When arranging a steam room, it is very important to choose the right stove, on which the quality of the bath as a whole will largely depend.

Initially, the search for a suitable unit is usually carried out by its power corresponding to the volume of the steam room, and by the manufacturer, who should have a good reputation. But what if you have already decided on the first and second, but cannot give preference to one or the other model?

Photo 1. The variety of sauna stoves is amazing, but not all of them are equally in demand.

In this case, there is only one way out: you need to study the similarities and differences, and choose the heat generator that, from your point of view, has more advantages. We hope that our article will help you with this.

Valery

I decided to write a review about the Hephaestus PB 03M stove and the facing made of soapstone. The bathhouse was built, the most difficult stage was choosing a cast iron stove. I came across this store, I was pleased with the selection, and the prices were not too high. Well done guys, they selected everything according to our wishes, an engineer came, took measurements and sent the specifications. We paid. Then the team arrived and installed the stove and cladding. The steam is very good! Thank you for your efficiency and responsiveness, it is a pleasure to cooperate with you.

How to keep heat from a stove indoors

Of course, choosing the right stove is half the battle. It is quite important to take care of high-quality vapor barrier. This is due to the fact that hot air is much lighter than cold air, therefore it collects closer to the ceiling.

Thus, it is highly undesirable for the ceiling to have holes, cracks or gaps through which steam could leak out.

To carry out proper vapor barrier you will need to do the following:

- Attach foil, a special membrane or penoizol to the floor beams.

- The slats are screwed onto the waterproofing layer at a distance of about 70 cm from each other. To increase the service life of the slats, they must be well treated with antiseptics.

- The lining is attached to the slats themselves.

- A hole for the chimney is cut in a certain place on the ceiling.

- The attic is insulated.

- An additional layer of protective membrane must be placed on the insulation layer.

- Floor boards are attached on top of the membrane in the attic.

Nikolay Sergeevich

When choosing a stove for the bathhouse, I was guided by reliability and economic indicators; Master Sauna consultants helped me choose a stove for the Hephaestus PB-03ms bathhouse. I choose my things quite carefully because... I am a former design engineer myself. What caught your attention? The design of the combustion system, equipped with the function of post-burning gases with a flame extinguisher and turbulent fins, allows you to heat the stove up to 750 degrees, while the temperature in the chimney is only 300 degrees. Of course, it is difficult to check these indicators, but the bathhouse warms up very quickly and the stone heats up evenly. I liked that the cast iron stove is 60 mm thick and keeps heat for a long time. I am completely satisfied with my choice, the oven is simply wonderful, many thanks to the company’s employees.

Distinctive features

Gefest is a domestic manufacturer of heating and climate control equipment and built-in appliances . To manufacture cast iron stoves, the company uses a special casting technology.

This way they achieve excellent thermal conductivity. The company's products are the only bath units that are entirely manufactured in Russia. Therefore, every stage of production is carefully controlled.

Hephaestus produces stoves for baths and saunas.

They are produced in the following forms:

- with a mesh for laying stone;

- for brick cladding;

- lined with a coil.

The models also differ in the volume of the heated room: up to 45 cubic meters. meters and from 45 to 120 cubic meters. meters .

The oven can be equipped with a cast iron damper or a door made of special heat-resistant glass. Through this “window” you can observe the combustion process and admire the flame.

The furnaces are equipped with a flame arrester and a secondary gas afterburning system . They allow you to maintain the temperature of the stones at 500–700 degrees. Therefore, the steam is finely dispersed - it is very light, pleasant and healthy. You can also set the sauna heater to smoldering mode.

Due to the fact that hot air remains inside, the steam room maintains a high temperature for a long time.

All models have a high efficiency coefficient - 87% . This percentage is achieved due to a special design. The combustion unit has two chambers separated by a flame arrester.

The gases of the burning fuel first move along the side walls, and then turn 180 degrees and move towards the outlet, moving along the recesses of the heater.

CAREFULLY!

The units operate on available solid fuel – wood or special briquettes. It is not recommended to burn coal in them and make the stove a disposal for various waste.

Gefest products are delivered unassembled . The kit includes a sealant. They can be installed independently or with the help of professionals.

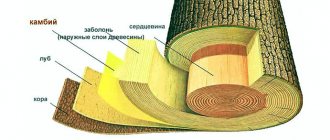

Material – cast iron grade SCh20-25 ChH10 . The wall thickness is from one to six centimeters. How are cast iron stoves different from steel or brick? Cast iron is an environmentally friendly and non-toxic material. It is not afraid of oxidation and corrosion. The alloy does not deform when heated and retains its strength.

Additional parts included . With their help, the distance from the firebox to the portal can be increased.

Particularly worth mentioning is the design of the stoves. They can be used both in the interior of a log bathhouse and a classic sauna. The doors are decorated with casting. Models for brick cladding can be decorated with ceramic tiles.

Karina

We purchased the Hephaestus PB-04 stove in the spring for our new bathhouse. Since our bathhouse is not very large, the Hephaestus PB-04 mesh stove was ideal for us according to its characteristics. We liked this stove because of its modern design, neat dimensions and, of course, the material, since cast iron is an ideal material for such products. And after the first fire, we were convinced that we had not made a mistake in our choice. To our great joy, the stove turned out to be very economical, it required very little wood to heat up, our bathhouse immediately heated up, and what is good news is that in the morning it was very warm in the bathhouse, thanks to such a wonderful stove.

DIY making

In order not to spend money on buying a new cast iron stove, you can make it yourself. To do this, you need to prepare tools, materials, carry out preparatory work, and perform step-by-step assembly.

Tools and materials

Before starting work, you need to prepare materials and tools:

- Wheel rims - 4 pcs.

- Cast iron sheets - the quantity depends on the size and complexity of the design. The thickness of the sheets should not be less than 3 mm.

- Red brick - about 300 pieces.

- Sand, crushed stone, cement.

- Metal pipes.

- Grinder, set of wrenches, drill with drill bits.

- Metal corners.

Preparatory work

Prepare a drawing on which the main elements of homemade furnace equipment will be marked. On it indicate the dimensions and joints of individual parts.

If the structure is massive, it is necessary to make a separate foundation. It is built together with the main one and must exceed the dimensions of the stove by 30 cm on each side. The foundation is made from a solution based on cement, sand, and crushed stone. Additionally, it can be reinforced with reinforcement.

Novikov Mikhail

We bought a Hephaestus PB-03 S stove. Like everything cast iron, the stove heats up quickly and takes a long time to cool down. In general, I don’t chase beauty, the main thing is that the stove is made of a high-quality pure alloy and creates the right microclimate so that you can steam, and not dance with a tambourine - add some mold here, add some dirt there, open it slightly here, and put a bowl of warm water here. It’s very cool that the firebox is not in the steam room itself, but in the dressing room. Very comfortably. I see a lot has already been written about steam, but I will say it too. The steam is really special and pleasant.

What brands of cast iron are preferable for a stove?

A very important question. When using cast iron for the manufacture of sauna stoves, its strength and heat resistance are important. The first is provided by the form of graphite included in its composition, and the second by alloying additives. The best would be the spherical shape of graphite, which is reflected in the marking with the letter “Ш” at the end of the abbreviation.

On a note! Heat resistance is most often ensured by the addition of nickel or chromium, or both. Nickel and its percentage are designated, for example, H20, chromium and its percentage - X16, X20, etc. Alloyed grades can withstand temperatures of, for example, 1000 degrees.

However, the fact that there are brands more suitable for the operating conditions of sauna stoves does not at all promise that manufacturers will be guided by this in their choice. Unfortunately, it is more determined by issues of production costs. And alloy cast irons are more expensive than regular gray ones.

By the way, the brand of cast iron can be deliberately hidden by the manufacturer - on the one hand, this is a trade secret, on the other, it is a concealment of information about quality. (And not only cast iron - the Finns hide the fact that their fireboxes are made of ordinary carbon steel, not alloyed in any way). Watch the video filmed at the exhibition of sauna stoves, where the guys walk around with a spectrometer and measure the composition of the metal of different stoves.

IMPORTANT! It is not a fact that the manufacturer admits which brand he used, but if you have the opportunity to find out, then be guided by the fact that ChKh16 or ChKh20 are quite suitable grades of high-chrome-alloyed cast iron in terms of heat resistance. Now it’s worth moving on to the specifics of the advantages of this or that furnace material

Now it’s worth moving on to the specifics of the advantages of this or that oven material.

History of creation

The Hephaestus trademark appeared in 2008, when the company’s management decided to expand its areas of activity. Further, the development of this area can be described in several stages, linked to years:

- In 2010, the development of the first bathhouse equipment projects began.

- Since 2012, serial production of Hephaestus stoves has been launched. At the same time, all the most successful technical and design solutions are patented.

- In 2014, production capacity was expanded by opening a plant in the Volgograd region.

- Since 2022, the company's products have been supplied to the market of the European Union. Its own stone workshop begins production, on the territory of which cladding materials for furnace equipment are produced.

- In 2022, the company will open a representative office in the United States.

Now the company has strengthened its position in the global market, expanded production to the manufacture of fireplaces, heating stoves for private homes, and industrial premises.

Installation and operation

Ovens are supplied unassembled. Since the finished structure can weigh up to several hundred kilograms, it is recommended to take 1-2 people to help.

During the first kindling, an unpleasant burning smell may appear, which appears due to the burning of the oil that coats the parts. It is strictly forbidden to heat the stove with wood waste or coal.

Hephaestus brand stoves are popular among many bathhouse owners in the CIS countries and Europe. Initially, the price of this furnace equipment may seem overpriced, but it is justified by the high build quality and durability of the entire structure.

Advantages and disadvantages

Advantages of Hephaestus equipment:

- Economical operating mode. It is provided by a system for secondary combustion of gases released when burning wood.

- High efficiency due to design features.

- Reliability, durability, high strength of individual elements, combustion chamber housing.

- Environmental friendliness. The materials from which the stove is made do not emit harmful substances when heated strongly.

- Resistance of the case to temperature changes and moisture.

- Possibility of installing an adapter extension, which allows you to increase the length of the combustion channel and move the firebox door into the next room.

- Attractive view.

- Preservation of heat in the steam room for up to 5 hours after the last installation of firewood.

The main disadvantage of furnaces is the high price, which is justified by the durability, reliability, and performance of furnace equipment of the Hephaestus brand.

Hephaestus ZK and Thunderstorm from Technolit

Technolit is a company whose sauna stoves have proven themselves well and are invariably in demand. And most often they buy models for steam rooms with a volume of 18-25 cubic meters. Therefore, we decided to conduct a comparative analysis of the most popular models: Hephaestus ZK 18 and Groza 18, Hephaestus ZK 25 and Groza 24.

Photo 2. Hephaestus ZK 18 and Groza 18, Hephaestus ZK 25 and Groza 24 (from left to right).

The design solutions used in the manufacture of these sauna stoves provide them with high performance characteristics and make them leaders in the ratings. Under the Groza trademark, the manufacturer has developed models of heat generators for Russian baths with reduced costs, but while maintaining the basic properties of all its products:

- High-quality cast iron of our own casting;

- Reliable prefabricated structure (groove/tongue);

- Direct heating heater;

- Afterburning of pyrolysis gases, etc.

Some parameters of the units under consideration are presented in the table:

| Steam room volume 24-25 cubic meters. m | Steam room volume 18 cubic meters. m | |||

| Hephaestus ZK 25 | Thunderstorm 24 | Hephaestus ZK 18 | Thunderstorm 18 | |

| Material | Cast iron SCh20 | Cast iron SCh20 | Cast iron SCh20 | Cast iron SCh20 |

| Firebox dimensions, mm | 529x419x614 | 455х341х595 | 478x393x538 | 341x405x555 |

| Furnace weight, kg | 260 | 162 | 166 | 145 |

| Chimney diameter, mm | 130 | 115 | 115 | 115 |

| Firewood length, mm | 450 | 400 | 350 | 360 |

Advantages and disadvantages

Hephaestus products have gained immense popularity in many countries due to the following advantages:

- budget models have a standard set of functions necessary for comfortable cooking;

- the entire line is sold at an affordable price, including options with additional options;

- the stoves are equipped with electric ignition, which eliminates direct contact with fire;

- more modern appliances have additional options: built-in timer with sound indication, powerful oven lighting, thermostat, gas control, grill and quick heating function;

- The stove comes with two baking trays (deep and flat) and a cast iron grate;

- More expensive models have double glazing of the oven, which prevents overheating of the equipment;

- a gas stove with a wide range of functions costs 2-3 times less than an electric stove with similar functionality.

Among the shortcomings, consumers note only the lack of any functions in some models. For example, there are stoves with partial gas control (oven or hob).

If the coating is enameled, it requires special care without the use of abrasives. Otherwise, scratches will easily remain on the surface.

Specifications

Technical parameters and features of the Hephaestus stove equipment for the bath:

- Heat accumulation continues even as the flame goes out.

- The approximate efficiency level of most furnace models is over 87%.

- The maximum area of heated premises is up to 120 m3.

- The heater fill temperature is maintained between 500–700°C.

- Classic types of fuel are firewood and briquettes made from compressed sawdust.

- The thickness of the walls of the Hephaestus furnace equipment body is from 10 to 50 mm.

The structures have a built-in flame arrester and a secondary gas combustion mode.

Among the main technical and design features of the Hephaestus furnace equipment, one can highlight the presence of an auxiliary element with which you can lengthen the combustion channel. This is necessary if the steam room is small and the kindling is carried out from the dressing room.

Product comparison: choosing which model to choose and buy

| Product photo | Product Name | Rating / Average price |

| Mini oven GEFEST PG 100 | 7400 rub. | |

| Mini-oven GEFEST EP Ns D 420 | 11370 rub. | |

| Mini oven GEFEST PGE 120 | 8950 rub. |

Rating of the TOP 15 best gas stoves Gefest 2022

| Place | Name | Price |

| TOP 4 best 4-burner Gefest gas stoves in price/quality ratio | ||

| 1 | GEFEST 3200-08 | Find out the price |

| 2 | GEFEST 6100-04 | Find out the price |

| 3 | GEFEST 3200-06 K62 | Find out the price |

| 4 | GEFEST 5100-04 0002 | Find out the price |

| TOP 3 best combined gas stoves Gefest with electric oven | ||

| 1 | GEFEST 6102-03 | Find out the price |

| 2 | GEFEST 5102-03 | Find out the price |

| 3 | GEFEST 6502-03 0242 | Find out the price |

| TOP 3 best Gefest gas stoves with gas oven | ||

| 1 | GEFEST 5100-04 | Find out the price |

| 2 | GEFEST 3200-08 K86 | Find out the price |

| 3 | GEFEST 3200-06 K19 | Find out the price |

| TOP 3 best Gefest gas stoves with automatic ignition | ||

| 1 | GEFEST 6100-03 | Find out the price |

| 2 | GEFEST 6100-02 0009 | Find out the price |

| 3 | GEFEST 5100-03 0002 | Find out the price |

| TOP 2 best tabletop 2-burner gas stoves Gefest | ||

| 1 | GEFEST 700-02 | Find out the price |

| 2 | GEFEST 700-03 | Find out the price |

Advantages and disadvantages

Hephaestus products have gained immense popularity in many countries due to the following advantages:

- budget models have a standard set of functions necessary for comfortable cooking;

- the entire line is sold at an affordable price, including options with additional options;

- the stoves are equipped with electric ignition, which eliminates direct contact with fire;

- more modern appliances have additional options: built-in timer with sound indication, powerful oven lighting, thermostat, gas control, grill and quick heating function;

- The stove comes with two baking trays (deep and flat) and a cast iron grate;

- More expensive models have double glazing of the oven, which prevents overheating of the equipment;

- a gas stove with a wide range of functions costs 2-3 times less than an electric stove with similar functionality.

Among the shortcomings, consumers note only the lack of any functions in some models. For example, there are stoves with partial gas control (oven or hob).

If the coating is enameled, it requires special care without the use of abrasives. Otherwise, scratches will easily remain on the surface.