Bath procedures always involve a large amount of moisture and steam, which can destroy any insulation. A vapor barrier for a bathhouse in this case will be an excellent way out. Vapor barrier films and membranes will protect the insulation from moisture and help extend its service life for many years. Let's take a closer look at the types of protective materials and how to use them correctly in bath rooms.

Features of bath vapor barrier

Vapor barrier in a bathhouse has its own characteristics due to the fact that the room consists of three different locations: a steam room, a shower room and a relaxation room.

Each of them has a different humidity coefficient:

- Most of the moisture is concentrated in the steam room, where hot air predominates and there is a lot of evaporation;

- the shower room does not warm up so much, so there is less steam here;

- The relaxation room is the least susceptible to the influence of steam, but it is also subject to its influence.

In this regard, it is necessary to select a vapor barrier material taking into account different vapor concentrations. Since it tends to rise upward, the ceiling and walls should be protected. Traditionally, they are covered with wooden lining, which easily allows moisture to pass through.

If a layer of vapor barrier is not laid between it and the insulation, the mineral wool will absorb water like a sponge and lose its heat-protective characteristics. As a result, the bathhouse will freeze in winter and will not give the desired effect.

Thus, for a steam room it is better to use foil material, which will reflect heat and warm the room from the inside. In the shower room it is rational to use a regular film against moisture, and in the rest room - a vapor barrier membrane. They will not only increase the efficiency of the insulation layer, but will also protect the structure itself from fungus and rot.

If penoplex or expanded polystyrene is used as an insulating layer, there is no need to install an additional vapor barrier.

What tasks do insulating films perform?

Izospan is a film or non-woven membrane used in thermal insulation structures to protect insulation from moisture, wooden and metal elements from rotting and corrosion.

Vapor barrier membranes are necessary when arranging multilayer building structures, mainly external ones. These are external insulation systems, pitched roofs, frame housing construction, and the installation of wooden interfloor ceilings.

The main task of the Izospan vapor barrier is to prevent the appearance of a “dew point” in the structure. Warm air tends to leave the room, and cold air tends to get inside. Without a well-equipped barrier, flows of different temperatures will meet in the density of the wall and condense into droplets of moisture. The result is that wet insulation freezes, thermal efficiency decreases, and mold appears inside.

Vapor barrier solves this problem - the membrane allows moist air to escape without being trapped in the thermal insulation layer. The dew point moves - condensation does not fall.

Materials for vapor barrier of baths

Vapor barrier of a bath involves the use of different types of materials depending on their properties. The following groups are distinguished:

- Polyethylene film is the most budget option, but it is also short-lived. When exposed to high temperatures, it wears out quickly.

- Vapor barrier film - consists of several layers with the addition of aluminum mesh. It has more durable characteristics and has a fleecy or foil surface.

- Vapor barrier penofol and isospan are modern materials that protect not only from moisture, but also retain heat.

- Kraft paper. If condensation or water gets in, the material loses its strength, so it is used only for a relaxation room.

- Aluminum-coated foil is suitable for absolutely all baths, as it is not afraid of heat.

Group I - Hydro-windproof membranes

These include: AQ proff, A, A (with OZD), AS, AM.

The main purpose is to protect enclosing structures from condensation and create vapor barriers in non-residential parts of premises (attics, basements). And also to compensate for temperature differences in heated and unheated rooms. It is necessary to understand how different aspects of a vapor barrier “work.” Although perhaps this is an educational program and all readers understand the physics of the process. So, I includes:

Izospan AQ proff is a three-layer durable hydro-steam and windproof membrane. AQ proff is laid over the insulation, without sheathing. It features excellent vapor permeability. The figure shows the main areas of application.

And with OZD (the same, but with thermal protective properties) – it reduces the risk of fire of structures and materials during operation of the welding machine. And also when using a gas burner or blowtorch during waterproofing of enclosing structures. Often used for ventilated facades. Vapor permeability = 1500 g/m²/day.

AS – three-layer membrane film. Purpose – vapor barrier of walls, roofs, as well as insulation from external moisture and steam emanating from the room; Vapor permeability = 1000 g/m²/day. The most durable brand of the entire group.

AM is a high-strength two-layer membrane. Purpose - laid out on top of the insulation and protects it from condensation and wind exposure.

Foil vapor barrier for a bath

For a steam room, the most suitable option for steam protection is a foil vapor barrier. This is a universal material that also has insulation properties.

It is used for walls and ceilings, attached with foil on the outside and insulation on the inside, resulting in a thermos effect in the room.

The following manufacturers of this material are represented on the market:

- Rockwool Lamella MAT is a foil vapor barrier of increased strength due to the perpendicular arrangement of stone wool fibers. The mat is not deformed during installation. Can be used at temperatures up to +250 degrees.

- Izover Sauna is a vapor barrier made of foil and glass wool, designed specifically for saunas and steam rooms. Izover does not require additional installation of films and membranes.

- Knauf Insulation is mineral wool with a filtered coating, designed for high temperatures of +600 degrees.

- URSA M-11 - vapor protection for wet rooms with a foil reflector.

- Izospan is a modern coating with a wide range of products for both vapor barrier and waterproofing, made of polypropylene film. This material is universal; it is used to cover both showers and steam rooms.

There are such types of isospan used in baths: FS, FX, FB.

Izospan FS is capable of reflecting heat radiation thanks to the metallized film. It protects the insulation and internal elements of the structure from vapors. It can withstand temperatures up to +80 degrees without losing its properties.

Izospan FX is a reflective heat-steam-waterproofing material in the form of foamed polyethylene fiber. The thickness of the product is 2-5 mm. On one side, the FS brand is covered with a foil Mylar film, which gives the isospan elasticity and flexibility.

Izospan FB consists of kraft paper and metallized lavsan. The material is capable of performing its functions at temperatures up to +140 degrees. The FB brand reduces heat loss through different surfaces, while retaining steam inside, and also prevents the appearance of dampness in the steam room.

Technical characteristics of Izospan FB

| Characteristics | Izospan FB | Unit |

| Density | 132 | g/m² |

| Thermal reflection coefficient | 90 | % |

| UV stability | 3-4 | months |

| Tensile load | 350/340 | N/5cm |

| Resistance to vapor permeation | vapor-tight | |

| Waterproof rating | waterproof | |

| Temperature Range | -60 to +140 | °C |

Bath ceiling vapor barrier

Everyone knows that warm air always rushes upward. In the bath room - to the ceiling. This important point must be taken into account when constructing a bathhouse and its arrangement, and care must be taken in advance to reliably protect the ceiling from excessive steam.

A vapor barrier for the ceiling is chosen in the same way as for walls - with a foil covering, since it is through it that a large loss of heat occurs in the event of improper installation of insulation.

It should be remembered that during installation of the vapor barrier film, it is necessary to ensure its complete tightness and not allow steam to penetrate under the skin through joints or gaps. For this purpose, all seams are treated with special adhesive tape or tape with a metallized coating.

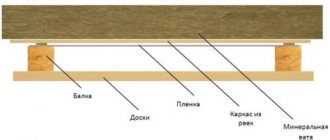

Vapor barrier of the bathhouse ceiling is carried out according to the following scheme:

- First of all, insulation is applied to the surface. To do this, select one of the universal materials based on mineral wool. The laying layer is twice as large as on the walls.

- If the ceiling is rectangular, it is recommended to glue the sheets lengthwise so that there are fewer seams.

- The film is placed on the ceiling overlapping the walls.

- The canvas is secured with staples at the edges, after which it is pressed with a stapler to the sheathing on the ceiling.

- Each subsequent canvas overlaps the previous one and completely covers the entire ceiling space.

- The joints between the films and the junctions between the ceiling and the walls are securely taped with foil tape.

- For reliability, at the final stage, another layer of insulation is laid on the roof side so that condensation does not fall on the insulation from above.

The insulation of the ceiling in the bathhouse is completed by the stage of filing the boards on the side of the steam room. Before fastening, the wood must be treated with an antiseptic.

What is it for?

The main purpose of this structural element of the ceiling cake is to protect its remaining elements from getting wet.

Everything seems to be clear. However, a logical question arises: is it needed in the entire bathhouse or can it be limited to the rooms that are the most humid - the steam room and the washing room?

The answer to this is simple: no, you cannot limit yourself to a steam room and a washing room, because vapor barrier is part of the standard ceiling pie, regardless of the room in which it is being built. Why is that?

The fact is that moisture accumulating between the fibers of stone wool significantly reduces its thermal insulation properties. After all, the main heat insulator is always air. We simply create a heat-resistant environment for it in the form of thin mineral wool fibers or clay partitions in expanded clay balls. Water, on the contrary, connects the fibers (this does not apply to expanded clay, the clay is baked there, and water does not get inside the balls), improving the conductivity of heat through this medium.

Condensation forms not only when the room is very humid, but also when there is a temperature difference between what is inside and what is outside. And humidity is present in any room and outside it; it is a natural component of the air.

CONCLUSION! Ceiling insulation is more a tribute to the properties of the heat insulator and wooden structures, which also do not tolerate moisture well, being destroyed by it, rather than a characteristic feature of a bathhouse or specifically a steam room with a washing room.

In the Russian steam room

The above does not mean that a steam room or washing room does not need increased protection from moisture. Steam is water droplets heated and suspended in the air, rising upward to the ceiling. If you don't put an obstacle in place, they will go higher, settling on the colder parts of the structures.

In terms of the amount of steam, the Russian steam room is second only to the Turkish hammam, but it is usually finished with tiles or mosaics, which makes it less sensitive. The Russian steam room is traditionally finished with wood, and if its surface layer, for example, lining, is inevitably sacrificed and takes on all the blows of increased temperature and humidity, then the inner layers can (and should) be protected.

We will talk about the methods of vapor barrier of the ceiling in a bathhouse a little lower, but for now it is important to draw conclusions - a Russian steam room clearly needs a well-thought-out and powerful vapor barrier. Does the same apply to the sauna?

In the sauna

It is not for nothing that the Finnish sauna is called “dry air”. In the orthodox version, the humidity in the sauna is minimal, amounting to no more than 5-15%. The Finns don’t pour much water on the stones, which is understandable - they either lay them out in a mound on top of the stove, or in a mesh covering the body, and this does not give the stones the heat needed to produce light, fine steam. Instead, the steam is thick and heavy.

In addition, the high temperatures of the Finnish steam room do not allow a person to easily absorb excess steam.

IMPORTANT! There is a rule - the higher the temperature, the less steam is needed for people to feel comfortable in the steam room. The reverse is also true

The third essential property of a sauna is its vigorous air exchange, which is achieved using natural or forced ventilation.

Let's summarize: the sauna has good ventilation and high temperature, both of which help eliminate excess moisture, so even the surface layer of the ceiling will not suffer much during the procedures. However, insulation of the ceiling is mandatory, which means you need to make sure that the insulation does not accumulate condensation even due to temperature differences. Therefore, it still needs to be insulated, except that the vapor barrier itself can be standard, but (since the temperature in the sauna is high) it must be designed for exposure to heat.

Proper waterproofing of the top of the insulation will also help, but more on that later.

Vapor barrier of bath walls

For the walls of the bathhouse from the inside, the same materials are used as a vapor barrier as for the ceiling. The step-by-step process of vapor barrier of walls in a steam room is as follows:

- The required amount of material is calculated along the perimeter of the walls plus an additional 15 centimeters for overlap on the ceiling. To minimize the number of joints, the film is mounted horizontally along all walls of the bathhouse.

- It is recommended to apply the material from bottom to top and with an overlap of about 10 centimeters on adjacent surfaces.

- Foil isospan is attached with the shiny side inside the room, the base to the insulation.

- The film is installed to the sheathing using a stapler at a distance of up to 20 cm.

- If the film is attached using strips, they are nailed to the sheathing at the ends and then fixed with nails every 20 centimeters.

- Each new part of the roll begins to be laid from a corner, overlapping the previous layer of insulation and the floor.

- If there are windows in the walls, the film is additionally taped along their perimeter.

- All joints are secured with tape to eliminate even small cracks.

- Finishing is done on top of the planks. In the case of fastening with staples, boards 2-3 centimeters thick are stuffed on top to ventilate the vapor barrier.

How much will it cost to vapor barrier a bath?

Using the example table of different vapor barrier materials, you can see the price per square meter of each product. This will give an idea of the average cost of installing a vapor barrier in a bathhouse. Knowing the area of the bathhouse, it will not be difficult to calculate how much its vapor barrier will cost. If you follow all the above installation rules, the bathhouse will be reliably protected from steam and moisture, which means it will last a very long time.

| Brand | price, rub. for 1 m2 |

| Rockwool Lamella MAT | from 92.0 |

| Isover Sauna | from 90.0 |

| Knauf Insulation | 55 |

| URSA M-11 | from 55.0 |

| Izospan FX | 40 |

| Izospan FS | 28 |

| Izospan FB | 30 |

Vapor barrier of a bathhouse is not a difficult job, but it is painstaking. Particular attention in this process is paid to the correct selection of a high-quality vapor barrier that will protect the room from excess moisture, fungus and damage to the insulating layer, as well as the correct installation of the material on the walls and floor of the steam room. If these points are taken into account, the film is properly laid, the energy efficiency of the room will increase significantly, which means that the bathhouse will delight its owners for many years.

Screenshot of cost from one online store

Dear partners and customers!

We are glad to see you on our website!

We draw your attention to the fact that recently there have been more frequent cases of counterfeit products appearing on the market, as well as fake Izospan materials that clone the appearance, symbols and use similar names.

Deceived by the external similarity of the products, buyers purchase low-quality goods, and as a result, problems arise with its use.

Hexa Nonwoven Materials LLC, a manufacturer of materials, has been working in the Russian construction market for 17 years, constantly developing its product range, improving technologies and equipment. We carefully control every stage of creating films and membranes so that the quality of our materials always remains at a high level, allowing us to create and maintain an atmosphere of comfort and coziness in your home.

Please be careful when choosing and purchasing materials! Remember that the joy of a low price quickly gives way to disappointment from a low-quality product.

How to spot a fake can be found here...