Wood always contains moisture, even there are custom-made bathhouses built from kiln-dried lumber, their moisture content is not zero. According to GOST 8242-88, the moisture content of kiln-dried lumber is 8-12%.

This indicator does not change only in a dry and heated room. On the street, wooden elements gain moisture up to 18-20%.

When thinking about which log house to choose for a bathhouse or home, keep in mind that the moisture content of logs and timber varies and always decreases or increases (with chamber drying) over time.

Fluctuations in humidity within a small range during the operation of a log bathhouse are normal. It is observed even after reaching equilibrium humidity and is associated with climatic changes in relative humidity.

When dried under natural conditions, the log reaches the same moisture content as chamber drying provides. This must be taken into account when thinking about which log house to order for a bathhouse or home.

Natural moisture lumber

Log baths are the best solution. Log baths are cozy and environmentally friendly buildings. Coniferous phytoncides improve health, and solid wood walls are characterized by high heat capacity.

Chopped baths

Log houses are cut from logs of natural moisture. In the warm season, the inner surface of the walls dries more slowly than the outer surface, which leads to cracking. The main part of the cracks is located outside the frame of the bathhouse or house.

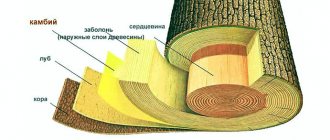

When building a new log bathhouse or house at different times of the year, the number of cracks due to drying of the wood does not change. But the intensity of the process can be reduced by leaving the subcortex (bast) on the log, which will reduce cracking. It is removed after shrinkage during finishing work at the stage of polishing the frame of the bathhouse.

Saunas made of rounded logs

Rounded logs are cheaper than hand-cut logs. The appearance of bathhouses made of rounded logs is presentable; due to the same volume of logs, neat exteriors are obtained.

For the production of rounded logs, blanks of natural moisture are also used. But machining increases cracking because all layers of wood are removed down to the vulnerable core. Therefore, significant cracks occur, log torsion and biological damage are observed. Rounded logs require intensive treatment with protective compounds, which ensures a long service life of the structure.

What functions should the finishing perform?

When choosing interior decoration for a bathhouse, you need to take into account several important points. The first question is whether additional finishing is needed in principle. If the bathhouse is built from large diameter logs, you can leave everything unchanged.

For buildings made of other materials, you will need clapboard or board. It will help create a special bath flavor inside the premises and provide high-quality insulation. Plus, the lining has different profiles and can be mounted vertically and horizontally, in the form of masonry or herringbone.

You can also use a block house or imitation log, and even an unedged board, which will give the interior of the bathhouse a special zest and unique natural flavor. To make the right choice, you need to familiarize yourself with the requirements for interior decoration in a bathhouse.

In addition to decorative ones, wall cladding has practical functions. It accumulates and retains heat, which allows you to spend a minimum amount of energy resources.

At the same time, the surface of the skin remains pleasant to the touch and does not burn.

To effectively perform its functions, the cladding material must have the following characteristics:

Be non-flammable. To give this quality to natural wood, it is treated with special compounds.

Absorb and retain heat without getting hot.

Have high moisture resistance and dry quickly.

Have a natural and environmentally friendly composition, do not emit harmful substances and unpleasant odors.

Chamber drying

Chamber-dried profiled timber is one of the options for building a log bathhouse. It is impossible to dry a chopped log for the construction of a log house for a bathhouse or a house, since the solid wood cracks severely, but timber and rounded logs can be dried to the following indicators:

- 12% outer layers

- 16-18% - internal part

But all kiln-dried lumber is expensive. Thus, the price for 1 m3 of rounded pine log of natural humidity with a diameter of 240 mm is 9,500 rubles, and a cube of rounded chamber-dried pine log of the same diameter costs 22,500 rubles. At the same time, to implement the project of a one-story 6x6 bathhouse, 30-50 m3 of logs will be required.

Advantages of chamber drying

- Dimensional stabilization

- Minimizes torsion and buckling

- Reduced cracking

Disadvantages of chamber drying

Research has shown that drying wood at high temperatures changes the physical and mechanical properties of wood. And before you build a log bathhouse in Moscow or another region, study the negative aspects. The exact figure depends on the drying technology and the type of wood. On average, this is:

- Compression along the fibers is reduced by 1-10%

- Radical chipping is reduced by 1-12%

- Impact strength – reduced by 5-11%

What kind of lumber can be dried in a kiln?

When thinking about which log house to choose for a bathhouse or home, keep in mind that it is unrealistic to dry a timber with a cross-section larger than 150x200, because wet wood will remain inside.

This is due to the fact that wood has low thermal conductivity, so in the chamber the internal layers are heated only to 50 °C, while the temperature sufficient to evaporate moisture is 100 °C or more. Such indicators are observed on external surfaces.

If we talk about rounded logs, then only pine with a diameter of 240 to 400 mm is subjected to forced drying.

Humidity of kiln-dried logs

Humidity 8-12% is found only in advertising; in practice it is higher. When installing a house and a bathhouse, the dry timber begins to absorb water until the outer layers reach equilibrium moisture. In different climates this figure ranges from 11 to 19%. The hygroscopicity limit is about 30% of the initial moisture content of the log from which the frame was built.

Pine

Pine is a good building material, but it is inferior in durability and durability to larch and cedar. It is quite durable and, if you do not plan to steam in the cold season, you will not freeze in a pine bathhouse. In addition, pine is the most affordable, so very often inexpensive baths are made from pine.

Benefits of pine wood

- Price - pine baths are the most inexpensive

- Strength

- Ease of processing

However, unlike cedar and larch, pine must be treated with antiseptic agents, because it is susceptible to rotting. The upper layers of wood are softer, able to absorb moisture and are especially susceptible to “blueing” of the fabric. Such a bathhouse will not last you long, but as an option for an inexpensive summer bathhouse for 5-7 years, it is quite functional.

Disadvantages of pine wood

- Fragility

- High thermal conductivity - pine baths are “cold” and quickly release heat. You can't steam in winter

- The need for additional treatment with antiseptic compounds

If you plan to steam in a sauna both in winter and summer, then cedar is more suitable. The sauna will serve for a long time, reliably and will help improve the health of the body.

Glued laminated timber

It is believed that laminated timber does not shrink, but in practice the shrinkage rate is 1-2%. Cracks in such houses and bathhouses also occur. In addition, there is laminated veneer lumber, made using glue of different qualities, which affects the environmental friendliness of the product.

The different quality of wood used to make lamellas and the degree of toxicity of the glue do not affect the humidity of wooden houses and bathhouses. All other things being equal, the quality of a bathhouse or a house made of laminated veneer lumber is influenced by the price of the wall kit and the cost of assembly work.

Internal and external cladding of the building

For a steam room, it is better to choose wood without a high resin content.

The materials used to decorate the building outside and inside have different requirements. It is important that the tree tolerates the environmental conditions in which it will be used.

Internal lining

The conditions of the steam room are more demanding in terms of the choice of materials than other rooms (shower room and relaxation room). Coniferous trees tend to overheat, and some hardwoods tend to rot from high humidity. The best options for a steam room would be linden, aspen and alder. A fragment of a wall with an area of 1-1.5 m² can be sheathed with cedar - this will give the room a pleasant smell. But it is important that visitors do not touch this area with their skin.

In the shower, the temperature is not so high, but there the wood is in direct contact with water. Larch is a good choice due to its moisture resistance. A budget option is to decorate the room with coniferous wood, but then you need to pay special attention to antiseptic impregnation. Pine and spruce are also suitable for the dressing room and rest room. It will be possible to warm up in them in winter, since coniferous wood retains heat well.

Facade finishing

Thick larch lining is suitable for this purpose. The main criterion for cladding the facade and veranda for summer recreation is moisture resistance. Therefore, any material is treated with an antiseptic with water-repellent properties and a varnish coating.

Features of construction from wood of different humidity

1) When building from logs of natural moisture

the main task is to compensate for the process of shrinkage of the log - that is, the loss of moisture from the wood to an equilibrium state. Loss of moisture along and across the fibers occurs at different rates, which is a characteristic property of anisotropic materials, which include wood.

The use of shrinkage compensators for the log house of a bathhouse and their constant regulation during shrinkage, processing of the ends of the log house, and the absence of rigid fasteners in the structure help to compensate for the processes of changes in the linear dimensions of the log house. After the main shrinkage is completed, the inter-crown gaps and cracks are sealed with acrylic sealant, which completely solves the problems of heat loss and aesthetics.

2) When building a bathhouse or house from chamber-drying material, the reverse process is observed:

the wood gains moisture to equilibrium. During the process, the timber or log swells and the connections between the structural elements are destroyed. To ensure the solidity of the log structure of a bathhouse or house, various metal fasteners are used, which are susceptible to corrosion and cause wood to rot.

About the rules for harvesting logs for the construction of a log house

Harvesting is the most important process on which the condition of the log house will depend for many years. Coniferous wood is selected for the log house; rot and wormholes are not allowed. The wood should be even, preferably of equal thickness. Harvesting is carried out only in winter, at the beginning. At this moment, the moisture content of the wood is minimal, and the content of natural resin and essential oils, which are natural antiseptics, is the highest. Such a forest is much less susceptible to wood diseases.

The diameter of the logs is important when logging, minimum 220 mm, the largest is considered the best.

After harvesting, the timber is transported as quickly as possible to the place where debarking will be done.

When debarking, it is also important not to damage the top layer of the log, under the bark and bast. The inner loose layer is more exposed to the environment, and drying occurs too quickly

Because of this, the surface of such logs may end up with cracks. Carpenters say that deep centimeter cracks appear only in logs that were processed mechanically, with milling cutters or electric jointers.

After the bark is removed, it is collected and burned, since tree beetles and other unnecessary company usually live in the bark.

If trees are cut down at the beginning of winter, they can be kept without removing the bark until spring. During summer felling - no more than 15 days. The fungal disease, noticeable to the eye as the blue discoloration of the trunks, begins to progress when the air warms above 10⁰C. When selling timber, they always tell buyers about the complete harmlessness and ubiquity of “blue stain”, but it is still a disease, and it is better to do without it.

After the logs are debarked, they are stored in stacks with ventilated intervals of 4-5 cm for ventilation and drying. The stacks are assembled on scraps of logs or thick boards with wedge stops at the ends to prevent the logs from rolling out. Under the stack you need waterproofing - a layer of thick polyethylene film or any other rolled material.

The logs in the bottom row are preferably of the same diameter. The next row of logs is laid on boards attached to the logs of the bottom row. The boards should be no thinner than 80 mm. The stack structure must be rigid and fixed in both directions. A gable roof is installed on top of the stack to protect from rain and snow. To make it more convenient to take logs to the log house in the future, thin logs are placed below, and the thickest ones are placed in the top row.

After laying the stack, all log cuts are coated with bitumen, PVA glue or clay so that drying occurs evenly along the entire length of the trunk.

If you plan to make a log house without compaction between the crowns in order to disassemble and re-arrange it permanently in six months or a year, then you can start cutting from undried logs. But if you are cutting a log house for a permanent place, immediately with inter-crown seals, then you need to take logs that have dried in a stack for at least 1 year.

Everyone understands that if you cut it from a damp forest, and in order to avoid the problem of mold and mildew, do a copious antiseptic treatment, there will be no particular benefit from such a tree. In addition, it may not help, since the wood, which has moisture inside, cannot be saturated with an antiseptic; it will only affect the top layer of the log. Even worse is to varnish raw wood, even with antiseptic treatment. This is a sure way to create conditions for the rapid spread of rot in the inner layers of the tree. The service life of such a log house can be approximately estimated at 15-20 years, in conditions of constant deterioration in environmental friendliness and safety. Drying logs to “equilibrium” moisture content should take at least two years, this is the traditional technology. And if you follow it, then you will not see cracks in the walls, strong shrinkage of the house and various cracks in the corners in your house, as well as wood diseases. A wooden frame can last more than 100 years; this has been proven over centuries of construction practice. Will serve both children and grandchildren.

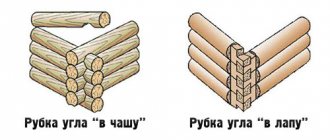

The next topic is about the design of the log house and cutting methods.

conclusions

Modern wooden baths and houses have many differences: the humidity of the walls, the shape of the crowns, the exterior and interior, the final cost, and environmental indicators. The most important thing to understand is that it is not the initial moisture content of the log or beam that is important, but the result of construction after a few years. The quality of the forest plays an important role. The table shows the main quality indicators of lumber in accordance with GOST 9463-88.

When deciding which log house to choose for a bathhouse or home, remember that high-quality profiled timber is not much inferior to expensive laminated veneer lumber. A rounded log that is properly processed looks better and lasts longer than an unkempt log.

Construction is carried out from “living” material – wood. Problems with further operation arise only for two reasons: non-compliance with the construction technology of log bathhouses and houses and lack of proper care for the wood.

Arrangement of the bathhouse from the inside

Having decided which wood for the bath you will use when building the walls, you should not forget about what will be inside. If you are afraid of the resinousness of coniferous wood, then you can additionally make interior decoration from lining. What kind of wood is used to line the inside of a bathhouse? As a rule, hardwood is used. Of the conifers, cedar or larch are preferable.

Lovers of steam baths will ask the question: which wood is best for a steam room in a bathhouse? Experts recommend using hardwood: linden, aspen, alder, etc.,

Shower cabins have become popular recently, but a conventional plastic design is not suitable for a wooden bathhouse. Manufacturers offer wooden showers for baths that will harmoniously fit into the interior of the room.

Construction of a bathhouse is a responsible step that requires a competent approach. Now you know what type of wood is best to build a bathhouse from, but you need to take into account many more nuances. You need to weigh your wishes, calculate your strengths and capabilities, and only then begin construction. And in order for the construction to be short and of high quality, it is better to resort to the help of specialists. In this case, the bathhouse will delight you and give you relaxation and health for many years.

Comparative analysis

The thermal conductivity of the materials is approximately the same. In spruce, due to the higher air content in the wood, this figure is slightly higher. But pine walls can be much thicker, since the diameter of the tree trunks of this species is larger.

Article on the topic: How a sauna affects pregnancy

The durability indicators of spruce are lower due to high moisture absorption, which can provoke the occurrence of fungi, mold, and rotting. The resin content in its wood is lower, and, accordingly, their release into the atmosphere is also lower.

On a note! The evenness and smoothness of the trunks greatly simplifies the processing of pine. The difficulty of working with spruce is due to the knotty nature of the species, but this is compensated by the high decorative qualities of the log house.

Both types of wood darken in approximately the same time, but pine untreated with special compounds gradually acquires a more intense brownish-red hue. This problem can be solved by installing decorative cladding or using special impregnations.

Important! Wood treatment compositions must be safe for health, not melt when heated, and not emit odors or toxic substances!

The ability of spruce to absorb and remove moisture outside causes greater “dryness” of bathhouse structures than those made of pine, which is at the same time subject to “blueing.”

The price of both types of wood is approximately the same, and they can be easily combined provided that healthy raw materials are chosen and the logs are prepared correctly. For example, pine is the optimal material for constructing lower crowns exposed to strong humidity, and spruce is ideal for constructing the upper part of walls, since it has high heat-saving and decorative qualities.