What is lining

The lining consists of smooth wooden boards 7-20 cm thick with a planed surface. This is a universal material. It is used for both interior and exterior decoration.

Thanks to the special tongue-and-groove fastening, the elements are quickly assembled. Working with this material does not require special skills.

It is worth noting that in Russia the most popular profile molding material is linden and oak lining.

Advantages of linden lining

- This modern material is distinguished by its environmental safety, as it consists entirely of natural material - wood.

- Has an aesthetic appearance.

- Finishing the surface with clapboard guarantees an even coating.

- Linden wood has a unique aroma and original texture.

- Installation of the lining is easy, quick and efficient, and most importantly, it does not require special knowledge.

Disadvantages of linden lining

The only drawback of the material is the softness of the wood. Therefore, installation work must be carried out extremely carefully. It is also worth noting the high cost of lumber.

Wood species

Below you will find a list of wood species that you can buy at a lumberyard: their features, qualities, pros and cons.

Linden

After conifers, linden is preferred - the cheapest species.

It makes a good lining for a steam room because:

- Linden “seals” the room, preventing heat from escaping;

- Distributes temperature evenly;

- Does not crack from excessive changes.

Low thermal conductivity solves the problem of burns, even if you lean your whole body against the wall. Linden is not afraid to come into contact with water, so you don’t have to worry about cracks.

Aspen

Aspen and linden have approximately the same qualities, but the former is a little more expensive.

Aspen lining for a bathhouse has poor thermal conductivity and is also not afraid of water.

You can safely steam at least every day - the lining will live for at least 10 years.

Aspen for a bathhouse is inferior in that it is very difficult to find good boards. At lumber yards it is presented in a smaller selection and often has class “B” and lower (there are knots and small defects).

Aspen has an amazing effect - gradual hardening.

The rock itself is soft, but over time it acquires enormous strength. Even a nail goes into wood with difficulty.

If the aspen has darkened over time, light sanding with sandpaper is sufficient. Only the top layer (about 1 millimeter) is oxidized.

Alder

Alder for baths is a traditional material used for several hundred years.

Has exceptional qualities:

- Thermal conductivity is minimal. The panels remain barely warm, even if the steam room is over 80 degrees.

- Smooth surface. Even unplaned ones require almost no processing.

- Water resistance. Can last more than 20 years without cracking.

Due to its natural qualities, humidity almost does not deform alder.

After drying, it returns to its original state.

Siberian or Canadian cedar

You can use cedar for a bathhouse if you are going to make it for centuries. Wood is very expensive and is not sold everywhere.

It has a characteristic brown color with a pink tint. It is not inferior in strength to oak, so processing is very difficult. It does not release resin, but when heated, essential oils begin to evaporate, filling the steam room with a pleasant aroma.

Over time, cracks and rotting do not form, even if you do not cover them with varnish or oil.

As a rule, cedar lining for a bath is used in a specific room - a steam room.

It makes no sense to decorate other rooms.

Larch

To the question: “Which clapboard is better to cover a bathhouse?” - many answer - larch.

This is a coniferous species, but its qualities differ from pine:

- Moisture resistant. Comparable to cedar, since the tree grows in conditions of high humidity. Not subject to cracks and rotting, even with daily use of the bath.

- Strength. It is almost impossible to break it, and there are no traces of impact, like on pine.

These qualities come at the price of thermal conductivity. The density of wood causes it to heat up due to temperature.

In addition, larch is very capricious in processing. It may crack during sawing or planing.

Oak

Oak lining for a steam room is now considered the standard. It has excellent resistance to moisture and temperature. If the oak is initially well dried, moisture does not accumulate in it.

The thickness of the sauna lining is usually more than a centimeter. The slats are heavy and massive, which complicates their installation. In addition, oak is very difficult to work with. Cutting it with a hand saw is not an easy task, so you need a power tool.

The price of oak is high.

Significantly higher than pine, larch, alder and linden. However, all the shortcomings are covered by 25 years of operation without visible damage.

Pine

Pine lining for saunas and baths is rare. It can be used for lining the entrance or dressing room, but not for a steam room with a steam room.

When heated, pine releases resin, which heats up to the temperature of steam - this is a 100% burn. In addition, it can stain towels or skin. Resin will be released with each kindling, so it will not be possible to etch it away.

Pine is ideal for dressing rooms and washrooms.

This is one of the cheapest breeds and is not susceptible to rotting or cracking. It is easy to work with, although due to its high viscosity it is difficult to grind and polish.

Rare breeds

Exotic breeds for baths are rarely used, only if luxury class is intended.

Among them the most common:

- Abash. African rock, which is characterized by high porosity. For this reason, it does not heat up at all even if the temperature approaches 100 degrees.

- Hemlock. An exotic pine species native to North America. It has extreme porosity and durability. Quite fragile, but does not have resinous secretions. It is ideal for the steam room, as it is impossible to get burned.

Scope of application of linden lining

Linden lining is excellent as a finishing material for wet rooms. It is installed not only on walls, but also on the floor and ceiling.

The material is resistant to high temperatures, so benches and shelves for baths and saunas are made from it. It is useful to lie on linden boards, as the wood strengthens and heals the body and spirit.

What to give preference

The desire of every homeowner to have their own bathhouse with a steam room in their yard is very understandable. This place is not only for taking a shower and a steam room for one; true connoisseurs of the Russian bath gather here for relaxation and communication after a busy, busy week. Considering that not every finishing material is useful for a bath, you need to make the right choice. The video in this article will help you understand that in the steam room of the bath there are absolutely no materials such as tiles, plastic and other synthetic products. The lining of the interior of the bathhouse is made of linden, alder, aspen or cedar paneling. Which one should you choose?

How to choose a lining

In order to make the right choice of material, it is necessary to take into account factors such as quality, appearance and profile. It is worth paying attention to how smooth the surface of the parts is. If upon inspection the slightest deviation is detected, then it is better to refuse the purchase immediately.

It will be important to check the joints of the profiles. They must connect seamlessly with each other. Otherwise, problems may arise during installation.

It is also necessary to check the material for moisture. To do this, lightly tap the lining. If the wood is damp, the sound will be dull, and if it is dry, it will be ringing.

Material classification

The entire range of materials is divided into classes:

- Extra. Belongs to an elite variety. The material has a perfectly smooth surface. There are no knots, chips or other defects.

- Class A. There may be slight deformations of the material in the form of chips and cracks. But their number should be minimal and not exceed 2-3 pieces per 1 linear meter.

- Class B. Uneven shade and the presence of knots and chips are acceptable. The diameter of defects should not exceed 10 mm.

- Class C. The material may be deformed by through holes left by fallen knots. The presence of a pale blue tint is considered acceptable for this class.

- The lower the class, the cheaper the material costs.

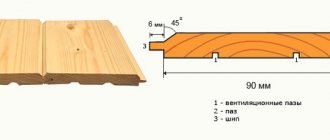

Differences between fake eurolining and regular lining

No one needs the original lining (Soviet-style with a very tiny lock equal to 20 mm and a humidity of 25%) today. Its quality and configurations undoubtedly leave much to be desired. Therefore, the appearance of eurolining became revolutionary in the market of facing materials. This was a real triumph for our regions. Everyone: contractors, ordinary consumers and developers began to buy it en masse in huge quantities for repairs.

The lining, marked with the abbreviation “Euro”, is produced strictly according to European standards (DIN 68–126). Unfortunately, most domestic manufacturers ignore them. Eurolining differs from domestic ones in virtually all respects.

The spike here is made in large sizes (8-10 mm). This makes it easier and more reliable to connect. This prevents the formation of cracks (especially in damp areas).

On the back side of this lining there are ventilation grooves.

The standard parameters of the europanel are 12.5 mm.

The key advantage and difference between this type of lining and the usual one is that the former is equipped with several profile options.

The requirements of European standards such as DIN 68–126 are very stringent, much stricter than those of the domestic GOST, namely:

The requirements for processing the front layer of lamellas are stricter. If there are knots on it, they must be additionally processed.

The grooves and ridges must be ground to perfection to ensure a clean, reliable and precise connection.

The board must be additionally (forced) dried to 10-15%. This protects the material from cracking and deformation.

When sorting, the manufacturer makes an additional selection taking into account natural wood defects and manufacturing shortcomings.

All this ultimately means that the buyer, when choosing a material, acquires a truly high-quality product of world standards.

Medicinal properties of linden

The unique, pleasant aroma of linden has a beneficial effect on the human nervous system, helping to relax, get rid of stress and accumulated fatigue. It is useful to lie on a linden lining that has been heated by steam.

It releases special beneficial substances, which have a positive effect on health and help cope with diseases such as:

- Cold.

- Cellulite.

- Gastrointestinal diseases.

- Disorders in the cardiovascular system.

- Cough with sputum difficult to separate.

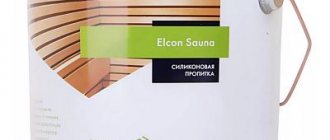

Additional material processing

Linden lining must be treated with an antiseptic. This must be done, because otherwise mold and mildew will form on the material. Therefore, additional processing will help extend the life of the lumber.

When decorating a room with linden lining, especially external walls, it is necessary to treat the material annually with varnish or stain. For internal processing, special types of varnishes that are safe for human health should be selected.

Not wood covering

If you don’t like wood and prefer other finishing materials, tiles, fiber cement and plastic are at your service. It is no secret that this material is cheaper, and some are even safe.

Plastic panels are only suitable in the rest room and locker room - this material cannot be used at high temperatures. Ceramic tiles and fiber cement have proven themselves better - they are durable and reliable materials.

Fiber cement boards and plastic panels

Fiber cement board for finishing a washing room in a bathhouse is a suitable material, which is a mixture of sand, cement and cellulose.

Density depends on the amount of air and water added. Medium-density slabs are intended for finishing houses and baths - the material does not break and has been serving for a long time for more than a hundred years.

Thanks to the presence of cement, the slabs are waterproof and heat-saving. The presence of minerals adds plasticity. Let's look at the main advantages of fiber cement boards.

- Completely environmentally friendly material without harmful substances;

- Good moisture resistance - there are bubbles inside the slabs that push water out;

- Fire resistance - the material is not subject to fire and can contain a fire;

- Strength and longevity - the service life of fiber cement boards is from 30 to 60 years. The material proved to be better than wood and plastic;

- Easy installation and reasonable price.

As for plastic panels as a material for finishing a bathhouse, the situation here is the opposite: like any brainchild of the oil industry, plastic finishing is completely unsuitable for bathhouses and other similar places. The material is prone to ignition and is filled with toxic substances.

The only suitable place for plastic panels is the locker room, that is, the least hot place where a person spends the least amount of time. Plastic, even at low temperatures, releases toxic elements into the atmosphere, which is felt in the form of an unpleasant odor. However, from a cost point of view, this is the cheapest option for finishing the premises.

Linden lining in the interior

Linden lining is quite often used in the interior. This is primarily due to the positive characteristics of the material, as well as fashion trends. This way the material can be combined with other finishing materials, achieving an original and unique result.

- The lining is applicable both in residential premises and in office rooms. Since the material is universal, it can be used to decorate a country house both inside and outside. It looks very attractive and makes the building stand out from other houses.

- Using the material you can visually increase the area of the room. It all depends on the location of the lamella. For example, by arranging parts vertically, you can visually raise the ceiling, while a horizontal arrangement will visually expand the space of the room.

Main profile parameters according to GOST

The main parameters of the lining are regulated by GOST standards for profile parts made of wood for construction and for softwood lumber. As for the profile length, there are no strict regulations. As a rule, lining from 2 to 6 meters goes on sale. There are also no special requirements for the profile width; this parameter varies from 13 to 120 mm. Buyers, as a rule, prefer to purchase the type of profile that is convenient to transport.

The width and length of the profile are taken as a guide when it is necessary to determine the volume of products purchased. Regardless of the parameters of the lining, the installation principle of the product is identical, which is very convenient for the buyer. If repair or dismantling work is necessary, it will be very easy to find a similar profile of the required size.

On the product packaging, as a rule, the parameters are indicated in the following order: grade, thickness, width, length. The characteristics of the profile values largely depend on the type of wood from which it is made. It should also be taken into account that Russian standards do not correspond to European ones.

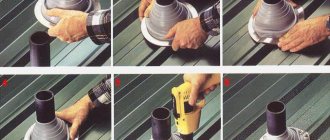

Features of material installation

Before the main work of installing the material, you first need to form a wooden profile frame. In this case, wooden beams can be replaced with a zinc profile. In this case, you will need screws for fastening, not nails.

It is important that the linden paneling be installed vertically. This is necessary to ensure that condensation does not accumulate in the expansion grooves.

Experienced craftsmen recommend leaving a gap of 10 cm when installing lamellas, and upon completion of installation work, you need to cover the corners with additional products made of the same material.

Care

In order to clean the material from dust and all kinds of contaminants, you must use a vacuum cleaner. But it is not recommended to wet the material, much less use chemical detergents.

But to remove stubborn stains, you can use a weak solvent solution. To prevent surface contamination, you can treat the surface with an antiseptic.