Place for a bath

When choosing a place to build a bathhouse, you should take into account the terrain, geometric dimensions and shape of the land plot. It is desirable that the structure be located on a hill.

In this case, it is easier to organize the drainage of used water. The bathhouse is located on a self-constructed site so that the entrance to the building is visible from the house

What is the difference between Finnish and Russian?

The Finnish sauna uses heat-reflecting screens that create a “thermos” effect in the steam room. They are corrugated metal or crumpled foil with a shiny surface.

It is enough to install screens under the wall cladding of the heater furnace. There are also a few additional differences:

- The Finnish sauna is often dry. The heat will be evenly distributed throughout the body, warming painful areas and joints.

- In the bathhouse, due to high humidity, the temperature can reach 65 degrees. In this case, even the internal organs will warm up.

Before starting design, it is advisable to consult a doctor. Not every person today can afford to visit a Russian bathhouse.

Design work

The construction of the bathhouse must be carried out in compliance with the requirements of Building Codes and Regulations 02/30/97. The building assumes the presence of: a covered canopy, a relaxation room, a washing room, a steam room, and a bathroom.

The design stage includes the development of working drawings for the general construction part, special interior finishing work, water and electricity supply, sewerage system, natural and forced ventilation system.

Selection of basic materials for construction

Construction industry enterprises have a wide arsenal of building materials for building a bathhouse in the country. A frame-type bathhouse has the lowest level of labor costs during construction.

The most common material is still natural wood. The cost of the timber is not cheap, but the performance characteristics cause puppy delight. Brick is often used for construction.

Questions and answers

In the case of using boards to build a bathhouse, is it possible to use unedged material or will the quality of the structure suffer from this?

No. You can safely use unedged boards if you have no complaints about their appearance. The main thing is that the wood itself is strong and dry.

Why do you need a vapor barrier if insulation is already used to lose heat?

Insulation and vapor barrier perform different tasks. Vapor barrier prevents the destruction of wood due to constant ingress of water and exposure to high temperature.

Does the wood need to be treated again after some time has passed since it was put into use?

Necessarily. To prevent the wood from drying out, use antiseptics and fire retardants from time to time. To be on the safe side, all wood can be varnished again once a year.

What is better: an individual project or a standard building?

An individual project is much more expensive, so if you are building a budget bathhouse, you should focus on standard small-sized projects.

Where is the best place to install the door?

It makes no difference what kind of bathhouse you are building. Always install the door on the south side if you plan to use the steam room in winter. This way the snowdrifts will melt quickly and will not block the entrance.

A budget sauna is a reality that everyone can implement on their own site. Careful familiarization with the characteristics of materials for construction, as well as knowledge of where costs can be reduced, allows you to build a durable structure for relatively little money.

Bathhouse construction technology

Work on the construction of a simple bathhouse at the dacha is carried out in stages and begins with preparing the site. After laying out the site, the strip foundation is concreted on pillars made of polyethylene pipes. For the construction of walls, 150x150 mm softwood timber is used. The roof traditionally has two slopes and is covered with wavy slate.

The next stage of construction is interior work. Partitions between rooms are made of timber with a section of 100x100 mm. The stove can be made of ordinary red brick. It would not be a sin to use an electric heater or a steel stove.

Do-it-yourself bath, step-by-step instructions

Of course, the most difficult and important part of construction is the construction of the bathhouse box. The higher the walls and the heavier the roof, the stronger the foundation must be, so in some cases it is not possible to build a building in one season. We have to lay the foundation of the bathhouse in the winter and assemble the walls from timber. And only in the spring, after all shrinkage processes have been completed, will it be possible to build a steam room and even put it into operation.

Preparing the area

The required amount of work associated with the construction of a bathhouse box depends on how lucky you are with the soil on the site. Since most owners plan to build a bathhouse not far from the main household, the foundation and frame should not create problems primarily with the drainage of groundwater on the site.

The approximate amount of preparatory work is as follows:

- Marking is carried out at the site of laying the foundation, the direction of water flow is determined;

- The fertile layer of soil is removed and removed; the foundation and the bathhouse itself can only be built on a base with a depth of at least 30 cm; everything higher will need to be removed and removed;

- If the terrain of the site is flat and there are no natural conditions for water drainage, then drainage will be required. The design of such a system can be copied from home.

Important! It is extremely important to build a drainage system, since baths have always been a source of water. Upon completion of construction, after the foundation shrinks, the soil will subside and a puddle of rainwater will form around the bathhouse.

Project of a foundation with a “patch” for a steam room

The final stage of preparation is pouring a sand-crushed stone cushion under the slab for installing the stove. The foundation for the furnace will need to be built in advance and strictly according to the project.

Pouring the foundation

The best foundation option would be a strip foundation reinforced with steel or fiberglass rods. At first glance, it is possible to build a foundation using a simpler scheme. Well, this impression is erroneous, since the box in the bathhouse is very light, and if the walls are made of foam blocks, then the entire building will be supported precisely by the rigid reinforcement of the foundation.

Easiest to build on a concrete strip

For a standard bathhouse 6x6 m or 6x4 m, shallow types of foundation strips laid on a sand cushion are used. After the trench is dug, a sand-gravel mixture is poured to the bottom, waterproofing and a reinforcement frame 25-30 cm wide are laid. For a bathhouse, you can do a direct pour into the ground; the strength of such a tape will be enough to support the weight of the walls and roof. In this case, the rigidity of the base is considered more important than its load-bearing capacity.

The concrete-filled strip is covered with film and left for at least a month. And if, for some reason, you have to build in winter, then for at least 3 months, to gain strength and shrinkage. The upper basement of the bathhouse foundation will need to be built from red brick. The concrete is pre-treated with mastic waterproofing or sheets of roofing material are laid, only after this it is possible to build a base up to 30 cm high.

Construction of the foundation is considered one of the most expensive. For example, if you order the construction of a foundation strip for a 6x6 m bathhouse, then most companies will agree to build for a price tag of at least 1.8-2 thousand dollars.

Communications supply

In order for the bathhouse to be used normally, it is first necessary to provide for the presence of sewer pipes and water supply. All other communications, including electricity or gas, are supplied “over the air”. Therefore, before building a brick bathhouse base, pipes are laid in its wall, through which water supply and sewerage will be installed in the future.

If you do not do this, then after erecting the walls you will need to drill holes in the base using special carbide annular drills. The technology is quite mature, but requires certain costs and equipment.

Construction of bath walls

With the laying of foam concrete blocks everything is quite simple; the first row is laid on waterproofing with the obligatory jointing with a reinforcing belt. Foam blocks are easy to process, so building a wall from foam block material is not particularly difficult; you just need to monitor the level and vertical deviation of the masonry.

According to the design, the box should shrink

Assembling walls from timber is somewhat more difficult. First, you need to decide on the selection of material for the first three crowns. It is this part in any bathhouse project that is considered the most vulnerable; the timber often rots and is damaged due to the large amount of moisture and poor waterproofing between the base and the crown. You immediately need to decide how to seal the gaps between the foundation and the timber. Polyurethane foam or any other mixture is not suitable for this purpose; the gap can only be sealed with mastic waterproofing.

Building a bathhouse box from timber is no more difficult than from foam blocks. Another thing is that the walls are less rigid and require additional packing of the cracks with special jute material or dried moss. The technology looks antediluvian, but in fact this is the best option for a bathhouse if you need to build a room that will last at least 20 years.

Creating partitions in the bathhouse

After assembling the main box, there is often a need to redesign the interior, build additional partitions, and separate part of the space for household purposes, storage of firewood and equipment.

According to the project, up to 80% of the surface of the bathhouse walls is covered with clapboard

Capital partitions inside the bathhouse are installed during the construction of the walls, all the rest are made using a frame method, for example, in a timber bathhouse they are sewn from wooden slats or remnants of timber. For foam block buildings, the partition can be built from a profile and plasterboard sheets. There is nothing unusual in this; a foam block box, as a rule, does not shrink, so there is no threat of destruction of additional partitions.

Bath floor

First of all, the soil must be isolated from the bathhouse premises, otherwise moisture and water vapor will penetrate and destroy wooden structures. The earthen base is covered with sand and laid with an insulating film, after which the question of how to build insulation and drain water into the sewer can be decided.

The simplest way is to lay a layer of expanded polystyrene sheets at least 100 mm thick. Waterproofing is laid on top of the insulation and a concrete screed is made. This is the so-called subfloor, through which dirty water will be discharged into the sewer receiving collector. Wooden joists are laid on top of the subfloor and the finished floor is laid. Traditional planks are laid with a gap between the floorboards to allow for ventilation and removal of moisture from the underground.

Creating a bathhouse roof

The humid atmosphere inside the bathhouse requires special measures to protect the ceiling. The ceiling has to be made double, in the form of a sandwich. In the lower part of the ceiling, covered with cladding, a layer of reflective thermal insulation is laid and vents are made, thanks to which it is possible to ventilate the room and remove condensation that has accumulated after bath procedures.

Metal slate roof

The roof structure of a bathhouse can most often be single or gable, usually uninsulated, with a cold attic. The main part of the thermal insulation is laid directly on the ceiling, so the rafters and roof sheathing are protected only by waterproofing and roofing. Moreover, the roof gables are made with enlarged ventilation windows in order to improve the removal of water vapor accumulating in the under-roof space.

It is better to build the ceiling and roof with backfill insulation

For large-sized bathhouses, the design often sets the roof in a hipped pattern, thus reducing the pressure on the walls and reducing heat loss due to improved wind flow.

Oven and shelves

It is impossible to build a comfortable and at the same time warm bathhouse without the right choice of stove. For modern projects, metal and cast iron wood-burning stoves, similar in design to potbelly stoves, are most often used. They warm up quickly, provide a huge amount of heat, and most importantly, you don’t need to try to build a particularly strong foundation; it will be enough to lay a sheet of thermal insulation on the floor.

According to the project, a gas stove-stove can be simply embedded into the partition

The second most popular is the electric heater. Its use solves a huge number of problems, for example, there is no need to look for a way to build a safe chimney. At first glance, it’s a trifle, but according to statistics, it is the incorrect arrangement of the chimney in the ceiling and on the roof that is the main cause of fires in a wooden bathhouse.

The use of electric heating elements will require making a separate project and building the grounding of the bathhouse in accordance with all the rules of the PUE. Otherwise, the slightest violation of the insulation can become deadly for the owners and visitors of the steam room. If we compare the economic part, then the use of firewood is considered more profitable than electric heating.

Internal equipment

The walls inside the bathhouse require additional thermal insulation and vapor barrier. It is necessary to insulate both foam block and timber buildings, regardless of the thickness of the walls. In addition, it will be necessary to build a ventilation gap between the outer wall and the insulation layer, otherwise the condensation that falls will quickly lead to the destruction of the timber or foam blocks.

The inner surface of the walls of the steam room and relaxation room must be finished with lining made of linden, aspen or cedar. Often, the design of a steam room is selected in such a way that the consumption of quite expensive cladding is minimal. It is necessary to construct the finishing of the shower room, dressing room and auxiliary premises from coniferous trees. In modern projects, this part of the cladding is usually made of waterproof MDF boards.

Additional accessories

In addition to the stove, the design of the bathhouse must be equipped with a full-fledged washing room and dressing room, so you have to purchase at least a shower stall, plumbing for the toilet and a boiler or heating tank for hot water.

Most connoisseurs of hot steam prefer to build and equip a full-fledged relaxation room with furniture, a sofa, room heating, and most importantly, effective ventilation.

Oddly enough, a long stay in a relatively small room with heated air and a large amount of water vapor is only possible with a normal flow of fresh air. Therefore, in any project it is very important to provide and build full forced ventilation, and not rely on simply ventilating the room using windows, vents and vents.

Recommendations from specialized experts

It is advisable to locate the building for bathing procedures as an independent building on an elevated site, which is remote from outbuildings and will not be at risk of being flooded by flood waters.

When determining the size of the bathhouse at the design stage, it should be taken into account that according to sanitary standards, one person must have at least five square meters of the total area of the building. Wooden structures must be impregnated with fire-retardant saline solutions.

Note!

- Do-it-yourself porch to the house - the best projects and construction ideas (125 photos of new products)

- DIY brick barbecue: diagrams, drawings, photos, dimensions. Review of simple and complex structures on a summer cottage!

- House with a bay window - 150 photos of the best planning and design ideas. Overview of all features of an architectural element

Foundation

A fairly common foundation design for a sauna house is reinforced concrete supporting pillars and a grillage. First, plastic pipes are buried into the ground to a depth of one and a half meters. Support pillars are placed around the perimeter and, without fail, at the corners of the building.

Frames made of class A3 corrugated reinforcement are inserted into the pipes and concreted, leaving the upper part of the reinforcing bars exposed. Now, along the perimeter of the house, formwork is made of multilayer plywood for the grillage, into which steel frames are inserted. After attaching the frames to the rods of the support pillars, the entire formwork is filled with concrete mixture.

Sewage system

When constructing the foundation, installation holes should be provided at the required level for laying sewer pipes. A drainage well up to one and a half meters deep is installed not far from the bathhouse. Then they fill it with large crushed stone to one third of the depth of the well, cover it with a wooden lid and install a ventilation mushroom.

The receiving manifold is made of plastic pipes with a diameter of 100 mm with a natural slope of five degrees. Wastewater receivers are installed from the washing department, sanitary unit, and only then proceed to the installation of floors.

Energy supply for the bathhouse

It should be remembered when designing a bathhouse that these are several rooms with a fairly high degree of humidity. Therefore, electrical equipment is subject to increased requirements for the degree of protection from elevated temperatures and moisture. Electrical work in the sauna house must be carried out in accordance with GOST 50571.7.702-2013.

Note!

- Do-it-yourself tandoor made of brick: ready-made drawings, dimensions, step-by-step instructions + 100 photo ideas

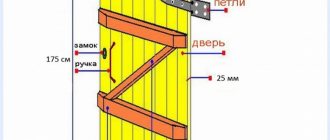

How to make a gate with a wicket with your own hands: step-by-step instructions, drawings, design dimensions, design, assembly and installation

Veranda attached to the house - 150 photos of beautiful and practical DIY options

For the recreation area, you can use LED lamps. The heaters in the steam room are connected with a copper cable in silicone insulation using high-speed protective shutdown devices for the current-carrying part. A properly installed energy supply system for a sauna house will protect users from electric shock.

What you can't save on

Even if the budget is very limited, it is strictly forbidden to save on the following points:

- Use of construction products without a quality certificate . Such building materials are several times cheaper, but there is no guarantee that they will not emit harmful fumes during use, especially when exposed to high temperatures. In addition, such materials can quickly fall apart and become completely unsuitable for further use.

- Saving on electrical wiring and related elements . You should not buy the cheapest sockets, hang uninsulated lamps and unsuitable wires. Such things will not only quickly fail, but they also increase the risk of fire and accidental electric shock several times.

- Use of unsuitable materials . If you want to save money, you should not replace recommended products with those that cost an order of magnitude cheaper, but at the same time, due to their performance characteristics, cannot be used in a bathhouse. This applies to insulation, flooring, and some types of wood. Unsuitable materials for specific conditions will not fully perform their task and will quickly deform or rot.

- Sauna stove and water heater . You should not buy handicraft products. They are not always safe; they may not be tightly sealed enough, which can cause a fire or burn.

Attention! Also, do not skimp on fuel for your sauna stove. Do not throw flammable materials into it that are not intended for use in enclosed spaces with high humidity and temperature. They can saturate the air with harmful substances, which will cause poisoning and even death.

Swimming pool in the bathhouse

Installing even a small pool in a bathhouse will require certain additional labor costs. The material for the pool can be reinforced concrete, plastic, metal, wood. The size of the pool depends on the financial capabilities and area of the premises. The reinforced concrete structures of the pool bottom and walls are plastered and decorated with ceramic tiles.

Oak boards prepared in a special way are used to make unique fonts up to one and a half meters deep. The most common pool metal is stainless steel. Drainage from such pools is periodically carried out by deep pumps into a nearby pond.

Bath shelves

Their width is about forty centimeters. They are usually made from pine or oak.

How to make a steam room

- Linden and aspen boards are used to decorate the steam room. Stone and ceramics are also suitable.

- Coniferous wood is not used because it releases resin when heated.

Small bathhouse in the country

Quite often there are cases where the size or topography of a summer cottage does not allow the construction of a full-fledged bathhouse. To realize your desire, you can agree to a small bathhouse in the country, the size of which in plan will be 3x3 meters, consisting of a steam room and a dressing room.

It is worth noting that a state of bliss can be achieved in such a small cozy bathhouse, if you do not elevate the degree of comfort of bath procedures to the rank of priority values. As a roofing material for a small bathhouse building, the most optimal solution would be polycarbonate sheets.

Note!

Do-it-yourself greenhouse - a review of the best ideas on how to build a good greenhouse on a summer cottage (80 photo ideas)

Do-it-yourself firewood rack for a summer residence: photos, examples of designs, dimensions. Review of simple and complex options for storing firewood on the site

- Do-it-yourself wooden gazebo - step-by-step instructions on how to build a beautiful wooden gazebo (100 photo ideas)

Which option will be the budget one?

The best way to make a bathhouse without spending a lot of effort and resources is to combine a steam room with a bathtub that already exists in the house. In this case, the owner will save himself from building a foundation and rough work, which takes a lot of time and resources.

The size of the bathtub is most often 3-4 m2 of total area. If the size of the building allows, the steam room can be expanded to include a locker room and the bathhouse itself. Such home structures should already have become trends, so manufacturers offer everything for quickly arranging a room. For example:

- High temperature heaters are available for purchase. The rays will emanate from the screen towards the person, warming up his body and internal organs. Infrared baths are recommended by experienced doctors, so there is no need to worry about radiation. This will be more effective than a budget sauna stove that uses stones.

- You can also purchase a ready-made sauna cabin. Companies often make them to order based on customer measurements. That is, there is no need to sheath anything additional; the camera is installed next to the bathroom.

For a small family, a 2 x 1.6 m cabin will be quite enough. At the same time, if the house uses stove heating, then you can make a room next to the heat source.

The preparatory work will not take much time; most importantly, the owner will be able to build several walls on his own. A mini bathhouse is often installed in the attic to save on sewerage by properly utilizing the free space.

Bathroom decoration

Working on the interior design of a homemade bathhouse in the country does not involve the use of expensive finishing materials. At the trade union price you can purchase finishing boards at any woodworking enterprise.

The flooring in the steam room and relaxation room is usually made of tongue-and-groove floorboards. Wood finishing materials when decorating the interior of bathhouses are not covered with paints and varnishes.

Design and layout of a bathhouse with a terrace

This is a small project, but at the same time a cozy bathroom. Such a structure can be considered as part of an estate or used as a separate element, as a mansion necessary for recreation.

The entrance is preceded by a terrace of 9.8 sq.m. M. Next comes a vestibule of 2.3 square meters.

This is followed by a transition to the rest room (15.9 m2).

From the bathroom, a corridor leads to the laundry room (7.8 m2) and then to the Turkish bath (7.8 m2). All rooms are arranged in such a way that only a minimal amount of heat escapes from the last room.

Much attention is paid to the heating and lighting systems. Windows are located in the billiard room, in the recreation room and in the smaller locker room. Therefore, even during the daytime there will be insufficient lighting. Solve this problem by using lighting in the lower part of the ceiling.

Modern Russian bath

A typical bathroom design involves the presence of several people at the same time. Consists of a vestibule, a dressing room (dressing room) and a steam room of 6-9 sq. m.

The most comfortable options include a shower, plunge pool or plunge pool.

Simple bathroom design with a swimming pool and shower

- In villages, toilets are often built with a laundry compartment to wash clothes and bathe children and the sick.

- The drum is needed to create a thermal barrier so that cold air does not penetrate inside.

Sauna with large relaxation room, shower, bath and small pool

- The dressing room area can be 4-6 square meters, with 1 window. In it you will relax and refresh yourself after a Turkish bath. For this you will need a bench 150 * 50cm.

Advice! The steam room door should not open towards the locker room, as the steam will wet the clothes. A more rational and economical solution in terms of space would be to make the exit from the doors of the Turkish bath and changing rooms towards the vestibule. This way you can heat the entire area from the stove.

- It is best to take a square-shaped steam room. To reduce the amount of heat leaving the Turkish bath, a high threshold and a small low door are made at the entrance. Also, for this, the height of the floor in the steam room is increased by 7-10 cm, and in the washing area, on the contrary, it will have to be lowered so that water does not penetrate into other rooms.

- A wood stove is usually installed in the corner by the door. Opposite are shelves for washing.

In the photo you can see an example of a project for a bathroom with a vestibule, a dressing room, a toilet, a toilet, a shower, a steam room, and a laundry room. The total area of the room is 24 square meters.

Variant of a modern Russian bath

The base is a concrete strip foundation or concrete blocks. The walls and beams are wooden. Slate is used for the roof.

Bathhouse with swimming pool

The classic Russian bathhouse does not offer such luxury, but today a pool in the bathtub is not uncommon. Selected projects boast a full swimming pool, gym and conservatory. But placing a small plunge pool under the same roof as a steam room is a common thing.

A one-story sauna measuring 8 * 10 will comfortably accommodate a spacious relaxation room, a separate steam room, a bathhouse and a room with a swimming pool. In this case, the entrance to the water block is through the rest room. The walk-through room, where three doors lead simultaneously, is the laundry room. You can only get into the pool from the Turkish bath through a shower.

A full pool can be replaced with a small pool. In this case, it is not necessary to allocate a closed room for these needs. It is enough to make the bathroom a little more spacious and install a hydromassage bathtub. This option is also suitable for small bathrooms.

Design and layout of a 7x12 bathhouse with a swimming pool

With a lounge and access to the terrace

A universal project that can be modified to suit the wishes of the potential user. Due to the versatility of all rooms, the sauna can be easily replaced with a steam room. Therefore, from the basic design, two very different designs can actually be obtained.

The first option includes a bathroom with a shower and a studio-style kitchen. The only thing that remains virtually unchanged is the bathroom with access to the terrace, which is present in both versions, even if it is significantly reduced in size.

The second option includes an additional dressing room and a full bathroom, which has both a toilet and a bathtub. This solution does not allow hosting a large company, but is more convenient from an operational point of view, as it clearly separates different functional areas. Therefore, the second option is more convenient for small businesses or families.

Consequently, this planning solution gives 17 sq.m of living space and 24 sq.m of total area. Another advantage of the project is the opportunity to enter the pool on the territory in front of the bathhouse, the presence of which always adds positive emotions from visiting the bathhouse.

Bathhouse with extensions

Another interesting bathroom layout option is to build a master bathroom that includes a steam room, laundry room, and possibly a bathroom. And all other rooms - guest rooms, bedrooms, recreation areas, a swimming pool and a jacuzzi - are built next to each other as needed.

Design and layout of a 5x12 bathhouse with a terrace

This option is ideal for those who use the sauna seasonally, during the summer gardening period. Or for those homeowners who do not have a large amount of money to immediately build a large complex.