 140 mm | From 96 mm to 140 mm | 96 mm | 140 mm | From 90 to 115 mm |

| Price | From 270 rubles per m2 | From 450 rubles per m2 | From 700 rubles per m2 | From 650 rubles per m2 | From 550 rubles per m2 |

Beautiful examples

- Wooden lining looks organically combined with other finishing materials, as well as with household items.

- Modern designers successfully use lining in various styles. Naturally colored material is usually used.

- Modern styles can also include clapboard decorative elements. In this example, the lining plays the role of an ideal background for bright accessories.

- The following example looks like a good design option - the lining harmonizes perfectly with decorative stone and exquisite ceramics.

For more useful information about lining sizes, see below.

Tips and recommendations for choosing the size of the lining

To choose the optimal size and type of lining, first of all you need to know exactly the parameters of the room (length, width, height) where the finishing will be carried out. If we are talking about the facade of a building, it is also necessary to take into account the parameters of the roof. If we multiply the width and height of the space to be finished, we get the number of square meters. This formula is convenient to use if the space requiring finishing has the correct shape.

If the room has an irregular or complex shape, it is necessary to separately calculate the parameters of individual sections and then summarize the obtained indicators.

In order to calculate the required amount of lining, you need to multiply the parameters of the room by the parameters of the thickness of the lining. And if you want to find out how many panels are in one cube, you need to multiply the length, width and thickness of the selected lumber. It is advisable to increase the resulting result by 15% in case of an unforeseen situation that may arise during the finishing process.

If such mathematical calculations make it difficult for you, then the easiest way is to contact representatives of the company where you are going to purchase the lining. Also, as a rule, the website of profiling organizations has an online calculator function that allows you to determine the preliminary order amount.

How to calculate the amount of facing material

The sheathing elements are assembled into a single monolithic shield. To calculate the amount of material, you need to know the original dimensions of the part. Grooves and protrusions are not taken into account. The total area of the wall is divided by the area of one finishing element. The result is the number of planks that need to be purchased to cover the plane.

Calculations are made one by one for each wall and ceiling. The results obtained are added up.

Advice! Masters recommend buying 10% more material. If this is not possible, you need to make sure that this sample is constantly on sale.

Calculation of the amount of material Source otdelkaexp.ru

Examples of using lining in the interior

The use of lining in the interior is explained by many reasons. First of all, this material allows you to create a cozy and comfortable interior without the help of professional designers and expensive finishing. The lining is beautiful in its natural form and does not require processing or sanding of the profile. In the production of the material, only natural raw materials are used, which are not harmful to health. Lining is a living textured material that retains heat in the room and allows clean air to pass through. In addition to these advantages, natural wood lumber has the following advantages:

- The molded product is affordable;

- If necessary, depending on the interior design, the profile can be painted in any color, creating bright accents in the room;

- Installing the material is simple and convenient; for this you do not need to call a team of professional craftsmen;

- Wooden finishing is always in fashion - such an interior creates a feeling of calm, comfort and warmth in the house;

Most of the popular design styles - Swiss chalet, Provence, country - use lining as the main finishing material. These are the ones we will talk about.

Kinds

In the manufacture of wooden lining, various types of wood are used.

The traditional types include the following:

- pine;

- aspen;

- linden;

- alder;

- deciduous;

- cedar.

Among the exotic species it is worth highlighting the following:

- abashi;

- ivory;

- iroko;

- hemlock.

If we take a separate type of pine lining, then its technical parameters and classification will vary significantly even for one type of product. Differences in humidity, type and grade of boards have implications for their cost. Everyone chooses those materials that will best suit the assigned tasks. For example, the level of humidity is an essential technical parameter, the indicators of which differ due to the fact that the lining has natural humidity, it is also called damp. The material is also processed in special dryers.

Processing in special dryers is carried out according to strict rules, since the quality of the products depends on this. The percentage of water in the treated lining is small or completely absent. By the way, if you choose pine lining, then it is worth keeping in mind that the natural percentage of humidity in these products is low. If the panel is dried, it will be a little lighter, but more expensive. This is due to the fact that wet pine is difficult to process.

Humidity affects the grade; for example, standard lining is a planed board made from unseasoned wood. The cost of this variety is affordable, so it is very common. However, the material is not used as a finish, but as a technical means, for example, to form a frame. The most suitable thickness of products for these purposes is 15 mm. Pine eurolining has the Western standard DIN 68126, which differs from the domestic one in the locking system. The products also have special grooves on the inside that help remove moisture. The humidity of the products is 12–16 percent, and the thickness of the panels is 16 mm.

The shtil option is a planed board, dried, with chamfers along the longitudinal side. The products do not have grooves, but they are usually wider than European versions, as they have dimensions of 145 mm. The standard European calm is sold in 90mm width. Wide panels reduce assembly time, however, installation of parts is considered difficult. To make the task easier, it is best to mount them horizontally.

Aspen lining is durable, rigid, and usually light-colored. At the same time, the original color of the material does not change over time of operation, as well as from external factors. Compared to other products, aspen options are more expensive, which is explained by the fact that there is very little knot-free wood used to make the material. The source material is of extreme value; the natural humidity of aspen is high. Often, when drying products, this factor is not taken into account, which leads to warping, cracking and changes in the geometry of the forms.

However, aspen is good as a finishing material because it is easy to process. Due to high humidity, the products have good moisture resistance. In many characteristics, the products are close to fake ones.

However, aspen has the best performance indicators. Fastening of aspen lining is allowed vertical or diagonal.

Alder lining is inexpensive and looks beautiful. It must undergo a drying procedure. After treatment, the final moisture content is about 12%. Often, during use, this type of product warps and cracks. To ensure that the finish remains beautiful over time, you should initially choose options with a wide tongue.

This will prevent the formation of cracks during drying. The thickness of the products is about 12.5 mm, and the width varies significantly - from 60 to 160 mm. Any of the options can be used for finishing. Experts advise choosing a wide alder lining. In general, aspen lining is good for finishing steam rooms and washing rooms in baths, since it does not absorb moisture at all.

Cedar lining, like other types, is processed in drying chambers. This option is considered durable, so it is often used as external cladding of a house. Like any coniferous lining, this type is very expensive, therefore it is used extremely rarely for its intended purpose. Lining made from exotic wood species is rarely found on the market. The cost of these products is expensive; it is unlikely that you can buy it cheaply. The characteristics of exotic wood are similar to conventional species, so when choosing, you should think about it and calculate the benefits more accurately from such an acquisition.

Knowing the exact dimensions of lining types will help in the calculations.

Types of finishes

Swiss chalet

This design style is best used in a suburban area with a home of any size. We will need a wide lining 6 meters long to decorate the roof. A sloping roof with large angles of inclination and a visor is the central part of the exterior. This element not only creates the feeling of a house in the Alps, but also serves to protect the room from negative environmental factors.

Traditionally, a Swiss chalet has 2 floors with a balcony, or it can be a one-story building with an open terrace.

Inside the house, the interior is also made using lining of various lengths. The walls and ceiling are sheathed using lumber.

Provence One of the most popular interior styles, used both in private homes and city apartments. Coffee shops and small restaurants often prefer this design. The use of living textured material - lining in large quantities - is the basic principle of constructing the Provence style. Lumber, as a rule, is painted in light pastel shades - olive, pale pink, soft lilac. Lightness, a feeling of comfort and homeliness, the absence of unnecessary decor and furniture - true Provence style.

Country This type of design direction is most often used for one space in a living room: living room, kitchen or bedroom. The main goal is to create a rustic, sophisticated style.

Simplicity, but with moderate gloss, comfortable furniture, but without modern trends, and necessarily finishing the walls with high-quality lining (it is advisable to use the highest grades and lumber from expensive tree species).

The interior styles given as examples are far from the only ones. With the help of lining of various lengths, you can make your dream of comfortable, cozy housing come true for any financial opportunity.

Peculiarities

lining for baths is most often used as a universal finishing material that adds practicality and aesthetics to the room. The lining is made in the form of panels with an absolutely smooth surface. It is suitable for finishing all bath surfaces: ceiling, walls, floor, which are perfectly flat and smooth. High rates of sound insulation with “breathable” walls, as well as the absence of condensation, are the main advantages in choosing finishing made from natural material - lining (wooden panels) in a bathhouse. It is not afraid of either high temperatures or constant humidity, but it perfectly covers the layer of insulating material and vapor barrier on wall and ceiling surfaces. Thanks to different types of design, it is easy to install, durable, and the room has an elegant appearance, conducive to enjoying bath procedures and truly relaxing.

We invite you to familiarize yourself with our range of materials

Larch lining - Extra grade

Wood Larch Width 96 mm Thickness 14 mm Length 3 m Qty.

in pack 4 things. 1850 rub/m2Larch lining - Prima grade

Wood Larch Width 96 mm Thickness 14 mm Length 3 m Qty.

in pack 4 things. 1500 rub/m2

conclusions

Summing up the results of the comparison, we can give several recommendations on which wood paneling is best suited for you:

- make your choice based on your personal preferences about beauty, because the main purpose of the decoration is to make visiting the bathhouse pleasant and to set you up for relaxation;

- for long service life of the boards, follow the recommendations for their use applicable to various rooms;

- do not use pine needles when decorating the ceiling of a steam room.

We hope that this article will help you decide which lining to choose for the steam room and other sauna rooms.

With respect to you and your home, the information portal ProfSovet.