Almost everyone knows about the benefits of a bath: it cleanses skin pores, improves blood circulation, and perfectly relieves nervous tension. The sheathing material plays an equally important role when constructing a steam room; most often, a special board or steam room lining is used for this purpose. You can learn from this article how and by what criteria to choose it.

Peculiarities

lining for baths is most often used as a universal finishing material that adds practicality and aesthetics to the room. The lining is made in the form of panels with an absolutely smooth surface. It is suitable for finishing all bath surfaces: ceiling, walls, floor, which are perfectly flat and smooth. High rates of sound insulation with “breathable” walls, as well as the absence of condensation, are the main advantages in choosing finishing made from natural material - lining (wooden panels) in a bathhouse. It is not afraid of either high temperatures or constant humidity, but it perfectly covers the layer of insulating material and vapor barrier on wall and ceiling surfaces. Thanks to different types of design, it is easy to install, durable, and the room has an elegant appearance, conducive to enjoying bath procedures and truly relaxing.

Kinds

Today, manufacturers offer various types of trees from which panels are made. Knowing the properties and characteristics of a particular rock, you can make the right choice as to which clapboard is best to cover the bathhouse for covering the surfaces, taking into account the purpose of the bathhouse. The selection includes information on the geometry profile and product type. All natural wood is divided into deciduous and coniferous species, which is also taken into account when choosing

Linden

Linden is considered a classic option for cladding a bathhouse. This is the solution to the question of which type of lining to cover the steam room with. Linden wood is not very dense, which prevents the material from heating up, even when it is very hot in the steam room. This allows you to obtain comfortable conditions for being in the steam room. When heated, linden emits a pleasant aroma, which is also beneficial for the lungs. Even with constant humidity, linden wood does not become stained with rot, and the color remains light and noble.

Pine

Surprisingly, pine is the most common wood for euro-lining for baths, although its properties are completely unsuitable for rooms with steam. It looks great in the room where people relax or in the corridor (dressing room). When considering which clapboard is best to equip a steam room, you need to take into account that pine wood leaks resin when the temperature exceeds +500, and you can accidentally get burned on it. In addition, this wood has low resistance to moisture (turns blue and rots) and high temperatures, as well as average heat capacity. You also need to take into account that pine lining necessarily requires treatment with chemicals before installation.

Aspen

Aspen panels have always been a popular material when the question was about which lining is best to use for a steam room. Aspen slats are valued for their durability, resistance to high levels of moisture and temperature fluctuations, as well as for preserving the color and structure of the steam room lining (panels). Also, the lining of aspen panels in the bathhouse emits a pleasant, slightly bitter aroma, relaxing the nerves.

Alder

Alder wood is the best finishing solution; what kind of clapboard is best to cover a steam room in a bathhouse. It has a noble texture and color, excellent performance properties, as well as a pleasant aroma, reminiscent of the smell of good cognac. But there is one drawback - it is expensive, and it is difficult to find truly excellent quality.

Cedar

Plastic and especially soft cedar wood, as well as beautiful texture and color, make the lining exclusive and rich. In addition, cedar wood contains essential oils, which give the steam room an unforgettable and lasting aroma. Cedar lining for a steam room is expensive, but elite.

Oak

Oak wood with a dense and beautiful texture is an excellent finishing material for lining a bathhouse with such clapboard and making furniture for it. Oak is durable and will delight its owners for decades.

Other breeds

Among other species that are used to decide which clapboard to cover the inside of a bathhouse, the most common are larch, abashi, hemlock, hornbeam, birch, ash and beech. Each of these tree species has its own advantages and certain disadvantages. Thus, hemlock is a coniferous species from America, used for finishing the outside and inside of the steam room. It is perfectly processed, holds fasteners remarkably well, and resists microorganisms and wood-boring insects. A wide range of colors allows you to create a unique and inimitable design.

Brooms

Bath brooms are made from a wide variety of branches and herbs, each for a specific purpose .

A pine bath broom releases a lot of essential oils when steaming, so its aroma is very strong. By inhaling it, you simultaneously disinfect the respiratory tract , which will be a good prevention of colds. The smell of pine needles also has a tonic effect on the entire body - after the procedures you feel a great surge of strength and vigor.

While hovering with such a broom, the body receives its benefits - this is a massage, a tingling sensation that causes a rush of blood to the skin, and the transfer of beneficial substances that the pine needles contain to the skin.

According to the rules, the broom is prepared right before the procedure from straight, young branches. It is advisable to wrap the handle or use gloves, because resin will be released.

The broom is not steamed, but is poured with boiling water for a quarter of an hour . Afterwards, you can wrap it in cloth and put it on the top shelf for another five minutes. Under the influence of boiling water, the needles will become softer, their touch will become more pleasant.

ATTENTION! This broom can only be used once. Its usefulness is one-time only.

If resin gets on your skin during the procedures, you don’t need to do anything - then wipe it off with alcohol.

Characteristics of lining made from different types of wood

When setting yourself the task of which clapboard is best to line a bathhouse from the inside, you need to understand the features of the ready-made material - clapboard, so that the finish is durable and healthy.

Features of spruce lining

A sauna rack made of spruce in its performance characteristics is practically no different from pine. The main differences are considered to be a looser texture and color of the lining. In addition, spruce wood is very sensitive to high humidity, which subsequently leads to rapid destruction of the wood. But the thermal insulation properties of spruce lining are difficult to overestimate. It is always comfortable and pleasant to be in a room lined with spruce.

Features of aspen lining

The main feature of aspen lining is its solid wood texture. It can be easily processed, but at the same time it is practically difficult to break. High levels of steam resistance completely eliminate doubts about which lining is better for a steam room.

Features of lime lining

Specialists involved in finishing baths and saunas are sure that there is no better finishing than lime lining. The lining does not heat up from the heat of the steam room and creates a pleasant microclimate, but it must be taken into account that all the splashes from bath procedures will leave marks on it. This in turn will affect the aesthetics of the room.

Features of black alder lining

The black alder wood from which the sauna lining is made is not exactly intended for this purpose. It has increased sensitivity to temperature fluctuations and has low resistance to mechanical damage. Often, with insufficient ventilation, microorganisms and fungi appear on the surface, and in order to prevent this, it must first be treated with a special antifungal liquid composition. But at the same time, black alder wood is durable and has a beautiful, rich color.

Features of pine lining

Resin leakage is the main drawback to using pine wood as a lining for a steam room, but finishing auxiliary rooms is welcome! Beauty and pleasant aroma will turn visiting the bathhouse into a real pleasure.

Features of cedar lining

Do you want an elite lining for your bathhouse? Choose cedar lining! Easy-to-process cedar lining, as well as a pleasant color and texture of the wood, with unlimited financial possibilities, is the best solution for choosing which lining is best for a bathhouse.

Features of larch lining

The gum found in hardwood paneling makes it particularly resistant to the development of microorganisms on its surface. This is an ideal option if there is a problem, which lining for a steam room is better. But it is quite difficult to process, can crack easily and does not have sufficient thermal insulation characteristics.

View this publication on Instagram

Publication from Manufacturer FOR BATH AND SAUNA (@predgorie23)

Tips and tricks

After choosing the type of wood for the lining, you need to decide on the type of material. The products are available in four types:

- Extra - an option without defects in the form of cracks and knots, characterized by ideal geometry and long service life. Suitable for any room, but due to its high cost, it is recommended for a steam room where durable lining is needed.

- A – boards with a smooth surface, a small number of knots and small cracks.

- B – there may be through and hairline cracks, knots, and rot. The number of defects is regulated by GOST.

- C – grade has many disadvantages such as cracks, curvature, and surface damage. It is used for finishing technical premises.

The internal lining of baths and saunas is mounted in two ways: with vertical or horizontal boards. The first option ensures that water quickly drains and removes moisture from the steam room. Eurolining for a bathhouse is mounted vertically, this allows you to visually increase the height of the room. The horizontal arrangement of the slats expands the space of the room. With this option, it is recommended to use conventional lining with close fitting parts.

Treatment with antiseptic agents can extend the service life of the finish. Safe water-based formulations are selected. The products are specially designed for use in high temperature environments. They do not contain harmful components.

When installing the lining, it is necessary to hide the fasteners. This is not only a matter of aesthetics - heated metal causes burns. Hidden fastening is done through a groove or tenon.

Which type of lining to choose

As with any other finishing material, lining has a grade, which determines its quality. The highest quality slats are dried at a maximum natural humidity of up to 12%. Properly dried material reveals its operational advantages, the main one of which is the ability to pass air (“breathe”).

By grade

Regardless of the wood for the bathhouse, the slats are divided into grades: A, B, C, Extra, Premium. Each grade corresponds to the presence (absence) of natural defects that were revealed during the manufacture of lamellas. The most expensive and high-quality grade is Premium, the wood of which is free of wane or knots, as well as other defects. The lowest grade slats are C. They may have many defects, but they are also the cheapest. In addition, the grade determines what surface the material will be attached to; if for walls you can even take grade B, then for ceilings the grade must be no lower than A.

For wood

When choosing which lining for a bathhouse is best, you need to pay attention to the wood. Firstly, the rock and its properties, secondly, the grade, and thirdly, the room where the finishing will be done. For paired rooms, not only ease of processing is taken into account, but also fastening features and other parameters.

Linden slats

Linden slats - a wide range of products in various modifications:

- standard with thickness from 12 to 25 mm, length up to 6 m, width up to 150 mm;

- eurolining with a thickness of 12.5 mm, length up to 6 m, width up to 160 mm;

- other modifications used for exterior finishing.

Aspen paneling

Aspen lining is most often made with a tongue-and-groove connection, which eliminates gaps during temperature and humidity fluctuations, and ease of processing is ensured by the plasticity of the wood. The lamellas are lightweight, making it possible to install independently and alone.

Alder slats

Alder lamellas as lining for a bathhouse, an inexpensive and practical solution, which lining is better to line a bathhouse from the inside. This is a completely environmentally friendly material that can be used as decoration for all rooms in a bathhouse or sauna.

From cedar trees

Cedar slats are suitable not only for finishing walls, ceilings or floors. They can be made into sun loungers, steps and other structural elements. Rich aroma and durability, high performance and aesthetic characteristics are the main criteria in choosing a material.

Abash abashi

Abashi wood is chosen by those owners of future baths who value not just exoticism, but also the excellent performance qualities of the material. Abashi has low thermal conductivity due to the porosity of the wood. Abashi lamellas are easily combined with other materials, do not “shrink” due to humidity, and the wood does not split during processing.

View this post on Instagram

Publication from Andrey Tupilin (@tupilin_andrey)

Larch

Larch slats are the most common material for covering a sauna or bathhouse. The wood is very dense, so processing is difficult.

Rare breeds

Abashi, hemlock and oak remain rare wood species to choose which lining to use for a bathhouse. Oak is durable, abashi is resistant to moisture, hemlock is resistant to rot, but this wood has not yet gained popularity among owners due to its price. The material is expensive, and even many specialist builders do not have experience in cladding these types of wood.

Installation

The casing of a sauna or bathhouse involves installing the lining using two fastening methods: vertically or horizontally. Horizontal fastening is carried out by laying lamellas, which are located parallel to the floor, and vertically - perpendicular. The horizontal method is more often used in practice, when installation is carried out with a tenon located at the top, and the groove of the next rail is put on the tenon of the previous one. This method is advantageous in that in case of persistent contamination, replacing panels is much easier than with vertical installation. As a rule, the horizontal method is used in Russian baths, where the steam is wet. The vertical method is suitable for Finnish saunas with dry steam.

Fastening is carried out:

- through connection with self-tapping screws or nails;

- hidden on screws or nails;

- on clamps (hidden).

The hidden fastening option is preferable, as it eliminates burns when touched during the steam room.

About finishing

Vertical finishing method

Even a non-professional builder can line a steam room with lining for a bath, if only he had the skills to work with tools. But before you start finishing, you should choose the method in which it will be installed. There are two options available.

- Vertical: The boards are oriented from floor to ceiling. It is considered easier to implement, provides high installation speed, and protects elements from excessive exposure to moisture - condensation flows down the lamellas. On the other hand, it rises with the same ease through the microscopic capillaries that permeate the wood. Vertical installation makes it possible to more effectively accumulate heat in the steam room itself.

Horizontal finishing method

- Horizontal: the slats are mounted parallel to the floor. Moisture getting into the finish is also unlikely, since the boards are attached with the groove down. A plus is the presence of sheathing, which provides a gap between the wall and the lining, which means it allows air to circulate in the space. A special advantage of this installation is the ease of replacing the lower fragments, which, due to high humidity, fail before those located above.

With your own hands

Experts recommend the first installation method for finishing saunas where the steam is dry, and the second for lining classic Russian baths.

Choosing a lining for the dressing room

The dressing room protects the rest room, wash room and other rooms from the penetration of cold air. But in order to create the overall design of the bathhouse, it is also sheathed with lamellas. Which sauna lining is better in the dressing room? Since there is no high moisture and temperature in the dressing room, you can choose any species of coniferous or deciduous trees, from expensive rare ones such as hemlock, abasha and oak, to budget pine or spruce slats. You can choose the middle price category: linden, alder, aspen, larch, etc. You also need to take into account the performance characteristics of the material. The grade of the lining in the dressing room is, in principle, not important.

Mounting methods

In order for the casing to serve for a long time without repair, it is necessary to choose the optimal method of fastening. The choice of fasteners depends on the purpose of the room. Do not overuse nails to avoid damaging the surface of the slats.

The lamellas are fixed:

- self-tapping screws - pre-make holes with a diameter equal to the diameter of the self-tapping screw. They work with a screwdriver. This method is chosen by masters;

- finishing nails - which are inserted into the groove and covered with another lamella. This method is not suitable for finishing a steam room, since high humidity and temperature contribute to the oxidation of nail heads and loss of attractiveness of the surface;

- staplers - fastening is carried out on the sheathing.

The use of ordinary nails requires caution when finishing brickwork, as nails may damage the surface and split the wood.

Choosing lining for a shower

Often, baths or saunas have a shower room, but this, in combination with the overall design, is lined with wood. Which lining for a bath in the shower will be the best? Considering that there is always water and humidity in the shower, there is no point in talking about expensive materials, because they will still have to be replaced after a few years. The best option is pine or spruce slats. They are inexpensive, easy to process and cover. In addition, by treating the lamellas with special anti-rotting compounds, you can increase their service life.

What kind of lining to use for a bathhouse that is heated with wood

Which lining will be better for a bathhouse that is heated with wood? The temperature in a wood-burning sauna in a steam room is not so high, but has high humidity. The human body normally perceives temperatures up to +600, and humidity should be no higher than 50%. Therefore, lamellas are selected that meet these indicators and should also serve for a long time. The main parameter in the choice is the quality of processing of the slats. For a wood-burning sauna, the optimal choice of the following wood:

- Linden;

- aspen;

- alder;

- ash;

- larch;

- birch.

If you have the financial opportunity, you can also sheathe it with oak.

View this post on Instagram

Publication from PLANED BOARD (@woodwoorld)

Which lining would be better for a steam room?

The steam room is the main room in the bathhouse. Here the temperature can rise to +1000. This means you need to choose wood that has high resistance to temperature and humidity. The most suitable lamellas for cladding are the following tree species: aspen and linden, maple and alder, larch and cedar.

Choosing wood for lining in the waiting room

The dressing room protects the rest room, wash room and other rooms from the penetration of cold air. But to create the overall design of the bathhouse, it is also lined with wooden slats. Which sauna lining is better in the dressing room? Since there is no high moisture and temperature in the dressing room, you can choose any species of coniferous or deciduous trees, from expensive rare ones such as hemlock, abasha and oak, to budget pine or spruce slats. You can choose the middle price category: linden, alder, aspen, larch, etc. You also need to take into account the performance characteristics of the material. The grade of material in the dressing room is, in principle, not important.

Choosing lining for a room with a shower (shower room)

Often, baths or saunas have a shower room, but this, in combination with the overall design, is lined with wood. Which lining for a bath in the shower will be the best? Considering that there is always water and humidity in the shower, there is no point in talking about expensive materials, because they will still have to be replaced after a few years. The best option is pine or spruce lining, as well as fir wood. It is inexpensive, easy to process and cover. In addition, by treating the lamellas with special anti-rotting compounds, you can increase their service life.

A video presentation will show which lining is best to use in a steam room.

The quality and properties of the material are very important in the selection criteria. The lining for the steam room is selected in accordance with the performance characteristics and properties of the wood. When choosing which lining for a bathhouse is best, they choose the materials taking into account the state of the steam (wet or dry). The lining for the steam room must be resistant to temperature and humidity, durable and aesthetically pleasing. Which lining is better for a sauna? The best options are linden and alder. With wet steam, what is the best lining for the steam room - temperature-resistant: alder and maple, linden and aspen.

View this post on Instagram

Publication from Stoves, fireplaces, grills in Kazan. (@teplotoriya.ru)

A separate class of lumber is “eurolining”

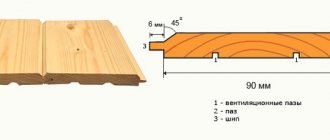

Eurolining board. Eurolining differs from ordinary lining in profile, since it is planed in accordance with European standards, where it first came to us from, hence its name.

At the first signs of “aging,” the lining is simply covered with decorative wax (impregnation) and again restores its original appearance. One of the key differences between real “Euro lining” and “lining” according to various GOSTs and STB are special longitudinal ventilation grooves made on the back side of the board . They are designed to speed up the removal of condensate, and such grooves also relieve internal stress in the material , which arises due to sudden changes in humidity and temperature in the finished room. Also, a special “tongue-and-ridge” connection , which is much deeper than ordinary grooves in the “lining”.