Good day, curious readers!

Have you decided to build a bathhouse? Don't know which insulation to choose for it? This matter must be approached extremely responsibly, since not all raw materials intended for insulation of building structures are suitable for thermal insulation of a bathhouse.

Why? Yes, because some materials are destroyed under the influence of high temperature and humidity (become harmful to health) or simply lose their properties, without which they are of little use.

But since the steam room in the private sector is a fashionable trend today, the demand for the construction of baths has increased significantly. This means that the need for good modern building materials has increased immeasurably. As they say, demand creates supply...

This led to the appearance on the market of a new high-tech product - penotherm, the characteristics of which, as manufacturers say, are simply amazing. Is it really? Now let's figure it out!

Penotherm: features of thermal insulation raw materials

Concept and production

Penotherm is a heat-insulating material intended for insulation of baths and saunas. It is made from foamed polypropylene and laminated with aluminum foil. There are several types of raw materials. The difference lies in the purpose of the material. Therefore, the composition of one or another type of product differs.

In general, the insulating element consists of polypropylene and technological additives, for example, plasticizers, stabilizers, foaming agents, fire retardants and many other components. Of course, the full composition of the heat insulator is known, but it’s not that important, the main thing is the result.

Steam thermal insulation for baths is produced in rolls, which is very profitable. Each consumer can buy exactly as much material as he needs for a specific purpose, without overpaying for extra square meters. It’s not for nothing that I mentioned vapor barrier, since the foil coating copes with this task perfectly.

According to the manufacturers, the product is manufactured using exclusively high-quality raw materials, innovative equipment, modern technologies and techniques. And also, if you believe the creators of steam and thermal insulation for baths, the insulation undergoes strict control at every stage of the production process: from the selection of components to its packaging.

Therefore, product manufacturers exclude the presence of low-quality and defective goods. And highly qualified experts, having carried out a lot of tests, confirmed the compliance of the products with the established requirements.

Where is Penotherm used?

Depending on the location of application, coatings with a metallized film or foil surface can be used.

- Penotherm for saunas and baths is characterized by increased resistance to high temperatures - temperatures of more than +150 degrees can cause a change in its characteristics.

- A layer of thermal insulation material Penotherm NPP LF represents reliable protection for wall insulation if it is used during the installation of ceilings - it can protect the structure from vapors and moisture.

- The use of insulation with a foil layer in swimming pools can provide vapor barrier and thermal insulation of the ceilings of structures.

For those users who decide to use Penotherm for a bath, they may hear extremely flattering reviews: installing a layer of material makes it possible to use the stoves in a steam room with a lower power.

Coating with foil film can save the craftsman from the need to attach a separate layer of extremely thin foil, which very often develops defects during installation. also no need to carefully search for holes and flaws in thin foil , because condensate that appears on its surface can pass through them.

Due to the presence of reflectivity, the insulation is capable of creating a real thermos effect indoors , while increasing the energy-saving characteristics of thermal insulation systems by almost a third. The effectiveness of this insulation is achieved due to the ability to stop radiant heat using a screen, which is the foil surface.

The characteristics of Penotherm make it possible to use it also as enclosing insulation, resistant to high temperatures, as well as under conditions of mechanical loads and elevated temperatures.

Varieties

As already mentioned, there are three types of Penotherm. So, so that you do not get confused and make the right choice, I will tell you about the types of products.

- The first type is NPP LE - vibration-damping raw materials made from polypropylene and a mass of technological additives by extrusion. Designed for “Floating Floors” construction. In addition, it is quite often used for soundproofing floors, since it is endowed with excellent vibration and noise-absorbing properties.

- The second type is NPP LF - a material made of polypropylene and laminated on one side with aluminum foil. Designed for steam and thermal insulation of rooms with high humidity and temperature.

- The third type is NPP LP - insulation made of polypropylene and backed with a metallized film made of lavsan. Intended for arranging the “Warm Floor” system or for laying other heating devices.

Thus, to insulate steam rooms, it is necessary to use raw materials of the NPP LF brand - option No. 2. I think this question is clear.

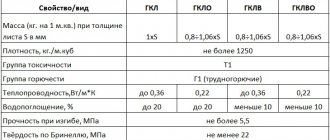

Manufactured brands of foil insulation and their properties

Foil side Penotherm

In addition to Penotherm with a foil side, the manufacturer produces a whole line of insulation made from foamed polypropylene. In particular, for “warm floor” systems, Penotherm NPP LP is produced, which has special markings for installing heating elements on one side covered with a metallized Mylar film. Another brand of insulation is also popular on the construction market: Penotherm NPP LE, which is used when installing floors for effective sound insulation. Bathhouse Penotherm has a wide operating temperature range: from -40 to +150 degrees. Aluminum foil, which covers one side of the insulation, has a thermal reflection coefficient of 90%, while the water absorption of the material is only 0.7% per day. Thermal shrinkage when exposed to high temperatures is only 1-3% in 24 hours. The thermal conductivity of foamed polypropylene is only 0.03. At the same time, the heat transfer resistance after the steam room is completely sheathed is further increased due to the thickness of the material. So for a thickness of 3 mm this coefficient is about 0.7, and for a thickness of 1 cm it will be equal to 0.9. The vapor permeability coefficient of Penotherm is very low and amounts to only 0.001. In addition to the performance characteristics, the manufacturer promises that in the event of force majeure, when a room lined with the material catches fire, it will not create any additional problems during fire extinguishing. Thus, according to fire characteristics, foil Penotherm belongs to class G2-G4. What it is? Thus, fire standards designate a material of moderate flammability, and in terms of toxicity level, the insulation has class T1, which includes low-hazard materials.

Selecting insulation and installing it indoors

The insulation manufacturer is the company Penotherm, which produces material with a thickness of 2, 3, 4, 5, 8 and 10 mm. The release form is a roll, which contains 25 linear meters for thicknesses from 2 to 5 mm, and 15 linear meters for thicknesses of 8 and 10 mm. The width of any rolls is standard and is 1.2 meters. For wooden bath walls more than 20 cm thick, you can use the thinnest Penotherm. A beam or log with a thickness of 15 to 20 cm is covered with 4 mm thick insulation; for thinner walls, 5 mm insulation is suitable. If the walls of your bathhouse are made of bricks or blocks 25 cm thick, then you will need an eight-millimeter Ural Penotherm. For thicker stone walls, ten-millimeter material is used. Insulating a steam room includes several operations:

- The thermal insulation flooring of Penotherm for a bath is overlapped vertically along the walls and along the ceiling. In this case, part of the panel should be placed on the floor. The foil layer is located inside the room. Installation is carried out using a stapler or small nails; all fastening points and joints are carefully taped.

- Stuffing of wooden sheathing under the finishing lining from 1-2 cm bars.

- The final finishing of the room with clapboard, while the board can be installed both horizontally and vertically.

Penotherm for baths and saunas is sold almost everywhere, weighs little, and installs quickly. The material will allow you to reduce the time it takes to warm up the room and keep it warm for a long time. For more information, watch this video:

Characteristics

The high demand for Penotherm is due to its excellent characteristics. I present them in more detail:

- operating temperature – +150 – –50°С;

- vapor permeability coefficient – 0.001 Mg/(m*h*Pa);

- thermal conductivity coefficient – 0.03 W/m2K;

- noise absorption coefficient – 22 dB;

- heat reflection efficiency – up to 92%;

- moisture absorption – no more than 0.5% per day;

- thickness – 2/¾/5/8/10 mm (solid choice);

- width – 1200 mm;

- winding – 25/30 lm/m2;

- load – 200 kg/m2;

- density – 40 kg/m2;

- flammability - G2/V1/D3.

To make it clearer, let's look at the advantages of the product.

Polypropylene is the basis for the manufacture of modern insulation materials

The basis for creating the material Penotherm NPP LE, just like LF, is foamed polypropylene. The advantages of polypropylene are:

- low thermal conductivity coefficient;

- not prone to absorbing water;

- ability to resist tensile and compressive loads.

Such characteristics allow the material to be used in saunas, baths, and “warm floor” systems.

Advantages

Foil vapor insulation differs:

- durability (more than 50 years);

- wear resistance;

- lightness;

- elasticity;

- environmental friendliness;

- resistance to the harmful effects of climatic factors;

- countering the negative influence of biological factors;

- not subject to the harmful effects of mechanical factors;

- resistance to the destructive influence of chemical factors;

- resistance to the negative effects of thermal factors;

- first-class sound insulation;

- excellent thermal insulation;

- excellent vapor barrier;

- good waterproofing;

- ease of installation;

- at a reasonable price, which is not unimportant.

In addition, thanks to such heat-reflecting material, the room heats up at lightning speed. The product also keeps the temperature at the proper level for a long time, giving the bathhouse a “thermos effect.” In addition, raw materials reduce energy costs by 30%. In addition, the insulation is absolutely safe for the human body. And the heat insulator is recycled, which does not contribute to environmental pollution.

No negative aspects were found, or rather, I cannot name them (or I don’t know).

The principle of operation of insulation

Different heat insulators can be used, but unfortunately, each of them is not without its drawbacks, especially since they are used in difficult conditions - at high temperatures and high humidity. Maybe it was this factor that contributed to the rapid popularization of a new insulating material - Penotherm.

The material is available with an aluminum foil coating or a metallized Mylar film coating. It is the metal-containing coating that serves as a thermal mirror, or, in other words, as a reflective element.

The characteristics of Penotherm indicate that aluminum foil, which reflects about 98% of radiant energy, allows you to maintain a high temperature in the steam room for a long time. Installation of a layer of Penotherm NPP LF will significantly reduce the percentage of heat loss through the ceiling, walls, and floors.

Scope of use

The scope of Penotherm is wide. It is used for insulation of private houses, garages and outbuildings. But more often it is used for thermal insulation of baths and saunas. However, it was precisely for them that it was created. With the help of an innovative product the following can also be insulated:

- roofs;

- attics;

- attics;

- walls;

- floors;

- doors (if necessary).

Having given preference to foil thermal insulation, you will not have to regret the purchase.

Installation instructions for the material PENOTERM® NPP LF

- Reflective thermal insulation PENOTERM® NPP LF is mounted directly on the wall and ceiling of the steam room of a bathhouse or sauna with a reflective coating inside the room. If necessary, the entrance door is thermally insulated.

- Installation of thermal insulation is carried out using a construction stapler or small nails; the seams are carefully taped with metallized tape. To ensure the removal of condensate, a small outlet of the material sheet is made at the junction of the wall and the floor.

- A wooden sheathing (2-3 cm thick) is attached to the reflective coating, onto which the interior finishing (lining, etc.) is mounted.

Rules and procedure for performing installation work

Note that the price of Penotherm for a bath is quite affordable, and installation is so simple that a person without special training can do it with his own hands.

- Thermal insulation is fastened along the ceiling and vertically along the walls, with part of the panel extending to the floor.

- The panels are laid overlapping, with the foil layer inside.

- They are fastened with a stapler or nails.

- Adhesive tape is applied along the joint line.

Next, a wooden sheathing is stuffed, and the lining is attached to it. The board can be filled vertically or horizontally.