The most popular finishing material for a bathhouse is lining; it is made from aspen, alder, pine, and linden boards are often used. This type of cladding is characterized by high performance characteristics: strength, resistance to moisture, steam, and temperature changes.

In order for the wood used to last as long as possible, it must be coated with special compounds that protect against the formation of rot and deformation.

Why is there impregnation in the bath?

Since wood is a natural and absolutely safe material, it is often used for interior decoration. But at the same time, it strongly absorbs moisture, as a result of which the surface becomes loose and is an excellent habitat for microorganisms, in particular fungi. Bacteria that have settled in wooden cladding through their vital activity provoke deterioration of the material and the collapse of the structure.

The market offers a fairly wide range of impregnations for saunas and baths, which are capable of creating a coating that protects the casing from the destructive effects of high humidity and temperature changes. In addition, they have excellent antiseptic properties. The undeniable advantage of such products is the ability to give the surface an attractive appearance, performing the function of a decorative finish.

Note! When choosing impregnation for baths and saunas, you should give preference to products that do not emit toxic substances.

Antiseptic impregnation for a bath allows you to extend the service life of the internal lining, preserve its appearance, and protect it from rotting and mold. These are unique products that do not form a film on the surface of the wood and do not prevent it from breathing.

Prevent and neutralize: methods and methods of prevention

If you are familiar with such a potential problem as mold, but your steam room is only at the construction stage, you have probably thought about how to treat the inside of a new bathhouse against fungus.

Taking preventive measures is much better than dealing with the consequences.

Here are some tips to help avoid trouble:

- The best building material is logs cut down during frosts. At the same time, the foundation for the future bathhouse also needs to be taken care of in the winter, but the walls themselves need to be folded when it gets warmer.

- Damaged parts should never be used; it is better to get rid of them immediately.

- Consider a proper ventilation system. Vents should be underground, under the attic and in the walls.

Nowadays, a lot of know-how has appeared in the construction of such structures, and it will not be difficult for you to protect the logs from rotting and the foundation from getting wet.

It is important to remember that it is better to pre-treat all boards and wooden parts with stains, preferably water-based. This will prevent the appearance of pathogenic fungal bacteria.

Photo from the site https://bane.guru

What to choose

Specialized retail outlets offer a huge number of impregnations for wooden surfaces; they differ in use, form, and composition.

Before you make a purchase of one or another protective equipment, it is recommended to clearly determine what tasks it should cope with, namely:

- what surface will be treated (floor, ceiling, benches, shelves in the steam room, the entire room);

- will an additional decorative coating be used or will the surface after treatment remain the same as before;

- will the degree of moisture protection inside the bath be sufficient;

- Is the application method convenient?

An essential indicator of high-quality impregnation for baths, including those made from logs, is the combination of its moisture-proof properties with the ability not to prevent the skin from breathing. Since the presence of film leads to blockage of the wood structure and subsequent problems leading to damage to the surface. It is also worth paying attention to the environmental friendliness of the selected antiseptic. Otherwise, low-quality goods at high temperatures and high levels of humidity in the room will release harmful substances.

If impregnation is selected for treating floors, then after its application there should not be a slippery coating. Tabletops and benches should be treated with products designed for regular wet cleaning. There are shelf impregnations on sale that can completely penetrate the wood structure and prevent the formation of burns on the body at high temperatures.

How to consolidate the result

Any efforts to treat mold on the lining in a bathhouse, as described above, may be in vain if the cause of the fungus is not eliminated. Preventive measures include:

- Proper ventilation in the bathhouse.

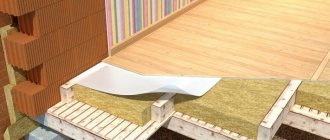

- Mandatory installation of hydro and vapor barrier materials under the lining.

- Regular heating during the cold season.

- Purchase of high-quality, industrially dried lining.

- Treatment of lamellas with antiseptic solutions before installation.

5/5 — (100 votes)

Kinds

Protective impregnations for wooden surfaces are divided into groups depending on the main component in their composition, as well as on the properties and method of application. According to the form of release, antiseptics are:

- aerosol;

- gel;

- in the form of a solution.

All types of impregnations for baths and saunas have water-repellent properties. Modern impregnations for baths rarely have only one function; they can often be used as universal preparations that can also protect wooden surfaces from the negative effects of elevated temperatures, excessive humidity and from damage by pathogenic microorganisms and harmful insects.

Based on their composition, the products are divided into water-soluble and oil-based. You can purchase a combined product in the form of varnish and paint, which is characterized by the effect of moisture protection and prevention from microorganisms. Most impregnations have additional performance qualities in the form of fire resistance and dirt-repellent function.

Tips and tricks for choosing material

In order to make the right choice and purchase a worthy product, you need to inspect the boards for all kinds of defects before purchasing.

- As a rule, sellers are against opening the package, but it is advisable to find a way and come to an agreement. Otherwise, you can purchase a low-quality product, paying a decent amount for it

- It would be a good idea to pay attention to the packaging. If the material is completely closed, then its high humidity is guaranteed. It is better to refuse such a purchase.

If the material is curved, then certain difficulties will arise during its installation. Even if you manage to install the product evenly, there is no guarantee that it will not warp over time.

The ridges and grooves must be smooth, without knots or chips. High-quality elements are easily attached to each other.

Differences between oil and water soluble products

The main distinguishing feature of water-soluble impregnations is the base on which they are made - acrylic. An additional component of the product is usually a special coloring color, which gives the treated sauna lining a certain shade. Acrylic impregnations with varnish are now very popular. They are used to treat baths inside and outside.

Despite the many positive characteristics of acrylic preparations, they have one drawback - gradual leaching from the wood structure. To maintain the natural cladding, it is necessary to carry out regular treatments. An excellent solution to this problem would be to first coat the surface with a waterproofing solution and then with bath impregnation. With such an integrated approach, the wood will last much longer.

Due to the absence of color and odor in acrylic, such preparations are especially suitable for interior work. This is a good option for those owners of baths and saunas who want to preserve the natural wood grain. On sale, water-soluble products are presented in the form of dry mixtures or ready-to-use solutions.

Oil impregnations are distinguished by their ability to penetrate deeply into the wood base, leaving a thin film on the outside. They are characterized by durability and can maintain their performance much longer, even at excessive levels of humidity, than water-soluble preparations.

Oil impregnations are characterized by a high degree of toxicity and the presence of an unpleasant, pungent odor, since they contain a solvent. Due to their toxicity, it is not recommended to use these substances indoors without following safety regulations. They can be used to treat the dressing room, outside walls, and utility rooms.

Installation

Sheathing a steam room with your own hands is quite simple if you do everything according to the rules and do not deviate from the installation instructions for this particular finishing material. You should not violate installation technology, since the profile, if installed incorrectly, will quickly become unusable.

Although the aspen profile has a high level of moisture resistance and has a considerable margin of safety, this will not save the panels, if installed poorly, from rapid wear of the material. To avoid negative consequences, a number of necessary requirements must be met:

- Mandatory gap between the profile and the wall to ensure ventilation;

- If the wall is subject to moisture or is itself damp, then it is necessary to treat such a wall with a moisture-proof solution;

- Impregnate the wooden planks of the sheathing generously with primer to prevent the appearance of rot and bark beetles. Also, the sheathing should be impregnated with a fire retardant compound;

- The profile is also treated with protective solutions, after which it must be dried in the yard or on the balcony, and then the panels are put into a steam room - a day before the start of work. During this time, the lining adapts to room temperature and, in general, to the atmosphere of the steam room. This condition must be met to avoid deformation of the panels after installation due to significant temperature differences.

The lining can be installed in three ways: horizontally, vertically and diagonally. The preparation of the walls will depend on which installation method you choose.

Another thing is important: no matter how you install your panels, the sheathing should be positioned perpendicular to your profile.

Laths for sheathing are selected based on the quality of the walls; as a rule, a lath with a cross-section of 40x20 mm or specialized metal profiles are used. If it makes sense to increase insulation by adding a layer of insulation, the slats can be thicker. A distance of at least 400-500 mm must be maintained between the guides. The length of the guide must correspond to the height or width of the walls, it depends on the installation method (horizontal or vertical). If the guide is shorter, the length is increased with an additional beam, the main thing is that the beam is in line with the butt rail.

The sheathing is fixed to the wooden wall with self-tapping screws, but if you have a brick or stone wall, then you need to use dowels. Additional bars are attached around window and door openings, to which platbands and wooden panels are mounted. Holes for sockets and other decorative inserts, as well as for various fasteners, are drilled using a drill attachment - a crown.

After installing the sheathing in your steam room, it is highly recommended to coat the decorative areas of the surface with wood varnish. This procedure will not only significantly improve the appearance of your steam room, but will also significantly increase the service life of the material you have chosen.

Some people use paint instead of varnish, but in this case the unique texture of the wood itself is hidden. The panels should be varnished every year, or at least once every three years. In this case, your profile will be in excellent condition for a long time.

It is important to understand that varnish is a flammable material, so after you have applied varnish to all panels, you need to cover the surface with a special fire retardant solution. Apply the solution to the surface with a roller or brush and then allow it to soak in.

The initial and final aspen panels are fixed at a distance of about 5 mm from the ceiling and walls. This is done to increase ventilation between the panels and the wall. After installing the initial and final panels, minor defects may be revealed, including hidden nail heads or screws; such defects are perfectly masked by baseboards or decorative inserts.

This cladding will serve you faithfully for many more decades; aspen reacts remarkably well to aggressive influences and will not crack, especially with proper use and proper care. Aspen lining for a bathhouse leaves only positive reviews from craftsmen who have dealt with this material, and this material is also widely in demand among modern consumers.

Processing different parts of the bath

Conditions in different parts of the bathhouse are different, therefore the requirements for finishing materials are different. In rooms where temperature and humidity are maintained at high levels, it is recommended to choose more expensive durable impregnations.

Waiting room

Among the most popular ready-made products are Sauna (Belinka) and Supi Saunasuoja (Tikkurila). Of the domestic impregnations, the U-409 remedy has proven itself well. It can be equally effectively used for processing wooden structures in baths, saunas, bathrooms, showers and living spaces. All these impregnations are made using only natural ingredients. After their application, a thin film is formed on the sheathing (eurolining) and logs, which greatly simplifies the removal of contaminants. They contain fungicidal and insecticidal components that help prevent the appearance and proliferation of pathogenic microorganisms in baths and saunas, which is especially important for the dressing room.

Another well-known antiseptic is Eurotex Sauna, which contains wax. A colorless wax antiseptic creates a protective film on the surface of a wooden structure. The product is excellent for treating benches and shelves. Impregnation volume of 2.5 liters is enough for 35 sq. m. After using this product, wood has a more attractive appearance, is easier to clean and retains its original color for a long time. The only drawback that can be noted is the presence of a clear specific smell inside the room, but after 3-5 visits it disappears.

Steam room

Considering that the air temperature and high humidity inside the steam room are very high, a special approach is needed here, in particular, you should know how best to treat the lining in the steam room. Natural oils and wax are suitable for these purposes. Some home craftsmen impregnate the boards with linseed oil with the addition of a natural aromatic composition. Often, from a variety of oils, hemp oil is chosen for impregnation. If you need a more economical option, you can use refined sunflower oil.

There is a fairly large selection of products for treating industrial shelves. These are impregnations from Russian and Eurotex Sauna, and Supi Laudesuoja oil from Tikkuril.

Note! It is not advisable to use ordinary paints and varnishes to protect benches, joists, shelves, walls and ceilings.

Wooden surfaces must breathe - first absorb moisture and then release it. If conventional compositions are used, then such surfaces lose this quality. In addition, in conditions of high humidity and high temperatures, the evaporation of harmful substances that pose a health hazard is added, and the bathhouse no longer becomes a cure for many diseases, as it has been for centuries. This can be compared to finishing a bathhouse or sauna with linoleum or siding, which is strictly contraindicated.

Classification of aspen lining

Premium

The most expensive material. Contains no core, knots, or other defects. It has a uniform texture and color.

Class "A"

The wood has no core, but there may be one knot every 1.5 m, a couple of resin pockets and cracks. The texture and color are uniform.

Class "B"

May have up to 4 knots per 1.5 m, a couple of resin pockets and through slots. The lining will most likely contain a stain or stains of contrasting color and mechanical damage.

Class "C"

Lowest quality material. The lining has many knots, cracks, chips and stains. Using this class for sauna cladding is not practical.

Types of lining

Homemade recipes

There is a recipe for homemade wax impregnation, which includes beeswax and linseed oil, the ingredients are taken in equal proportions. The grated wax is melted in a water bath, and then it is mixed with the second component and allowed to cool.

It is recommended to use harmless protective materials to impregnate the walls of the steam room. The use of oils allows you to create a greasy film on the surface of a wooden structure and protect the wood itself from penetration deep into dirt. There is one minus here. For some time after contact with the treated surfaces, a greasy film will be felt, but soon the oil will be absorbed and partially erased, leaving only a protective film.

A good result is obtained after using melted natural wax. This impregnation is easy to do with your own hands. But the surface must first be thoroughly cleaned, degreased and only then wax applied.

Disadvantages of the material

But this material has one nuance. This is a tendency for rot to form on the middle part. To prevent such a nuisance, it is important to use adult trunks that have reached forty years of age to make lining.

It is worth noting that aspen of impeccable quality with a perfectly smooth surface has a fairly high price.

Why is it necessary to treat concrete?

Impregnation has a strengthening effect on a new concrete floor, but it can also be used to treat an old floor with some defects to restore its original appearance and properties.

Speaking in more detail about its effect on concrete, we can highlight the following:

- Impregnation will increase the wear resistance: the floor will better withstand temperature changes, moisture, and mechanical stress, such as impacts;

- The concrete floor constantly crumbles, creating dust. Impregnation will help get rid of this problem by binding small particles of concrete;

- The treatment will also significantly increase the service life of a new or slightly worn floor;

- An untreated concrete floor will need repair, so treating it is also a money saver.