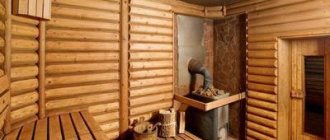

The traditional material for building a bathhouse is wood. And this is no coincidence; the benefits of bath procedures are most fully manifested in a log steam room, in which a special microclimate is created, filled with the healing aromas of natural wood. But on the other hand, high humidity and extreme temperatures characteristic of a steam room do not have the best effect on wood, which quickly deteriorates in such conditions. Treating the bath with oil will help prevent destructive processes. In this regard, in the article we will focus on two main points: what are the best oils and impregnations to use in a steam room, as well as how to properly treat the internal surfaces of a bath with oil compositions.

The need for bath treatment

As noted above, a bathhouse is a room with special conditions in which high temperatures and humidity are constantly present. Wood is characterized by high hygroscopicity, that is, it strongly absorbs moisture.

In a steam room, the tree becomes an ideal environment for the development of pathogenic processes. Microorganisms appear in it, insects settle, mold and mildew form. As a result, the tree can completely turn black and turn into dust.

Once the process has begun, it is very difficult to stop, especially when it comes to a fully functioning steam room. To prevent the occurrence of such manifestations, it is necessary to protect all internal parts of the bathhouse frame in advance at the construction and finishing stage by treating them with special compounds.

There are many products for interior treatment of a wooden house and bathhouse. This review is dedicated specifically to oils, so we will only consider oil formulations.

The relevance of the use of protective compounds

There is an opinion that using materials from expensive types of wood and proper ventilation is better than treating wood in a steam room

means of paint and varnish production. This is explained by clogging of pores, the chemical composition of liquids and mastics, and the need to periodically update the coating. The latter cannot be done without mechanical cleaning of the surface of the lining, which damages the wood fibers.

Let's figure out whether it is necessary to process the lining in the steam room. Intensive ventilation of the room really allows you to remove moisture and dry the lining. This helps reduce the risk of mold, mildew and bacteria to a minimum. However, biological damage is not the only phenomenon that leads to the destruction of wood.

In the bathhouse, the temperature rises and falls. Any tree changes in volume because of this, which leads to the appearance of cracks.

Cracks in the lining Source www.svoyidoma.ru

And they become favorable areas for the development of bacteria, fungus and mold. In addition, microvoids quickly become dirty. Without a protective cover, the lining turns black, regardless of its resistance to changing operating conditions. As a result, whether it is necessary to process the lining in a bathhouse is a necessary measure.

What oils are suitable for baths

Oil is a traditional bath treatment product. In earlier times, when there was not such a variety of means for protecting wood, steam rooms were covered with expensive oils of anise, rose, and lavender.

These compositions not only protected the log walls from moisture and rot, but also filled the room with a special natural aroma. Inexpensive hemp and linseed oils and wax were also used for processing, which have not lost their relevance today.

All oil compositions used in the steam room can be divided into two large groups:

- For treating walls and ceilings.

- For impregnation of benches and other surfaces in direct contact with the skin.

General requirements for oils for steam room processing

- Oil impregnation should provide reliable protection to the wood, and at the same time should not deprive it of its ability to breathe.

- An important condition is the environmental friendliness of the oil composition. Therefore, to cover the bath room you need to choose natural products. Synthetic impregnations contain chemical components that, when exposed to high temperatures, form harmful volatile compounds that are released into the atmosphere. In a small confined space, harmful substances are especially dangerous and can cause serious poisoning.

- For a bath, it is necessary to use moisture-resistant impregnations that are well absorbed into the wood structure, protecting it from moisture.

Products for treating walls and ceilings

When choosing a wood preservative to cover the internal surfaces of the steam room, in addition to the special conditions of the bath room, it is necessary to take into account the type of building material. Usually these are logs or clapboards. For floors, walls and ceilings made of these materials, you can use non-toxic acrylic-based varnishes, which do not emit any odor at high temperatures, natural oils and waxes, as well as special impregnations for saunas.

Acrylic varnishes form a protective film that can withstand temperature changes and exposure to water and steam. The varnishes contain antiseptics, so the surfaces do not require additional antiseptic treatment. Natura Teknos acrylic varnish has proven itself to be excellent, forming a translucent protective coating under which the wood grain is clearly visible.

One of the best means for internal treatment of wooden surfaces of a log bathhouse and a log house is linseed oil. This is an inexpensive natural product with antiseptic and hydrophobic properties. The oil penetrates into the deep layers of wood, providing it with reliable protection. The composition can be used both in pure form and in the form of a mixture with beeswax.

In addition to the pure product, there are various impregnations on sale based on linseed oil, which contain natural resins and pine turpentine. The most popular products are those under the brands Caparol, Tikkurila, and Remmers.

Oils for bath canopy

Manufacturers produce special oils for shelves that do not form a film on the surface, since when heated it can cause burns. In addition, the impregnation must be of high quality and should not cause allergic reactions on the skin.

- The oil compositions Sauna Natura from the Finnish manufacturer Teknos, Supi Laudesuoja from the Tikkurila brand, and Eurotex Sauna have proven themselves better than others in this group of products.

- A good wood preservative is carnauba orange oil wax. The product contains flaxseed and orange oil. The composition turns out to be very thick and resembles mastic in appearance. It is used to cover benches and backrests in saunas.

- Another product used to treat floors is beeswax. In addition to wax, the composition includes linseed oil and gum turpentine. This impregnation is less resistant to high temperatures than carnauba wax, so the coating will have to be renewed periodically, because Over time, its protective properties weaken.

Briefly about the main thing

To process lining in a bathhouse, materials that are resistant to temperature changes, humidity, and washing are used. Also important is inertness to fungus, mold, bacteria, and a safe composition for humans.

When heated, many materials release toxins and other harmful substances, so the use of antiseptics, fire retardants, drying oils, varnishes with solvents and acrylic resins is unacceptable for the steam room.

For walls and ceilings, impregnations, mastics, oils and some varnishes are used. For shelves only oil or wax based formulations. This prevents the formation of a thick film to avoid burns.

Bleach is used in any room of the bathhouse, but before further processing of the wood, it is necessary to wait until the chlorine evaporates and the hydrogen peroxide decomposes.

Antiseptics and fire retardants are classified as pre-treatment agents for wood, but are not used as independent coatings. They protect the lining and help reduce the consumption of the finishing coating.

Ratings 0

Rules for applying oil impregnations

- Before applying impregnation, the surface is thoroughly cleaned of dust and dirt and, if necessary, the old coating is removed.

- Then the wood is sanded, dried and the dust and shavings formed as a result of sanding are removed.

- The impregnation is mixed well and applied to the surface with a short-bristled brush.

- Within 7-10 minutes after treatment, remove excess with a soft, lint-free cloth.

- The surfaces are allowed to dry and then polished.

- If necessary, repeat the treatment.

The drying time for each layer ranges from 4 to 24 hours. The exact time required for a particular product to dry is indicated in the instructions. In addition, the drying time is affected by the humidity and temperature of the room, as well as the absorbency of the wood species. In any case, it takes at least a day for the surface to dry completely.

How and with what to cover the shelves so that the coating lasts longer?

The durability of the coating on a wooden surface depends not only on the composition of the product applied, but also on the tool used, application conditions, number of layers, etc.

What is better to process - tool

If you purchased a store-bought product for bath shelves, the instructions will tell you what to use. However, there are not many options.

Either it will be

a brush (pay attention to the instructions - in some cases they write that it should be made of natural bristles ), or a clean cloth. In some cases, you can use a sprayer. Again, different impregnation compositions can be either ready-to-use or require heating.

If you use homemade impregnation , then before starting work you need to heat it to 50-60 degrees.

The brush is used only if the impregnation is sufficiently liquid . The stripes it applies should not overlap so that “steps” are not created (this applies to hardening impregnations). The brush is very convenient for applying oils.

A cloth is better for waxing . When rubbing the thick mixture, try to distribute it evenly, but you don’t have to remove the excess right away. If, after applying the layer, you heat the oven, then there will be a classic “waxing” - the wax itself will spread as it should. (When waxing items not for a bath, they are heated with a hairdryer or burner.)

How many layers

The number of layers of impregnation is also usually specified in the instructions. Since the means are different, we will only venture to roughly name the number of layers and the time interval between them. Let's say it's two coats applied one hour apart.

The number of layers depends on both the properties of the impregnation and the porosity of the wood. The more pores, by the way, the higher the consumption of the product - it can increase by about two times.

Regarding the drying time : they are also different, in some cases a day is enough (according to the instructions), in others the time can last up to two weeks.

How often should the coverage be renewed?

The answer to this question depends on what tool you used. The fact is that oil impregnation, although it is easier to apply than wax impregnation, also lasts much less than the latter.

So, for renewing a layer of oil impregnation, the period is called from six months to 2 years, and for wax impregnation - several years (without specification).

However, you should focus on the condition of the wood. If you used tinted impregnation, then you can see from it exactly where it came off. If the impregnation is colorless, focus on the condition of the wood - has it become wetted with water and swollen from it? In these cases, of course, there is no need to wait for the time promised by the manufacturer.

Features of oil treatment

- If pure oil (usually linseed) is used, it is heated to 50-60 degrees before processing.

- The composition is applied either with a brush with natural bristles or with a cotton cloth.

- Apply the oil in a thin, even layer.

- The product is applied 5-6 times with layered sanding.

- After covering the next layer, wait for it to dry, then sand and apply the next one.

- It takes at least 2-3 weeks for a surface coated with linseed oil to completely dry.

If a mixture of oil and wax is used to process the bath, then the ingredients are taken in a 2:1 ratio to make it. To prepare the product, add heated wax to hot oil and then mix well.

The mixture is applied with a foam sponge strictly along the fibers. When the first layer has dried, remove the residue with a waffle cloth and treat the surface again.

Processing Tips

To extend the service life of wood, it is recommended to treat surfaces with protective impregnation at least once every two years. It is better to plan these works for the autumn. You need to choose the impregnation that is marked that it is intended for use in bath conditions (appropriate temperature, humidity).

An antiseptic for a bath should be applied exclusively to a cleaned surface. From the wood, you first need to clean off the old varnish, paint (if there was any), damaged layers, sweep away the dust, and then apply the product only with a soft and wide brush. To prepare the surface, it is most convenient to use a grinding machine.

To add a tint to the protective impregnation, you can add a little dye. The lower crown of the bathhouse frame is best treated with a bitumen-based composition; it perfectly protects against rotting.

The foundation must be protected with waterproofing, otherwise it will begin to rot over time. It is advisable to cover surfaces that will most often come into contact with water with several layers of impregnation. You can use the bath only after the composition used has completely dried.

The traditional material for building a bathhouse is wood. And this is no coincidence; the benefits of bath procedures are most fully manifested in a log steam room, in which a special microclimate is created, filled with the healing aromas of natural wood. But on the other hand, high humidity and extreme temperatures characteristic of a steam room do not have the best effect on wood, which quickly deteriorates in such conditions. Treating the bath with oil will help prevent destructive processes. In this regard, in the article we will focus on two main points: what are the best oils and impregnations to use in a steam room, as well as how to properly treat the internal surfaces of a bath with oil compositions.

Why is there impregnation in the bath?

Since wood is a natural and absolutely safe material, it is often used for interior decoration. But at the same time, it strongly absorbs moisture, as a result of which the surface becomes loose and is an excellent habitat for microorganisms, in particular fungi. Bacteria that have settled in wooden cladding through their vital activity provoke deterioration of the material and the collapse of the structure.

The market offers a fairly wide range of impregnations for saunas and baths, which are capable of creating a coating that protects the casing from the destructive effects of high humidity and temperature changes. In addition, they have excellent antiseptic properties. The undeniable advantage of such products is the ability to give the surface an attractive appearance, performing the function of a decorative finish.

Note! When choosing impregnation for baths and saunas, you should give preference to products that do not emit toxic substances.

Antiseptic impregnation for a bath allows you to extend the service life of the internal lining, preserve its appearance, and protect it from rotting and mold. These are unique products that do not form a film on the surface of the wood and do not prevent it from breathing.

Why is it necessary to protect all elements of the steam room?

A properly constructed bathhouse has high-quality hydro- and vapor barriers.

Wooden elements: bath bench, shelves, table, etc. must also be protected from external harmful influences. This is especially true for the steam room, where it must be safe and durable. The bathhouse shelf is sanded and covered with Tikkurila antiseptic.

The steam room is the main room in any bathhouse; the shelf needs to be strong and safe. Exposure to hot steam and water makes the tree vulnerable, and without special treatment the canopy will last no more than 1 year. It is not customary to make a canopy made of anything other than wood in a steam room, and this material does not like water. If you take high-quality wood and carry out proper processing, the wooden structure will last a long time.

Initially, it is necessary to take into account the type of wood from which the structure is made. The shelves are made from aspen, which hardens when exposed to water, linden with a pleasant soft texture, it does not heat up at high temperatures, or alder. The latter is difficult to find in construction markets, so it is used less often.

Any type is not afraid of hot steam and is easy to process. The price of the material is higher than that of pine or spruce, but it is better to overpay once. There are several types of wood that are not very common in Russia, but are imported to us from southern countries. These include: abash sedela, ofram, miranti. They have a pleasant texture and are not afraid of moisture and steam. Their prices are high. They are used mainly in expensive finishing.

Any shelf, made from expensive abash or our linden, must be treated with special compounds for the steam room after installation.

You can often hear user reviews that it is better not to process shelves at all. The fact is that incorrectly selected compositions can negatively interact with human skin at high temperatures. The shelves are simply sanded to a completely smooth polished surface. Experts are always debating whether or not to treat shelves. It is impossible to give a definite answer. It is bad not to treat wood, since in bathhouses with poor ventilation the shelves quickly darken and become moldy; it is also not worth treating with a low-quality composition. Everyone chooses for themselves, but if you decide to leave the shelves untreated, then high-quality ventilation is necessary.

What is the benefit of processing

Almost all owners of personal plots who build steam rooms strive to build a room not only for washing, but for comfortable relaxation. That is why they choose natural wood as the building material for the shelves, which is ideal for a steam room. The technical characteristics of lumber make it possible to use wooden boards in rooms with extremely high air humidity, but at the same time, the service life of natural raw materials without pre-impregnation of the shelves is too short.

Since the high hygroscopicity of wood leads to the rapid absorption of moisture, the material of the shelves becomes an ideal place for the appearance of various kinds of microorganisms. The result of all these processes will be rotting of the wood. It turns black, fungus and mold appear on it. Often, the lack of impregnation leads to the accumulation of a large amount of dirt in the pores of the wood, which, in turn, provokes the appearance of parasites in it that destroy the structure of the tree.

Special antiseptics make it possible to reduce the risk of wood contamination, thereby extending the life of wooden shelves and improving the appearance of a product that you may have made yourself.

Today, stores have a huge number of different products that cover the shelves in the bathhouse. They are effective impregnations that not only protect natural wood from rotting, but also give it an aesthetic appearance.

What to choose

Specialized retail outlets offer a huge number of impregnations for wooden surfaces; they differ in use, form, and composition.

Before you make a purchase of one or another protective equipment, it is recommended to clearly determine what tasks it should cope with, namely:

- what surface will be treated (floor, ceiling, benches, shelves in the steam room, the entire room);

- will an additional decorative coating be used or will the surface after treatment remain the same as before;

- will the degree of moisture protection inside the bath be sufficient;

- Is the application method convenient?

An essential indicator of high-quality impregnation for baths, including those made from logs, is the combination of its moisture-proof properties with the ability not to prevent the skin from breathing. Since the presence of film leads to blockage of the wood structure and subsequent problems leading to damage to the surface. It is also worth paying attention to the environmental friendliness of the selected antiseptic. Otherwise, low-quality goods at high temperatures and high levels of humidity in the room will release harmful substances.

If impregnation is selected for treating floors, then after its application there should not be a slippery coating. Tabletops and benches should be treated with products designed for regular wet cleaning. There are shelf impregnations on sale that can completely penetrate the wood structure and prevent the formation of burns on the body at high temperatures.

Protective impregnations for wooden surfaces are divided into groups depending on the main component in their composition, as well as on the properties and method of application. According to the form of release, antiseptics are:

All types of impregnations for baths and saunas have water-repellent properties. Modern impregnations for baths rarely have only one function; they can often be used as universal preparations that can also protect wooden surfaces from the negative effects of elevated temperatures, excessive humidity and from damage by pathogenic microorganisms and harmful insects.

Based on their composition, the products are divided into water-soluble and oil-based. You can purchase a combined product in the form of varnish and paint, which is characterized by the effect of moisture protection and prevention from microorganisms. Most impregnations have additional performance qualities in the form of fire resistance and dirt-repellent function.

How to choose the right shelf oil

Processing the shelves is an important condition for maintaining a healthy atmosphere in the steam room. When choosing oil impregnations, it is important to pay attention to the composition. The beneficial active ingredient is flax. This natural antiseptic prevents rotting, the development of parasites and mold, and the formation of cracks. Synthetic resins are 50 times heavier than flax molecules and are not able to penetrate very deeply into the pores of wood.

Before deciding what to cover the shelves in the bathhouse or steam room with, it is important to consider that the oil must create a hydrophobic coating and maintain an aesthetic appearance. The durability of the wooden base is the main task that the chosen impregnation should fulfill. You can’t save money; it’s better to purchase proven and high-quality products.

Read all about the bathhouse: from foundation to finishing on our blog banya-guru.ru.

Differences between oil and water soluble products

The main distinguishing feature of water-soluble impregnations is the base on which they are made - acrylic. An additional component of the product is usually a special coloring color, which gives the treated sauna lining a certain shade. Acrylic impregnations with varnish are now very popular. They are used to treat baths inside and outside.

Despite the many positive characteristics of acrylic preparations, they have one drawback - gradual leaching from the wood structure. To maintain the natural cladding, it is necessary to carry out regular treatments. An excellent solution to this problem would be to first coat the surface with a waterproofing solution and then with bath impregnation. With such an integrated approach, the wood will last much longer.

Due to the absence of color and odor in acrylic, such preparations are especially suitable for interior work. This is a good option for those owners of baths and saunas who want to preserve the natural wood grain. On sale, water-soluble products are presented in the form of dry mixtures or ready-to-use solutions.

Oil impregnations are distinguished by their ability to penetrate deeply into the wood base, leaving a thin film on the outside. They are characterized by durability and can maintain their performance much longer, even at excessive levels of humidity, than water-soluble preparations.

Oil impregnations are characterized by a high degree of toxicity and the presence of an unpleasant, pungent odor, since they contain a solvent. Due to their toxicity, it is not recommended to use these substances indoors without following safety regulations. They can be used to treat the dressing room, outside walls, and utility rooms.

Advantages of using oil for baths and saunas in finishing

- Dirt-water-repellent properties. Polymerizing deep in the wood, the oil reliably seals the soft fibers, preventing moisture and dirt, cosmetics and detergents from getting inside.

- Antiseptic properties. The special composition of the mixture of oils and waxes, as well as the use of biocides, prevents the development of microbes and mold inside the wood.

- Environmental friendliness. Vegetable oils and waxes do not emit toxic substances; they are used to impregnate wooden utensils and children's toys.

- Appearance and ease of application. Wood oil for baths and saunas does not form a film. The tactile sensations of the wooden surface are preserved. The coating highlights the grain of the wood. Oil can be applied with a brush, sponge or rag.

Processing different parts of the bath

Conditions in different parts of the bathhouse are different, therefore the requirements for finishing materials are different. In rooms where temperature and humidity are maintained at high levels, it is recommended to choose more expensive durable impregnations.

Waiting room

Among the most popular ready-made products are Sauna (Belinka) and Supi Saunasuoja (Tikkurila). Of the domestic impregnations, the U-409 remedy has proven itself well. It can be equally effectively used for processing wooden structures in baths, saunas, bathrooms, showers and living spaces. All these impregnations are made using only natural ingredients. After their application, a thin film is formed on the sheathing (eurolining) and logs, which greatly simplifies the removal of contaminants. They contain fungicidal and insecticidal components that help prevent the appearance and proliferation of pathogenic microorganisms in baths and saunas, which is especially important for the dressing room.

Another well-known antiseptic is Eurotex Sauna, which contains wax. A colorless wax antiseptic creates a protective film on the surface of a wooden structure. The product is excellent for treating benches and shelves. Impregnation volume of 2.5 liters is enough for 35 sq. m. After using this product, wood has a more attractive appearance, is easier to clean and retains its original color for a long time. The only drawback that can be noted is the presence of a clear specific smell inside the room, but after 3-5 visits it disappears.

What compounds should absolutely not be used?

All wood treatment products have an organic or chemical basis. But here it is worth understanding that the furniture in the steam room is often exposed to high temperatures. Therefore, in order to avoid the release of toxic substances that are found in the compositions of antiseptics and other chemical-based preparations, craftsmen categorically do not recommend using such compositions for furniture in the steam room.

Most often, chemical-based preparations are presented in the form of varnishes or paints. There are also a large number of aerosols, impregnations and other products that contain aggressive chemicals. Therefore, when choosing drugs for shelves, you need to carefully familiarize yourself with its main components.

Homemade recipes

There is a recipe for homemade wax impregnation, which includes beeswax and linseed oil, the ingredients are taken in equal proportions. The grated wax is melted in a water bath, and then it is mixed with the second component and allowed to cool.

It is recommended to use harmless protective materials to impregnate the walls of the steam room. The use of oils allows you to create a greasy film on the surface of a wooden structure and protect the wood itself from penetration deep into dirt. There is one minus here. For some time after contact with the treated surfaces, a greasy film will be felt, but soon the oil will be absorbed and partially erased, leaving only a protective film.

A good result is obtained after using melted natural wax. This impregnation is easy to do with your own hands. But the surface must first be thoroughly cleaned, degreased and only then wax applied.

Where to use impregnation?

Experienced bathhouse builders recommend treating only wood that is exposed to the most intense contact with water. These are, first of all, shelves and the lower crowns of the walls. The walls above the shelves and the ceiling in a steam room with normal ventilation do not need to be treated with anything. if you have wooden floors, then they can also be coated with a protective composition, but the optimal material for the floor in the steam room is, as experience shows, ceramic tiles with a non-slip surface.

Since we are already talking about the floor in the steam room, let’s also say that in order to create minimal humidity in the room after use, the floors must be properly organized. All remaining water must flow into a special drain hole, which is connected by a pipeline to the general sewer system of the bathhouse or leads to a separate drain tank.

In general, as we have already said, the use of wood treatment products inside a bathhouse is not necessary if ventilation is properly organized and the premises are regularly ventilated. However, it is obvious that if you coat the wood with protective compounds, it will last longer. In this case, the healing effect of bath procedures will be partially lost. So this is a purely economic question - what is more important to you: the 100% health-improving effect of visiting the bathhouse or minimizing the cost of replacing interior decoration, shelves or other furniture in the bathhouse, which will fail first.