Everyone has long known the ardent love of Russians for fast driving, but baths evoke no less warm feelings among our compatriots. High temperature, high humidity and healing steam strengthen the health and immunity of those who have the healthy habit of regularly steaming. To create a truly warm bathhouse, a log or timber frame made of hard wood is usually used, which retains heat for a long time and has healing properties due to the high content of phytoncides. Experienced craftsmen have noted that more than 80% of heat loss in a bathhouse occurs through the roof, so it is very important to make and install the rafters correctly. In this article we will talk about the features of the structure of the truss frame of a bathhouse roof, which must be taken into account during construction.

Options for roof designs for bathhouses

Before you start building a roof in a bathhouse, you need to choose the best option. It should be as simple as possible, but reliable, since it is needed to protect the structure from rain and snow.

The bathhouse can have a regular gable roof

Most often, baths are:

- attic;

- roofless.

The roof structure itself depends on this. This is also affected by the frequency of operation of the bath. For one that will be used all year round, it is best to choose a gable one with an attic, as it is warmer. There you can equip a rest room.

The gable roof of the bathhouse can be with an attic

Summer baths are usually built without an attic, but are designed to install a tank of water for heating under the sun. This type of roofing is easier to construct.

A bathhouse with a gable roof without a roof looks very beautiful

According to their shape, roofs can be:

- single-pitched;

- gable;

- multi-slope.

Shed roofs are the simplest. Typically used when attaching a bathhouse to the main house or other building. The rafters rest firmly on opposite walls at a certain angle of inclination.

The optimal tilt angle is 20–30°, but if the bathhouse is built in areas with high levels of precipitation, then this parameter increases to 45°.

A wooden bathhouse is most often built with a pitched roof

Gable roofs are installed on separate structures. They consist of two parts connected to each other at an angle. For areas where a large amount of snow falls in winter, the connection angle should be quite sharp (from 45 to 80°) so that precipitation can easily drain and does not put pressure on the roof from the outside. And in areas where there are frequent winds, there is a minimum slope so that in the event of strong gusts it does not fly off the bathhouse.

The angle of a gable roof depends on climatic conditions

Multi-pitched roofs are usually not erected on small bathhouses, as this is not entirely rational and convenient. But if a large bath complex is being built, then it will be appropriate here. It has a beautiful appearance and allows you to arrange additional rooms under its arches (relaxation rooms, billiard rooms, storage rooms, etc.). The disadvantage of the roof is the complexity of its construction.

A hip roof is suitable for a large wooden bathhouse

That is why masters often choose this option.

How to make a gable roof diagram correctly

The best option for a small bathhouse is a gable roof. It can be inclined and hanging. The first option is equipped with additional wooden stops for greater stability. Hanging systems rest only on the mauerlats or ceiling beams. At the top, the rafters are supported by crossbars.

A simple gable hanging roof is suitable for a bathhouse.

Hanging systems

Rafters of this type are used for those baths in which there are no walls, but only solid partitions. Due to this type of construction, the load is concentrated mostly in the upper crown of the bathhouse.

- Using bolts, the ends of the rafters are connected to each other from above;

- The lower ends are sawn off at an angle;

- The crossbar must be installed between the upper and lower rafters;

- The finished structure is moved to the top of the building;

- At this stage, jibs are used to secure the outer trusses. The jib can be removed only after checking for verticality;

- Next, it is necessary to install central trusses in the same way, the distance between which must be at least 1 m;

- Next, the rafters need to be fastened together using lathing.

So we find out how to attach rafters to a bathhouse.

Preparation for installation: sizing, drawings

For convenience, all calculations will be made for a bathhouse with a side of 5 m. It is recommended to build it from sawn timber, and use the top row as a mauerlat.

Before making rafters, it is necessary to make all the necessary calculations and measurements, as well as determine the angle of inclination of the roof and the dimensions of the wooden elements.

The roof system is subject to certain loads:

- the mass of rafters, sheathing and the roofing material itself;

- snow load and wind factors;

- workers' weight;

- the likelihood of natural disasters (they are not taken into account in our country, since they have a low percentage of the likelihood of their occurrence).

When calculating the thickness and width of the rafter system elements, take into account the totality of all types of loads.

The diagram will help you calculate the material

The lower elements of the rafters are placed on the Mauerlat, and they bear lateral and vertical loads. Horizontal ones are placed on crossbars. The ridge part of the rafters takes on the compression forces in the horizontal direction. Rafter spans are subject to the greatest degree of bending.

The choice of material depends on the loads on the rafter legs

When calculating the load, it is necessary to use correction factors that depend on the height of the house.

In order to determine the load, it is necessary to multiply the standard by the specified coefficient

There are also different snow load values depending on the climate zone.

If the weight of the roofing material is specified by the manufacturer, then the loads can be calculated independently

Belonging to a certain climatic zone can be seen on a special map.

Snow load map of Russia

Assembly technology

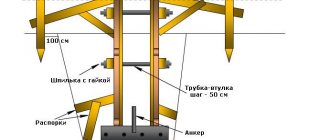

If, according to the project, an internal load-bearing wall is planned in the bathhouse, then it is better to make a layered rafter system consisting of a mauerlat, vertical posts, a ridge purlin and stops. If only the external walls are load-bearing, then it is only possible to install a more complex hanging system. In general terms, the installation of rafters for a bathhouse roof is carried out as follows:

- First, a support beam, called a Mauerlat, and a bed are laid on the upper belt of the load-bearing walls. Secure it with long metal pins or anchor bolts.

- Then the racks are installed on the bench. To ensure that they maintain a vertical position during installation, they are temporarily reinforced with supports.

- A ridge girder is laid on the racks. The correct installation of the ridge beam is checked using a building level.

- Then the rafters are installed in increments of 60-120 cm to make it convenient to install the insulation. The rafters are fixed using nails, staples, metal plates or sliders.

Experienced craftsmen note that trusses for a bathhouse roof can be assembled on the ground, and then, ready-made, lifted and installed on the Mauerlat.

Technology for attaching rafters to the Mauerlat

Choosing roofing material

The wood that is used for the construction of the rafter frame must have a minimum number of flaws (primarily this concerns knots and cracks).

For the roof of a bathhouse, pine or spruce boards are most often chosen due to their high degree of strength. This wood is easy to process. Experts recommend using grade I lumber, well treated with antiseptic and antifungal agents. But for a small bathhouse, grade II or III material is suitable.

It is recommended to use pine boards for rafters

You can use laminated veneer lumber with a high degree of strength without signs of deformation. But such material is expensive.

Recommended moisture content of timber:

- 20% (if the inside of the bathhouse ceiling is completely covered with finishing materials);

- 23% (if some roof elements will be located on the street, for example, a canopy over a veranda or terrace).

Wood for a roof must be dried naturally (in a dry room at a low temperature) for 2–3 years or in special chambers at the highest possible temperature.

There are a large number of roofing materials:

- ondulin;

- metal tiles;

- soft tiles;

- roofing felt;

- slate;

- euroslate;

- metal profile.

The most popular and affordable materials are metal tiles and corrugated sheets, which are characterized by their low price and long service life.

The corrugated sheet is made of galvanized steel with a special coating. Its main difference from metal tiles is the thickness of the metal. For example, corrugated sheets with a thickness of more than 1 mm are not intended for roofing.

Thin corrugated sheeting is used for the roof

Advantages of this material:

- high performance;

- ease of installation (sheets can be easily selected according to the exact size of the roof slope);

- light weight;

- affordable price.

There are also disadvantages, for example, low sound insulation characteristics, less attractive appearance compared to metal tiles, short service life (about 5 years).

Advantages of metal tiles:

- high degree of corrosion resistance;

- excellent sound absorption, which provides multilayer material;

- long service life (about 50 years);

- wonderful appearance.

Despite its positive qualities, it is not suitable for installing pitched roofs, since it can only be laid at an angle of at least 14°. Corrugated sheets have no restrictions.

Metal tiles are ideal for roofing

Ruberoid is an inexpensive but short-lived material. It is easy to install and does not require much labor. For a budget roof covering for a bathhouse, roofing felt can be called a completely acceptable option.

Ruberoid is suitable for installing a pitched roof

Slate is an affordable roofing material that is suitable for a bathhouse. It has a fairly long service life (about 40 years) and does not require additional care. Installation of slate sheets is carried out quickly, which is very important in the final stages.

Euro slate has an attractive appearance

The disadvantage of this material is the high degree of water absorption, so after 2-3 years moss and various harmful lichens may appear on it - painting will help to avoid this. The high fragility of slate is also a significant disadvantage. Therefore, it is better to pre-drill holes into which fasteners will be driven.

Regular slate is also suitable for roofing

Installation of ceiling beams

After the walls of the future bathhouse are built, the first step towards installing the rafters is the installation of ceiling beams. The basis for installing the beams will be the upper two crowns of the structure. Beams can be installed in two ways:

- Through holes are cut in the crowns and beams are laid in them. Thus, the wall is considered open, and the ends of the beams face the street.

- Blind holes are cut into the crowns, occupying only part of the log. In this case, the end of the beam is in a wooden log, and the wall is considered blank.

The first option is less popular, because the influence of precipitation on part of the beam is great. As a result, it will become unusable and its reliability will be significantly lower.

The way in which the ceiling beams are secured determines how the rafters will be attached.

What material and tools are needed

In order to build a gable roof for a 5x5 m bathhouse, you need:

- boards (pine or spruce) - 50x150 mm (the distance between the rafters is recommended to be 90 cm);

- unedged board for temporary fixation of rafters;

- edged board - 20x100 mm (length 3 m);

- metal corners;

- metal plates - thickness 2 mm;

- bars - 50x50 mm;

- bolts with washers and self-tapping screws;

- glued plywood, OSB or unedged board for sheathing;

- slats - 20x50 mm;

- insulation, vapor barrier and waterproofing material;

- metal tiles or corrugated sheets.

Tools:

- Bulgarian;

- electric jigsaw;

- stapler;

- hammer;

- tape measure - length at least 10 m;

- sharp knife;

- electric screwdriver;

- antiseptic agents and impregnations.

Briefly about the main thing

To ensure that the roof for the bathhouse is durable and resistant to operational loads, the construction of the structure is carried out using generally accepted technologies. The usual, time-tested solution is a single- or gable roof.

Each of the designs has its own advantages: the lean-to design is more economical, but the gable design allows you to create conditions for year-round use of the bathhouse.

When developing a project, it is important to determine the type of roof (cold or warm) and the type of rafter system (suspended or layered). Mauerlat is an important component of the structure, but some buildings do without it. The choice of material parameters for the rafter structure (for example, the thickness of the boards) also depends on the area of the bathhouse and the type of finishing coating.

Ratings 0

Video: how to properly make a roof for a bathhouse from a log house with your own hands

Only if the roof of the bathhouse is installed correctly can you be sure that it will serve for many years and withstand any natural conditions. Therefore, the construction of this element must be taken very seriously and responsibly, since it takes on heavy loads, and therefore must be as strong and reliable as possible. And then you and your friends can enjoy relaxing in the steam room at any time of the year.

- Author: Elena Davydova

Rate this article:

- 5

- 4

- 3

- 2

- 1

(7 votes, average: 4.7 out of 5)

Share with your friends!

Video description

About the installation of bathhouse rafters in the following video:

Layered

Rafters are made of thick boards or timber; they form the roof slopes. The peculiarity is the emphasis on the roof ridge. That is, the rafters rest with their upper end against the ridge girder, and with their lower end against the mauerlat.

Raised rafters are used in the construction of pitched roofs; they are laid along the slope. Posted rafters do not require tightening, making installation easier and faster. If the walls are made of brick or block material, a mauerlat beam must be laid between the frame and the rafters.

Height

When it comes to the height of the roof of a bathhouse, you need to understand that we mean its angle of inclination. And it is not an arbitrary value, but depends on what winds blow in your area and how much precipitation falls.

ADVICE! Proceed from the fact that increasing the angle of inclination simultaneously increases the wind load and prevents the retention of precipitation on the roof surface.

The minimum angle of inclination at which a roof is considered pitched starts at 2.5 degrees. Less - flat roofs, and up to 10 degrees - pitched roofs, but even these will have problems with removing precipitation and will require manual cleaning. But the accumulated snow means hundreds of kilograms pressing on the roof!

The maximum angle of inclination will be considered equal to 60 degrees. It is believed that the maximum amount of snow will put pressure on a roof with a slope of 30 degrees, and with a slope of 45 degrees the snow will slide down on its own.

Another factor associated with the choice of angle of inclination is the technical characteristics of the roofing material. You can select the material for the optimal angle of inclination for your area, or you can rely on the material and look for a compromise with climatic optimum.

BY THE WAY! An increase in the angle of inclination will also entail an increase in cost.

Maps and explanations for them, as well as simplified calculation formulas, can be found in this article. We strongly recommend that you familiarize yourself with them and study the formulas that will determine the load and affect the calculation of the roof mass.

However, you can use a simple life hack: you are not the first to build, take a closer look at your neighbors’ buildings, talk to them about problems with the roof, if any, and the optimal degree of inclination will be determined without unnecessary hassle. And the material will also be clearer.

The cost of constructing a roof, identifying errors and eliminating them

I'm always interested in finding out how much my work would cost if I didn't do it myself. Therefore, having completed the construction of the roof of the bathhouse

with my own hands, I decided to calculate what the savings were.

The cost of a do-it-yourself bathhouse roof

The cost of materials was 24,420 rubles:

- board - 150x50x5500 mm 28 pieces for 350 rubles;

- block - 50x50x5500 mm 20 pieces for 120 rubles;

- roofing sheet "Ondulin" - 36 sheets for 220 rubles;

- polystyrene foam - 50 sheets for 50 rubles;

- glassine – 4 rolls, 100 rubles each;

- polyethylene film 200 microns thick - 20 m. p. for 70 rub./meter.

For comparison, I took the price that one of the neighbors was asked to install a similar roof with insulation. Together with the price of materials, it amounted to about 60,000 rubles. And this is almost two and a half times more expensive. And they did the roof in a week, while it only took me four days of pure time (except for the winter period, when the bathhouse stood under a temporary roofing felt shelter).

Errors

Of course, over time, some errors and shortcomings emerged that had to be eliminated or will have to be eliminated in the future:

- Incorrectly oriented roof - the ridge is located from west to east. As a result, the northern slope is practically not illuminated by the sun, so it is overgrown with moss. It is impossible to change the direction of the roof, but replacing Ondulin with metal tiles after its service life is quite acceptable. Moss practically does not form on this material, and the color of the bathhouse roof can be made the same as on the house.

- Not the best insulation, which birds love to peck and mice to chew on. When replacing the roofing material, it would be advisable to replace the foam insulation with mineral wool. It will be easy and inexpensive. It's a pity, at one time there was simply nowhere to buy one. In order to protect the foam from birds, it was necessary to cover the holes from the ondulin waves with a galvanized mesh with a 10x10 mm mesh. They cannot be tightly sealed to ensure ventilation of the roof.

- If necessary, it is better to do lightning protection simultaneously with the roof. I had to install it after a year. It was very inconvenient to move around the finished roof.

Currently, the roof of the bathhouse has served faithfully for more than ten years, providing the premises with acceptable conditions for its use both as a bathhouse and as a living space.

If my story interests you, share it with your friends using the social media buttons.

Subscribe to site news or our site groups on social networks to always stay with us. Everything about the construction of a bathhouse from the foundation to the roof is in the section “Bathhouse made of timber. How I built it with my own hands"

Making the correct cuts on the rafters

Now let's move on to practice. First of all, you definitely need to make a convenient template according to which you will make even, identical rafters:

And follow these instructions:

You will have to tinker with the rigid mount:

If we are talking about moving units, then follow this principle:

In practice, everything is actually simple:

As you can see, the eyes are afraid, but the hands do!