Among the huge range of insulation materials for baths, consumers increasingly prefer aluminum foil. This coating is affordable and simple. It perfectly retains heat indoors, eliminating the rapid cooling of the building. This reduces energy costs and guarantees a comfortable stay inside.

Among the main advantages of this material are:

- high fire-resistant qualities;

- good steam and moisture resistance;

- high reflectivity coefficient;

- excellent anti-corrosion properties.

Vapor barrier properties prevent the leakage of hot steam, which then does not accumulate in the coating. Aluminum foil does not deform, does not emit harmful substances or fumes, and is durable and hygienic. The canvases are highly plastic, they are resistant to ultraviolet radiation and are easy to install. They are immune to chemicals and can withstand high temperatures for a long time.

Foil perfectly protects adjacent adjacent rooms if the bathhouse is located inside the house. If installed correctly, even thin sheets will not tear or deform. However, this material must be purchased with a margin of 7%. Bath foil is good because it can withstand temperatures up to 145 °C. Combined with high reflectivity, this property allows you to retain heat inside the steam room for 2.5 hours longer compared to other insulation materials. This provides the effect of a thermos. Thermal insulation is universal in use and is suitable for surfaces that do not require special treatment with fungicidal substances.

Foil insulation

The most innovative material for thermal insulation of baths is insulation with foil.

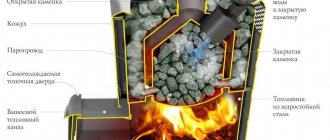

It can be used to protect all surfaces of the steam room from heat loss. Foil insulation consists of a foam or paper base on which reflective foil is applied. The thickness of such material does not exceed 1 cm.

Principle of operation

The principle of operation of insulation with foil is to reflect radiant heat from the surface. Thermal insulation efficiency increases by at least 70%. A steam room with such insulation heats up much faster. You can save on heating a steam room by installing heater stoves of lower power.

Features of application

Foil insulation plays the role of a hydro- and vapor barrier layer for walls, ceilings, and steam room floors. With their help, washing rooms or relaxation rooms in a bathhouse or sauna are protected from heat loss.

The steam room uses reflective thermal insulation based on kraft paper. This material can be used at higher temperatures.

Installation

install directly on a beam or log with the foil surface inside the room. The joints of the sheets must be taped with aluminum tape. An air gap (no more than 15 mm) must be left between the insulation and the interior finishing of the walls and ceiling.

To remove condensation, leave a small exit of the sheet at the junction of the wall and the floor., carried out using high-quality materials and observing all technological nuances, will provide comfortable conditions for medical and hygienic procedures, reduce fuel costs, and protect all internal structures from premature wear.

Suitable wood species

Wood for lining should not contain a lot of resinous substances.

When choosing the type of wood for lining a bathhouse with lining, take into account the purpose of the room. Coniferous boards are not recommended for cladding a steam room. Due to the high temperature, they release resin, which causes burns upon tactile contact, and aromatic components, which in high concentrations provoke an allergic reaction. Steam room decoration uses hardwood:

- Linden - the low heat capacity of lumber, the pleasant aroma and golden hue of the boards ensured the popularity of lining when finishing saunas. The wood is durable, easy to process, and lasts a long time in extreme conditions.

- Alder - the lamellas have a reddish tint, and when heated, they release healing tannins. The wood dries quickly and is resistant to moisture. It has a soft structure with a small number of knots. One of the advantages is the affordable cost.

- Aspen is a light-colored species that does not deform from moisture or temperature fluctuations. The lining heats up slightly and is safe for use in a steam room.

After cladding, the wood is coated with moisture-repellent compounds.

For other rooms, lining the inside of the bathhouse with clapboard can be done with any type of wood:

- Larch is the wood that is most resistant to moisture, has a solid structure and a beautiful pattern. Due to its strength it is difficult to process.

- Pine – has a pleasant aroma and is not subject to rotting. The material is strong and durable, suitable for cladding dressing rooms and rest rooms.

- Spruce board is distinguished by a small number of knots and resin, the light shade does not darken over time. Advantage – low cost.

- Cedar is an expensive reddish-brown material that emits a pleasant aroma with medicinal properties. Wood is not afraid of moisture and has high thermal insulation characteristics.

When choosing a lining, its grade is taken into account. For a steam room, class A or extra material is required. Such lamellas have a smooth surface without knots and defects, which during operation become a source of cracks and deformation. In other premises, the use of class B products with minor defects on the surface is allowed.

Bath foil: pros and cons of use

- A bathhouse, and even more so a steam room, are places with a very specific temperature regime and high humidity. Bath foil is ideal for this environment because it can easily withstand large temperature changes.

- Most insulation materials lose their properties when wet, so they are usually protected with a layer of waterproofing. Thin aluminum easily takes on this function, since the metal does not absorb moisture.

- Its high ability to reflect infrared rays ensures the preservation of heat inside the bathhouse and steam room.

- The ease of installation makes the installation of foil insulation feasible even for a non-professional. There is also no need for special equipment.

Which bath stones are best to choose?

- The downside is that moisture that has not been absorbed by water accumulates on it in the form of condensation, which can cause rotting of the finishing coating or the growth of fungi on it, but this can be treated with a ventilation gap between the aluminum and the same lining.

- The high thermal conductivity of the aluminum from which it is made would also be a big disadvantage if it were not compensated for by a layer of insulation with low thermal conductivity that follows the metal.

- Another disadvantage is the corrosion of the foil, that is, the formation of an oxide film on its surface. Of course, such a film worsens reflectivity. But the purity of the metal (the absence of impurities) significantly slows down the oxidation of aluminum.

- Well, temperature + water hammer, but more on that below

Principles of insulation depending on the type of building

The choice of insulation depends on the material from which the bathhouse is built. We need to talk about each type of building in more detail.

Made of brick

Sheathing with foil and clapboard is usually done in brick baths. Carrying out work:

- Without additional insulation of walls, ceilings, and in brick baths, it is impossible to achieve an optimal level of comfort.

- All brick surfaces are covered with foil. The individual sheets are glued together with metal tape.

- The sheathing needs to be secured over the reflective sheets. It must be independent so that there is good ventilation between the wooden frame and the foil layer.

If there is no ventilation, condensation will accumulate inside, which will cause the wooden frame to rot.

Made from concrete

To insulate concrete surfaces, ordinary foil will not work. You need to choose a material that has a backing. It is fixed on top of the waterproofing layer.

Made of wood

It is not necessary to cover wooden beams with foil. To achieve an optimal level of comfort, it is enough to correctly caulk the seams between the logs. You can cover the ceiling in the steam room with foil. It needs to be secured with the reflective layer down, the sheets overlapped, and glued with aluminum tape.

Foil properties

Which shower cabin to choose for the bathroom

Among the characteristics that bath and sauna foil has, the most important is the ability to reflect about 97% of infrared rays. If this material is used to cover the steam room continuously, the thermal energy will be retained as much as possible. The fact is that IR rays are not absorbed by the walls, but are reflected towards the room.

Foil is ideal for a steam room because:

- the material can withstand temperatures up to 300 degrees and even higher - this property depends on its type;

- does not emit substances harmful to the human body;

- has a small specific gravity.

In addition, aluminum foil has the following advantages:

- moisture resistance;

- plasticity;

- durability;

- vapor tightness;

- resistance to corrosive processes.

Features of finishing material

Cladding with clapboard over foil layer

A special microclimate is created in the bathhouse and sauna, characterized by increased temperature and humidity. To finish them, you need a material that can withstand such conditions, is aesthetically pleasing and safe. The best option is wood. Finishing the bathhouse with clapboard will provide comfort, healing phytoncides and attractiveness of the interior. The material has low thermal conductivity, does not burn the body on contact, and dries quickly.

Lining is a thin board with a longitudinally located tongue and groove. After assembly, there are no cracks or gaps left on the surface. One of the varieties of lumber is eurolining. The slats have 2 grooves on the back side, which serve to remove moisture and prevent deformation when drying. They are made only from dried lumber, the tongue-and-groove joint is characterized by an increased size - up to 8 mm. The use of eurolining improves the ventilation properties of the cladding, its durability and quality.

Advantages of using lining in a bathhouse:

- The material is environmentally friendly and safe; under the influence of high temperature, substances beneficial to health are released.

- Decorative appeal of the cladding, wide possibilities for decoration.

- Resistance to moisture, temperature fluctuations and mechanical damage.

- Availability of installation on your own without the involvement of specialists.

- Long service life without loss of performance characteristics.

- Excellent heat and sound insulating properties.

The nuances of installing foil and foil insulation in a sauna

Cedar or pine: which species to choose for a wooden house

The choice of foil heat insulator depends on the material from which the bathhouse is built. In some cases, just aluminum foil is sufficient, while in others it is recommended to use only insulation for sheathing.

Option #1: Insulating the log house

If the walls of the bathhouse are made of thick logs, then covering them with foil is a waste of money. The quality of caulking is more important here, and it is simply pointless to additionally insulate the log house. In this case, the thermal insulation layer will have little positive effect.

In a log sauna, foil insulation should only be used when covering the ceiling. Upstairs it will be of at least some use, especially if the ceiling is made thin and without an insulating layer on top.

You can also cover the walls around the stove with aluminum foil without a backing. Such a screen will reflect heat in the form of infrared radiation into the steam room, instead of wasting it on useless heating of the wall behind the heater.

Thick foil makes an excellent screen for a sauna stove

When covering the ceiling, foil insulation is laid with a reflective layer down, overlapping and with a slight overlap of 5–10 cm on the walls. The joints must be taped with special aluminum tape.

It is very important to create a sealed layer without the slightest loopholes for steam

After installation, the foil can be left as is. This way condensation will definitely not accumulate on it. But from an aesthetic point of view, it is better to cover it with clapboard. To do this, you will need to fill a sheathing of 40x40 mm bars, to which the wooden planks will be nailed.

Option #2: Cladding a brick or frame structure

If the walls of the sauna are made of brick or frame technology is used, then they will have to be insulated with foil heat-insulating material. Otherwise, the heat in such a bath will not stay long.

Installation diagram of foil insulation on walls and ceiling in a bathhouse

The sequence of work in this case is absolutely identical to the technology used in a log house. Only covering with foil is done in a circular manner over the entire area of the walls and ceiling to create a thermos. It is necessary to block all possible ways of heat escape to the maximum.

Ideally, the sheathing for the lining should be made independent, with a gap between the frame and the foil. The larger the space, the better the ventilation and less condensation. And this is the most important point in insulating a steam room.

Ventilation of bath rooms

Before insulating the steam room, a ventilation system is designed. For room ventilation, natural or forced systems are used.

- Ventilation is arranged with one lower hole, opposite the flue stove mounted on the wall. The heated steam rises and cools. It is mixed with the incoming fresh flow from the inlet window and drawn out by the stove's blower system.

- The heating furnace can be installed below the level of the floor covering, so that the blower system is located in the gap between the floor and the insulation. The entrance windows are located at the top of the basement and in the flooring of the bathhouse. The air passes through the underground passage, into the steam room and is drawn into the stove's ash system.

- The supply window is mounted at the bottom of the steam room next to the heating system. To prevent a draft from forming, an exhaust window is installed at the top behind the partition. The natural system is equipped with a device that regulates air flow.

- The use of such ventilation does not deliver the expected effect because the air quickly heats up when entering, rises up and is drawn out. For additional fresh air, the doors are opened, which is unacceptable when taking the procedure.

- You can install ventilation on one end wall, opposite the heating system. The incoming air flow is further enhanced by a fan, this type of ventilation is called forced ventilation.

- For efficient ventilation, windows are placed in opposite lower planes. The exhaust ventilation window is additionally equipped with a fan. After entering the room, heated air rises to the ceiling, cools and is drawn out by a fan.

There are three holes for air flow for efficient air exchange:

- one window downstairs, near the stove;

- another window in the floor, where there is a gap between the floor of the room and the insulation;

- the third hole is on the opposite wall from the stove in the upper part.

A device for forced ventilation is installed in the upper window. The window area is calculated based on the area of the bathhouse: per 1 m² - volume 24 cm².

Only properly installed room ventilation will extend the life of the sauna room.

Thickness of walls and insulation used

The insulating effect is obtained by using paper-based foil correctly, taking into account its thickness. This table is used to determine:

| Wall composition | Wall thickness, mm | Material thickness, mm |

| Concrete | 350-370 | 80-100 |

| Brick | 250-350 | 100-150 |

| Wooden log house | 100-150 | 60-80 |

| Wooden log house | 150-200 | 40-60 |

| Wooden log house | From 200 | up to 40 |

This calculation involves the development of insulation for the walls of baths and saunas. The reflective layer of aluminum is mounted only indoors.

Criterias of choice

When choosing insulation, you need to consider a number of factors:

- To secure it to a wooden frame, it is better to choose foil with a backing. You can make it yourself from mineral wool, foamed polyethylene, or kraft paper.

- The material must withstand heating up to at least 100°C.

- On the packaging you can read what thermal radiation the foil insulation will reflect. The indicator must be at least 95%.

- The material must be durable.

- The foil and substrate should not emit harmful substances when heated strongly.

Advantages and disadvantages

Advantages:

- environmental cleanliness;

- high reflectivity;

- ease of installation;

- resistance to fungi and mold.

The main disadvantage is low mechanical strength. You need to work with it carefully so as not to damage it.

Characteristics of foil at 100 microns

On sale today is bath foil 100 microns, which is polished and has the form of a roll. Its width is 1 m if we are talking about the hard variety. Annealed foil has a width of 0.5 m. The length reaches 10 m. One roll weighs 2.5 kg.

This bath foil, whose thickness is 0.1 mm, can be used at temperatures up to 650 °C. Its reflectivity is 97%. The material has a smooth surface and can be used in the construction of heated floors, air ducts, furnaces, boilers, as well as for insulation for various purposes. The layer effectively protects against fire, it is resistant to corrosion and retains heat in the coolant.

Such foil in rolls acts as an excellent vapor barrier. It can replace materials such as:

- glassine;

- roofing felt;

- bitumen paper.

The latter release harmful substances when exposed to temperature. Foil can be used as an independent reflective insulator and in combination with other thermal insulation materials. The polished surface is an ideal reflector and improves thermal insulation efficiency.

Operation is possible not only indoors, but also outdoors. This area of use includes insulation of roofs, attics, attics, floors, walls, pipes, ceilings, ventilation, ceilings, water heaters, caravans and wall sections behind heating radiators. This foil acts as solar reflective panels on windows.

Types of insulation with foil for baths

During operation, a thin, soft foil sheet is easily wrinkled and torn, which is why new technologies for its use have emerged.

Currently on sale:

- foil paper;

- textile;

- insulation.

Foil paper

Its other name is laminated foil on a paper base for a bath. It is an elastic and dense material and has excellent vapor barrier properties. It is produced in two types: foil plus kraft paper and foil plus paper plus polyethylene.

Foil fabric (foil fabric)

This soft two-layer material is made from fiberglass and foil. The thickness of the foil fabric is in the range of 0.12–3 millimeters. The panels need to be fastened end-to-end. Foil fabric is used to insulate bathhouses; it can be used to sheathe walls near the heating unit.

Its main characteristics:

- ability to withstand temperatures up to 500 degrees;

- resistance to mold and other harmful microorganisms;

- good moisture resistance.

Foiled polystyrene foam

The insulation is made from expanded polystyrene and covered with a thin layer of aluminum foil. The material is produced in sheets measuring 1.2 x 0.6 meters with a thickness of 2-10 centimeters. They are used to insulate the premises of a bathhouse building from the inside. The sheets are equipped with stepped locks that prevent the formation of cold bridges.

Foiled polystyrene foam has the following qualities:

- does not absorb moisture;

- reflects about 98% of thermal energy;

- differs in vapor barrier properties;

- resistant to chemical influences;

- safe for health;

- has a long service life.

Foil polyethylene foam

This roll insulation with a thickness of 2 to 10 centimeters has a one-sided or double-sided foil coating. It is used when arranging thermal insulation for the interior of baths.

Foil mineral wool

It is produced in rolls or in the form of mats of different thicknesses. Has excellent thermal insulation properties. Ideal for insulating frame bath buildings. The use of rolls or mats with foil makes finishing work easier and more convenient.

Selecting a foil coating based on the recommended layer

In order to achieve high-quality coverage during installation work, you should adhere to the thickness of the foil thermal insulation. It will depend on the material and thickness of the wall. If the base is brick and the thickness of the steam room wall reaches 37 cm, then the recommended layer should be from 8 to 10 mm. If the base is concrete or brick, and the wall thickness varies from 25 to 35 cm, then the foil insulation should have a thickness of 10 to 12 mm. In the case of a wooden frame from 10 to 15 cm, you must use foil thermal insulation, the thickness of which varies from 6 to 8 mm.

When using the same material, but increasing the wall thickness to 20 cm, you should use a foil layer from 4 to 6 mm in thickness. Foil for a bath will have a layer of 2 to 4 mm if the wooden frame is more than 20 cm thick.

Glass wool or basalt wool can be used as an additional heat-insulating layer. Similar mineral heat insulators are also suitable. Aluminum foil or similar coatings will reflect heat into the room, so it is better to install such a layer in a steam room insulated like a pie. This recommendation is relevant for saunas and baths made of concrete or brick. The advice is also suitable for frame buildings. If the external walls of wooden log houses are sufficiently thick, the layer of additional thermal insulation can be neglected, but when choosing a foil material, you should not give preference to thin sheets of kraft paper in foil.

Foil layer made of polystyrene foam and polyethylene foam

A film made of polystyrene foam or polyethylene protects the room from moisture for much longer, as it does not tear or crack. Film made of polyethylene and polypropylene can even serve as insulation for the external walls of a bathhouse. It is resistant to ultraviolet radiation and other aggressive natural factors.

The outside walls also need to be insulated if the bathhouse is located in the northern region PHOTO: vse-postroim-sami.ru

The price for such films is low. Today you can find different options on sale, including those based on cellulose and viscose. A high-quality layer should be slightly rough to the touch.

Minuses

Disadvantages are also important to consider. If you attach foil to a cold wall, the material will show itself negatively. It is imperative to use an additional insulating layer between the wall and the foil.

There is no point in using foil for those who do not save on fuel and who do not care about long heating times. There is no benefit from foil if the bathhouse is sufficiently insulated with other materials.

The absence of foil makes the steam softer and there is no sharp water hammer. For example, sauna logs without foil smooth out temperature shocks well.

Aluminum accumulates in the body. This has a bad effect on a person’s condition and well-being. The metal accumulates in the lungs and negatively affects them. Remember also about aluminum cookware and why almost everyone refuses it. When heated, aluminum cookware releases metal ions. When eating food, aluminum gets ingested.

Source of the article: https://zen.yandex.ru/media/remonts/ne-obshivaite-folgoi-baniu-problemy-i-vred-aliuminievoi-folgi-5f3f4542feee9a1c2fb80edb

Performance characteristics by type

Manufacturers offer sauna foil in different designs. This determines their geometric parameters and operational characteristics. We invite you to get acquainted with the main varieties and their features to make it easier to make an informed choice.

Foil comes in different types PHOTO: zharpar.rf

Rolled foil

This material is produced in sheets and rolls. The thickness of the rolled material is 0.007 - 0.2 with a width of 0.01 -1.5 m. For bath insulation, materials with a thickness of 30 - 100 microns are mainly used. Contains about 99.5% aluminum. Depending on the design, the surface of the rolled foil can be:

- smooth, not requiring additional finishing;

- for finishing. After insulation, finishing material is attached to the surface;

- finishing

Rolled foil has different thicknesses and widths PHOTO: i0.wp.com

Paper-based foil and foil fabric

Paper-based foil is often called foil or laminated. The material has sufficient elasticity, optimal density and excellent vapor barrier properties. Manufacturers offer two types: based on kraft paper and paper with polyethylene. This insulation:

- able to withstand heat of +130ºС, which is especially important for a bathhouse;

- resists compression load well;

- keeps its shape;

- easy to cut;

- Allows various mounting methods. It is possible to use nails, staples, screws;

- installed inside the bathhouse.

The paper base provides elasticity PHOTO: bannydvor.com

Foil fabric consists of two layers: foil and fabric. It has a thickness of about 0.12 - 3 mm. The sheets in the bathhouse are attached end-to-end. The material can be used to cover walls adjacent to the heating unit. Such material for a bath:

- able to withstand heating up to 500ºС;

- resistant to mold and harmful microorganisms;

- has good moisture resistance.

Foil fabric is the best solution for a bath PHOTO: i.sunhome.ru

Foiled polystyrene foam and polyethylene foam

The basis of foiled polystyrene foam is polystyrene foam, onto which a thin layer of aluminum foil is applied during the manufacturing process. Supplied in sheets measuring 1.2 x 0.6 m. It can have a thickness of 2 – 10 cm. The presence of stepped locks helps prevent the appearance of cold bridges. Foiled polystyrene foam is safe for health. Does not absorb moisture. This bath material has:

- reflection of up to 98% of heat;

- good vapor barrier properties;

- chemical resistance;

- long service life.

Foligron polystyrene foam is capable of reflecting a large percentage of heat PHOTO: pol-exp.com

Foil polyethylene foam for baths has a thickness of 2–10 cm. The foil can be attached on one or both sides. It is actively used in arranging the interior of a bathhouse. It can heat up to a temperature of no more than 100ºС, which precludes its use for covering the surface adjacent to the furnace.

The thickness of foil polystyrene foam is selected individually PHOTO: avatars.mds.yandex.net

Foil mineral wool in rolls and mats

Foil mineral wool is supplied in mats and rolls. May have different thickness. Has good thermal insulation characteristics. Can be used for insulation of frame baths. The convenient release form greatly simplifies installation work.

Foil-coated mineral wool is in demand when insulating a bathhouse PHOTO: vosaduly.ru

Reviews of foiled mineral wool

Foil-coated mineral wool can be presented in soft rolled and hard mats. According to experts, this expands the scope of use. Among the main advantages of the first of the mentioned types, according to consumers, a high degree of moisture and vapor barrier should be highlighted.

As for foil wool in the form of rigid mats, they have excellent insulating properties and are easy to install. The thickness of soft rolls can reach 10 mm, and the maximum exposure temperature, as home craftsmen emphasize, is quite high and reaches 125 ° C.

Aluminum foil: another scam by manufacturers?

Aluminum foil for bath insulation is a thin (on average 30-300 microns) layer of aluminum, which is used unchanged or in combination with kraft paper, fiberglass, or roll insulation. The main argument of opponents of using foil in a bath is that aluminum has high thermal conductivity.

Based on this, thermal energy can easily pass through the metal layer and end up outside the steam room. In fact, everything is not quite like that. Firstly, high thermal conductivity will “work” against us only in the case of direct contact of the foil with a heated body (for example, with a wooden paneling or blockhouse). Secondly, in addition to thermal conductivity, there are other methods of heat transfer.

Finishing

The insulation for the walls inside the bathhouse with foil cannot be left uncovered. Foil has low strength. In addition, the material can never be installed without a single wrinkle, so this coating looks very mediocre. To eliminate this, a fine finish is applied.

For bathhouses this is traditionally wood. In front finishing it is used in the form of lining (thin board) or block house (thick board with imitation of a log house or timber). Foil under the lining in the bathhouse is an economical and practical solution. The fastening of the front trim is adhesive and with self-tapping screws, which are recessed and sealed with wooden plugs.

What is foil for?

Foil is a thin layer of aluminum 30-300 microns thick. That is, it is a metal with high thermal conductivity, and also very thin. It turns out that it is not able to insulate anything. But it's not so simple:

- First of all, the thermal conductivity indicator is taken into account if the material is tightly pressed to the body emitting heat.

- In addition, the sauna uses three types of thermal energy, or, more precisely, methods of its release.

Heat transfer methods

So, three methods of transmission:

- Using thermal conductivity.

- Convection option.

- Infrared radiation.

The first two are discarded immediately. But IR rays need to be dealt with. They are distinguished by any heating unit. And a person feels their presence in the form of heat acting on the body. There's a reason they're called rays.

This is a completely different type of energy. So they (the rays), hitting the surface of the aluminum foil, are reflected from it and return back to the room. Which is what you need for a sauna or steam bath. True, it’s hard to call foil insulation, so consider it a reflector.

But that's not all. Aluminum foil is an excellent vapor barrier material. It does not allow moisture and air vapor to pass through. In fact, inside the sauna (bath) a room is formed that is as sealed as possible, like a thermos. This means that such a room will heat up quickly and maintain the temperature for a long time.

Using insulation

Of course, the foil itself will not be able to contain all the thermal energy. Therefore, it is recommended to lay insulation under it. Although today you won’t surprise anyone with the heat-insulating material on top of which that same foil is attached. These are penofol and foil penoplex. True, these materials are not cheap. Therefore, we offer a cheaper option.

Reviews of foil in rolls

This material is sold not only in the form of panels. If you want to purchase foil for a bath, you can choose the material in rolls. It is characterized by low cost, which is complemented by ease of installation. Installation of such foil is possible only on fire-resistant heat-insulating material with fastening with metal brackets.

Buyers like that the sheet thickness is minimal and can be 0.5 mm. The roll width is 1500 mm. According to consumers, the temperature range is quite wide and varies from -50 to +75 °C.

Advantages and disadvantages of the material

Foil usually always comes complete with another type of insulation. It is rational to install it in combination with glass wool and other denser materials. If these conditions are met, the material will have the following advantages:

- Vapor barrier and thermal insulation - thanks to this, hot steam does not pass into the middle of the insulating material, thereby preserving its properties, as well as the heat inside the room.

- Fire safety. The material can withstand high temperatures and is not flammable. Prevents fire from spreading to other walls.

- Possessing good soundproofing properties. Suppresses noise from the street and inside the steam room by almost 70%.

- Reducing the heating time of the bath. Thanks to properly equipped insulation of the internal walls, heat will quickly fill the steam room and be retained in it.

It is better to paste only with special tape. An ordinary tape will not withstand the weight of insulation PHOTO: potolok-exp.ru

Scheme of thermal insulation with foil in a bathhouse made of timber PHOTO: v-banyu.ru

Despite the large number of advantages, this material is not without disadvantages. These include:

- constant formation of condensation;

- you can’t do without ventilation equipment;

- air does not penetrate well, which can cause dampness and mold;

- poisonous properties of aluminum (this metal can glow in the body).

Proper care of the room and regular ventilation can reduce all the disadvantages to a minimum. Therefore, after each bath, you should not forget to open doors, windows and vents.

When insulating the ceiling, they try to use individual technology PHOTO: deluxemm.ru

Criterias of choice

When choosing insulation, you need to consider a number of factors:

- To secure it to a wooden frame, it is better to choose foil with a backing. You can make it yourself from mineral wool, foamed polyethylene, or kraft paper.

- The material must withstand heating up to at least 100°C.

- On the packaging you can read what thermal radiation the foil insulation will reflect. The indicator must be at least 95%.

- The material must be durable.

- The foil and substrate should not emit harmful substances when heated strongly.

Advantages and disadvantages

Advantages:

- environmental cleanliness;

- high reflectivity;

- ease of installation;

- resistance to fungi and mold.

The main disadvantage is low mechanical strength. You need to work with it carefully so as not to damage it.

Manufacturers and prices

Manufacturers:

- URSA;

- "Izolon";

- "Penofel".

The average price of 1 roll is 600 rubles.

Properties of foil insulation for a bath

In addition to retaining heat in the bath and reflecting effect, the material has high performance characteristics:

Quick installation

. With the help of such a heat insulator you can hide imperfections in walls and ceilings. It is convenient to install even in hard-to-reach places.

High level of thermal insulation

. Compared to its counterparts, insulation with foil provides the most effective heat retention.

Warm-up efficiency

. Warming up a high-quality insulated bath requires less time, and therefore less fuel. Therefore, the use of foil insulation allows you to reduce heating costs.

Additional vapor barrier

. Thanks to this, condensation does not collect on the walls, and therefore the finish will not rot or mold.

Versatility

. This material is successfully used not only for wall insulation. They also insulate the ceiling - the place where hot steam collects, and there is a need for maximum protection.

Heat resistance

. Some heat insulators with foil can withstand temperatures from 0 to +1500 degrees. When heated, they do not deform.

Waterproof

. This property allows the material to be used in many areas of construction, including the construction of baths.

Soundproofing

. Correct installation allows you to reliably protect the room from extraneous noise.

Durability

. The insulation does not rot, absorbs steam, and does not attract insects and rodents.

Safety

. At elevated temperatures and humidity, foil materials do not emit toxic substances.

In addition, the market offers a wide variety of such insulation materials. You can choose the one most suitable for your bath.

Covering installation

To ensure the most effective and high-quality coating and ensure a comfortable stay in the steam room, you should follow a number of tips when laying the material.

When laying foil materials in steam rooms of non-commercial baths and saunas, it is sufficient to use rolled or kraft foil with a thickness of at least 3 mm. For large steam rooms, foil on a mineral or basalt base is suitable. When locating a bathhouse inside a house or in a basement, it is important to take into account central heating and the location of its sources, if possible using it for additional heating of the steam room air. Before starting work, it is necessary to provide for the removal of condensate by making a small withdrawal of the canvas from the ceiling to the walls, as well as from the walls to the floor. To do this, the foil material is laid with an overlap of 15-20 cm and taped with foil tape.

A gap of 1-2 cm will allow the condensate to dry out during the period between heating the bath

Ventilation gap on the ceiling

The installation process of foil occurs in several stages; the most convenient to use are rolls or sheets 60 cm or 1.2 m wide.

- The walls of the steam room need to be lathed with beams with a cross-section of 5x5 cm. The distance between adjacent planks depends on the width of the material. For rolls of 600 and 1200 mm it is 60 cm, for foil materials with a width of 1000 mm and 1500 mm - 50 cm. The bars are fastened with self-tapping screws of a suitable length.

Lathing

Fastening the sheathing beams to the ceiling

Fastening the sheathing beams to the floor

- A layer of mineral insulation is laid between the slats so that it does not protrude beyond the level of the beams.

Measuring the distance between the sheathing bars

Fastening insulation boards to the ceiling. In the photo - the use of foil insulation

The insulation board is tightly inserted between the sheathing bars

For internal walls, you can use 50 mm thick insulation. For external use, a 100 mm slab is suitable or it is possible to lay 50 mm thick slabs in two layers

- A foil material is fixed on top of the insulation layer with the obligatory placement of a reflective layer inside the steam room. The joints of adjacent canvases or sheets can be glued with metal tape, but it should be remembered that under the influence of high temperatures the glue can soften and the panels will separate, breaking the tightness.

It is best to fix the foil with staples or nails, nailing them directly onto the beams. If the width is large, the foil material is fixed not only at the edges, but also in the middle.

- The laid foil is sewn up with clapboard, leaving a one and a half centimeter air pocket, the main function of which is to reduce the thermal conductivity properties of the foil layer and to maximize the reflection of all the rays that hit the foil back into the steam room. An air pocket will allow you to create a sheathing for the lining. Choose planks 10-20 mm thick and fix them with self-tapping screws.

Fastening the sheathing under the lining

Installation of lining

Clapboard wall and ceiling

Sometimes the order of arrangement of materials can be changed - a layer of foil is stuffed onto the insulation layer placed between the sheathing bars, staples or nails, which is fixed on top with thin slats placed strictly on top of the sheathing with self-tapping screws of sufficient length.

Bathroom wall decoration

In some cases, wooden sheathing can be placed on top of the insulation layer, laying foil over the entire area of the walls, including. and on the uneven bars. Then it is impractical to leave air pockets, and the lining is fixed directly on the sheathing. But, as practice shows, purchasing combined heat-insulating materials with a layer of foil is not only more economically profitable, but also significantly simplifies the entire installation process.

Attaching lathing to aerated concrete walls

It is correct to attach the block to concrete walls through spacers 2-3 mm thick to leave a ventilation gap

Level the bars

For attaching self-tapping screws to aerated concrete walls, ordinary nylon dowels No. 6 are suitable.

Water supply pipes run under the clapboard cladding

When installing the sheathing, avoid contact with the floor

The offset from an unprotected steel chimney when passing through the ceiling must be at least 50 cm

Installing foil over insulation

Fastening the lining

Video - How to properly decorate a steam room in a bathhouse

Arranging steam rooms using foil materials allows you to save 25-30% on heating raw materials for stoves, as well as extend the service life of the structure, preventing the development of fungi, mold and microorganisms harmful to humans.

Installation of insulation with foil

When installing foil insulation for a sauna, you must follow the following rules:

- The layer with aluminum foil is directed indoors.

- When installing the material on the ceiling, it runs down onto the walls, and from vertical surfaces onto the floor. This is necessary for the drainage of condensate.

- Ventilation is required in the steam room.

- A gap of at least 30 mm is left between the foil layer and the finishing of the bath.

The sequence of installation work depends on the type of insulation. The penofol roll is rolled out, cut into sheets of the required length and secured to the walls with a stapler. For basalt wool, it is necessary to make a frame according to the thickness of the material. The mats are laid in the finished sheathing. The joints of the canvases are glued together with metallized tape. 30×50 mm slats are placed on top of the heat-insulating layer. The lathing will provide the necessary ventilation gap between the insulation and the casing of the steam room.

How to calculate the amount of material

To calculate the lining, you can use an online calculator.

The simplest option for calculating the amount of material required for lining and insulating a bathhouse is by the area of the premises. You will need to measure the height, width and length of the rooms.

The area is calculated using the formula S=2HL+2HD, where:

- H – height;

- L – length;

- D – wall width.

The area of existing window and door openings is subtracted from the result. The area of the ceiling is calculated separately - its length and width are multiplied.

You can calculate the amount of lining in square meters manually or using an online calculator. It is worth adding 15% to the received quantity for a reserve in case of damage to the lamellas.

Step-by-step instructions for insulating a bathhouse

To begin with, we note that if the steam room is small, then foil in rolls or kraft foil, the thickness of which is at least 0.3 centimeters, will be quite sufficient. But if the steam room is quite large, then it is better to give preference to materials based on mineral wool. Also, be sure to think about how the condensate will be drained: if the ceiling is insulated, then the foil from it must be taken to the walls, and if the latter are insulated, then to the floor. The overlap should be approximately 15-20 centimeters, and all joints, we repeat, should be taped with metallized tape.

The installation process itself is not complicated and consists of several simple steps. Let's look at the features of each of them in more detail.

Step one. To begin, build a sheathing on the walls using a 5x5 centimeter beam. As for the pitch of the sheathing, in this case it depends on the width of the insulation. If it is 60-120 centimeters, then the step, accordingly, should be 60 centimeters; for foil, the width of which is 100-150 centimeters, this is 50. To attach the bars, use self-tapping screws of a suitable length.

Step two. Place insulating material between the sheathing beams. Try to do this in such a way that the heat insulator does not extend beyond the level of the slats.

Step three. When the main insulation is installed, lay a foil covering on top of it, always placing the latter with a reflective layer inside the room. To seal the joints between the sheets, you can use metallized tape, but remember that the glue, being under prolonged exposure to high temperature, softens, which means that the sheets may well separate, which leads to a violation of the tightness of the entire coating.

It is advisable that the bath foil be fixed with nails or staples - the latter should be nailed directly to the bars. And if the width of the foil is large enough, then it should be fixed both at the edges and in the center.

Step four. Cover the fixed foil with clapboard, not forgetting about the air gap 1.5 centimeters thick. This layer is necessary in order to reduce the thermal conductivity of the foil in order to maximum reflect all the rays that hit the coating back into the room. Obtaining this kind of air “pocket” is possible thanks to the construction of a wooden sheathing under the lining. For this sheathing, try to use bars, the thickness of which is within 1-2 centimeters, and for fixation, use the same self-tapping screws.

Sometimes the sheathing can be built on top of the insulating layer - in this case, the foil will be stuffed immediately over the entire area of the steam room, even onto the beams. If so, then there is no particular need to create air “pockets”, and the lining can be fixed directly to the sheathing. However, practice shows that the use of combined materials, including a foil layer, is preferable not only in economic terms, but also because of the significant simplification of all installation work.

Thermal requirements for a bathhouse building

The bathhouse building must warm up quickly and retain heat for a long time, but at the same time use fuel economically. Such conflicting requirements force builders to think carefully about solving the problem. Fuel for the stove must be high-calorie. All heat produced must remain indoors. All routes for its leakage must be blocked.

From the point of view of a heating engineer, heat in a bathhouse is distributed by convection (the movement of hot air), heat transfer (from one heated body to another with close contact) and infrared rays (low-frequency electromagnetic waves).

Foil is proposed as a heat reflector (infrared transmission) back into the bathhouse. But the foil itself turns out to be shielded from the stove, and infrared rays almost do not reach it. So it reflects only a small fraction of the heat produced by the stove. But foil, when laid correctly, can cover all the cracks and prevent hot air from escaping. The joints of the foil sheets are glued with special foil tape. It is also good.