Stone

Natural stone is as fire resistant as brick.

It is equally suitable for finishing a stove, but its appearance is much more decorative. The finishing of the stove is carried out not with raw stone, but with finished products made from it. These are tiles or special stone elements for finishing fireplaces.

Classic types of stone are used: marble, granite, but in a bathhouse they may be inappropriate in design and expensive. In this case, they are replaced by cheaper sandstone and slate stone. Slate stone is often cut into flat pieces, so its price is very low.

Information. Finishing with stone requires more masonry experience than working with brick. We have to deal with uneven pieces, different thicknesses of seams. It is better to entrust this finishing to professionals.

Finishing the stove in a bathhouse with decorative stone begins with the selection of material. Untreated stone is cheaper, but its surface in a bathhouse can quickly become dirty.

The part of the portal that is laid out on the floor is especially susceptible to contamination.

Despite the fact that untreated stone looks beautiful, it is recommended to use a polished and honed version for a steam room.

Nuances when working with the floor

When tiles are laid on the floor of a washing room or shower, the first thing you need to do is maintain the slope.

This is very important, otherwise the water will stagnate in the room and will not leave on its own through the sewer drain.

It is advisable to make markings using a strip or lacing before starting work. This will help you see the required slope more clearly visually.

To maintain the seams, which are a prerequisite for floor tiles, it is necessary to use special crosses 3 mm thick. If you ignore this rule, then over time, due to strong temperature changes and high humidity, the tiles will simply crack and begin to peel off.

Popular types of stone for finishing a bath:

- Serpentinite (coil) The stone has healing properties: eliminates headaches, relieves nervous tension, stabilizes blood pressure, helps get rid of diseases of the digestive organs and colds;

- Soapstone chlorite (talcomagnesite). Helps improve memory, lifts mood, fights stress, improves immunity. In our work we use production facilities from Finland and Russia;

- Jade. Looks beautiful in the form of a panel. It has an expensive look, impressive in different finishes. The mineral is useful for rheumatism and osteochondrosis, and prevents the appearance of cellulite.

Possible problems

The most common mistakes and tips for avoiding them:

The large distance between the stones creates the feeling of a “broken” stone. Such a seam does not look very aesthetically pleasing. Due to poor quality primer, some stones may fall out of the overall composition. Therefore, you should immediately treat your work with respect and do the job well the first time. You need to cut stones with a grinder very carefully, because

If you move carelessly, you can damage them, break them, or chip the surface. It is necessary to select the surface decor with great care to avoid disappointments. A wide variety of colors and textures of stone finishing allows you to choose the appropriate option for every taste. If you disturb the arrangement of the rows at the beginning of the work, you may end up with chaotic masonry, which will have a bad effect on the appearance of the product.

Tiles

Tiles are a classic solution for finishing stoves. They have cheap production technology and very reliable installation. The external surface, finished with tiles, looks like high-quality, thick tiles.

This appearance will be achieved only if you use tiles without a pattern on the front surface. They do not produce a special decorative effect, since they do not differ much from the usual tiles. The only benefit is in the strength of the fastening, which is why other tiles with a three-dimensional pattern on the front side are more popular.

Tiles are laid in the same way as tiles, but require a significant thickness of the finishing layer. If a portal for a sauna stove is made from them, then part of the wall and floor is covered with tiles. They don’t have to be used on the floor if the stove foundation is raised above the floor by one or two brick rows.

If the tiles have holes for wire, then it must be used.

The diameter of the rods is selected according to the instructions. Larger diameter means higher strength, but the complexity of installation increases.

On average, tiles are the same thickness as one brick.

They can just as well be used to create the same protective layer.

Benefits of brick

This solution can be seen in almost any bathhouse. The brick finish protects the wall from overheating. Very often this protection is made even more powerful and extended to the floor. Finishing the stove in a bathhouse with brick performs both a protective and decorative function. For it, the same type of brick is taken as for the rest of the stove, or another facing brick of the required appearance is additionally purchased.

The rules for brickwork for walls, the stove and the protective portal around the stove are general.

Strict adherence to row levels and neat and thin seams are necessary.

On the walls and in the oven, bricks are laid with overlapping seams. If the portal is laid out in one layer, then it is not at all necessary to comply with this requirement. This is why you can often see protective portals where bricks are stacked on top of each other.

The horizontal row is checked by level. Covering the wall with bricks is plumb. For a corner stove, three planes are laid out with bricks, two on the walls and one on the floor.

Attention! A more durable option would be to lay them in one layer with a parquet pattern or according to the usual pattern, as for a half-brick wall.

For a stove near the wall, there are only two, of which one is located on the floor, and the second is on one wall. Brick, even if it is laid in one layer, has good thermal insulation ability. Its masonry is carried out directly on wooden walls and floors without other fire-retardant insulation.

It is advisable to lay out the horizontal part of the portal in one row between the foundation of the furnace and the subsequent masonry next to it. This advice should only be followed with brick sauna stoves. It is not suitable for metal ones.

Important! When finishing with ceramic tiles, decorative plaster or steel sheets, the use of additional thermal insulation materials is mandatory.

In baths, thick fireproof cardboard, mineralite or basalt wool are most often used. There are also basalt cardboard and other materials that are a variation of the previous ones. Minerite is the most preferred. These are ready-made boards specially designed for thermal protection in areas around stoves.

Types of stone suitable for stove finishing

Figure 2. Options for artificial stone

There are many types of artificial stone. Not all of them are suitable for cladding bases that are subject to temperature changes. Let's consider the suitable ones.

Porcelain tiles

Artificial stone is another common name for ceramic granite. Visually, the material does not have to resemble at all what it is associated with. Rather, it is an analogue of ceramics or glass. However, in terms of strength, porcelain stoneware is superior to both and natural prototypes. Being fired in a kiln at high temperatures, the material does not react in any way to the thermal effects of the fireplace. He doesn’t care about mechanical load either – within reasonable limits.

There are several types of ceramic granite. If you wish, you can find hundreds of collections that imitate stone not only at the level of physical and chemical characteristics, but also externally. There are materials with both strict geometry and a “natural” silhouette. You can use any slabs, but the latter type is preferable for those who decide to finish the stove themselves.

Porcelain stoneware contains various types of clay, feldspar, mineral additives and pigments. The multi-component mixture is pressed under enormous pressure and then fired at temperatures above 1200 degrees. This provides excellent strength characteristics.

concrete stone

One of the most popular types of artificial stone, which is most often used when decorating stoves. The composition includes sand, cement, dyes, plasticizers, fillers and water repellents. Materials of this type are distinguished by good contextual indicators and accessibility - lining the stove with concrete artificial stone will not strain the budget.

Gypsum-based stone

It has excellent strength characteristics. Any imitations are possible. Due to the properties of gypsum, it is well suited for lining heated surfaces.

Choosing tile adhesive

The stone is laid on tile adhesive. We will not repeat the importance of resistance to high temperatures. But this is not the only criterion for choosing a composition.

Artificial stone is usually not large in size. But if the oven is lined with dimensional materials, you need to take care of adhesion. In such cases, you need to purchase glue designed to work with heavy slabs. And in general, it’s better not to skimp and buy a mixture with excellent grip.

If the base is properly prepared, the glue calculation is carried out according to the diagram specified in the instructions. Otherwise, the quantity must be adjusted taking into account deviations of the furnace surface from the plane and vertical.

Finishing the stove in the bathhouse with various materials

The finishing around the stove in the bathhouse can only be made from safe fire-resistant materials. The most common one is brick, but this is not necessary. Other materials are also suitable:

- Red stove brick, decorative facing brick;

- Tiles, ceramic products for decorating fireplaces;

- Natural stone: various slabs and tiles made from it;

- Decorative plasters (applied only with a thick fire-retardant layer);

- Steel fire-retardant finish (requires good design work).

As you can see, the choice of materials is quite large. Brick is reliable and practical. The rest of the materials are taken either because of the design, or when the budget for bricks is not enough, but another fire-retardant material is already available. We will consider the finishing of each type of material in more detail.

Information. High demands on moisture resistance are imposed by the operating mode in which the steam room operates in the bath; the finishing around the stove is made only from moisture-resistant materials. Various gypsum and fill insulation materials are not used.

How to prepare stones for laying

If you have installed a new stove, before laying the stones you need to heat it well, completely filling the tank with water. The fire in the firebox is maintained for at least 2.5-3 hours, until the smell from burning paint and other materials used in the manufacture of the stove disappears.

Before placing stones in the sauna heater, they must be washed from dust and dirt. This procedure is necessary for any stones – both store-bought and independently collected. You can use a brush or dishwashing sponge with a hard abrasive layer.

Decorative plaster

Plaster for stoves began to be used relatively recently. Indeed, a good stove does not need to be plastered. It is made either of high-quality brick, which in itself looks decorative, or of metal, which also does not need plaster.

In this case, we are not talking about plastering the stove itself, but about creating a protective separating layer of plaster between the walls and the stove. Plaster is quite suitable here.

Finishing the walls in the bathhouse around the stove with decorative plaster is especially often done when the stove is not placed in a steam room.

In this case, the requirements for moisture resistance are much lower.

Material calculation

Before planning a trip to the shops, you will need to first take all measurements from the planes that will be covered. You should not neglect the treatment of adjacent surfaces, which will also be exposed to high temperatures. The floor, adjacent walls and ceiling will also need to be protected with fireproof shields.

Tile adhesive is calculated separately; manufacturers attach instructions directly to the packaging, so now you only need to know the area that will be covered.

Don’t think that you can avoid cutting tiles, this is impossible, so you will need to purchase or borrow a tile cutter.

Marking the base

Where to start? And how to ensure even seams? Marking the walls helps with this. It is necessary to determine the starting points of installation. To do this, use a laser or water level. The latter option is preferable if you have a limited budget. It is in no way inferior to the technological version. Plus, in a small area, using a laser does not have any pronounced advantages.

The following recommendations will help you understand where to start and how to work:

- in most cases you need to start from the corners (at least there should be whole elements in the corners);

- with seamless cladding, it is better to lay the stone from the bottom up, and when laying with subsequent jointing (especially when laying porous slabs), it will be more convenient to go from top to bottom - this way the slabs will not become dirty;

- whole slabs - the most visible places; usually these are the top and corners, but you need to look at the situation;

- Usually the bottom row is left for last - it is more convenient to cover the floor with trimming, rather than adjusting the floor covering to the stove stone.

Based on this, the starting points are determined. After this, either lay the first row along the laser mark, or pull the beacon cord (according to the marks).

Styling tips

Installing wall or floor tiles in a wooden, brick, or block bathhouse will be no more difficult than performing the same work in a house or apartment

It is only important to remember that such decor requires a flat base with good adhesion. When laying the tile floor, the slope specified during installation of the rough base structure is observed.

Before installation begins, it is necessary to clean the room, get rid of debris, and remove dust. For work you will need:

- tiles (the quantity is calculated in advance, with a margin of 10%);

- glue;

- notched spatula;

- cuvette for solution;

- construction mixer;

- tile cutter;

- mallet;

- working surface for cutting;

- cross-shaped plastic inserts;

- grout.

The floor is pre-waterproofed and primed. If necessary, it is leveled. Walls in rooms with high humidity are also covered with a layer of waterproofing 1 m from the floor. It is better to start installation from the corner part or the drainage point. Each row is verified using a building level. For installation on the wall, a lower support beam is used, then it is removed.

The glue should not be applied too much. A small layer is enough to secure the product. Use a spatula to scoop the solution onto the tile or the surface to which it is attached. After fixing to the chosen place, each decorative element is tapped with a mallet for a tighter fit and better adhesion. Cross-shaped inserts are laid between the tiles horizontally and vertically. After the glue dries, the resulting seams are rubbed down.

Useful tips for choosing tiles for a bath in the video below.

Finishing the stove with bricks

Traditionally, the stove lining is made with brick. This material is also suitable for wooden walls near the stove. It is an additional heat accumulator.

At the same time, the brick acts as a protective screen that prevents burns and has a presentable appearance. You can also line a metal stove with bricks.

Kinds

The following types of bricks are used for cladding the stove:

- ordinary ceramic brick (solid);

- refractory fireclay brick.

It is not recommended to use silicate and hollow bricks. It will not hold heat well and will collapse. Fireclay brick is preferable to use, but it is more expensive.

Instructions

- The laying is done using a mortar specially designed for ovens. It will ensure optimal structural strength.

- The foundation design must be designed to withstand such a load. Otherwise, you will have to make a separate foundation.

- The masonry is done in half a brick. The brick is placed on the bed. We start laying from the corner, bandaging 1/3.

- For heat exchange, ventilation holes must be provided in the masonry.

- Between the rows we reinforce the masonry with mesh.

- After completing the masonry, we perform jointing.

Examples of brick lining a stove in a bathhouse in the photo:

Photo 1

Photo 2

Photo 3

Photo 4

Photo 5

Conclusion

The choice of one or another material for lining the stove in the bathhouse is determined by the result that needs to be obtained in the end. The most interesting option in terms of heat preservation is tiling, but it is also the most labor-intensive and expensive. If you want to veneer your stove cheaply, there is such an opportunity.

The most budget option is plastering the stove. It is best to line a metal stove with bricks. This will significantly increase the heat capacity of the oven and it will take longer to cool down.

Another great option is porcelain tiles. When deciding how to line a stove in a bathhouse, pay attention to the quality of the materials used.

To insulate the space around the stove, it is advisable to use mineralite. This is an excellent sauna cover. They are used for lining the sauna - covering wooden walls, although these slabs can also be used to cover a house.

Using the step-by-step instructions in this article, you can not only choose the right material in the best way, but also do the lining of the stove itself and its surfaces with your own hands. This became the main purpose of this material.

When is this required?

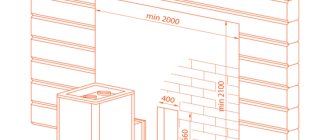

There are times when there is no need to protect walls. If the stove is located at a safe distance from the wall from a fire safety point of view, the installation of protective screens and other measures can be neglected. The distance from the walls that is required to reduce the heat from the source varies:

- A stove laid in a quarter of a brick should be located no closer than 35-40 cm from the wall;

- A metal stove without lining should be placed a meter away and no closer;

- A metal one with a lined furnace can be installed 70-75cm from the wall.

However, not every steam room has the opportunity to fulfill these requirements, due to the small area. The layout of steam rooms with an area of 6-8 m² can hardly accommodate the necessary set of items for the steaming procedure. Therefore, the need to insulate walls with special sheathing is relevant.

Preparing the furnace for work

Before finishing, preparatory work cannot be avoided. They are needed for smooth application of plaster and high-quality wall cladding. The first step is to remove the old plaster if the stove has been used before.

This process is carried out with a spatula and water. If the old plaster contains cement, then you will have to use a chisel or hammer. If the old material is successfully removed, the wall should be cleaned down to the brickwork.

The next step is to run a wire brush or sander over the surface of the oven.

Important! To properly attach the plaster, you will need to spray the walls with water and clean the seams between the bricks. New masonry must be dried and cleaned of dust and other defects.

New masonry must be dried and cleaned of dust and other defects.

After cleaning, the walls need measurements. Using a building level, the correctness of the corners is assessed and, if necessary, they need to be plastered to level them.

Brick oven plaster

Plaster can rightfully be considered the most budget-friendly type of finishing. There is a wide variety of folk and modern methods. The basis for most solutions is clay. At its base, asbestos, cement or gypsum can be added to the finished mixture. The construction markets offer a large selection of ready-made dry mixes. Such compositions are not inferior in quality to traditional ones. They have good heat-resistant properties, are durable and reliable.

Basic rules for plastering brick kilns

- The new oven should dry out and shrink. To do this, it is heated several times, gradually increasing the heating temperature. You can start facing work only a month after the completion of the masonry.

- The surface of the stove is cleaned of any remaining masonry mortar. The seams are selected to a shallow depth and reinforcement is made.

- To ensure that the plaster dries faster, the oven is heated before starting work.

- The first layer of solution is made more liquid. They apply it, filling voids and forming corners. Subsequent layers are leveled and sanded to a flat surface.

The plastered stove can later be whitewashed or painted. For these purposes, there are a large number of different compositions. The cheapest and most environmentally friendly are mixtures based on lime and chalk. However, such dyes have a number of disadvantages. They can smear and crack if binders are not added to their composition.

In the modern market of paints and varnishes, polymer-based and organosilicon-based paints can be distinguished. These dyes can withstand high temperatures, moisture and ultraviolet radiation. If you want to emphasize the structure of red brick, you can also coat an unplastered stove with such compositions.

How often do stones need to be replaced?

The durability and heat resistance of each breed depends on its initial characteristics and on the mode of operation of the bath. Basalt has the longest service life - it can withstand up to a thousand heating and cooling cycles. There are breeds in which this figure is several times lower.

It is impossible to say exactly at what point the stone will become “dead” and lose its ability to retain heat. This becomes clear when changes occur in the operation of the steam room: it takes longer to heat up and cools down faster. In this case, the stones should be sorted and completely or partially replaced.

But it’s better not to wait until the last minute, but to regularly inspect the heater, unload stones, clean them of plaque and soot, remove broken and porous specimens - they are of little use.

Stone

Finishing the sauna stove with stone would also be appropriate. This material can be natural or artificial. In terms of fire resistance, stone is not inferior to brick. But the appearance of the stove becomes more impressive. The stone is known for its high decorative value.

It is worth considering that the finishing is carried out with stone that has undergone special treatment. Raw material is not suitable for these purposes. Natural stone is used to make elements that resemble tiles or blocks in shape. But on the reverse side they should be flat. There are different types of stone. The most popular finishes are granite and marble. However, they may look out of place in a steam room.

The cost of the presented varieties of stone is quite high. Therefore, many bathhouse owners choose other types of materials. It could be sandstone, shale. The second option is often sold chopped in large pieces. For this reason, the cost of the presented material is low.

Wooden lining of a sauna stove

Wood is used in various fields of construction. The material is suitable not only as fuel for the stove, but also for beautiful decoration. Wood is strong and light at the same time, so it does not have a significant impact on the base of the bathhouse. When choosing wood as a decor, do not forget that the material does not have high thermal conductivity, so turning your idea into reality should be approached carefully. Wood is best suited for creating accents, finishing the floor, ceiling, corners of the steam room or bed.

Many people know about the low level of fire resistance of wood; therefore, the material is not recommended for use near an open fire source. Wood trims remote areas of the room, having previously treated the element with fire retardants.

Using tiles

The tiles on the stove in the bathhouse are afraid of thermal expansion, therefore, when performing work, it is important to carefully follow the technological process. The lining of the stove in the bathhouse does not tolerate negligence

Kinds

Typically, 7 types of tiles are used for cladding:

- Terracotta is a tile that has not been glazed. It consists of terracotta clay and fireclay, which are mixed in a certain ratio. Such tiles have been known for several centuries. A correctly implemented technological process greatly influences the final quality of the material. This tile can be easily recognized by its characteristic red tint.

- Clinker tiles - clay is the main raw material. The material is obtained by pressing, then it is fired at a temperature of +12000C. The crystal lattice of the clay changes and the tile acquires the properties of ceramics.

- Majolica is very difficult to produce. Previously, only manual labor was used for drawing. Now there are industrial designs. The glaze on the tile is obtained by firing. Properties resemble terracotta tiles.

- Tiles are the most preferred option due to the air gap between the tiles and the oven wall. This layer works as an additional heat insulator, allowing the stove to retain heat near itself even longer.

- Porcelain tiles can also be used for lining a stove. Marble chips added during the production of porcelain stoneware give the material unique decorative properties and high strength. Due to this, porcelain tiles are rapidly gaining popularity.

- Fireclay is able to withstand direct exposure to fire. Fireclay is pressed into blanks and fired at a temperature of +13000C.

- Tile - only a material with a high heat resistance coefficient can withstand temperature loads.

Expert opinion Nikolay Davydov Stove maker with 15 years of experience

Based on their properties, the most preferable option for lining a stove is tiles. It is also the most labor-intensive. The most budget option is special tiles with a high heat resistance coefficient, but with its help it will not be possible to finish the hottest areas.

Instructions

Do-it-yourself tiling of a sauna stove is done as follows:

- It is necessary to properly prepare the surface. All traces of old finishes must be removed from the wall. Each seam should be selected at 10-15 mm.

- We dilute a deep penetration primer and add marble chips to it. Carefully prime the surface. Do not forget that the primer must dry (at least 24 hours).

- We stretch and fix the metal mesh using dowels. Such reinforcement will significantly increase the strength of the structure.

- The tiles should not be laid on an uneven surface. We level the wall with plaster. We recommend using stove mortar that is specifically designed for plastering stoves. The plaster must be allowed to dry for 48 hours.

- Apply the facing adhesive evenly to the entire surface of the tile. Carefully cover the surface of the stove and press lightly. The tiles can be leveled in about 10 minutes. Then the glue will set. We check the correctness of the masonry using a level. The glue layer should not exceed 1 cm. To make the seams even, we use special crosses. The thickness of the seam is 2-3 mm.

- When the glue dries, we grout the joints.

Foundation arrangement

Now on the Internet you can find many drawings, photos, and plans for building a foundation for lining a stove in a bathhouse with bricks. What is this building?

The foundation is made in the form of a quadrangular well, the height of which is equal to the height of the furnace. To cover the metal walls, use solid or masonry with windows, through which not only fuel is thrown in, but also ventilation around the heating surface is enhanced.

According to experts, wooden floor beams can withstand up to 650-700 kg of load. Although practically, it is not recommended to give a load of more than 400 kg per 1 m². Therefore, it is advisable to further strengthen the existing frame with an iron structure from an angle (50 mm), or screw piles, provided that approximately 180-200 bricks weighing 3.5 kg each will be used for the screen.

Foundation construction algorithm

- Cut a square of a certain size in the floor (if it is already installed), dig a pit approximately 35-45 cm deep.

- Fill the bottom with coarse crushed stone, lay waterproofing, and install formwork.

- Place pieces of reinforcement in the foundation frame, apply the required amount of mastic waterproofing, and fill the structure with concrete approximately 15-20 cm above the ground.

- Bring the “pillow” to the floor level with ordinary bricks, on which the stove and lining will be placed.

- Wait about 3 weeks until the concrete shrinks, then lay thermal insulation and steel sheet (3-5 mm thick) under the stove.

Preparation of the solution

In order to properly line an iron stove in a bathhouse, it is best to use a classic clay-sand mortar. You can add a small amount (about a sixth) of grade 400 cement to it. This ingredient can only strengthen the entire structure, since the temperature of the future screen will not be high enough.

Since little clay is required, it is best to buy it at a building materials store. For rural residents, such a problem as purchasing clay should not exist.

To prepare the solution, you need to take sifted sand and mix it with clay in equal proportions. Add water gradually until you get a thick mixture that can easily slide off the trowel.

What other materials are used to line a sauna stove?

It turns out that not only bricks can be used to line sauna stoves. Granite or marble slabs are an excellent substitute. They also tolerate temperature changes well, have a large mass and high thermal conductivity. In addition, such finishing will give the bath room an unusually beautiful and unique look. Not everyone can afford such luxury, from a financial point of view. But if you have some leftovers, you can use them to build a stove partition.

True, the installation of such slabs is a little more difficult in comparison with brickwork. To ensure a beautiful appearance of the lined stove, it is necessary that the work be carried out by a specialist. At the very least, the owner needs to at least consult with such a person.

Minerite slabs are also used to construct a heat shield. With their help, the wall is mounted much easier and faster, even in comparison with masonry, and is able to withstand temperatures of 360-400⁰C. But the heat capacity of this material is low, so it can be used as a good partition that will not be able to accumulate heat.

Tiles

A stove with tiles is a rather labor-intensive process. Technology has simplified things a bit. But until now, the construction of such a furnace takes 4-5 months, if you use the classic version. The laying and lining of the furnace occurs simultaneously. Although, in a simplified version, you can line a finished stove.

Expert opinion Nikolay Davydov Stove maker with 15 years of experience

The drawing can be anything. Usually Russian folk motifs are used. The sizes of tiles are regulated by GOST 3742-47. Permissible deviations should not exceed 1 mm in all directions. Thanks to standardization, the cladding process has been significantly simplified. The most important thing is to choose the right material.

Instructions

You should be guided by the following rules:

- Material of manufacture. Impurities in colored clay will not allow the production of high-quality tiles, so it is not used. In contrast, white clay is an ideal raw material.

- The quality of a product is determined by its ability to absorb water. The more pores in a tile and the larger they are, the less quality the product will be.

- Choose tiles made by pressing.

- The surface of the product should not have a dull appearance and there should be no cracks on it. This happens when a product undergoes only one firing.

For cladding, tiles must be sorted by shade. They will need to be laid in such a way that the transition is not noticeable. The size is adjusted using a rasp and an angle grinder on all sides. Defective tiles should not be thrown away immediately. They can be used later.

The next step is to mark. The thickness of the horizontal seam should not exceed 3 mm, vertical - 1 mm. Now let's move on to installation.

Lay out the first row.

The process is very labor-intensive, but the result is worth it. The first thing to do is to properly prepare the tiles for installation. This will ensure the best result.

The installation order is as follows:

- immerse the tiles in water, waiting until the clay absorbs water;

- the clay in the tiller will increase the heat capacity, so you need to fill it halfway;

- steel brackets allow you to correctly connect the tiles to each other;

- We connect a row of tiles to a row of the stove using wire.

Scheme for fastening the tiles: 1 – lump, 2 – pin, 3 – wire, 4 – staples.

Subsequent rows.

- drill holes in the masonry;

- We use screws and wire as a connecting element;

- We fasten the steel pins using wire;

- we place the tile on the pin and bend the last one;

- the dry solution will fill all the voids between the tiles.

Sauna stove in tiles

How to cover a stove

To carry out such work, no special schemes or orders are needed, since the task is quite simple - the partition is erected around the perimeter of the sauna heater with the specified gap from it. If the stove body is round, then the masonry can also be made curved, as shown in the photo below.

To cover a stove in a bathhouse with your own hands, you must first install it in place and connect the chimney pipe. If your stove is equipped with an external firebox, then before installation you should cut out a piece of the wall from the dressing room side. The minimum size of the opening is calculated as follows: the dimensions of the external channel + plus the width of 1 brick (120 mm) + 2 cm. Then proceed in this order:

- Prepare clay-sand masonry mortar.

- Lay the first row of stones continuously around the perimeter of the heater. Before applying the solution, soak each brick in a bucket of water.

- In the next row, leave 3-4 openings where cooled air from the lower zone of the steam room will enter.

- Lay out the remaining rows to the top of the stove, maintaining a seam thickness of no more than 5 mm and constantly checking the vertical and horizontal of the partition with a building level.

Important point. When constructing a brick screen, remove excess mortar from the inside of the masonry, otherwise it will block the passage of air. The structure of the partition is shown more clearly in the video:

If you are covering the entire stove, including the top, then the bricks of the vault are placed on iron corners (without mortar!), resting on the side walls. In the same way, fire doors are installed, which are fixed in the masonry with steel wire. The stove is ignited after 3-4 days, when the solution is completely dry.

Methods

There are several solutions on how to beautifully decorate, lay and insulate a stove. Based on the type of lining, two options are considered.

- When lining the furnace on four sides at once, such a scheme will be called a full lining.

- If one of the sides is not involved, then this is a partial layout. The main difference is the controllability of convections.

This question becomes especially relevant for those who want to build a Russian bathhouse. The controllability of convection allows you to regulate the steam; it remains either in the device itself or fills the room. This way the heat is adjusted and controlled.

There are certain options for how to enclose an iron stove with bricks.

- Solid masonry. The efficiency of the device may be low, there are obstacles to convection. Therefore, it is rarely chosen for construction purposes.

- Discharged masonry. The solution is also not often used in the construction industry. The main reason is that the screen efficiency decreases.

- Vents from the top and bottom. This is the most popular solution. Convection becomes more controllable.

Additionally, masonry can be brick, half-brick and quarter-brick. The best option is half-brick masonry, since the thickness and stability of the walls of the structure are freely adjustable.

Briefly about the main thing

The main rule for laying stones in a bathhouse is that the largest elements should be placed closest to the heat source, leaving free passages between them for the movement of hot air. As it rises, it will heat up the next layers, composed of a smaller fraction. It is also advisable to take into account the thermal conductivity and heat resistance of stones, laying down the strongest rocks that easily give off heat. Ideally, you should choose the filling for the heater taking into account its design, so that one condition for proper installation does not contradict another.

Finishing the stove in the bathhouse - choosing material for decorative cladding

A Russian bathhouse built according to all the rules is always a source of pride for its owner. After visiting the steam room, your health improves and problems fade into the background - this is a place where you can have a wonderful rest

The “heart” of a bathhouse building is considered to be a stove, the lining of which is of no small importance

Stove in the bathhouse

The main room in the bath building is the steam room, where the temperature should be high during the procedures. Steam is no less important. In order for the steam room to function in the desired mode, the stove, the main element of the entire bath, will help to achieve the necessary parameters.

When building or purchasing a heating unit, you must pay attention to the compliance of its functionality with a number of requirements:

- quick heating of the room;

- resistance of the furnace structure to high temperatures;

- the ability to work for a long period;

- beautiful appearance.

Of no small importance for the full functioning of the furnace in the future is the quality of the materials used for its manufacture.

Sauna stove lining

A heating unit installed in a sauna building must not only provide the required temperature conditions, but also have a beautiful appearance. One of the best solutions in this case is deservedly considered to be lining the stove in the bathhouse.

When finishing a stove structure, the following are most often used:

Each of the above materials has its own quality characteristics.

Using tiles for finishing stoves

Tiles are a popular type of material used to decorate a sauna stove due to its affordable price and ease of installation.

When lining a stove structure, the following types can be used:

- Clinker tiles. For its production, clay is used, adding energy melters, fireclay and various dyes.

- Majolica tiles. These ceramic products are made from fired clay and covered with glaze. The finished product has a bright and rich color, which is clearly visible in the photo. If desired, ornaments and designs can be applied to such tiles.

- Terracotta tiles. In terms of the components used in the production process, it has much in common with Majolica. But such a lining for a sauna stove is not covered with glaze. The main advantage of “Terracotta” is its high strength. The product is produced in a round shape.

- Marble tiles. A stove with such a finish looks presentable, creating an atmosphere of coziness and comfort in the room. These marble products are characterized by strength and durability. This type of tile has no disadvantages.

Finishing the stove with bricks

This design option for the heating unit is not only economical, but also easy to implement.

Finishing the stove in a bathhouse with brick has advantages, including:

- rapid heating to the desired temperature and maintaining it for a long time;

- The furnace structure is not destroyed by steam and moisture.

Stone in the design of sauna stoves

When the stove in the bathhouse is decorated with decorative stone (artificial or natural), the interior of the room takes on a noble and aesthetic appearance. If the heating unit in a bath building is lined with such material, it belongs to top-class buildings.

Application of steel case

When using this type of finishing, a metal frame is placed on the surface of the furnace and covered with steel panels. Thanks to the steel case, heat is retained and at the same time the optimal level of heating of the room is ensured. But this type of cladding has a significant drawback - when the furnace heats up, the material also begins to heat up and a person’s touch to it is fraught with serious burns.

Plastering the walls of the furnace structure

If you choose the most inexpensive and simplest option than finishing a stove in a bathhouse, then using plaster will be the optimal solution.

The work is carried out in two stages:

- The walls of the stove are plastered to remove dust and dirt.

- The second time, plaster is used to level surfaces, leveling chips and dents.

After completion of work, it is advisable to whitewash the stove structure with lime.

Tiles for cladding

An ancient method of tiling is laying tiles. This finishing of the sauna stove portal and its surfaces gives the structure an unusual and rather original appearance. As a result of tile cladding, the stove in the room becomes a separate element of the interior.

Only a master can perform this reliable and durable finish. As a result, the stove structure has a higher degree of heat transfer compared to the use of other finishing materials.

How to decorate stoves and fireplaces in a private home with your own hands? Finishing methods

A folded stove does not always look complete and in almost all cases requires additional intervention using finishing materials

If for one owner the functionality of the device is enough, and he does not want to cover it with anything other than plaster, then for another, it is important that the guests of his house are amazed by the elegance of artificial stone or correctly selected tiles

Plaster

This type of finishing involves covering the stove with the same mortar that was used for masonry.

It not only loses to other materials in terms of external components, but also reduces efficiency by 5-10%, reducing the thermal conductivity of the furnace.

The time for heating the walls increases by 20-30%.

Therefore, before applying plaster, you need to think about whether it is worth saving or whether additional investments are possible.

Reference. Plaster without the use of top material looks dull, but it will save a lot of money if the task is only the practical use of the stove, that is, heating the room.

Whitewash

Our ancestors also whitewashed the stove for each season, since expensive materials were not available to all people. In order to whitewash a stove, you do not need to have great skill. This is the simplest finishing method: lime or chalk mortar is applied to the stove

It is important to remember that this type of coating requires careful treatment on the part of residents, since white color is easily soiled

Coloring

Modern manufacturers produce various heat-resistant paints. It is this type of material that is necessary when covering the surface of a folded stove, since its wall will often be exposed to thermal stress when ignited. If desired, the painted surface can be coated with a special varnish.

Photo 1. Painting the stove with white paint. When lining such products, it is necessary to choose heat-resistant materials.

Is it possible to coat it with clay?

The use of clay mortar to strengthen the stove is justified by the fact that it contains sand, which strengthens the surface of the walls and provides additional protection against chips and other cracks. This type of finishing is not original and is used mainly for practical purposes that do not involve giving the house individuality and implementing design ideas.

Decorative artificial stone: gypsum, acrylic. Photo

Many homeowners want to see their stove lined with stone. But not everyone can afford to buy expensive materials. For these purposes, artificial stone is used for decoration, which in many properties is not only not inferior to natural stone, but also has additional positive characteristics:

- simple masonry that even a novice craftsman can handle;

- the oven being laid out will not be bulky, because the material is light in structure;

- saving money when choosing finishes;

- wide choice of shapes and colors;

- the opportunity to realize various creative fantasies when decorating the interior.

In addition, the material differs in structural diversity:

Gypsum dough. Externally it resembles natural sandstone and has good strength characteristics.

Photo 2. Finishing the fireplace and the walls next to it with artificial stone based on gypsum dough.

Acrylic stone. Even more durable than the previous version.

Photo 3. Fireplace with acrylic stone cladding, the color of which resembles natural marble.

- Artificial stone with the presence of natural stone chips.

- Porcelain tiles. It consists of several types of clay, mineral salts, marble chips and pigments. Great resistance to mechanical damage and high temperatures.

Photo 4. Fireplace covered with black porcelain stoneware tiles.

Heat-resistant composite. The material is made based on concrete, quartz or minerals. In terms of strength it can be compared to granite.

Finishing the stove in the bathhouse with various materials

The finishing around the stove in the bathhouse can only be made from safe fire-resistant materials. The most common one is brick, but this is not necessary. Other materials are also suitable:

- Red stove brick, decorative facing brick;

- Tiles, ceramic products for decorating fireplaces;

- Natural stone: various slabs and tiles made from it;

- Decorative plasters (applied only with a thick fire-retardant layer);

- Steel fire-retardant finish (requires good design work).

As you can see, the choice of materials is quite large. Brick is reliable and practical. The rest of the materials are taken either because of the design, or when the budget for bricks is not enough, but another fire-retardant material is already available. We will consider the finishing of each type of material in more detail.

Information. High demands on moisture resistance are imposed by the operating mode in which the steam room operates in the bath; the finishing around the stove is made only from moisture-resistant materials. Various gypsum and fill insulation materials are not used.

Fire protection system in the partition

To achieve maximum heating efficiency in a bathhouse, it is advisable to place the stove in a partition. In this case, it will heat the partition, and not the outer wall or corner, which is much more rational and profitable, since firewood or gas will be well saved.

The partition in the bathhouse near the stove should be well protected. All the same methods are suitable for this as for the usual placement of the furnace. You can use all the techniques described above (brick, tile, metal) both for the outer wall and for the partition.

A brick partition in a bathhouse near the stove will be the most convenient option. It should be noted that brick partitions are often found in wooden bathhouses. Basically, they are made there for design reasons because of the beautiful facing bricks, but the option with a stove is much more functional.

The result is a highly efficient bathhouse for heating; the partition-stove in it is located in the center of the building and does not lose heat. In this case, the portal around the furnace is made lighter. For its construction, it is appropriate to use the same brick as for the rest of the partition. In this case, you will not need to purchase additional materials. If the design requires it, you can use any other option.

Important! Any brick partition in a wooden bath always requires a separate, reliable foundation. Making it hanging is unacceptable. It is convenient to combine the foundation of the partition and the furnace.

Ceramic tile

Perhaps this is one of the universal materials that are often used for any purpose. This tile gained its popularity due to its relative cheapness and good characteristics. The only limitation of this material is its maximum heating temperature. The tiles do not have any locking connection or hook that would help the material resist deformation at high temperatures. That is why it is not recommended to use it for stoves that become very hot during operation. But for a fireplace this is a suitable option.

Ceramic clinker tiles cope much better with this task. In addition, it can imitate any type of finish. There are products with imitation brick, tile, wood, granite or marble. In addition, clinker tiles are more wear-resistant, stronger and more durable. And the coating can be matte or glossy.

If you want to have an original and inexpensive finish for your fireplace or stove, you can combine the option with decorative brick and ceramic tiles. This neighborhood also looks beautiful.

An important point: when finishing the stove with tiles, you need to choose a high-quality glue or composition that is not afraid of high temperatures. Otherwise, no matter how high-quality the tile is, it may fall off due to cracked adhesive. You shouldn't skimp on this.

But you can learn how to properly tiling a stove with your own hands from this video. This will help you complete the task quickly and efficiently, while saving some money on hiring workers.

Let's move on to choosing decorative tiles

For tiling with ceramic tiles the following are mainly used:

- porcelain stoneware;

- tiled tiles;

- clinker;

- terracotta.

Tile is not entirely suitable for decorating stoves. It is commonly believed that this is just the name of a ceramic slab, but this is not so. Its ability to withstand overheating is much lower than other options.

We can say that such material is a relic of the past, but if the choice still falls on it, additional protection will be required in the form of heat-resistant adhesive for lining stoves. In addition, it will not be possible to use glazed tiles.

Each tile manufacturer has a certificate of conformity, which details the characteristics of the material.

Of the listed options, porcelain stoneware most meets the requirements for finishing tiles; the material itself is extremely durable; many manufacturers use mass dyeing followed by firing, that is, even if chipping occurs, the color inside the slab is exactly the same as on the decorative surface.

Types of cladding for furnace devices

Before starting finishing activities, it is necessary to take a responsible approach to the choice of materials for decorating the stove. They must have the following performance properties:

- High temperature resistance.

- Improved heat dissipation.

- Practicality and durability.

- Presentable appearance.

Application of bricks

The finishing of a brick oven must be done in conjunction with the masonry. This solution has a beautiful design and competes with more elite design options, including granite or marble.

To improve the adhesion of bricks, you need to use products where one side is rough and the other is smooth, or vice versa. The selected brick must be fire-resistant and absorb thermal energy. To do this, a layer of ballast made of fine dry sand should be fixed between the surfaces. This action will prevent damage to the finishing layer in the event of expansion of heated metal and improve heat transfer.

Using ceramic tiles

Lining the stove with ceramic tiles is intended for those stove structures that perform heating functions. However, the material has a number of restrictions on use, since it does not withstand temperature deformations, because has no hooks or locking connections. Experienced craftsmen have learned to combine brick laying with ceramic fragments, believing that this approach effectively enhances the furnace.

To decorate a Russian stove with tiles, you can use the following varieties:

- Porcelain tiles.

- Majolica.

- Clinker room.

- Terracotta.

Terracotta tiles

This type of tile is highly resistant to maximum temperatures (up to 1000°C) and meets all environmental standards. The production process does not use chemical additives or dyes, and multi-colored clay is used as the starting material. Using this finishing, you can stabilize the temperature regime and increase the service life of the stove structure.

Clinker tiles

The clinker version does not have the same heat transfer as terracotta, but it is also popular for lining stoves. Among the advantages of the material are:

- Ability to retain heat for a long time.

- Durability.

- Presentable appearance.

The disadvantage of clinker tiles is their slow heating.

Majolica

The material was named after the tropical island of Mallorca, from where it was brought to the Russian Federation. The lining of stoves and fireplaces with majolica symbolized the high wealth and elegance of the owners of the premises. The production of majolica is carried out according to the same principles as terracotta tiles, but a layer of design with a different shade or texture is applied on top of the clay. This makes the material expensive.

Porcelain tiles

You can cover the stove in your home with porcelain stoneware. This material is characterized by a long service life, water resistance and strength. It is also not afraid of exposure to chemicals, so the finish can be cared for using detergents.

Tiles

You can make a beautiful decorative stove using a universal solution - tiles. This finishing material is not afraid of temperature changes and is particularly practical. The back side of the tiles is equipped with special protrusions, which ensures reliable fixation of the masonry and tiles.

Cladding a home stove with stone

To finish the exterior of the stove with stone, you can use both artificial and natural materials. This finish is characterized by environmental safety, strength and durability, while it makes the stove design stylish and original. Natural stone is expensive, so only wealthy people can afford it.

An artificial option can be considered as a budget alternative. Outwardly, it does not differ from natural one and at the same time costs much less.

Soapstone chlorite

To line a brick stove, it is worth considering a material such as soapstone. It is created from volcanic rock, which is characterized by improved strength properties and heat resistance.

The cost of soapstone is quite high, which is due to the good marketing strategy of the brands that sell it.

Features of installation work

With walls, the technological process is no different from installing cladding in any other premises. The surface must be strong, smooth and clean. The base is first pre-treated with preventive agents against fungus and mold, then impregnated with a moisture-resistant primer to ensure good adhesion to the glue.

Bathroom floors are more difficult to work with. The most important point here is the arrangement of natural drainage of water from the entire area indoors.

One of the schemes for arranging drainage from a bathhouse Source kanaliza.ru

Here are some solutions depending on the relevant conditions:

- a drainage embankment is installed under the subfloor - this is permissible in the case of highly absorbent soil, when the risks of freezing and heaving are eliminated;

- drainage is formed from pipes, trenches or through a pit - it is necessary in dense soil, on top of which water can accumulate;

- a storage well is installed to forcibly remove liquid - the only solution when it is not possible to drain water by other means from under the building.

The simplest option is to connect to a centralized sewerage system. Here it will be enough to lay and embed a separate channel into the main line. The connection to the latter is made through fittings and siphons, which prevent the reverse flow of wastewater.

After arranging the drainage or sewer system, you can begin to work on the rough foundation. Here it is important to provide a smooth transition of the platform towards the drain hole for the floor in the bathhouse made of tiles with a slope. There can be one or several points.

Example of drain hole design Source sanamore.ru

As a rule, a space is formed between the floor and the ground for natural ventilation through vents. The second common option is to form a cushion of compacted sand and gravel, which subsequently becomes the base for a concrete screed.

Oven screen options

It is recommended to line the sauna stove with half a brick; this is the best option. If the screen is made as thick as a brick, it will take a long time to heat up. In addition, a foundation will have to be built for such masonry. If you resort to a quarter-brick design, the bathhouse room will warm up quickly, but the radiation will be harsh. Regardless of the thickness of the masonry, the distance between the surface of the metal stove and the wall varies in the range of up to 10 cm.

The screens can be a solid structure with ventilation windows, while the chimney is often also made of brick. Another solution is possible: to cover only certain elements of the furnace.

As for decor, there are many different options. The neatly executed masonry itself looks quite beautiful. The color of the red brick contributes to the design of the stove structure. At the owner's request, the bath stove can be faced with porcelain stoneware, decorative brick, natural stone, and tiles. The choice is a matter of taste and the costs planned for these purposes.

Criteria for choosing a full or partial furnace lining

Many bathhouse owners, having decided to line the stove with brick, doubt what type of cladding to choose. If you surround the device with brick walls on all four sides, you will get a complete one, otherwise it will be partial.

Whichever option is chosen, the difference will be in the control of convection. In simpler terms, problems may arise for lovers of Russian baths. If a controlled convention is organized, then it is possible to close it, in this case the hot air heats not the steam room room, but the brick casing, transferring the heat into the steam room softer.

To control the flow of warm air from bottom to top, special openings should be provided. If necessary, they are closed or opened using special doors or pieces of brick.

But open cladding, when the stove is not closed on one or more sides, is most likely an aesthetic aspect and a safety issue, since it is less likely to get burned from a brick than from hot metal.