The basis of a wooden house is a log house, which is a box assembled from prepared logs or timber. The logs, fastened together in the corners with cut-out “locks,” are laid in horizontal rows, each of which is called a “crown.” In order for the logs to support the weight of the structure, the log production technology must be strictly followed. Ensuring that the contacting elements fit as closely as possible is the main task of builders when assembling a log frame.

Knowing the basic nuances and features of various types of log joints will help you make the right choice. The technology for cutting a log house from timber and logs differs in the way the corners are arranged, otherwise the rules are the same.

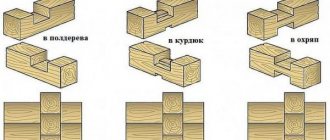

Main types of log houses for the castle

The appearance of a wooden house depends on how the log house was cut - with or without a remainder. If the frame has corners with perfectly matched ends, then it is folded using the “no residue” method; this type of lock is called “in the paw”. If the logs protrude beyond the wall, the method is “with a remainder” (in Russia it is called “in oblo”), the type of lock is “chalice”.

The main tool for cutting log houses is an ax (carpenter's or adze). When working with an ax, the rings of wood that open during the cutting process become jammed, which to some extent protects it from external factors.

When using a chainsaw, the side cut of logs in a log house becomes smooth, the pores of the wood open and become accessible to atmospheric phenomena, which leads to rapid rotting. A log house will last longer if it is sheathed.

Both types of locks – the “bowl” and the “claw” – have different options.

Log house “in a bowl” (with remainder)

A simple “bowl” is carved into the lower crown of the log house. The design of such a bowl is a longitudinal groove with a semicircular cross-section.

Simple bowl

“Bowl in ridge” is a “bowl” lock with a ridge cut out at the bottom, which is designed to ensure the strength of the corner connection and seal the frame.

Bowl in comb

The fat tail lock has a tenon cut into the log of the lower crown, which is inserted into a groove made in the upper log. This type of lock is difficult to cut, but is the most reliable.

Castle in the fat tail

The Siberian bowl (“in the okhlop”) is cut down in the log located on top, and, as it were, “slams” the lower one - hence the name “in the okhlop.”

Siberian bowl (“to the clap”)

The “bowl” lock has several varieties, which are based on the same elements as in the “bowl”: the comb and the fat tail. Depending on the options for their use, locks are called “lock with a comb”, “lock with a tail (spike)” and “lock with a comb and tail (spike)”.

A lock "in the okhryap" is used, as a rule, in the construction of buildings for utility purposes, since the connection density is insufficient for a residential building. This is a complex castle, cut in two logs (upper and lower), which is why it is called double. The lock has only two varieties: a simple “ohryap” and “ohryap with a fat tail (thorn)”.

The castle is "in a state of disrepair"

Loghouse locks “in the clutch” (without remainder)

Log houses without residue are those buildings whose ends of the logs are at the level of the walls. In this case, logs or beams are connected with locks of the “paw” type. These connections are not very strong and do not have good thermal insulation. For comfortable living at any time of the year, such a log house should be clad on the outside.

Connection to the paw: 1-straight paw with a cut; 2-oblique paw (dovetail); 3-oblique paw with undercut

The “foot” can be straight, oblique (“dovetail”) and oblique with a notch (groove).

Other types of log house locks

The main types of log houses and castles were described above. In addition to them, there are a large number of other methods of building wooden houses, which have different origins and features.

Hook cutting

Hook cutting is a structurally quite complex method of angular connection of logs, characterized by increased strength. This type of fastening has two varieties.

Hook connection

In the first case, the bowl is cut down to ½ the thickness of the log. At the ends of the logs, a kind of hook is obtained with which the logs are connected. This connection guarantees absolute windproofness of the corner.

Hook connection: 1-walls inside are round; 2- the walls inside are smooth.

A distinctive feature of the second option is that, due to the logs hewn on one side, the walls inside the building are smooth. Thanks to this, the usable area of the room is significantly increased.

Finnish log house

Finnish bowl (Finnish groove)

House cutting using Finnish technology is similar to the Russian “bowl”. The difference is in the radius of the inter-crown groove (it should be less than the radius of the bowl) and its configuration. The Finnish groove has two “tenons” at the bottom, and grooves are made at the top. As a result, the crowns fit tightly to each other, and the blowing of the walls is reduced. The intercrown seal is completely located in the groove, and not outside it, and is not affected by moisture, which leads to damage to the wood.

Swedish castle

Swedish cutting

Swedish cutting is fundamentally different from all others, first of all, in appearance - aesthetic and very creative. Hexagon - this is the shape of the ends of the logs. The bowl, accordingly, is not round, but in the shape of a trapezoid. Cutting a Swedish log house is very labor-intensive, so it is done when there is a need for beautiful, unusual angles.

Norwegian castle

Norwegian log cutting is a technology widely used in Scandinavian countries - Finland, Sweden, Norway. Therefore, the names “Norwegian” and “Scandinavian” log cutting are identical.

Carriage

Lafet (half-beam) is a building material from which a Norwegian log house is made. The carriage is a thick pine trunk hewn on both sides. The corner connection “Norwegian castle” or “house from a gun carriage” is one of the most reliable technologies for constructing wooden houses.

A distinctive feature of the Scandinavian castle is its wedge-shaped section. A wedge-shaped tenon cut into the top log is “settled” into a groove made in the bottom log when assembling the frame. From the outside, the design is similar to a saddle.

Norwegian castle

A wooden house in the Scandinavian style looks monumental and neat. Thick logs reduce the number of crowns, therefore, the log house has significantly fewer “cold bridges”.

Norwegian house from gun carriage

Smooth interior walls make the interior of a Scandinavian home very stylish.

Canadian bowl

Canadian bowl

Canadian log cutting is a technology similar to the Scandinavian one: the corner connection is made like a Norwegian castle with a wedge-shaped tenon. Round logs are used and a trapezoidal cup is cut into them. When laying, the insulation is immediately cut off so that water does not get into it. The result is walls without gaps and cracks, which look like a solid mass.

Canadian log house

A simplified version of the Canadian log house is a “saddle” log house. Due to the absence of a tenon and a groove for it (a distinctive feature of this type of felling), the tightness of the corner is significantly reduced, which makes the log house short-lived.

Canadian bowl, tongue-and-groove connection

Log house “into the pillar” (“into the fence”)

Log house in the fence

This ancient technology of wooden construction is used quite rarely today. Log houses for commercial buildings were cut in this way. The principle of construction of this type of log house is radically different from all traditional ones. Logs with spikes at the ends are laid between vertically dug posts with grooves cut out. Making a log house “into a pillar” does not require much time or special skill of builders.

So, we looked at the features of making log houses. In addition to logs, another type of lumber is used in wooden house construction - timber. Houses made of timber, like log houses, have a frame as a base, but the corner connections are made slightly differently.

Video description

What it is and how this spring unit works is described in the video:

When building a wooden house, the question always arises of how to connect two beams lengthwise or fasten a corner. Each master has his own preferences in this matter: one adheres to methods that have been proven over centuries, the other trusts more modern methods using special fasteners. And this issue needs to be discussed in advance, after independently studying all the possible options and deciding what is your priority: speed and reasonable cost of installation or quality and reliability.

Cutting log cabins from timber

The classification of types of corner joints when cutting log cabins is the same as for log cabins. A frame made of timber can be with a remainder (“in a bowl”) or without a remainder (“in a paw”), locks have the same names: “in an okhryap”, “in a fat tail”, “in a half-tree”. The only name that cannot be used is “in the oblo”: the timber has a rectangular shape and it is not possible to make a rounded (oblo) notch in it.

However, there are methods of corner notches that are unique to this type of building material - “on tenons” (root or insert).

The connection of beams in a log house (with or without a remainder) is called joining. Let's look at the main docking methods.

Joining the timber with the remainder

"Half a Tree"

Half-tree connection

This joining method (the simplest) involves cutting a rectangular groove with a depth of half the thickness of the timber - hence the name.

"In the fat tail"

Fat tail connection

An additional spike ensures a strong and reliable joining of the beams. Carpenters with a high level of skill are required to perform a quality connection of this type.

"To the brink"

Connection in okhryap

A connection in which the main task is to correctly calculate the width of the jumper. When working with timber, due to its standard geometry, cutting can be done using a template (as opposed to working with a log). Error-free sawing significantly speeds up work.

Joining the timber in the corner without leaving a trace

When building houses and bathhouses from timber without residue, the traditional types of locks are “half-wood” (with smooth parallel edges) and “paw” (with edges shaped like a trapezoid). The second type of connection is a little more complicated, but it guarantees greater protection of the corner from drafts.

Connection of timber: a - into half a tree, b - into a paw

Spiked joints (in a warm corner)

With this method of cutting timber, a tenon inserted into the groove protects the corner from freezing and blowing due to the formation of an air lock. Connecting the timber “in a warm corner” in itself guarantees the absence of cracks, and an effective addition is punching all joints with jute.

Cutting “in a warm corner” is the most commonly used method of joining beams in Russia.

Straight tenon

Connection in a warm corner - straight tenon

Straight tenon is used when constructing buildings with a wall equal to the length of the beam. When cutting a log house, it should be taken into account that the size of the groove is determined by the size of the tenon, that is, balance must be maintained. If the tenon is large, then the groove, accordingly, should also be the same. A groove that is too deep can weaken the beam, which will affect the strength of the connection, so careful calculations must be made before cutting.

A properly designed corner can withstand wind and other loads well.

The uniform shrinkage of a timber frame guarantees the preservation of the weak part of the timber in the corner.

Half swallowtail

Connection in a warm corner - half dovetail.

A distinctive feature of this type of lock is a spike up to 5 cm wide, shaped like a cone. The cone securely holds the beams, which makes the frame more durable. The limit on the size of the tenon is set so that during the shrinkage process the timber in which the groove is made does not crack.

Making a half dovetail tenon is not particularly difficult for a specialist. To speed up work, you can use a template. This connection is used when the length of the wall exceeds the length of the beam.

Corner tenon

A triangular-shaped corner tenon is used quite rarely, since the knot is less durable, although it does not have through gaps. The technology for sawing a corner tenon is no different from those mentioned above. A builder who is skilled in working with a chainsaw only needs to turn the bar slightly to obtain this type of connection.

Requirements for connections between timber and logs

Connecting timber during the construction of a bathhouse

When building a bathhouse, timber (or logs) can be connected to each other in the corners and longitudinally. The corner connection of the timber is used in the construction of the entire structure of main walls, as well as when installing partitions in the bathhouse

.

The longitudinal connection of the beam is used if the length of the material is not enough to erect one wall (for example, the wall of a bathhouse should be 6 meters long, and the beam should be 4 meters long).

The following requirements apply to the longitudinal and angular connection of the timber:

- The bath box must be sealed from the outside and inside

- The design of the bathhouse must be stable

- Heat loss from the building should be minimal

These are the main requirements for connecting timber and logs to each other. It should also be noted that depending on your woodworking skills, you need to choose the right connection method, because There are strong but complex types of corner fastening material that you may not be able to do.

Frame-timber technology

This technology is similar to the method described above for cutting a log frame “into a pillar” (“into a fence”).

The frame is made up of vertical posts with grooves. Bars with ready-made tenons of the desired shape at the ends are stacked on top of each other. The tenons inserted into the grooves make the corners airtight and reliable. Since the joint itself is not visible, the structure has a very neat appearance.

The use of a single template for all tenons provides a significant advantage in the production time of the log house and in the ease of its installation.

Butt connection

For beginners, the easiest option is to connect profiled timber using the butt method. The ends of the beams are cut evenly and fixed at the corners using steel brackets or plates with spikes.

However, this method of joining timber cannot be called very durable and airtight. Therefore, it is better to use it for non-residential outbuildings.

Butt connection of beams

To strengthen corners assembled end-to-end, dowels are often used - vertical rods made of hard wood (oak, birch, hornbeam).

We invite you to familiarize yourself with: Standard sizes of plastic panels

Joining timber on a straight flat key (dowel)

The optimal joining option is the “warm corner” method, also called the “root tenon” connection. At the end of the beam, an internal protrusion-spike is cut out, which protects the seam from blowing and increases the strength of the corner.

A common corner joint method is the dovetail. It differs from the root tenon in its trapezoidal shape, which makes the contact area of the beams denser and more rigid.

Fastening the log house

A very important point in the construction of log houses, both log and timber, is the fastening of the elements to each other. The need for this procedure is explained very simply: the tree dries out over time, as a result of which the logs and beams can change shape or unfold. The crowns of a log house thrown out in different directions are not a pleasant sight. Well, living in such a building (it’s hard to call it a house) is out of the question at all.

What are they collecting for?

Fastening elements can be metal or wood.

It should be noted right away that nails are not used in log house construction! Only non-drying laminated veneer lumber can be secured with metal studs.

In all other cases, the log house is assembled using wooden fasteners - dowels and dowels.

This approach is justified by the fact that drying wood will simply “hang” on metal pins that do not change in size, as a result of which large gaps appear between the crowns.

Nageli

Nagel

“Nagel” translated from German means nail. In practice, this is a round, triangular or square long block. Round dowels are used in wooden house construction. Square and triangular dowels are more complex in design and therefore are used less frequently.

Bars with a diameter of 25-30 mm are driven into drilled holes with a diameter of 1-2 mm less. To make dowels, hardwood is used - spruce, oak or birch. There are certain requirements for this type of fastener - wood moisture content is no more than 12%, absence of knots or other defects, treatment with antiseptics is mandatory. Compliance with these standards guarantees the strength of the entire structure.

The length of the dowel depends on the cross-section of the timber. The formula for calculating the length is very simple: the height of the three beams (crowns) is multiplied by 0.8.

The assembly of a log house on wooden dowels is carried out in the following order: first, the lower 2-3 crowns are fastened, then the two rows laid on top are attached to the upper beam or log from the first bundle. This algorithm is maintained until the frame is assembled, that is, until it reaches full height.

Assembly on dowel

The placement of dowels for a log house is done in this way: in the lower bundle, the first dowel is installed in the middle of the log at a distance of 200-600 millimeters from the edge (end), the subsequent ones - after 1.5-2 meters. In the second bunch, the pins are driven in in a checkerboard pattern relative to those already installed. It is very important to maintain a checkerboard order - the dowels should not overlap each other!

The holes for the dowels are drilled to a depth slightly greater than the length of the beam - during drying, the log or beam should “sit” in place and not hang on the fastener.

Experienced craftsmen use small tricks when working with dowels. For example, to make the depth of the holes the same, a tie is made on the drill with masking tape or colored electrical tape, which helps to orientate. Or they use machine oil (working oil) to smoothly fit the block into the groove - unnecessary blows can lead to cracking of the wood. The forces and strictly vertical direction of impact on the dowel when hammering should be controlled.

Real dowels are expensive. But there are various lumber available for sale from which they can be made. The most budget option is a dry “elite” board without defects, sawn and cut into bars of the required size.

A suitable alternative is ready-made cuttings of suitable diameter (for mops or rakes) - you just need to remove the knots and cut them into pieces of the required length.

Dowels

Assembly on dowels

Dowels are an analogue of dowels. But the sizes of the dowels are such that they can only fasten a couple of logs (crowns). Drilling additional holes in both the bottom and top logs requires time and some precision. Installing crowns on dowels is quite hard work. For these reasons, assembling log houses from logs or beams using dowels is a less popular method.

Connection fastener

With the advent of modern fasteners made of durable alloy and galvanized steel, many construction processes have been simplified, including the installation of reliable connecting units in timber structures. Some of them have been used for a long time and are traditionally popular. Others appeared relatively recently, so they may be unknown to people whose profession and interests are not related to construction.

Traditional fasteners

The simplest and most reliable of them are dowels or dowels made of hard wood. They blend perfectly with the base material without causing it to deform, crack or rot. In combination with adhesives, they allow for durable fastening.

Assembling a log house on steel dowelsSource remontik.org

Pins are also metal. Their main advantage is their high strength and durability, which is why they are often used to fasten timber crowns vertically.

Nails and staples, which used to be almost the only types of fasteners for wood, are now trying not to be used in the construction of permanent buildings, since the ferrous metal from which they are made is incompatible with wood. It corrodes easily, damaging the wood and gradually deteriorating. For the same reason, it is not recommended to use homemade dowels cut from reinforcing bars.

Modern fasteners

A wide variety of fasteners are made from perforated rolled steel with a thickness of at least 2 mm with an anti-corrosion coating. It is made from:

plates of different lengths and widths with holes for screws and anchors. A large assortment of standard sizes allows you to solve problems such as connecting beams together along a length of 150 by 150, fastening rafters at the ridge part, or strengthening a sagging joint without lower support;

Galvanized connecting plateSource www.sibwindows.ru

- connecting corners from the same source material can be simple or reinforced, with an additional stiffening rib. The range of these products includes both equal-shelf corners and those with different shelf lengths. They are used to strengthen the corner connections of a log house, fasten rafters, floor beams, create a frame for internal partitions, etc.;

- supports are fasteners of complex shapes that allow you to create reliable corner T-shaped joints without making locks. For example, attach floor beams to the walls. Their standard sizes correspond to all standard dimensions of timber sections.

An improved analogue of a perforated plate is a nail or serrated plate. With its help, structural elements located in the same plane are reliably fastened.

Using nail plates, you can assemble trusses and splice timber along the lengthSource cdn.mitekea.com

Threaded rods are also very popular in wooden construction. They tighten the joint by tightening the nuts on both sides of it.

And the most modern fastener, which allows not only to connect the crowns with each other, but also to compensate for the shrinkage of the house and the appearance of cracks between the beams, is the “Strength” spring unit.

Design features of the log house

Wooden house-building technologies have their own characteristics associated with the specific qualities of the building material – wood. Shrinkage, shrinkage, exposure to the external environment - these indicators are characteristic only of wooden buildings. Therefore, during construction, special techniques are used, without which logs stacked on top of each other will not form a log house (the basis of a house).

Prepared log a - compensation cut, b - lunar groove

Longitudinal grooves

The log house should be cut in such a way that there are no cracks in the walls. This requires cutting out longitudinal grooves.

The width of the groove depends on the climatic conditions in which the residential building is being built. Winter temperatures reaching 30° below zero are not dangerous if its width is more than 12 centimeters. If the frost reaches 40 degrees and below, the groove should be 14 cm wide.

A semicircular groove, also called a “lunar” groove, is cut along the entire length at the bottom of the log. Since the log is laid on top, rain and snow water cannot penetrate into the inter-crown space.

The radius of the lunar groove affects the quality of fit of the logs: its smaller size (compared to the log itself) allows you to lay a layer of insulation in the resulting space, the protruding edges of which should be protected from moisture. In the case when the diameter of the groove is equal to the diameter of the log, gaps form between the crowns. The fact is that, as a result of uneven shrinkage of the logs, the crowns cannot sit in the right place to make the joint airtight. Such walls require mandatory insulation.

Compensation cut

This design feature protects the logs in the log house from the formation of cracks that appear under the influence of moisture. Wood is a natural material that is very susceptible to its influence.

The task assigned to the compensation (or unloading) cut is to minimize the number of cracks and give the ones that appear a single direction.

Only an experienced specialist can perform cutting, one of the most difficult operations. This is almost jewelry work, since the cut must be made to a certain depth (no more than 1/3 of the diameter) and along the entire length of the log, without touching the locks. If the slightest mistake is made, the cut can become a conductor of cold into the house.

How to connect beads lengthwise

The easiest way is half a tree. Its configuration and shape are similar to those made when connecting a corner. But the disadvantage of this splicing method is that when longitudinal forces arise, which can occur during drying or movement of the soil, such a connection is easily broken. A continuous gap is formed.

Connecting timber in length

The oblique rim lock has the same disadvantage: it is easy to disconnect. If you need reliable joining of timber, use a straight rim lock. As you can see, due to the protrusion, pressed by the crowns located on top and the weight of the roof, it will resist the forces of longitudinal tension (and compression too). It is more difficult to implement, but much more reliable.

Tags: log, timber, connect

« Previous entry