The internal insulation of baths, saunas and hammams has features unique to these objects. In addition to energy saving, “climate” cladding should provide:

- rapid heating of the room;

- thermal inertia (slow cooling after stopping the furnace fire);

- high level of vapor barrier.

Today, foil insulation for a bathhouse is considered necessary, and in some cases, a sufficient element to ensure the above conditions. To understand why this material is a generally accepted standard, it is necessary to consider the physics of heat transfer processes in a steam room.

The need for thermal insulation of the bath

Foil insulation significantly reduces heat loss in the bath.

The steam room is good for health, it promotes skin rejuvenation, dilates blood vessels, and speeds up metabolism. When constructing a bathhouse, builders take into account special design requirements. It should warm up quickly and maintain a high temperature for a long time. To meet these requirements, reflective thermal insulation for the bathhouse is installed. Without high-quality insulation, the steam room will not be able to function, or the heating costs will be enormous. Practical bathhouse owners note the advantages of thermal insulation:

- the service life of the bath is extended;

- the amount of time the temperature rises to maximum is reduced;

- the consumption of wood, coal or electricity for heating the sauna is reduced;

- basalt insulation increases the fire safety of the building.

Thermal insulation is installed inside or outside buildings. In the case of insulating a steam room, a material is selected for interior work. Several layers are installed sequentially, including vapor and waterproofing. The use of insulation for baths and saunas with foil allows you to get by with one material that performs all the listed functions.

Insulation of the base on screw piles

Wooden bathhouses at dachas are often built on screw piles, so the technology for covering the base is practically no different from finishing the lag covering:

- To begin with, the heads of the screw piles are tied using support beams;

- The grillage mounted on the joists is additionally waterproofed to prevent rotting;

- I use bitumen mastic or roofing felt as a waterproofing agent;

- Then, on screw piles, inside the grillage, logs are installed that will serve as a rough foundation for the floor;

- A cranial beam is attached to the lower part of the log, after which it is sheathed with boards;

- At the final stage, the floors on screw piles are sheathed with a heat insulator (foil insulation, mineral wool, penoplex).

In the video clip, experts talk about the advantages and features of hydro- and thermal insulation of floors on screw piles.

Criteria for choosing insulation for a sauna

The insulation must withstand high temperatures and humidity.

When choosing the optimal insulation for a bath, you should focus on the basic requirements for the material:

- coefficient of thermal conductivity;

- presence of a reflective layer;

- moisture resistance;

- working temperature;

- thickness;

- flammability.

The specificity of a sauna with high humidity and temperature requires paying attention to the quality of the material. Difficult conditions negatively affect the insulation, reducing its service life. Manufacturers take into account the requirements for thermal insulation of baths and create special series with appropriate markings. An important factor is the absence of harmful emissions when heated. When purchasing insulation, you should read the manufacturer's information.

In bathhouses with wood-burning stoves, it is worth taking into account the flammability of the material. Basalt or mineral wool does not support combustion; polyethylene foam melts.

Natural

Natural or natural insulation materials have found wide application in improving the thermal insulation of bath structures. Since ancient times, people have used felt, flax tow and moss as inter-crown heat-insulating material. These products are valuable because they provide natural air exchange. In addition, natural heat insulators have bactericidal properties and practically do not rot.

Other advantages of natural raw materials include:

- environmental cleanliness and harmlessness to human health;

- long service life;

- low cost;

- low thermal conductivity.

However, natural insulation materials are not without their drawbacks. Their main disadvantage is flammability. Of course, the material can be pre-treated with fire-resistant compounds before installation, but because of this, the raw materials will not be completely environmentally friendly.

Another disadvantage is the high risk of damage to the heat insulator by rodents and birds. Natural materials can harbor insects that can “negate” the thermal insulation properties of the insulation. Also, some of the materials may cause serious allergic reactions.

Characteristics of insulation with foil

Characteristics of insulation

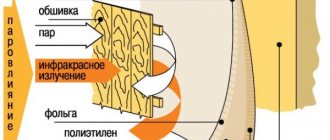

The use of insulation for a bath on the inside of the walls with foil or a metallized coating allows you to create the effect of a thermos. Heat transfer from heating devices occurs due to infrared radiation. To prevent energy from leaving the premises, a metallized screen is installed to reflect it. It is advisable to cover all areas of the structure with thermal insulation: ceiling, walls, floor. A continuous coating will reduce heat and moisture loss.

It is impractical to install foil without a layer of insulation. This is a thin material that is easily damaged during installation. In addition, aluminum has high thermal conductivity, which is unacceptable in baths and saunas. Correct installation and a layer of thermal insulation material eliminate the problem.

Main characteristics of foil insulation:

- High ability to reflect infrared radiation 90-97%.

- Low thermal conductivity due to the cellular or fibrous structure of the material.

- Vapor tightness – the aluminum layer coating does not allow vapor molecules to pass through, no installation of additional protective films is required.

- Waterproofing - the material does not absorb moisture.

- Resistance to high temperatures - insulation materials are designed for operating temperatures over a wide range, the upper limit being 150-300°C.

- Availability of installation - most insulating materials are available in the form of rolls and mats, which allows you to install them yourself.

In addition to thermal insulation properties, sauna insulation with foil has vapor barrier and sound-absorbing properties.

Insulating a bathhouse ceiling with mineral wool is a rational solution

The Russian bathhouse is a unique place for relaxing and healing water treatments and socializing. Strong immunity, beautiful skin and a body cleansed of toxins - these are the results of constant visits to the bathhouse. However, the effectiveness of bath procedures cannot but depend on the quality insulation of the bath.

Everyone has long been accustomed to the fact that it is necessary to insulate internal surfaces (floors, walls, ceilings) in apartments and houses. However, high-quality insulation of the bathhouse is no less necessary. If in an apartment it is enough to insulate only the walls, then a bathhouse and a private house need careful insulation of the ceiling. The thing is that heated air becomes lighter and rises. If the ceiling is not well insulated, then the hot air will pass directly to the roof and heat the air around the house, which is a waste of heat.

Technology

Mineral wool must be insulated from water vapor. To do this, it must be covered with a vapor barrier, which must be sealed and waterproof. Today, foil is often used for vapor barrier, taped at the joints with aluminum tape. Among the new products on the construction market is foil insulation, a modern material made on a fiberglass base. In addition, glassine, membrane insulation or ordinary polyethylene film are often used.

The bath ceiling can be:

If the ceiling is hemmed, that is, the boards are hemmed to the floor beams, insulation must be done from the attic side. 2 layers of vapor barrier (glassine, roofing material, etc.), a layer of mineral wool, and again a layer of vapor barrier are laid on the ceiling.

In the case of a panel ceiling, each panel is covered with a vapor barrier film, mineral wool is laid on it and covered with a vapor barrier. All this is covered with boards.

The easiest way to insulate a flat ceiling. The technology here will be the same as in the case of a false ceiling. To do this, a vapor barrier is rolled out on the boards from the attic side, then a layer of mineral wool 200-250 mm thick is placed on it and completely covered with a vapor barrier. Next, the floor is covered with boards.

Advantages and disadvantages

Among the advantages of mineral wool insulation are the following:

this material almost does not conduct heat and can well insulate a room, including from extraneous sounds;

Everything has its downside, and mineral wool as a material for insulating the ceiling of a bathhouse, unfortunately, was no exception. It has few disadvantages if you compare their number with the number of advantages, but these disadvantages are very significant. Let's look at them:

mineral wool cannot be crushed or compacted, because the compacted fibers greatly lose their thermal insulation properties;

Selection of foil material

Rolled heat insulator

Thermal insulation with foil for a bath differs in technical characteristics and properties. The choice of insulation is influenced by the structural features of the room, fire safety requirements, and the complexity of installation. Mineral wool is recommended for stone and concrete buildings. This is a reliable material of considerable thickness that will provide an appropriate level of insulation.

A building made of timber or logs does not require much effort to maintain temperature. Wood itself is a good heat insulator. In this case, penofol or kraft foil is sufficient. A review of popular options will help you decide which material is best to use.

Rolled heat insulator

Insulation in the form of a rolled sheet can be from 20 to 150 m long. The thickness of the material ranges from 2 to 40 mm. The basis is foamed polyethylene or propylene. Thanks to the thin coating of aluminum, the material reflects thermal radiation. Penofol is popular in the domestic market. The material is produced with one-sided or double-sided foil coating with a self-adhesive base.

Rolled foil without a base is laid on the surface of the walls after the insulation. Strips 1-1.5 m wide are mounted overlapping. The resulting surface is highly resistant to temperature (up to 650°C), moisture and steam.

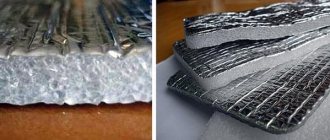

Basalt wool with foil layer

Basalt wool with foil

Mineral or basalt wool is a universal fibrous insulation. It is resistant to fire and moisture, provides excellent thermal insulation of the room. Foiling the outer layer reduces heat loss and creates a vapor barrier. Among the assortment of leading manufacturers Izover, Parok and Rockwool, you can select special materials with foil for insulating a bath.

- For anti-condensation insulation, ROCKWOOL ALU is recommended. The material is supplied in mats. Its fibers are located perpendicular to the surface. During operation, the strength and elasticity of wool is not lost. The Sauna Butts series is designed for insulation of saunas and baths. Mineral wool slabs with a thickness of 50 and 100 mm serve as heat and vapor insulation. The material is intended for indoor installation.

- Izover Sauna roll insulation is quickly installed on walls and floors and provides reliable insulation. It is safe for health and does not produce harmful emissions when heated or wet. The material allows you to save on the installation of membranes and films.

- The popular insulation of the Paroc brand is offered in the form of lamella and stitched mats. They are easy to use and can be quickly mounted on an insulated surface. The aluminum layer is reflective. Basalt wool does not change its thickness during operation.

The quality of thermal insulation depends on the thickness of the selected mineral wool. The optimal option is 5-10 cm. Basalt wool is fireproof, does not rot from moisture, and has a long service life.

Kraft foil

The use of insulation with a layer of aluminum allows for maximum preservation of infrared radiation inside the steam room. The multilayer construction consists of kraft paper and foil, in some cases polyethylene is added to reinforce the material. Common types:

- foilsolone or foil glassine - an elastic material based on cardboard with a corrugated aluminum coating;

- foil-fabric - fiberglass insulation, backed with foil, reflects up to 97% of radiation, withstands temperatures of about 200°C;

- isolar – bath foil 50 and 100 microns thick with the addition of polyethylene film, resistant to fire and temperatures up to 300°C.

Among the types of insulation, it is worth noting a new product - PIR slabs from TechnoNIKOL with a foil lining. The line of bath insulation products creates a reliable barrier between the cold from the street and the hot, humid air of the steam room. The plates are lightweight, low water absorption, and resistant to deformation

Floor, doors and windows

When we talk about how to insulate a bathhouse from the inside with your own hands, it usually means increasing the thermal resistance of the ceiling and walls. However, drafts and a cold floor can also take away a lot of heat (see also the article Insulating the floor on a loggia: selection of materials and procedure).

How are these problems solved?

- It is enough to make a frame of thick felt around the perimeter of the door to the steam room. It will reliably close the cracks through which it can pass through.

- It is enough to insulate the frames of wooden windows in the steam room, washing compartment and dressing room with cotton wool. The insulation of plastic windows comes down to gluing with foam rubber self-adhesive strips: plastic is not placed in a steam room with its high temperatures, and in other rooms there is no need to worry about thermal decomposition of polymers.

- How and with what to insulate the floor? The instructions depend on its type:

- The surface of a wooden leaking floor is covered with expanded clay. Boards are laid on the carefully leveled backfill.

- Installation of a concrete leaking floor begins with digging a half-meter pit.

Then the following layers are located from bottom to top: 5 centimeters of sand; 20 centimeters of foam; 5 centimeters of concrete with foam chips in a 1:1 ratio; waterproofing (for a relatively cool floor, you can use polyethylene or even roofing felt); 5 centimeters of concrete with vermiculite (a natural mineral with low thermal conductivity) in a 1:1 ratio; reinforced 5 cm screed.

A slope for water drainage is made when pouring the screed; The boardwalk is laid on top of the joists.

This multi-layer design is virtually impervious to the cold.

- In the case of a solid floor, 10-20 centimeters of insulation - foam plastic or mineral wool - is laid on top of the rough screed. It is covered with waterproofing with obligatory overlap on the walls; then a reinforced screed 5-10 centimeters thick is laid. Tiles are usually placed on it.

In the photo, the tiled floor is covered with grated flooring. It will not burn even at high temperatures; In addition, it is much more difficult to slip on it.

Installation of insulation with foil

The joints are glued with aluminum tape.

When installing foil insulation for a sauna, you must follow the rules:

- The layer with aluminum foil is directed indoors.

- When installing the material on the ceiling, it runs down onto the walls, and from vertical surfaces onto the floor. This is necessary for the drainage of condensate.

- Ventilation is required in the steam room.

- A gap of at least 30 mm is left between the foil layer and the finishing of the bath.

The sequence of installation work depends on the type of insulation. The penofol roll is rolled out, cut into sheets of the required length and secured to the walls with a stapler. For basalt wool, it is necessary to make a frame according to the thickness of the material. The mats are laid in the finished sheathing. The joints of the canvases are glued together with metallized tape. 30×50 mm slats are placed on top of the heat-insulating layer. The lathing will provide the necessary ventilation gap between the insulation and the casing of the steam room.

You can insulate a bathhouse and sauna with your own hands. Popular materials with foil will provide the necessary level of protection against heat loss and allow you to save on heating.

Features of insulation of different types of walls

The choice of insulation directly depends on the material from which the walls in your bath are built. But the insulation work itself and the final “pie”, as a rule, look identical:

- the insulation is attached to a frame made of wooden bars or a metal profile;

- for the steam room, a double layer of insulation is used (to retain heat longer);

- vapor protection and waterproofing are used;

- a counter-lattice is installed (to create a ventilation space), onto which finishing (finishing) materials are stuffed.

Insulation of brick walls

It is recommended to use dowels as fasteners, because... brick, like concrete, is highly durable. You can choose a metal profile as a frame.

ADVICE. Be sure to choose galvanized metal parts to reduce the risk of rust and subsequent deterioration.

For brick baths, a thicker layer of insulation is used, taking into account the region, climate and weather conditions. Minimum thickness – 10 cm.

Insulation of foam concrete walls (or made from other building blocks)

It differs from the insulation of brick walls only in the complexity of installation: walls made of blocks are demanding in terms of load (it should not be excessive) and method of fastening.

We recommend using a U-shaped frame, which must be secured with a pair of self-tapping screws, and using galvanized ties as the remaining connecting elements. So that the frame elements are fastened together and the structure stands on the floor. Thermal insulation layers can be secured using fixing threads (using a nylon cord), the ends of which can be secured using a construction stapler.

Galvanized screed for mounting the insulation frame

Frame and panel walls

Wooden blocks can be used as lathing, the cross-section of which should be equal to the thickness of the insulating layer. It is imperative to make a vapor barrier and waterproofing layer (so that condensation can flow down and not settle on the insulation or wall material). It is necessary to leave a ventilated space between the insulation and the internal walls.

Frame wall pie. Read more about insulating frame walls here.

Insulation of walls in wooden baths

The use of heat-insulating materials in a wooden bath can be limited to only one option: foil. But it also plays the role of a vapor barrier rather than wall insulation. A log bathhouse itself retains heat well and only needs proper insulation of the crowns and high-quality sealing of all cracks.

Briefly about the main thing

Reflective insulation works according to a special principle based on a layer structure. The main layer consists of a porous or fibrous material; on top (sometimes on both sides) it is complemented by a layer of aluminum foil or metallized film.

It is the shiny surface that does the main job of retaining heat in the room. Additionally, it serves as a steam, hydro and sound insulator, and if the installation technology is violated, it causes the appearance of a thermos effect.

Common foil materials include polyethylene foam, basalt and glass wool, and foil polystyrene foam. To fix the material on the surface, you need a stapler or dowels; the joints are fixed with aluminum adhesive tape.

Areas of use

The installation of reflective heat-insulating material, insulation of enclosing structures, ceilings of a bathhouse - all this can be done directly on a log or beam with a foil surface facing the inside of the room. In this case, the joints of the heat-insulating layer are carefully glued using aluminum tape.

An air gap is required, and the thickness between the interior decoration of the steam room and the reflective thermal insulation should be 10-15 mm. To ensure condensate drainage at the junction of the wall and the floor surface, it is necessary to perform a small release of the canvas.

Advantages

The use of the original Isover Sauna material is a guarantee of reliable thermal protection. The insulation will create and maintain the necessary temperature conditions in the room. Experts noted the highest thermal conductivity coefficient of the material.

In a bathhouse, thick and soft steam is very important. Without it, the steam room will not perform its intended function. Insulation from the Isover brand boasts an excellent vapor barrier.

The product will not only keep the heat inside the room, but will also protect against unnecessary sounds and noise.

Fire safety is an important characteristic for finishing materials. The insulation from the above series has fire resistance class G1. This indicates low flammability. The material is made on a non-flammable basis, which makes its use safer and more practical.

The product boasts a long service life. Only certified products have this property. Over the entire service period, the insulation will fully retain all its performance characteristics. This quality is significantly influenced by the correct installation of the cladding.

For the convenience of customers, the company offers a huge variety of mat thicknesses: 50 mm, 100 mm and 150 mm. In this case, the maximum parameters can reach 12500x1200x50 millimeters.

Manufacturers took care not only of the effectiveness of the material, but also of product safety. Insulation is an environmentally friendly product, completely safe for people of all ages and animals. The material is recommended for use in facilities with high environmental and hygienic requirements. For example, if there are people with allergies in the house.

Laying Isover Sauna mineral wool is a simple, easy and straightforward process that does not require special skills. For this work, specialists are involved only as a last resort. The sheets are attached to the structure using a stapler.

Due to the special texture and composition of mineral wool, it demonstrates excellent resistance to rotting processes, the formation of fungus and other destructive biological influences. This indicates the high environmental friendliness of the product.

The structure of reflective thermal insulation

Combined insulation materials with a base layer with low thermal conductivity and an outer mirror metal layer are capable of shielding infrared radiation. The epithet “foil” is applicable to all types of insulation with foil; The name may differ depending on the base material. Combined thermal insulation has the following properties:

- Compound. The mirror layer is made of ultra-thin polished aluminum foil. It reflects 95-97% of infrared rays. The rest of the energy is spent on heating the metal layer; it is then absorbed by the base layer. The base is made from different materials.

- Technology. Foiling of the base is carried out in two ways: the foil is glued or sprayed. Products with spraying are often found among insulation materials for wallpaper. They are cheaper than foil ones, but the sprayed layer is too thin to effectively retain and reflect thermal radiation. Only materials with a glued layer of foil have the required effect.

Thermal insulation under warm floorsSource utepliteli-77.ru

- Various release forms and sizes. Insulation is available in the form of rolls, slabs, and mats. Cylinder-shaped materials are needed to protect pipes.

- Diversity. Some brands have foil applied on both sides. This material is convenient to use in frame structures. There are materials with perforated foil or with an adhesive layer. Insulation for walls inside a house with foil and an adhesive base does not require sheathing.

Megaflex

This is bath foil that has higher quality parameters compared to its competitors. Megaflex can be used at temperatures above 300 degrees. Bath foil is highly reflective. If the installation technology is followed, this product will help create a sufficiently sealed system, which prevents the spread of steam outside the bathhouse.