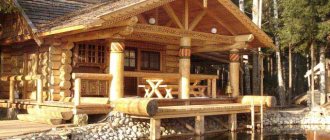

A bathhouse made of large-diameter logs is a real decoration of a suburban area. The DrevMaster company cuts log houses from solid debarked logs; we do not work with rounded logs. If you are interested in beautiful and impressive architecture, uncompromising quality of hand-cutting, an individual project, and as a result a real wooden bathhouse, we can help.

Advantages of log houses made of thick logs

In addition to aesthetics, log baths made of thick logs have a number of advantages that distinguish them from typical template buildings:

- Such baths are durable, rare and expensive material undergoes careful selection and multi-stage quality control;

- The wood itself is of higher quality and denser;

- Do not form through cracks and cracks even after shrinkage;

- There is no need to additionally insulate the log house from the outside or inside;

- No finishing of either the facade or the interior is required;

- Absolutely environmentally friendly due to the absence of synthetic insulation and membranes;

- Excellent thermal insulation properties - the larger the tree, the fewer crowns and corner joints;

- Does not require annual caulking and insulation - this is facilitated by manual cutting technology using Canadian or Norwegian technology with an upper bowl;

A log bathhouse constantly breathes, providing a healthy indoor microclimate. And the correct selection of wood and antiseptic treatment with strict adherence to deadlines and technology will make your log house literally eternal: you will not have to change the lower crowns after several years of use.

Construction and operation

Barked logs, as a building material, have their own characteristics. In addition to the fact that such log houses look very beautiful and unusual, they breathe well, have a good ability to regulate air humidity, warm up quickly and retain heat well.

Thermal insulation

The main advantage of wooden buildings is good thermal insulation. But wild logs are more demanding for additional processing than other materials.

The thickness of the log varies along its length. Therefore, during construction, a very careful and competent selection of logs for each crown is required. When laying, even with careful adjustment, cracks may form, so a natural sealant – jute – must be used. We lay it in several layers, carefully fixing it with a construction stapler.

Reliability

The tree is more susceptible to moisture or parasites. To prevent the logs from getting wet, the bathhouse is built on a high base, often the lower crowns are made of larch, the roof is carried further than on a brick building, and good ventilation is provided. In the first 2-3 years, the resin contained in the logs prevents excessive moisture absorption by the log house, but after that the logs must be regularly treated with an antiseptic.

Environmental friendliness

Wood is an environmentally friendly material if it is not treated with too toxic impregnations. Even after treatment, the sauna’s ability to breathe remains.

Selection of wood for construction

We work with wood that grows in our region and climate and is perfectly adapted to the harsh and unpredictable Ural weather. You can order a log house for a bathhouse made of pine, cedar, spruce, larch or aspen. Large diameters are most often found in pine and cedar. Pine is a more budget option, cedar is more spectacular and expensive. A cedar bathhouse has special phytoncidal properties.

For construction, we use wood from the roots, harvested strictly in winter. We select the material for each specific project only after completing the design stage. We personally travel to the northern regions to select suitable material. Only whole, healthy wood is used, free from defects, fungi and rot. We sort the logs by diameter and roundness, value specimens with curly butts, be sure to leave them when cutting and decorate the log house with them.

Log selection

When choosing a solid log for construction and installation work, special attention should be paid to such an indicator as flatness. This indicator demonstrates the difference in diameters at the ends of the harvested log. The thickness of a tree trunk when growing in natural conditions cannot be the same along its entire length. This is due to natural biological reasons. So, for example, if the diameter at the root is 42 cm, then the opposite side will have a diameter of about 36 cm. In the process of laying logs in the walls, you need to lay the logs with a thinner end on a thicker one. This way the wall is equal in height on both sides.

When choosing a log, you should pay attention to the fact that the thicker the material, the better it resists the effects of low temperatures, but here it should be noted that the cost of thick logs is much higher.

The best option is to select logs with approximately the same diameter along the entire length of the material. The optimal diameter of the material for the European part and northern regions of the Russian Federation is considered to be 220-240 mm when the structure is used only in the warm season and more than 260 mm when the bath complex is used year-round.

The selection of forest for the construction of a bathhouse complex should be carried out on the standing ground in a plot allocated for logging. The preparation and storage of such material is carried out in a special way. Large diameter logs for the construction of a bathhouse are processed manually. For this purpose, special tools must be used - staples. Using this tool, the bark is removed from the material, but a protective layer is left on the surface. This protective layer helps preserve the warmth and strength of the wood.

The outside of the log must be highly polished.

When choosing logs for the construction of a log bathhouse, you should remember that the material, which has a thickness of 22 to 28 cm, is used for the construction of residential complexes. The cost of such logs is quite affordable, and this type of building material is available to most land owners.

Logs with a thickness of 30 to 40 cm are used for the construction of permanent buildings.

The most reliable and expensive are log houses made from larch, oak and cedar.

A log house assembled from logs with a thickness of 40 cm or more is very expensive and does not always justify the costs incurred when using it in construction.

Log bathhouse or turnkey bathhouse

We work according to any convenient scenario. We cut the frame at the construction site and install it on a pre-prepared foundation on the client’s site. If necessary and with prior approval, we carry out excavation work, lay communications and pour the foundation for the log house.

A turnkey bathhouse is the delivery of a facility from A to Z. We start with design work and end with the implementation of an interior design project. For each stage of work, we sign a contract and agree on an estimate.

Cost and prices

We discuss the cost of any object individually with each client, because there are no two identical baths, even if they are built according to the same project. Different wood and log diameters can change the price of the final object by several hundred thousand rubles. Therefore, here we can only provide indicative prices:

- Design - a ready-made project from our catalog - free of charge. Design from scratch – 300 rubles m2;

- Construction – from 18,000 per m2;

- Delivery – agreed separately, depends on the distance of the client’s site from Yekaterinburg;

- Assembly of the log house at the client’s site is immediately included in the cost of services.

All prices are fixed in the contract before the start of construction work. An important application is the construction estimate, which we draw up based on the approved project. The document provides for all possible costs, including delivery and assembly of the log house on site. Therefore, the price of a bathhouse with a terrace does not change during construction.

Finishing of wooden baths

In order not to spoil the microclimate, it is necessary to choose the right finishing materials for interior work. The main thing is that the log house of the bath house does not lose the ability to “breathe”, that is, regulate air exchange and humidity in the room:

- For the steam room, lining is used from wood species with minimal resin content: deciduous (linden, alder), valuable (Canadian cedar, larch), exotic (abash).

- A popular solution is a wood-fired sauna. A stove is placed in the log house. Near the stove, you can make the finishing from natural stone (talc chlorite, soapstone) or architectural concrete.

- Antiseptics based on linseed and orange oils are in demand. We are official dealers of this German company. Finishing a bathhouse with a terrace or a log house using Remmers products is the best solution.

- For finishing, we recommend using products without driers based on natural oil, vegetable and beeswax. Water-based varnishes are also acceptable.

- Insulation of walls and decoration of cracks is carried out using the “Warm Seam” technology using acrylic sealants from global manufacturers.

- For cladding rooms with swimming pools, we use ceramic tiles, thermowood and natural stone. Wooden surfaces are treated with deep penetration waterproofing compounds and effective antiseptics. Dehumidifiers are also recommended.

- When choosing special models of stoves, you can operate an 8 by 8 bathhouse, or a log house of a different size in two modes: Russian and Finnish steam room. The difference between them is the temperature and humidity conditions. Steam generators are additionally recommended for saunas. The bathhouse designs include boiler rooms and the possibility of firing the stove from different rooms.

Deadlines

Construction of a bathhouse takes from 65 days:

- implementation, processing of the project - from 2 to 10 working days;

- earthworks and foundation - organization of the foundation - work time depending on the type of foundation - from 3 days;

- felling of a log house - depends on the area, number of cuts, height of the room - from 30 days;

- delivery of logs and materials - depending on the distance from Yekaterinburg - from 3 days;

- roof installation – from 14 days depending on the complexity of the structure;

- engineering systems (water supply, sewerage, electrical) - from 14 days.

Important! Finishing is possible only a year after installing the log house on the foundation. Prices for building materials may change over the course of a year, so we calculate the budget for finishing separately.

What are the disadvantages of a round timber bathhouse?

Log houses for baths are characterized by the same disadvantages as other wooden structures. We know about all the features of working with wood and take them into account before building a bathhouse. The price of a log house includes a comprehensive fight against rot, insects and fungi, because these are the main disadvantages of wooden buildings. These are the protection measures we take:

- During transportation, the wall set of the bathhouse and log house is treated with a transport antiseptic. Impregnation of wood with certified antiseptics is carried out during the assembly of the log bathhouse, which allows you to treat all hidden surfaces. It doesn’t matter whether the bathhouse is made of a log house with two floors or one – the protection technology remains the same.

- When finishing walls made of logs, sanding is first done, after which the wooden surfaces are re-antiseptic. Applying the compounds to a sanded log increases the depth of penetration. Beams, sheathing and rafters are impregnated with a primer with an antiseptic component. This is done regardless of the purpose of the building: a bathhouse, a guest log house, a house for permanent residence or a gazebo.

- Re-application of protective compounds on a log bathhouse with a veranda, attic or terrace is carried out in accordance with the manufacturer’s recommendations: from 3 to 5 years, depending on climatic conditions.

- When developing a project for a bathhouse from a log house, constructive protection against rotting is worked out: a bathhouse frame is made with the main roof removed, terraces are created and a high base is designed.

- The first crown of the bathhouse frame is placed on a backing board treated with an antiseptic. Also, for frame crowns, we recommend using moisture-resistant larch, which is not susceptible to rotting.

- Wooden surfaces that come into contact with the heating parts of the stove are finished with non-combustible materials. The places where the sauna stove chimney passes through the wooden floor and roofing system are insulated in accordance with SNIP. A safe and warm turnkey log cabin with a stove is our specialty!