Installing a floor in a bathhouse is one of the most important stages in the construction of a structure. A properly laid floor reduces the load on the foundation, which is distributed evenly, thus extending the life of the structure. Correct installation of the floor in the bathhouse becomes a guarantee of convenience and safety. In addition, compliance with the installation technology is also necessary due to the nature of the object, because the room regularly has high humidity and elevated temperature, as a result of the abundant use of hot and cold water. Therefore, it is necessary to approach the installation process, the choice of material and its processing especially responsibly.

Wood species for bath floors

Depending on the type of flooring being laid, one or another board is used for the bathhouse floor. Leaky floors are installed from ordinary planed, unpainted timber. Floors that do not leak are made of tongue and groove. These parameters relate to the technological aspects of installing the floor covering, but strength and durability depend on the choice of wood species.

The wooden floor in the bathhouse is made from the following types of wood:

- cedar;

- larch;

- oak;

- Linden;

- pine;

- aspen.

The main disadvantage of coniferous species is the presence of resin ducts with a secretion in the wood. When the air temperature regularly rises, the resin comes to the surface - “cries” with hot tears, which can cause serious burns on the human body. However, this disadvantage is short-term. After a short period of time, with regular use of the bath, tearing stops. This usually takes from five to ten warm-ups of the room.

Otherwise, coniferous wood consists of continuous advantages. The resins that they contain are recognized as the richest resource of natural antiseptics. Thanks to these properties, the boards are protected from putrefactive fungi, various parasites and microorganisms that quickly develop in a humid, warm environment.

When choosing a wood species, it is recommended to take into account not only aesthetic, but also expedient characteristics of the application. Knots and cracks require attention. Light knots are acceptable; dark ones may fall out over time. Most often, such knots are found in material made from spruce.

Features of tree species:

- Larch. Strong and durable wood. The composition contains essential oils that have a beneficial effect on the human body, including the cardiovascular and immune systems. It has antiseptic properties that protect against the formation of rot and fungi. The only drawback of wood is its high cost, which starts at 18 USD in the lowest class. per m2.

- Oak. Despite its strength and durability, it is practically not used in the construction of baths. Large weight and complex processing are significant disadvantages, but more important is the fact that with constant temperature changes and alternating dry and wet air, the board cracks.

- Cedar. It does not crack or dry out, does not deform and can withstand any temperature, and most importantly, it is not subject to rotting processes. Warm, pleasant to the touch and noble in appearance, the material has healing properties and has a beneficial effect on human health, as it contains essential oils.

- Pine. The most affordable material, and therefore the most popular in wooden construction. High-quality dried pine does not crack or deform. However, the material does not have resistance to fungi, rot and parasites that destroy the tree from the inside. This is why pine boards are not used as bath floorboards. In addition, they secrete resin for too long and in large quantities. The price of pine floor boards per m2 is from 9.5 USD.

- Linden. The most suitable material for baths. It has been used since time immemorial in the construction of classical Russian baths. Light translucent linden creates a special microclimate in the room. In addition, the tree has medicinal properties - it has a beneficial effect on patients with respiratory diseases, weak immunity and liver problems. However, with so many positive characteristics, it is not recommended to use linden in arranging the floor in a bathhouse. The board is susceptible to the formation of fungus and rot. The price for a linden board starts from 5.5 USD. per m2.

- Aspen. Inexpensive and easy to process wood. When properly dried, it does not crack or deform. It is not recommended as a base for the floor in a bathhouse, as it quickly darkens under the influence of high temperatures.

Larch

Larch is one of the most durable woods. This wood is used to make decking boards and materials for building facades. Larch is not afraid of water. That's why they decorate the area around the pools. As in the case of cedar, larch wood contains useful compounds. Which are not averse to being released into the air when heated.

Larch is not afraid of rotting due to the fact that it contains a natural antibiotic gum. It not only protects the tree, but also improves human health. At first, larch wood secretes resin. It may cause burns. And this is the main disadvantage of larch, along with the high cost of the material.

Necessary wood treatment before installation

Before you learn how to make a floor in a bathhouse, you should study in detail the information on the processing features of the selected material for installation. With constant use of the premises, the conditions can be called difficult, especially regarding the coverings of the steam room. The material is exposed to water, saturated water vapor condensing on surfaces, and sudden temperature increases.

There is no high temperature and steam in the sink, but the impact of chemical detergents and cleaning agents is added. Also equally important is the effect on the ground floor. During periods of high water, water can penetrate from below and flood the floor. Another negative factor is the large temperature difference between the room and the space under the floor. Favors the active development of various microorganisms, fungi and mold, and with them the process of rotting of boards.

Protective measures are more than necessary! Moreover, the question should be posed not about whether protection is needed, but what treatment agent to choose. The task of choice is complicated by the same specific bath conditions. The selected product should not be subject to decomposition under the influence of temperatures and hot water, and should not emit substances harmful to human health. Most materials become hazardous when used in a steam room. These are plywood, polystyrene foam, chipboard, and most paints and varnishes. The selected treatment agent, namely impregnation, must have an antiseptic composition with the possibility of maximum penetration into the wood.

Types of impregnation

Impregnations for wooden floors are presented in the following groups:

- antibacterial;

- moisture-proof;

- fireproof;

- whitening;

- darkening.

Antibacterial impregnations prevent the growth of all kinds of bacteria, and with them the rotting of wood, which is a natural process in conditions of high humidity during bath visits.

Moisture-proofing agents seal the wood after penetrating into the very depths of the wood, protecting the material from destruction. The label of each product indicates the degree of penetration of the solution and the type of wood on which it can be used.

Fireproof protective agents create a non-flammable layer on the outside of the board, but do not completely protect against fire. That is, no one cancels precautionary measures!

Darkening impregnations are purely decorative in nature, and often contain components that protect wood from moisture and microorganisms. Bleach helps delay the replacement of darkened boards for some time by applying local treatment to problem areas.

Construction and installation of a floor in a bathhouse on screw piles

Most of the presented products can also be used to process lags. They also need protection from rotting.

Wood floor treatment

The use of impregnations allows you to protect, but not completely prevent, the processes described above. In any case, it is necessary to resort to preventive measures:

- Ventilate the room after each use.

- Washing and cleaning the bath to minimize the possibility of unwanted bacteria.

- Periodic heating of premises even in the absence of operation.

However, let's return to processing the wooden floor. This is a fairly simple procedure. It is more difficult to choose impregnation. But once it is purchased, all you have to do to create the perfect protection is follow the instructions.

Step by step steps:

- Grinding the surface to be treated with a grinding machine or sandpaper.

- Cleaning wood dust with a broom or vacuum cleaner.

- Impregnation treatment after the wood has completely dried by applying with a roller and brush in hard-to-reach places.

- Impregnation is applied in several layers. You can use the same product or several different ones with different compositions. The combination of drugs will simultaneously protect the tree from moisture and bacteria. Between applying layers, be sure to wait until the previous layer is completely dry.

- Coating the floor with varnish or paint.

The last procedure is not mandatory, only advisory.

Construction and installation of a leaking floor in a bathhouse

There are several possibilities on how to make a floor in a bathhouse. One of the simplest options is a leaking floor. It does not require insulation. Only used when it's warm outside. A distinctive feature is the absence of drainage of used water from the surface, which flows through cracks in the floor directly into the ground. For clay soils, it is subsequently recommended to organize water flow into a well or drainage pit.

How to organize a leaking floor when laying joists on the ground:

- Leveling the site.

- Arrangement of the base by backfilling with gravel and compaction with compaction. On clay soils - create a slope towards the drain.

- Installation of support columns under the logs.

- Before installation, treat the joists with an antiseptic.

- Installation of logs.

- Wood flooring requires special attention in the area of the deck boards and walls, between which a gap of at least 3 mm should be left, which will prolong the useful life of the wood.

High-quality work makes it possible to lay a leaking floor for approximately five years. After a while it will definitely need to be replaced. Most often, pine is used for leaking floors, and a little less often - linden and aspen. The thickness of the board for the plank covering is at least 3 cm, the optimal option is 5 cm.

Advantages of pouring floor:

- quick installation;

- low cost;

- saving money on thermal insulation and waterproofing;

- drainage into a simple drainage pit.

Disadvantages of a leaky floor:

- impossibility of use in regions with cold climates;

- short service life and regular replacement;

- using only high-quality hewn boards.

Design and installation of a non-leaking floor

Non-leakage floor technology is more complex and consists of the following stages:

- Making a reservoir for collecting water.

- Installation of liquid drainage into a drain using a pipe of 20 cm in diameter at a slope of 5-7 degrees.

- Organization of a sand and gravel cushion for screed with mandatory compaction and tamping.

- Concrete screed, the thickness of which is at least 5 cm.

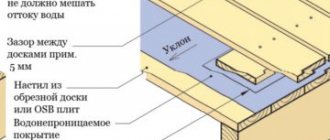

- Waterproofing the floor. This is a mandatory step, since it is impossible to properly make floors in a bathhouse without a waterproofing material, for example, ordinary roofing felt.

- Installation of logs and laying insulation between them in the form of mineral wool, expanded clay, polystyrene foam.

- Secondary waterproofing.

- Subfloor, which is an auxiliary floor.

- Finish floor. It should be done with a slope towards the drain. The flooring is attached directly to the joists using screws or nails.

The material most used when laying non-leaking floors is edged planed tongue and groove board with a thickness of at least 3 cm. Logs are wooden beams measuring 50x50 or 70x50, beams are logs 100x100 and larger.

The floor can be covered with different types of wood - both coniferous and deciduous. Most often, pine or linden is used for a bath. The approximate service life of this coating with proper installation and maintenance is more than ten years.

What is taken into account when preparing material

In addition to the choice of wood species, other characteristics also play an important role. First of all, it is necessary to take into account quality indicators:

- Grooved board. For the floor in the bathhouse, a regular or tongue-and-groove board can be used. The difference lies in the formation of the end. In the tongue-and-groove version, a longitudinal tenon is formed on one side, and a corresponding groove is formed on the other. As a result of the use of such products, a locking connection is provided, which makes it possible to tightly fit and create a leak-proof floor covering. Naturally, profiled boards have a higher cost, but the quality of the floor also increases significantly.

- Humidity. A very important parameter for any wood is the presence of residual moisture in the structure of the material. For the floor it is necessary to use only well-dried products, i.e. with minimal humidity. Wet wood will warp as it dries, causing an uneven surface. The optimal humidity value is considered to be within 7-9%, at least not more than 12-13%.

- Dimensions. The thickness of the board for the bath floor ensures its mechanical strength. In principle, it significantly depends on the properties of the wood, i.e. depending on the type of tree. So, when using an oak board, a thickness of 20-25 mm is sufficient; to ensure the same strength, a pine board with a thickness of 40-45 mm is required. Typical tongue and groove boards are offered in thicknesses ranging from 27-37 mm. The choice of this parameter is determined by real loads taking into account the area of the room.

On a note! The width of the board also affects the reliability of the flooring and the likelihood of deformation. The narrower it is, the lower the risk of its curvature in cross section.

The most commonly used board is 10 cm wide. If you use well-dried material, you can safely choose a width of about 17-20 cm.

Features of floors in different rooms

Any bathhouse has three required rooms:

- steam room or steam room;

- washroom or shower;

- dressing room or dressing room.

Each of these premises has special requirements regarding both the design and properties of the floor. The most careful consideration should be given to the flooring in the steam room and wash room.

A step-by-step guide to installing a floor in a bathhouse with your own hands

Points that require attention:

- Washing room. Allows you to use both types of flooring – leaky and non-leaky. When choosing, you should take into account the operating conditions. The main aggressive factor in the washing room is high humidity. That is, the floor will have to be changed regularly. This should be taken into account, leaving the opportunity for dismantling and drying the boards, as well as good ventilation, which will increase the service life of the floor several times. The ventilation system must be in place and work without failures.

- Steam room. Humidity and high temperatures allow the use of both types of flooring, and also require conditions similar to a shower room.

- Locker room or rest room. The operating conditions of indoor floors are almost no different from ordinary rooms with normal humidity and temperature. The ideal floor option is with a conventional design, without a water drainage system.

- Waiting room. Just like a locker room with a guest room, it does not require a drain or a special arrangement or floor design. The latter is made from convenient wood using suitable technology.

Standard design

In the steam room, the floor should rise slightly compared to the zero level. You can make it higher by only 8-10 cm, and the desired effect will already be achieved - maintaining a high temperature in the room is ensured. In the washing department the floor is made below the finishing level. This improvement will help prevent excess water from entering the remaining compartments of the bath.

When installing the floor in a bathhouse, it is important to follow the consistent laying of materials

- The most common floor design in a bathhouse (layers from top to bottom).

- Finish coating.

- Wood or concrete (final row).

- Small air space.

- Lining (small layer).

- Insulating layers (hydro- and thermal insulation is required, sometimes noise insulation is added separately if there are industries, clubs, or other establishments that are a source of noise near the bathhouse).

- Lathing.

- Insulating layers (in cold winters to protect the floor structure from cold or moisture).

- Rough floor.

- Wooden beams for sheathing.

- Waterproofing (laid on the ground).

The order of laying materials when installing the floor

Racks

The first thing you will need to install wooden flooring yourself is joists and beams. The optimal size is 150x150 mm. This is the supporting floor onto which the decking is attached. The lags are laid on supports in the form of brick or reinforced concrete columns. The thickness of the posts should be more than 150 mm, which allows you to get a slightly larger area under the joists.

The height of the racks must correspond to the top line of the foundation if using the strip option. A columnar foundation or on screw piles requires laying the logs at the same level with the embedded crown so that the upper horizon of the beams coincides with the upper line of the supports.

Before installation, all wooden elements are treated with protective agents, including an antiseptic. Only after this the waterproofing is laid with roofing felt, roofing felt, bitumen or glassine.

Preparing the foundation

First you need to carefully prepare the foundation.

At this stage, it is recommended to follow certain instructions:

- Floor joists are laid and fixed. It is best if the floor is made of larch in the bathhouse, but the more familiar pine is also suitable for this.

- Boards made of the above materials are attached on top.

- The lags must be laid out along the minimum distance between the walls, positioning them transversely to the direction in which the used water flows out.

- It is best to install support posts made of brick or wood under the joists so that the floors do not “walk” and are more rigid. For greater stability of the supporting elements, a reinforced concrete base can be installed under each, with an area slightly larger than the cross-section of the support.

In strip-type foundations, the upper support levels are adjusted to the top of the bath base; in other cases, the crowns of the embedded group are taken as supporting elements under the logs.

When placing the logs, it is necessary to maintain a slope in a certain direction in order to create the desired direction, guaranteeing the free flow of water. For this reason, it is best to place them with slight excesses, without adhering to the same size. When arranging a leaking structure, there is no need to maintain an inclined angle, because water will flow out through the cracks between the boards.

Underground

The choice of floor type and drainage of water in a bathhouse with wooden floors depends on the composition of the soil. If it easily absorbs water, like sandstones or sandy loams, then the issue will be resolved with little effort. It is enough to dig a hole and fill it with filtration materials. The filter can be ordinary crushed stone. Water will break against it and quickly seep to the drainage layer.

Clay rocks almost do not allow water to pass through. In this case, a hydraulic structure is installed in the underground from a tank and pipes leading into the pit. Water can drain by gravity or under the influence of auxiliary elements fixed in the structure.

For a non-leakage floor, drainage of drainage water is arranged in the underground, for which a hydraulic structure is used. Also of particular importance is the arrangement of floor ventilation, built on the presence of gaps and holes.

Which ones and how to lay them

We have selected several videos that will help even beginners understand the flooring process. Not all of them are talking about bath floors; which boards are laid is also not always obvious, but the technology is the same if tongue-and-groove material is used, and if a poured floor is made, then two templates of equal thickness are inserted to leave standard gaps.

The first video describes in detail the theory of creating all the floor devices used in the bathhouse and the drain underneath it.

In the next video you can borrow some techniques, but you still shouldn’t use a channel:

The installation of flooring on a balcony is shown here, but the good thing is that everything is done according to the rules, and the author also showed how to deal with low-quality material that is supplied in sealed packages graded A-B, which makes it impossible to calibrate it on site.

The authors of the following video, which shows the installation of larch boards with tongue and groove in a house, give a lot of hacks and tips:

Well, one last piece of advice: since the board will still be deformed from moisture, lay it so that a hump is formed on top. To do this, at the end you need to look at where the arc of the annual rings is pointing - correctly, so that the arc bends downwards (the hump of the arc is downwards) - it will lead in the opposite direction. If installed correctly, the water will drain and the floor will be less likely to rot.

Good luck with your flooring so that you can live longer without repairs! In addition, readers will be interested in materials on the construction of the roof and ceiling of the bathhouse.

Joists and flooring

Leaky flooring types are installed quickly and easily. The first board is rigidly attached to the wall with nails, and the rest are laid relative to the first in increments of 40 mm, which allows for sufficient gaps for water to drain out. This design does not require a specific method of laying joists, so you can start laying them from any wall.

A non-leakage floor requires a slight slope in the direction where the water drain is located. The installation of a leak-proof structure begins with a rough flooring, to which an insulation cushion is attached, including systems of vapor barrier, waterproofing and thermal insulation layers. A finishing coating is laid on top. These should be tightly fitted edged or tongue-and-groove boards, which are secured with nails or cap screws.

Installation of heated floors in a bathhouse

Opinions about the need for a warm floor in a bathhouse on wooden floors are divided into two opposing points of view. At the same time, competent organization of the process, observance of subtleties and nuances will allow you to install a completely safe system.

In the bathhouse, the floors can be water or electric (film and cable). It is better to give preference to an electric heated floor, since it has many advantages that a water floor, built on the assembly of water pipes, requires reinforcement of the floor with a reinforced screed, does not have. The electrical system is easy to install and is sold as pre-fabricated units, neatly placed on a backing that is poured into concrete.

Important! Conductive systems with heating cables must not be installed in wooden floors. It is better to opt for infrared heated floors.

When installing heated floors, you should pay more attention to the floor covering being laid. A tiled floor will heat up faster; wooden grates can be placed on top. If we are talking about laying a wooden heated floor, then it is better to entrust the work to professionals. The main thing is to know that this type of flooring is possible and has a lot of advantages, one of which is quick drying of the wood, which will avoid the appearance of parasites and rot in the material.

Material moisture

Bath floor boards can be tongue-and-groove or non-groove, have a smooth or grooved surface. In this case, an important indicator for wood is humidity.

Wet material dries gradually, over time, at a deeper level.

When purchasing a wet floorboard for a bath, the normal humidity parameters at room temperature are 12%. Under other conditions, the material should dry naturally.

- If the tree purchased by the client has a cylindrical trunk, during drying and subsequent cutting it may shrink and twist.

- In this case, cracks may appear. For these reasons, you should buy bath flooring with standard humidity parameters.

- And if they are exceeded, the material must be dried naturally.

- Only then will the floorboard be smooth and last a long time in conditions of high humidity.

Tips and tricks

Laying a wooden floor is only valuable when done with your own hands. To facilitate and simplify the work, you should listen to the advice and recommendations of specialists:

- The boards are laid so that water flows easily along the joint line.

- Large beams avoid accumulation of moisture under the floor, as they form a gap of 150 mm.

- To dampen or reduce footstep noise, fiberglass is installed under the floor. The material is placed on the waterproofing layer, only after that the logs are installed.

- The boards to be laid must be well dried. Humidity should not exceed 15%. Otherwise, the tree may twist, dry out, delaminate, or undergo any other type of deformation.

- Ventilation requires proper drainage. It is brought out from under the floor along the wall into the attic with a separate pipe.

- Boards with a tongue-and-groove system are an ideal solution for leak-proof flooring.

- Non-rotting materials are used as insulation - expanded clay, expanded polystyrene, polystyrene.

- Normal underground ventilation depends on the presence of ventilation holes in the foundation, which are required.

When installing wooden floors in a bathhouse, it is necessary to take into account the type of soil and foundation, the functional purpose of each room, as well as the microclimate and its features. These parameters should be taken into account not only when choosing the type of floor, but also the wood from which it will be installed, as well as the features of installation work and the presence of waterproofing with insulation.

Board dimensions

The dimensions of the board directly depend on the characteristics of the room and its size. When determining the width, it is important that the building material matches the size of the room. Otherwise, users will need additional tools to trim it.

Important! the floorboard does not fit in close proximity to the wall. The standard gap should be 1cm.

When choosing thickness, you should pay attention to the rigidity parameters. It is important that the floorboard does not sag or bend.

High-quality flooring must be installed in accordance with installation requirements, in particular, the ratio of the thickness of the material and the distance between the joists must be calculated in advance. The smaller it is, the stronger the flooring.

Important! If you have no experience in designing and carrying out calculations, you should seek the help of specialists and do not make ill-considered decisions.

If the owner of a bathhouse expects short-term use of the material (replacing the board after 55 years), you can start building a floor for the bathhouse without any special calculations.