A bathhouse is a structure within which processes involving the use of large amounts of water occur.

This applies to the washing and steam compartments or a room that performs the functions of both at the same time.

To ensure that the building is not exposed to the aggressive influence of a humid environment, it is necessary to get rid of waste water in a timely manner, for which a drain is installed in the foundation. In this article, the reader will find useful information on how to make the foundation of a bathhouse with a drain with your own hands.

Material for the base of the house

Now there are two opinions about the design of the plinth, when the question arises of what material to choose for the plinth of the house:

- the basement part is made of concrete, as a continuation of the monolithic foundation

- the base is made of brick

Laying a brick plinth was not even discussed in the past. The plinth must be brick, period. Just 10 years ago it was not fashionable to raise the foundation higher than 150mm above the ground.

If we compare concrete and brickwork, then in terms of thermal properties, without a doubt, the brick plinth wins. Because, for a residential building, a brick plinth with a masonry thickness of 510-640 mm is laid out. This thickness of a brick wall does not require additional insulation in snowy regions of Russia.

But recently, the technology of insulating concrete walls has come into fashion. And this plinth technology is now preferable when constructing a permanent residential building, because, simultaneously with the insulation of the plinth, horizontal insulation of the blind area is done, which provides an advantage as a protective measure for foundations from freezing.

If you are not going to insulate the basement part of the wall and the blind area of the house from the outside of the house, then without any options, laying a brick base is suitable for you:

- easier

- warmer

- cheaper

- does not require additional finishing

But this is a subjective opinion.

If it is easier for you to monolith the base, then, of course, choose this option. Because in both options, the bathhouse is a structure that does not require a high underground. The maximum height of the base for a bath is 300-400mm.

And if you choose a brick base for a bathhouse, all the same, its thickness will be no more than 250 mm (in brick), due to the fact that it is not necessary to make a wide foundation for a log house from 200-240 mm logs. And this thickness of brickwork is not much warmer than a concrete wall. And during seasonal use (in summer), warm material for the base is not of great importance at positive outside temperatures.

What to do with the floor

In a bathhouse on a columnar foundation, the floor will be cold if some steps are not taken to protect it. To do this, after the foundation is erected, a pseudo-base is installed.

It can be built from any available materials - wood, bricks, blocks or slate. The main task of this structural element is to block access to cold air and moisture into the space between the floor and the ground.

The simplest and most reliable way to protect the floor is to build a plinth from slate sheets:

- a trench no more than 300 mm deep is dug between adjacent posts;

- the bottom of the trench is filled with crushed stone: layer thickness - 150 mm;

- the trench prepared in this way is filled with concrete;

- Slate is buried in the uncured concrete mixture.

The question you want to get an answer to is which underfloor heating is better, water or electric?

What is reinforcement of a columnar foundation with a grillage?

The top edge of the slate should be flush with the top of the post. The pseudo-base is tied around the top with a steel corner. The space under the floor is filled with expanded clay.

The question arises of draining water from the washing room. Many owners, when installing a floor in a bathhouse on a columnar foundation, install a galvanized pallet under the finished floor. The water accumulating in it is drained out through the pipe.

It is impossible to answer the question unequivocally: which foundation for a bathhouse is better - columnar or strip. Of course, the first option is much more economical than the second.

But if you are going to build a solid brick bathhouse, then you will have to tie the pillars together with a powerful grillage. In this case, it is better to abandon the pillars and erect the building on the usual strip foundation.

Video about making a columnar foundation for a bathhouse.

Brick plinth on strip foundation

Basement is the lower part of the external wall of a house, built on a foundation and designed to protect the walls from the destructive effects of moisture. A house without a basement is at risk of mold infestation and rotting, may lose its ability to resist cold weather and increase heat transfer between the interior and the street.

One of the indisputable conditions is the strength of the base, because it bears the entire weight of the walls of the house. That is why the materials used must be of high quality, characterized by frost resistance, low moisture resistance and pressure resistance.

There are three plinth options used in construction:

- Outgoing - goes beyond the wall. This option is justified in two cases - it is part of the building design (esthetically it is more advantageous) or there is a need for enhanced insulation of the basement floor. It must be equipped with a slope or groove for water drainage.

Tips and tricks

When choosing materials for the interior decoration of a brick bath, pay special attention to comfort and benefits. For example, porcelain stoneware is cold, so that your feet are comfortable, you will have to wear shoes

Better comfort will be facilitated by the installation of special wooden pallets.

Unusual materials can be used to decorate the walls of some bathhouse rooms. For example, a high-quality and non-hazardous option will be made from natural stone. Special salt stones will provide greater benefits. However, judging by the reviews of the owners, this will require not only additional costs, but also careful consideration of the interior design.

The best option for decorating a bathhouse is wood. However, due to high humidity and temperature changes, wood tends to darken. If you notice this, do not be upset, it will not require repairs, this situation is considered normal.

Calculation of bricks for the plinth

The calculation of a brick per plinth for its purchase and delivery is as follows:

- First, the volume of the brickwork is calculated. To do this, we multiply the perimeter of the foundation by the width of the masonry and its height. For example, the dimensions of the foundation are 4x3 m. with a foundation width of 300mm. The perimeter is 14 m. The masonry will be brick-width (250mm) and 4 rows high (70*4=280mm). We obtain the volume of the future masonry equal to: 14m*0.25m*0.28m=0.98 m3.

- In 1 m3 of brickwork, the average consumption of bricks is 400 pcs. We multiply our masonry volume by 400 pieces, we get: 0.98 m * 400 pieces = 392 pieces.

There are 300-330 pieces in a pallet (depending on the manufacturer). This means you need to buy 2 pallets. With reserve. The brick will remain, but it is never superfluous during construction. You can, in the future, make a simple brick grill.

Calculation instructions

To determine the size of the base of the bathhouse, it is important to take into account the weight of the future structure and the distinctive features of the soil.

Types and sequence of wall masonry

The construction of brick walls should begin after waterproofing the foundation. For this purpose, roll materials such as roofing material, technoelast, glass insulation or various bitumen and bitumen-polymer mastics are used. Most often, walls are built using the single-row ligation system, since it is simple and can be installed alone without much difficulty. This design represents a change in spoon and butt rows of bricks. It is used when it is not planned to use the front layer of facing bricks.

For those who are not familiar with the technology of laying walls: a spoon row is a row of bricks that are laid with their side along the wall, and a butt row is laid with short ends to the outside of the wall.

There are three main types of brick walls:

- Continuous masonry, when bricks are laid in two rows without a gap between the rows.

- Masonry with a ventilation gap of 40–60 mm.

- Lightweight masonry. It consists of two walls, between which insulation is poured, be it expanded clay, fine slag or other analogues.

Most often, it is the third type of structure that is used, since it allows you to reduce the pressure on the foundation and save on building materials, since brick is quite expensive these days.

Solid masonry is no less popular, as it is more durable and reliable.

Regardless of the type of masonry chosen, they all start from the corners. First you need to lay out six rows of bricks on the mortar in the corners. A cord must be drawn along each row. They are wrapped around nails, which are inserted into the seams between the bricks at a distance of 3–4 mm from the vertical of the row. The cord helps determine the evenness of the masonry. A building level and plumb line are also used for this purpose.

If necessary, the base of the bathhouse should be laid out of solid brick, and the walls themselves should be made of hollow brick.

When laying, it is important to work quickly so that the cement mortar does not have time to set. If construction work is carried out in the summer, the brick is pre-moistened with water

The thickness of the layer of such a solution should be 2–3 cm.

There are several variations of solid masonry, including:

- "single-row"

- "multi-row"

They differ in that with a single-row laying there is a constant change of tying and spoon rows, and with a multi-row masonry system the tying rows go through 5-6 spoon rows.

When laying bonded rows, it is necessary to apply the mortar with an indentation of 10 mm when filling joints and by 30–35 mm when laying waste areas. If you have bricks lying around with any defects, do not rush to throw them away; it is better to use them for laying tray rows, in addition to corners and support areas.

Internal load-bearing walls must have a thickness of at least 20 cm. Transverse walls usually consist of halves or quarters of bricks. If the length of such a partition exceeds 1.5 m, then they must be additionally strengthened with a reinforcement belt every three rows.

Door and window frames are installed directly during the masonry process. Wooden blocks as thick as bricks are installed in the side parts of the openings. They are wrapped in a layer of roofing felt and tarred.

Ventilation holes must also be provided here. Usually in such baths a supply and exhaust ventilation system is installed. It consists of two holes: one regulates the air flow, the second is the exhaust hole. The first is best placed under the bottom of the stove, and the second is as far as possible from the heater, 7–8 centimeters below the ceiling level. You can also provide special dampers that will help regulate the air flow in the steam room.

Partition in a wooden bath

This option is also quite possible. This solution is not particularly practical, so it is used mainly for design reasons. In this case there are two options:

- Made of facing bricks with a mandatory frame made of another material;

- Made of brick with a masonry thickness of one brick and on its own foundation.

Using facing bricks for an internal unplastered partition is more practical. Facing brick, especially if it is hollow, has low strength, so its masonry must be attached to some kind of foundation. A wooden frame structure is quite suitable.

A brick partition in a wooden bathhouse can be created with your own hands without special purchase of facing bricks. In this case, the masonry must be done in one brick, and the structure must be built on a stone or concrete foundation.

The thickness of one brick requires twice as much materials, but ordinary building bricks without external surface defects will do for them. Taking into account the price of facing bricks, a larger quantity of ordinary bricks can often cost less.

The choice of which brick is needed for the partition in the bathhouse is based on design and cost considerations. There is a great advantage to facing bricks. It comes in a wide variety of options.

In a wooden bathhouse, the thickness of the brick can be any. In a brick bath, it must match the dimensions of the main brick, which is used for laying the outer walls.

Types of socles

This is determined by the location of the front wall of the plinth in relation to the façade:

- speaker This option is used when it is necessary to increase the load-bearing capacity of the base. In this case, the element is extended two to three centimeters beyond the wall plane. There is a drawback - you will have to take measures to remove rain moisture flowing down the building;

- sinking. The façade wall hangs over the basement. It is best to use this option when durable building materials that do not require additional finishing were used to make the base;

- in one plane. The base part and the wall are in the same plane. This method is rarely used and mainly on outbuildings of secondary importance. The finishing layer is made of one material.

There are no specific requirements for the height of the basement - everything is determined by the presence of the basement and the foundation itself.

Protective non-combustible wall coverings

Walls adjacent to the hot furnace walls are susceptible to spontaneous combustion. To prevent their overheating, special casings consisting of heat-insulating and non-combustible materials are used.

Option #1 - reflective trim

Sheathing consisting of a combination of non-combustible insulation and metal sheets is effective. In this case, thermal insulation is attached to the wooden surface, which is covered with a stainless steel sheet on top. Some use galvanizing for these purposes, but, according to some data, when heated, it can release harmful substances. It’s better not to risk it and buy a stainless steel sheet.

Foundation reinforcement

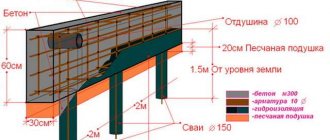

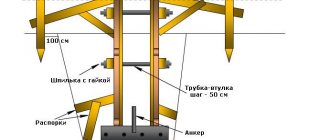

The reinforcing structure is made of reinforcement with a thickness of more than 12 mm for longitudinal laying, and 6-8 mm for perpendicular and vertical laying. To make a reinforcing belt you will need: a grinder, welding wire, a welding machine and a tape measure.

The structure consists of more than four longitudinal, perpendicular and vertical reinforcing rods. The complete structure must be supplemented with formwork, and the finished foundation must rise 5 cm above the ground. Additionally, the corners must be reinforced, and the cut of the reinforcing belt must form a rectangle or square.

The next step in the process of making the foundation of a bathhouse is cutting the reinforcement to a certain length, after which the longitudinal and perpendicular rods are laid out on the ground and tied with wire at the points of contact. It is undesirable to weld the frame, because because of this there is a high probability that it will lose its integrity during the process of compacting the poured solution or during the operation of the finished bath in the future.

The longitudinal reinforcement is laid with an overlap of 30 cm and tied.

The gaps between the perpendicular and vertical reinforcement should be equal to or less than 50 cm. If a strip foundation with a width of 120 cm is laid, then it is advisable to make a frame that has not two, but three longitudinal reinforcing bars.

The same should be done if the foundation has a large height. In addition, in the upper part the frame should be reinforced with U-shaped clamps, which serve to increase the strength characteristics of the belt and minimize the chance of cracking of the strip foundation.

The frame in the corner parts must be supplemented with reinforcement placed at 45 degrees to the horizontal rods.

Laying concrete mortar

- The finished solution is poured into the formwork, leveled, pierced with a probe or bayonet shovel (to remove excess air), and tapped from the outside of the formwork with a wooden hammer.

- If it is possible to connect to the electrical network, then an internal vibrator can be used to compact the concrete mixture.

- At sub-zero temperatures, the strip foundation is covered on top with a film and a layer of sawdust or any insulation.

- After three days, the formwork can be carefully removed.

7. Construction of the base. After making sure that the concrete strip foundation is sufficiently strong, you can proceed to the next stage - constructing the base.

Construction of a recessed brick plinth on a reinforced concrete strip foundation

The following instructions are intended for construction on a ready-made foundation.

Setting angles when building a plinth

One of the most important rules for laying a plinth is the correct alignment of the corners, because incorrectly aligned corners will lead to further curvature of the walls and, accordingly, defects in the construction of the building.

The simplest way is this:

Place a row of dry bricks in all corners, determining the width of the planned base. Angles are set according to level.

Using a tape measure or twine, measure the lengths of all sides and both diagonals - the dimensions must coincide down to centimeters and be correspondingly equal.

It is also worth checking future walls for possible curvature, using the same twine along the inside of the line from corner to corner.

Waterproofing the upper surface of the foundation

Insulation is necessary to further protect the base from groundwater.

Two layers of roofing felt are laid on the foundation in the following ways:

- on bitumen mastic or heated bitumen;

- connection with a burner, treating the surfaces of roofing material.

You can use rubemast, glass roofing material (stekloizol), euroroofing material.

Brick plinth laying

After setting the corners, it’s time to start laying the base. To create it, bricks are usually used, bonded with cement-sand mortar. Only solid red brick is used for construction.

It is advisable to start the laying from the corners, then lay the rows opposite each other on one side with a thickness of the applied mortar of about 20-25mm.

A plumb line checks the accuracy of laying the vertical surface after 3-4 rows of bricks.

After the final check of the corners, the wall laying begins. To make the row even, a thick fishing line is stretched between two corners.

The minimum height is at least 4 laid rows, finishing in the form of natural stone, finishing tiles or siding is allowed.

If the house has basements, ventilation holes are left in each side of the base at a height of 10-15 cm from the soil, measuring from 7 x 25 to 15 x 25 cm. If the length of the building exceeds 3 meters, the vents are in increments of 2.5 meters and covered with nets or small gratings.

Basement waterproofing

To protect against moisture penetration, you need to lay waterproofing materials, making a distinction between the plinth and the brick wall; for cheap construction, you can use, for example, roofing felt, folded in half. Of course, you don’t have to make do with only them; the choice of materials for insulation is now quite extensive. Double waterproofing is necessary in order to protect the house not only from the external influence of the elements, but also from the influence of groundwater on the foundation.

Bath base: finishing options

Content:

- Materials for the bath base

- Finishing the base with siding

- Preparation

Frame for siding

- Siding fastening

- Plastering the base of a bathhouse

- Preparation for plastering

- Applying plaster

To create an air gap for floor insulation, after building the foundation, they immediately begin building the basement. This design helps distribute the load evenly from the building to the foundation. It is also necessary to protect walls from getting wet and mechanical damage. Traditionally, the height of the base is 0.4-0.5 meters. It is better to carry out its cladding before assembling the log house or erecting walls.

Finishing materials for the base of the bath

To make a building look aesthetically pleasing, it is important to choose the right cladding option. It should not only be attractive in appearance, but also durable, because the durability of the entire structure depends on the quality of the finishing material.

The most common methods of cladding the base of a bathhouse are:

- Plastering and painting

. Suitable for brick buildings. One of the varieties is mosaic plaster. The advantages include good air exchange, simplicity and efficiency of implementation, and various color options. As for the disadvantages, the main one is the fragility of the coating. Such a base will need to be plastered and tinted every few years.

Tiling

. One of the most popular options for finishing the base of a bathhouse. This material is easy to install, has good thermal insulation characteristics and protects the surface from atmospheric agents.

Cladding with natural stone

. A durable material that can be used to implement a wide variety of exterior design ideas, as it comes in a wide variety of colors and textures. Natural stone looks very respectable.

Artificial stone finishing

. A variety of colors, practicality and durability are the main characteristics of this material. With its help, you can veneer the base of the bathhouse with your own hands. It is produced in the form of regular figures (squares, rectangles) or shapeless elements. The last type is used to create a unique design.

Siding covering

. The use of this material allows not only to give the base an aesthetic appearance, but also to protect it from external influences. Siding is available in different textures. Some of its variants imitate brick, wood, and stone. It is successfully used for finishing the base of a log bathhouse and a brick structure. It can withstand significant temperature changes and mechanical stress.

Finishing with facing bricks

. The masonry is done in half a brick. Any dressing system is allowed. Installation of this material is quite complex and time-consuming.

- Available materials

. Despite the emergence of many new building materials, old methods are still relevant. To finish the base of a steam room at a summer cottage, leftover tiles, glass fragments from colored bottles, and broken dishes are often used. These elements are usually combined to create a pattern.

It is important to choose the material for finishing the structure in accordance with the type of base:

- Monolithic, concrete or brick structures are usually installed on a strip foundation, since the base performs a load-bearing function.

As for columnar bases, a hinged plinth is installed for them, which performs a protective function rather than a load-bearing one.

Technology for finishing the base of a bathhouse with siding

Siding is easy to install. Anyone can cope with the work, even without special construction skills. Depending on the surface area, finishing the bathhouse base with your own hands will take several days. For cladding, you can use wood, metal or vinyl siding. The latter is made of polypropylene, to which special frost-resistant substances are added, as well as components to increase the strength and elasticity of the panels. In addition, it will not cost much.

Preparing for finishing the bathhouse base

You need to start finishing only after high-quality insulation and waterproofing of the structure. It is also important to make inspection and ventilation holes. The best option is to install hatches for this at a height of 15 cm from the blind area. It is advisable to cover them with a metal mesh to prevent pests and ice from entering in winter.

All wooden elements must be impregnated with antiseptics and fire retardants. If the base is brick or concrete, then level it with adhesive and cover it with a primer solution. It is advisable to treat the surface with protective impregnations in several layers. We start lining when they are completely dry.

Installation of siding frame

When choosing material for lathing, give preference to galvanized metal profiles. They are more durable and do not corrode. A wooden frame will last much less.

We carry out the work in this order:

We attach profiles to the surface in a vertical position in increments of 10-15 cm. We firmly connect them to each other with galvanized fasteners.

At a level of 8 cm from the bottom finishing point, we fix the starting rail in a strictly horizontal position.

We fix the corner slats. Using a building level, we align them strictly vertically.

We fix the brackets with thermal washers to form a kind of square “network”.

Features of fastening siding to the base of a bathhouse

Having chosen a material that imitates stone, wood or brick, you need to ensure that the overall pattern, if any, is observed.

We perform finishing in the following sequence:

- We attach the first panel to the starting strip and slide it into the corner strip. We secure the individual element with self-tapping screws.

We insert the second part onto the starting strip and push it towards the first. We fasten it using the tongue-and-groove system. Be sure to leave a gap of a few millimeters between the elements.

We cover the remaining surface with the material and install the finishing strip.

Install the last element. If necessary, cut the panel to the required size and insert it into the finishing and corner strip.

Rules for plastering the base of a bathhouse

You can plaster the base of a bathhouse using different mixtures. There is a special mosaic plaster on sale, which contains small grains (0.8-3 mm in diameter). After application, it looks like a multi-colored mosaic. This plaster is a good option for finishing the base of a bathhouse, as it is steam and waterproof. However, before you apply it, you will need a base. The latter is always made of cement or lime-sand plaster.

Preparation for plastering the bathhouse base

Before you begin plastering the base, its surfaces should be prepared. If plaster is applied to the surface of a long-constructed building, it is necessary to thoroughly clean the base of paint and dirt. After the walls are leveled, they need to be coated with a primer.

If there are deep cracks or potholes on the base, they should be repaired using a special repair compound. Remember, if you are going to plaster a base insulated with expanded polystyrene or polystyrene foam, you need to take care to improve adhesion - apply notches and treat with a primer.

Technology of applying plaster to the base of a bathhouse

You can begin work on applying a layer of plaster a couple of days after the surfaces have been coated with primer.

We carry out the procedure as follows:

- We level the surface using a spatula and a special compound. Apply the adhesive composition on top using a notched trowel.

We create a reinforcing layer: we press the reinforcing mesh to a third of the depth. We smooth the surfaces with a special trowel.

After several days, we again treat the base with a primer.

We lay the plaster with a spatula and smooth it using a trowel.

To ensure that the layer is even and has the same thickness (about 15 mm), we use “beacons” during the application process.

After the layer of plaster has dried, we grout it. To do this, we select a special metal grater in the form of a mesh. The mashing process must be carried out when the composition is not completely dry, but has already set.

How to sheathe the base of a bathhouse - watch the video:

Monolithic

The second type, which is also often used in the construction of baths, is monolithic. It is stronger than tape and can withstand heavy loads. It is a monolithic concrete slab. It is not afraid of either freezing or thawing of the soil, or soil displacement.

In such circumstances, the foundation with the bathhouse will move along with the soil and will not be damaged in any way. Based on its characteristics, it is most often built on unstable sandy and heaving soils, which are characterized by a high groundwater level.

Timber and log bathhouses on clay soil do not need such a capital foundation; the previous type is best suited for them. But if you plan to build a bathhouse from blocks, then it is better to choose a monolithic version.

Each type of foundation has several variations, and monolithic is no exception.

The first subtype is a slab on a tape. It is somewhat reminiscent of an inverted bowl, and thanks to the tape it becomes more stable, which is why it is becoming more and more popular abroad.

However, for a bathhouse made of a log house or a heavier structure, a simple monolithic slab is best suited. It is cheaper than a slab on a belt and does not require additional labor.

At the preparatory stage, the site for construction is cleared. Then the excavation of the pit begins to a depth of 1.5 m. The clay from the pit is replaced with sand or gravel, and all this is leveled.

Attention! The surface should be as horizontal as possible. Otherwise, deformation cannot be avoided

It is best to use a laser level or hydraulic level to control the horizon

The next stage is the installation of formwork from building boards, the thickness of which is at least 25 mm. The structure must be rigid, so as to withstand the pressure of concrete when pouring. You can check this by simply kicking the formwork. If it takes the hit, then everything is fine and you can continue.

But even if it breaks, there is no reason to be upset. It would be much worse if it broke from the concrete without fulfilling its main purpose.

Next, reinforcement is installed into the finished formwork. It is laid crosswise in several rows. As a result, we get several grids, the first of which is located 50 mm above the sand cushion, and the last one at the same distance from the surface of the concrete slab. It should be at least 20mm away from the walls.

At the same stage, pipes for ventilation, drainage and water supply are installed. The sewerage system should be laid below the freezing level, and the pipes should preferably be attached to fittings. Once the foundation is poured, it will be impossible to fix anything. There are two options for draining the sewer system: into a central system or into a septic tank. It is often unprofitable to discharge wastewater into a central system, and a septic tank is an ideal option.

Moisture protection

For a good log bathhouse, it is important to properly waterproof the foundation. The safety of the structure depends on this procedure. It is important to additionally insulate the floor, because in a bathhouse the main part of the heat can escape through the pouring floors.

For strip foundations, roofing felt is most often used. It is laid on the base, glued with hot bitumen lubricant.

The blind area is important for a bathhouse. If you neglect to install it, the wastewater will wash away the soil and the bathhouse will become distorted.

Logs with a diameter larger than the wall material are used as the first crown. The first crown is carefully secured and insulated.

How to choose a place for a brick bath

The most important thing is that the place for building a brick bathhouse is dry. Therefore, if there is a lake or river nearby, the point of construction should be at least 30 meters from them, otherwise, during a spring flood, high humidity in the air or even flooding cannot be avoided.

In addition, it is important to take into account fire safety requirements - the distance to any neighbor’s house should be no less than 12 meters - if the bathhouse will be heated with wood. But if a gas or electric boiler is planned for heating, and there will be no smoke, then this distance can be safely reduced to 5 meters

However, a do-it-yourself brick bathhouse can be attached to any other residential building - this will not only save materials, but it will be much easier to install electricity and sewerage.

Advantages and disadvantages

Of course, there are no ideal building materials. Therefore, brick, like any other material, has its advantages. Let's look at them below.

- Durability. With proper installation and operation, such a building can be used for more than 100 years!

- Environmental friendliness. When heated, brick does not release any chemicals.

- Fire safety. The likelihood of a brick bath igniting is almost zero.

- Design. Since the brick structure is very stable, it is possible to build a structure of various shapes and sizes, create an unusual, interesting layout, and so on. In addition, the brick itself, if the external walls are built for decorative purposes, looks quite attractive and solid.

- Brick does not rot and is not susceptible to fungus and other microorganisms.

- The shrinkage period of a brick bathhouse is much shorter than that of a bathhouse made of a wooden frame or timber.

There are also a number of disadvantages.

- High cost of material. A very contradictory opinion of the majority of inexperienced masters. In fact, the differences in price when building baths of the same size and the same design are minimal.

- High heat capacity. It will take several times longer to warm up a brick sauna than to heat the same wooden sauna.

- High thermal conductivity. Brick conducts heat and cold well, but this problem can be solved with high-quality vapor barrier.

- Hygroscopicity. Brick walls can absorb moisture, which will inevitably lead to deformation and destruction of the walls. The problem can be solved by installing a layer of waterproofing.

- Due to low vapor conductivity, bricks tend to change color and collapse. Good vapor barrier and ventilation will save you from this.

Types of foundations for baths

I would like to note right away that bathhouses are usually relatively light (compared to a house) buildings; accordingly, the foundation experiences less load and fewer demands are placed on it. And yet, in order for the foundation of the bathhouse to serve for a long time, and its walls not to crack, warp or sag, the foundation must be reliable and solid.

It is known that the foundation is designed to protect walls from absorbing ground moisture and taking on the load from the building. The type of foundation chosen depends on the nature of the soil (its moisture content, density, composition, etc.), groundwater level (groundwater level), the size of the bathhouse and the material from which the walls of the bathhouse will be made. In addition, the foundation is selected based on the nature of the landscape, the slope of the site (for example, if the slope is significant, then it would be better to look towards a pile, columnar, or screw foundation).

The characteristics of individual foundations (such as the depth of a strip foundation, the type of cushion under it) also depend on the depth of freezing of the soil in your region. Let's consider these parameters, and depending on it we will select the foundation.

Ground water level

This is a very important parameter. It is not difficult to determine it - you need to dig a hole to a depth of 2.5 -3 meters with a hand drill or shovel. The hole needs to be covered with polyethylene and monitored for a week or two. If there is water in the hole at a height of more than 2 meters from the surface, the groundwater level is high; if there is no water in the hole, then you are lucky.

The fact is that with a high groundwater level, the foundation needs to be built more thoroughly. After all, what is water? This is the main destroyer of the foundation and the house. In addition to the fact that it can gradually wash minerals out of the soil, leading to a change in its structure, it has the property of expanding when freezing, which creates the so-called. heaving force - the soil, increasing in volume, pushes out the foundation. And if this happened evenly over the entire area of the foundation, then it would not be so scary, but most often this happens unevenly (for example, the northern side of the house, and therefore the foundation under it, freezes faster than the southern one), and because of this unevenly distributed load on the foundation, distortions occur and cracks appear if the foundation is weak (low grade of concrete, shallow depth, poorly reinforced, etc.). We will talk further about how to avoid heaving forces and level them out.

In addition, water getting into the micropores of the foundation or, even worse, being capillarily sucked through the foundation into the masonry (brick, blocks, etc.) and staying in these pores, small cracks, cells, when freezing, expanding gradually destroys the material, therefore Each material has such an indicator as the number of freezing cycles. It follows that the foundation also needs to be carefully waterproofed, as well as the masonry from the foundation. This is usually done with roofing felt or bitumen. But liquid glass, various coating mastics and waterproofing compounds can also be successfully used, as well as adding special additives to the concrete itself to create hydraulic concrete that does not allow water to pass through.

Freezing depth

Another important parameter on which the type of foundation and its depth depends. Let's look at the table of freezing depth by region/city below.

Table of freezing depth by city

Now let's remember our UGV. We will also take into account the heaving properties of individual soils. The most heaving soils are loams and clay, and the least heaving soils are gravelly soils and rocky soils. In general, the rule here is this: the soil that is most inclined to absorb and retain moisture swells the most, and vice versa. So, if our soil is not heaving, then when calculating the depth of the foundation, there is no need to make an adjustment for the freezing depth. But if we have heaving soil, and even a high ground level, then we need to take into account the depth of freezing (the depth of the foundation should be about 20 cm below it), and take a whole range of additional measures - thorough waterproofing, drainage, and always a warm blind area , replacing heaving soil with non-heaving soil - making a cushion under the foundation from crushed stone and sand, and also backfilling around the foundation with non-heaving soil.

What mistakes should not be repeated when building a bathhouse?

Surely many have encountered the need to build a bathhouse on their property, because this is a truly useful and pleasant building. Having your own bathhouse, you can always take a break from a busy work week, relieve stress and improve your health. In the steam room you can relax perfectly and get a fresh boost of strength for the coming week. We wrote about how to do this in one of the previous articles. But today we will try to summarize the results of building our own wooden bathhouse, which has been standing for more than 4 years, and give some advice based on our successes and mistakes. Let this knowledge help you build your own beauty and health center in a suburban area.

Small tricks when pouring a foundation

For a Russian bath it is not necessary to prepare a heavy-duty, deep and high foundation.

A small tape about 40 cm deep and 20 cm above ground level is enough. The construction of a bathhouse is quite light, and such a base perfectly serves its purpose. Making a deeper foundation with reference to freezing of the ground and the danger that the building will simply fail after severe frosts is not at all necessary and, one might even say, pointless. In winter, the foundation is under a layer of snow and nothing threatens it, and if the winter is not rich in precipitation, you can shovel the snow a couple of times. This will save quite a decent amount during construction. To make the tape more reliable, we laid its entire perimeter with iron at the time of pouring. And as a result, we received a reliable foundation that did not show a single crack. In order to protect the lower crowns of the frame from moisture and its result - rotting, we laid out a small base of sand-lime brick and waterproofed it with glass insulation. But with the internal area of the bathhouse base, we acted quite cunningly; someone suggested it just in time. Instead of leaving soil under the floor or filling it with sand, we poured a small layer of concrete just under the proposed washing area and built a small slope of water and discharged it through a pipe into a shallow underground channel with a sump in the form of an old tank and outlet into the gutter. This way we avoided the dampness and unpleasant odor in the bathhouse.

How to seal the grooves of the log house?

It is traditional to seal the grooves between the links of the log house with fresh moss. While the erected bathhouse shrinks, the moss dries and becomes an excellent heat insulator. There is also a more convenient material - linen tape tow. It is sold in rolls, and it is very convenient to use when assembling a log house, roll it out and lay the next log. Besides, you don’t need to go to the forest and mess around with damp moss. This is what won us over. We decided to seal the joints with tow, which seemed to save time and effort. But we ended up with a real headache. The fact is that such tape does not completely fill the space between the logs and we were forced to go through each connection with a spatula and seal it with additional tape. As a result, it took twice as much as planned. And that is not all. When winter passed and the weather began to warm up, the birds began to build nests in nearby trees, and from what do you think? That's right, from tow from our bathhouse. Now every year we have to compensate for the damage from our smaller brothers. Therefore, do not be fooled by convenience and simplicity - follow the traditions that have developed over centuries!

Possible problems with boards

The ceiling in an already established log house is usually assembled from the so-called tongue and groove - a thick board with grooves for joining.

It retains heat well and prevents dust from waking up from the attic. If possible, purchase already dried boards, and if only fresh ones are available, then use them immediately. The problem is that if you leave them to sit for a while, even a couple of days in dry weather, some of the boards may become “propellers”. We encountered this when building a bathhouse - several boards, due to their irregular curvature, could not fit into the groove and the only thing that saved us was that they were taken from us with a good margin. There is also an opinion that the floor should also be tongue-and-groove, and that if you take a regular edged board, the floor will dry out and there will be large cracks, making your feet cold in the bathhouse. Due to our negligence, we covered the floor with an ordinary board, and then it turned out that it did not dry out. The fact is that these boards are constantly exposed to water: from above, when the bathhouse is in use, and from below, when moisture under the floor evaporates. This prevents the boards from drying out all year round.

Ceiling height

And one more moment when we went against numerous pieces of advice.

It is traditionally believed that the lower the ceiling in the bathhouse, the better and hotter it will be in the future. When, when ordering a log house, we indicated a ceiling height of 2 meters, the master was surprised and said that this was too much, saying that they usually order no more than 1.8 m. But such ceilings seemed too low to us, and we remained with the same decision. And they did the right thing. Now you don’t have to bend your head in the steam room, and a well-built stove provides plenty of heat. When the time comes to build your own bathhouse, carefully weigh each step and do not repeat the mistakes of others in order to get a great place to relax away from the bustle of the city.

7dach.ru

Features of foundation construction

The most convenient foundation for building a brick bathhouse is a strip foundation. Its depth should be at least a meter, and even more in clay soils. To set it up you should do the following:

- Step 1. A pit is dug into which 15-20 cm of sand is poured. Next, you need to water it well and compact it.

- Step 2. The second layer is laid on the sand with 10 cm of crushed stone in a cement-sand mortar, and then sand again. And this is how several layers alternate.

- Step 3. Now the formwork is laid and the reinforcement cage is installed, which is then filled with cement mortar. After that, a vapor barrier is laid, consisting of two layers of roofing felt, and for protection from rain, an inclined blind area 1 meter wide is constructed from oily clay, gravel and sand.

- Step 4. A comprehensive drainage and drainage system for the bathhouse is installed

Yes, you will have to spend money on such a foundation, but it’s better not to build it for a brick bathhouse.

Roof

The floor beams are installed directly on the bricks in the prepared holes. The ends of the beams that will be in contact with the brickwork are wrapped with roofing felt, only the end part remains uncovered. The simplest option is a pitched roof. After laying the beams, make the flooring from the boards.

To provide waterproofing, the beams are wrapped in fabric asbestos, which is secured with a stapler. When the beams are hidden, a mixture of clay and sawdust is placed on top. For this roof, a proportion of 2 buckets x 2 buckets is sufficient. When the mixture dries, it is sprinkled with sand.

The chimney location requires special attention. Following the recommendations of specialists will help avoid a fire. Wood should not come into contact with the chimney. This area is sutured with a metal sheet.

Next, the rafter system of the brick bath is assembled and the lathing is performed. Roofing material, for example, slate or corrugated sheet, is laid on top.

The place where the stove will stand and the chimney will pass indoors is insulated with metal.

The space around the chimney in the ceiling area is insulated using expanded clay. The lower reflector is attached to the fittings.

Another sheet of metal is installed on top of the expanded clay layer.

During the construction of the brick bathhouse, the Rus-9 stove was used.

Alternative methods for constructing a plinth

In some cases, craftsmen use non-standard structures to construct a bathhouse base, for example, from ordinary ordinary brick, sand-lime brick, slate, wall stones, and the like. It is also worth noting that it is not advisable to use any wall material as a plinth material, since it is not intended for direct contact with the ground. In this case, it is recommended to build the structures together with the massif from the base.

If the foundation is made in the form of piles, then it is preferable to make the above-ground part in the form of a reinforced concrete monolithic belt. The last and first row of the plinth, made of red brick, should be placed in a poke, and the inner ones - in a spoon. This will ensure a good bond and also give the necessary rigidity. If there are more than 5 bricks nearby, then the base should also be “plugged” on the 5th row.

If the foundation ends at a level that is equal to the ground level, then additional brickwork can be made as a plinth for the construction of wooden walls of the bathhouse. It is recommended to use silicate-type bricks, because they can interact quite well with a humid environment.

Ventilation outlets must be provided. It is recommended to make a reinforcing belt of concrete and reinforcement on top of the masonry. Waterproofing is laid under the wall and brick, because in this case three types of materials are used for the walls, foundation and base.