Electric sauna stoves are in great demand today - there are many who want to make a sauna in their home or even apartment.

Samples of heaters that have a capacity of up to 40 kg of stones can only be suitable for saunas, and up to 120 kg can be used in the “Russian bath” mode. But no matter what the capacity of the oven may be, the procedure for filling it itself is associated with some safety rules, which will be presented below.

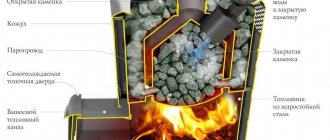

Laying stones in an electric heater

An electric heater is a container inside which heating elements ( tubular electric heaters) . They are located at a certain distance from each other, which allows installation between individual heating elements.

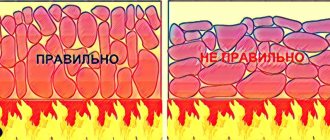

The main difference between filling an electric heater is the size of the fractions. A relatively small fraction is taken, somewhere around 4-7 centimeters on the larger side. The stones are placed between the heating elements in such a way that there is always a small space between them, as well as between them and the heating elements.

If you place the filler too tightly, the heating elements will not be able to give off heat as they should, so they will go out of the passport heating mode. And elements that regularly overheat will fail before their average service life. In addition, dense packing increases the heating time of the bath. And yet, the last layer of stones should completely cover the heating elements that do not reach the side of the electric heater.

Here the stones are somewhat large for this stove and it doesn’t make sense that they stick out so high on top, the tops won’t warm up anyway

By the way, the installation order is no different from that mentioned above:

- sort the stones into batches of the same size;

- Place the larger ones down.

Weigh the filler and compare the weight with that recommended in the electric heater’s data sheet. You should know that both overload and underload are equally unacceptable.

It is worth going through the contents of the heater in such a stove 1 or 2 times a year to get rid of dust and broken stones - cracked, broken into pieces.

Useful video

Video on the topic: a visual demonstration of how to properly place stones in an electric heater.

Rules for choosing artificial stone

In all the variety of products offered from this artificial material, it is easy for an unprepared buyer to get confused. To prevent this from happening, it is necessary to identify the main positions by which this material should be selected.

Criterias of choice

Base materials. They can be very diverse - granite, marble, sand chips, gypsum. The choice will depend on preferences and the style in which the stove or fireplace is lined.

Safety certificates. In the production of facing materials, many substances containing complex chemical compounds are used. Therefore, a hygienic certificate for the product is required. Type of substrate. Finishing the stove with flexible stone involves the presence of curved surfaces. Regular rectangular blocks are suitable for strict geometry with angles of 90 degrees. Date of production. Artificial elements must rest for at least a month before they can be worked with

You should pay attention to the production date of the batch on the packaging.

The best manufacturers

Is it possible to line a stove with artificial stone without buying expensive European materials? Below are comparative examples to help you navigate the prices and make your choice:

- Artificial elements of the “Byzantium” series. Russian production from New Technologies Stone. Price per 1 sq. meter - 1130 rubles.

- Artificial alpine slate. Available in several colors. Russian production. The cost is 540 rubles per 0.5 sq. m. meters.

- Gypsum cement tiles "Chateau". Produced by Russian. Environmentally friendly inorganic materials are used as dyes. The price is 290 rubles per 0.5 sq. meters.

- Artificial elements of the Milan series. Russian production from New Technologies Stone. Price per 1 sq. meter - 1064 rubles.

- Artificial cream facing stone REDSTONE Old Peter SP-13/R. Russian production, price per 1 sq. meter will be 1250 rubles.

- Facing elements White Hills Fjord Land, lilac color. Russian production, 45 pieces per package, price per 1 sq. meter will be 1160 rubles.

- Facing elements “Ideal Stone”, Booth collection. Produced by Russian. The cost is 990 rubles per 1 sq. meter.

- Artificial facing stone Ideal Stone, Jurassic marble collection. Produced by Russian. The cost is 1390 rubles per 1 sq. meter.

- White Hills North Ridge siding, white. Russian production, 15 pieces in a package, price per 1 sq. meter will be 1450 rubles.

- White Hills Rutland cladding elements, white. Russian production, 21 pieces in a package, price per 1 sq. meter will be 1320 rubles.

Stones for electric heaters: which ones are better

An electric heater is a type of sauna stove that is suitable for all types of natural stones that have the properties necessary for a sauna . Let us remember that we are talking about heat capacity and thermal conductivity , thermal expansion and heat resistance .

The best stones for an electric heater are those that optimally combine acceptable indicators for all these characteristics. Plutonic rocks have particular heat resistance (the ability to withstand multiple cycles of cooling and heating) , heat capacity and thermal conductivity are inversely dependent, but the heater is more important than the first (note that cheap rocks have excellent performance). As specific examples, we will name: jadeite, dunite, peridotite. Representatives of other classes will also work, for example, soapstone - this stone is recommended by the stove manufacturers themselves. as well as crimson quartzite, gabbro-diabase, porphyrite. Jade is also expensive, but beautiful.

Thermal expansion will affect the packing density - the higher the indicator, the more empty space will have to be left.

The only requirement specific to an electric heater concerns the size of the stones. They should be smaller than for other types of ovens, as mentioned above.

Choosing stones for a bath

Before we begin choosing stones for a bath, let's first name the qualities that they should have. Nobody wants to go through the heater every month, which means they shouldn’t deteriorate quickly (the fact that sooner or later destruction awaits any rock is beyond doubt).

Destruction depends on the thermal stability of the sample, on its ability to withstand cycles of heating and cooling. What breeds are best suited to this? – Those that were formed at great depths, at high temperatures and pressures. This is fully applicable to the class of plutonic rocks (the deepest lying igneous rocks), to a lesser extent to volcanic rocks, because when they form, an amorphous structure often appears, that is, volcanic glass, which will be fragile.

Metamorphic rocks are sometimes stronger than their igneous counterparts - we know this from the example of quartzite and quartz. But sedimentary rocks are too weak to withstand heating, even if they are a product of the breakdown of igneous rocks.

The second important quality is heat capacity. In practice, a high heat capacity means that the stone will continue to give off heat for a long time after heating has ended.

Heat capacity depends on the structure of the substance, its density and mass. This means that the higher the density, the more heat accumulates.

The third quality is the heating rate, which is a consequence of the thermal conductivity of the material. The better the heat is conducted, the faster the material heats up. Although it should be taken into account that the best conductors cool faster.

So, first of all, let’s categorize the available breeds. Igneous ones include:

- Basalt;

- Gabbro-diabase;

- Granite;

- Dolerite;

- Dunit;

- Jade;

- Peridotite;

- Porphyrite;

- Chromite.

White quartz is of both igneous and metamorphic origin. The list of metamorphic ones will be shorter:

- Raspberry quartzite;

- Nephritis;

- Rodingitis;

- Soapstone;

- Jasper.

Now it’s worth looking at what values density, heat capacity and heat transfer take in each specific case. If a range is given, this means that stones from different deposits may vary within these limits.

| Breed | Density g/cm³ | Thermal conductivity coefficient W/(m*K) | Specific heat capacity kJ/(kg*K) |

| Basalt | 2,6-3,25 | 0,4-3,5 | 0,5-2,1 |

| White quartz | 2,6—2,65 | – | 0,75 |

| Gabbro-diabase | 2,79-3,3 | 1,7-3,3 | 0,8-0,9 |

| Granite | 2,34-2,76 | 1,1-3,9 | 0,2-1,5 |

| Dolerite | 2,79 – 3,3 | see basalt, gabbro-diabase | see basalt, gabbro-diabase |

| Dunit | 3,28 | 1,1-1,9 | 0,6-0,8 |

| Jade | 3,25-3,35 | 2,3-3,6 | 0,88 |

| Raspberry quartzite | 2,68 | 2,6-7,6 | 0,7-1,3 |

| Jade (amphibolite) | 2,95-3,4 | 1,6-2,9 | 1,0-1,2 |

| Peridotite | 3,2-4,4 | 3,8-4,9 | 0,9-1,1 |

| Porphyrite | 2,67 | 0,7-3,5 | 1,6-1,7 |

| Rodingitis | 2,99 | – | – |

| Soapstone chlorite | 2,7-2,98 | 3,3 | 0,98 |

| Chromite | 4,5-5,0 | – | – |

| Jasper | 2,6 | – | – |

You may wonder: why is such heat-intensive basalt not used in heaters? The reason is simple: basalts (not dolerites) often contain volcanic glass, which makes them fragile. In addition, the spread is quite large: from 0.5 to 2.1.

But porphyrite is undoubtedly an excellent choice of stone for a heater. It is suitable for a bathhouse, and its heat capacity is high. It does not heat up too quickly, and its density is average, but it will give off heat the longest.

Unfortunately, there was no data on chromite, but judging by the reviews, it is quite good for a bathhouse. There are no indicators for jasper either, but its data should not differ much from quartzite.

We also have a sign indicating the “longevity” of the stones in the bathhouse. It should not be considered completely reliable - some figures may be exaggerated, others understated (for example, gabbro-diabase in reality can last more than 6 years, but here they say 2 years), but when choosing stones for a heater, you can approximately use it as a guide. In addition, the service life of artificial fillers is also given here. Yes, and the compilers assumed the frequency of using the bathhouse once a week.

| Name | Term |

| Nephritis | 10 years |

| Jade | 4 years |

| Jasper | 2 years |

| Chromite | 5 years |

| Quartz | 3 years |

| Soapstone chlorite | 3.5 years |

| Dunit | 6 years |

| Quartzite | 4.5 years |

| Porphyrite | 5 years |

| Gabbro-diabase | 2 years |

| Cast iron | 6 years |

| Porcelain | 10 years |

*** In conclusion, it remains to add that it is better to select stones for a bath together with a geologist, and it is most profitable to do this in a quarry. If this is not possible, then at least check the stones before purchasing - for sulfides, serpentinite, and also for strength. We can only wish you good luck!

Find out more in the section on bath stones:

About laying in the oven and separately about laying in the electric heater;

How to choose what to pay attention to;

Rating of the best stones according to readers, in the article about the best stones.

Laying stones in the Sawo 60 electric heater

The Sawo company produces good equipment for baths, among which there are quite budget models that are in demand among domestic consumers. Since readers have shown interest in being told how to lay stones in a sawo 60 electric heater, we are meeting them halfway.

By the way, this is exactly the case when artificial stones cannot be used. The manufacturer generally advocates that his heater be purchased complete with his own stones (made of soapstone, presumably). And if the owner does not have experience in collecting or buying pebbles, this may be a good option.

- Rinse and dry the selected stones.

- Place them evenly, with sufficient gaps.

- Don't let them lean on the heating elements.

- Air should circulate easily near the walls.

- It is also important to ensure that the upper rows completely cover the heating elements. (Only in this case will the heater operate normally.)

How to cover a stove with artificial stone with your own hands

Cladding a stove with stone with your own hands is a fairly simple matter. But it requires a certain set of tools, surface preparation for cladding, calculation of the required amount of material required, as well as jointing.

List of required tools

To carry out such work, you will need a few tools:

- A grinder or angle grinder equipped with a disc for concrete.

- Trowel for plastering work.

- Construction level.

- Measuring tool (tape measure or ruler).

- Master OK.

- Rubberized bucket for cement mortar.

Calculation of material quantity

Before purchasing the required amount of material, you should measure the surface to be covered and calculate the total area of work. Another 10-15% should be added to the resulting figure, since parts of the decorative elements will be cut off, and they may also be damaged during transportation.

The required amount should always be rounded up. If the material is sold in packages with a certain number of pieces in it, then you should take packages from one batch and with an estimated reserve. It should be remembered that the color of artificial stone in different batches of the same model may differ.

Surface preparation

Before starting the main process and covering the stove with decorative stone, you should carefully prepare and level the surfaces of the stove on which the installation will be carried out. To do this, you need to moisten the brickwork using a spray gun, and then apply a solution of plaster or sand-cement mixture. The work is carried out using a trowel.

Layers of plaster are laid with uniform movements from top to bottom, their thickness should be 5 - 8 millimeters. Additionally, it is recommended to reinforce this layer using a special mesh, or hemp or tow. Upon completion of plastering the surface, it should be carefully primed using solutions with high adhesive properties such as “Betonokontakta”.

Artificial stone laying technology

- Cladding work should be carried out starting from the corners of the stove.

- Using a trowel, a layer of mortar is applied to the decorative stone element, then it is applied to the primed surface and the mortar is leveled with light movements from side to side.

- Excess mixture is removed using a trowel.

- Upon completion of laying a number of elements, using a building level, their pressing into the solution is adjusted.

Rules for seaming

There are seamless and jointed options for laying artificial material on a stove or fireplace. The installation option with jointing is more reliable when exposed to high temperatures. After laying the main part of the artificial stone is completed, the joints are filled using a bag with a cut off edge, and excess mortar is also removed.

How to lay stones in a sauna stove on a heater: rules for selecting and placing stones

We will send the material by email

There are many difficulties and nuances in the construction and arrangement of a bathhouse. Some of them are related to the equipment of the furnace, which should not only heat the room well, but also provide it with the right steam. The heater, its design, volume, location and filling are responsible for this part of the work. And if you don’t know how to place stones in a sauna stove correctly, you cannot count on the quality of sauna procedures and the long operation of the stove. It’s these little things that many people simply don’t attach importance to that determine how “light” the steam will be in your sauna.

What properties of stone are taken into account when laying

The choice of stones for a bath is influenced by their cost, as well as a number of physical and chemical properties. First of all this:

- safety - when water is heated and evaporated from it, the stone should not release substances hazardous to health;

- strength directly dependent on heat resistance - the material should not be destroyed by exposure to high temperatures;

- Heat capacity – the ability to accumulate a large amount of heat and retain it for a long time.

Not all rocks have a full set of these important characteristics, so it is impossible to fill the heater with boulders of unknown origin found on the banks of a river or in the mountains. It is better to buy them in specialized stores, having inquired in advance about the properties of the selected filler.

But the listed properties have little effect on how to properly place stones in a sauna stove in order to get the maximum return and benefit from them. It is more important to consider thermal conductivity and size. And if great importance is attached to the aesthetic component of the steam room interior, then so is the appearance.

Types of stones, their characteristics and effects on the human body

Scientists from the Moscow Scientific Center conducted a whole study in 1999 and determined which stones are best suited for steam baths. The main criteria that were emphasized:

- Harmful additives and impurities are not allowed in the composition;

- meet quality characteristics (tolerate high temperatures, keep warm, warm up quickly and evenly, etc.;

- Suitable for use in wooden saunas.

| Breed name | Characteristic | Average price in retail chains, rub./kg |

| Jade | It has a positive effect on the genitourinary system, normalizes the functioning of the heart muscle and nervous system. It has a dense round shape and good heat dissipation. Low moisture absorption coefficient, durable. In ancient times it was used to make weapon tips; in the Middle Ages it was used to build fortresses and castles. Semiprecious stone. | From 980 |

| Soapstone chlorite | Helps improve immunity, lowers blood pressure, increases blood circulation, and cleanses the respiratory tract. It tolerates high temperatures of more than 1000 °C and can hold heat for more than 24 hours. Used to make heat-resistant cookware. | From 860 |

| Gabbro or Diabase | Black colored stone. It has a positive effect on the respiratory system and is useful for asthmatics. It practically does not absorb water and heats up quickly. Used to make building material. | From 530 |

| Raspberry quartzite | Can heat up to 2700 °C and holds heat well. Due to its unusual appearance and color, it is used not only for filling the heater, but also in declaring elements. It has a positive effect on male potency and improves blood circulation. The steam formed on the stones has healing infrared radiation. Due to its low cost and high quality characteristics, it is a real find for a bathhouse. | From 520 |

| Quartz white | This is the most common type of bath stone, which is why it is popularly known as “bath stone”. It acquired its white color due to the high concentration of oxygen in it. When cooled, the breed releases ozone, which has a positive effect on the condition of the skin. White quartz is used to charge water in cosmetology. Holds heat well and warms up quickly. The only downside is that it doesn't last long. | From 120 |

| Peridotite | This is a very beautiful stone. which can have a color range from light gray to rich black. But the stone has poor healing properties, so it is used for laying on the bottom of the heater. Heat accumulates quickly, but also cools down in 2-3 hours. | From 120 |

| Basalt | It retains heat well and is used to make protective elements against fire. In baths, peridotite is used as a base for medicinal rocks. | From 70 |

We invite you to familiarize yourself with: Installing a stove in a bathhouse with an external firebox

The price of bath stones may vary depending on the region and volume of purchase. But you can save money and collect the material yourself.

Laying options

The choice of how to properly place stones in a sauna stove depends on their characteristics. In order for the temperature in the steam room to remain high for a long time even after the fire in the firebox has gone out, it is necessary to properly equip and fill the heater. The main task is to spend less time and fuel on heating the stones and ensure their slow cooling. This can be done in different ways.

Laying taking into account thermal conductivity

This installation method is used when stones of different types with different degrees of heat transfer are used as a filler for the heater. In order to heat the entire mass up to the very top as quickly as possible, it is necessary that the lower layers heat up easily and transfer heat to those located above. That is, the lower the stone lies, the higher its heat transfer coefficient should be.

This is interesting! In the royal baths, instead of stone, cast iron cores were placed on the bottom, the thermal conductivity of which was many times greater. They are still used in modern Sanduns.

We present the maximum thermal conductivity coefficient for the main rocks used in heaters:

- crimson quartzite – 7.6;

- soap chloride – 4.7;

- jadeite – 3.6;

- basalt – 3.5;

- porphyrite – 3.37;

- gabbro-diabase – 2.98.

Laying according to shape and size

If you use a stone of the same type, it is advisable to purchase it not of the same size, but of several different fractions from 5-6 to 12-15 cm on the long side. To understand how to correctly place stones in a heater in a sauna, you need to think logically: the larger the element, the greater the amount of heat required to warm it up. This means that it is better to place it closer to the heat source.

It follows from this that the installation must be done in layers, reducing the size of the cobblestones in the direction from the heat source outward. In this case, be sure to take into account the design of the stove and the heater itself, which can be open or closed.

However, small stones also have less surface area in contact with neighboring elements, which reduces heat transfer and heating rate. This problem can be solved by correctly positioning the stones in relation to each other and to the heat source, taking into account their shape.

What rocks are recommended for laying in the heater?

For permanent use, it is recommended to use rocks with the most suitable properties

It is worth noting that these stones are presented in specialized stores of bath accessories

Conventionally, rocks suitable for laying in a stove can be divided into three classes - accessible and inexpensive, middle class, and top quality material. The differences are mainly related to the properties of the stones. The most expensive brands have high heat capacity and a long service life. The middle segment is represented by stones that combine both good appearance and the possibility of long-term use. The budget segment is usually represented by a group of stones that are the most common and available in the region. However, the budget segment of stones, with additional processing - giving a rounded shape, forming packaging with stones of different fractions, can significantly increase in price and compete with the middle, or even premium class.

The following types of stones are mostly presented on the market:

- Basalt is the most popular type of budget material. It is durable, has high heat capacity, and retains its shape for a long time. Unlike granite and marble, it does not crumble into small fragments. It can be both in raw and polished form.

- Gabbro-diabase is an excellent material for long-term use in a private bath. Its volcanic origin makes it resistant to temperature overloads. The mineral composition of this stone is very rich and therefore this stone is most popular as a healing agent in bath procedures.

- Quartzite is a stone that is excellent for use in heaters for large steam rooms. It heats up well and retains heat for a long time, however, it cracks relatively quickly and is therefore recommended for use in conjunction with other types of stones.

- Peridotite is a rock that can withstand not only high heating temperatures, but also significant temperature changes. It has, according to connoisseurs, a whole range of healing properties.

- Soapstone is a mineral with one of the highest heating temperatures. Without changing its properties, it is able to withstand temperatures up to 16,000 degrees. Stone is considered one of the most valuable materials for filling a heater.

- Jadeite is a natural stone that is considered a bath jewel. It not only has excellent physical properties, it is also distinguished by its interesting appearance. This breed is usually classified as a premium type of stone for a steam room.

As practice shows, in addition to the stones recommended for use in a sauna stove, it is also necessary to point out points that simply need to be treated with special attention. First of all, this is something that cannot be used for laying limestone and sandstone

These rocks have difficulty withstanding high humidity and temperature. They are unsuitable for a heater - they do not hold the temperature well, cool quickly and begin to crack when moisture gets on the surface.

The second point is that for the heater you cannot use stones with traces of cement or those that were used for paving roads or filling a railway embankment. Such specimens were repeatedly treated with chemicals, traces of which are unlikely to be removed even after several years. That is why it is recommended to purchase a certified product for bookmarking at a hardware store.

What else to consider when filling the heater

To get the maximum benefit and pleasure from bath procedures, just knowing the rules for laying stones is not enough. It is also advisable to understand their impact on health, be able to determine the required loading volume, and clean and replace them in a timely manner.

How much stone do you need?

When buying a ready-made factory furnace, they focus on the characteristics declared by the manufacturer and select equipment of the required power. As a rule, the volume of the heater in such stoves is sufficient to warm up and maintain the temperature in the steam room, the size of which the stove is selected for.

When installing a homemade brick or metal heater, the required number of stones is calculated based on the volume of the room. It is believed that for every cubic meter there should be about 40-50 kg.

Video description

This short video explains how to determine the weight of a stone backfill:

Can different breeds be used?

There are no and cannot be any objections to mixing stones of different origins in one heater. On the contrary, this approach makes installation easier.

- Allows you to optimize costs by using inexpensive materials for the lower layers.

- Lay down the strongest and most heat-resistant rocks.

- Create an aesthetically attractive composition from stones of different colors.

Which form to choose

Many questions are related not only to how to place stones in a sauna stove, but also to the choice of their shape and processing method. They are polished, tumbled and chipped.

- Stone polished or polished by river water has a surface that is too smooth and does not hold water well.

- Chip stones are more susceptible to destruction than others due to existing cracks and thin edges.

- Galvanized and bunded elements are the most suitable, since during processing thin edges are cut off, and specimens with cracks are discarded.

In addition, stones with irregular, uneven edges have a larger heating surface; it is easier to lay them with the formation of air gaps between them. And a rough surface holds water better.

What types of sauna are there: Finnish, Russian, Turkish

The most common bath regimes in Russia today are the Russian and Finnish bath conditions. The Turkish one lags significantly behind in this regard, since it bears little resemblance to what most associate a bathhouse with.

As for the former, both, roughly speaking, are nearby on the same temperature-humidity diagram. In order not to complicate understanding, we will explain everything “on the fingers”.

A person in a steam room is simultaneously affected by heat and steam

In this case, the proportion of both is important. That’s why choosing a stove for a steam room is so important.

On a note! In order not to harm your health, you need to adhere to the rule: the more steam, the less heat there should be, and vice versa, the more heat, the less steam you let in.

Bath thermometer-hygrometer, measures air temperature and humidity

The bathhouse turned out to be akin to art precisely because the main role here is played by the skill of the steamer, a suitable stove and the ability to handle it. Because the heat can be different (soft and hard), and the steam can be different (heavy and light).

The conditions of a Russian bath are easy to remember - the temperature is about 55 degrees and the humidity is about 55 percent.

A Finnish bath (also known as a sauna) is a temperature of 90 degrees or higher, but with a humidity of 5-15 percent.

A Turkish bath (aka hammam) is a temperature of up to 40 degrees and almost 100% humidity.

As for steam, for a Russian bath you need light steam, which is formed when water is heated to a temperature above 100 degrees (this is only possible when the stones are heated strongly - up to 400 and above). In a hammam and even in a sauna, the steam can be ordinary, heavy - the same as you see in the kitchen when the kettle boils. This is acceptable, because there is too much of it in the hammam, and too little in the sauna, and the temperatures are such that it does no harm.

Accordingly, the stove you choose should be able to maintain the desired temperature and produce the right amount of steam of a certain quality. We analyze in detail the choice of electric ovens in another article. And here our task is to find the right use for the Harvia electric heater.

Harvia electric heaters: in which sauna is it better to install them?

Harvia Delta D23 oven. Harvia Photos

The ability of an electric stove to produce steam is very limited, but the reasons for this will be discussed below. At the same time, it has excellent capabilities for quickly heating the steam room to a given temperature and maintaining it using automatic means.

IMPORTANT! In other words, a regular Harvia electric heater, without additional accessories, is only suitable for a sauna. There is no point in using it for a hammam

And if you want to set up a Russian bathhouse with such a device, you will have to purchase a model with a steam generator.

How to prepare stones for laying

If you have installed a new stove, before laying the stones you need to heat it well, completely filling the tank with water. The fire in the firebox is maintained for at least 2.5-3 hours, until the smell from burning paint and other materials used in the manufacture of the stove disappears.

Before placing stones in the sauna heater, they must be washed from dust and dirt. This procedure is necessary for any stones – both store-bought and independently collected. You can use a brush or dishwashing sponge with a hard abrasive layer.

How often do stones need to be replaced?

The durability and heat resistance of each breed depends on its initial characteristics and on the mode of operation of the bath. Basalt has the longest service life - it can withstand up to a thousand heating and cooling cycles. There are breeds in which this figure is several times lower.

It is impossible to say exactly at what point the stone will become “dead” and lose its ability to retain heat. This becomes clear when changes occur in the operation of the steam room: it takes longer to heat up and cools down faster. In this case, the stones should be sorted and completely or partially replaced.

But it’s better not to wait until the last minute, but to regularly inspect the heater, unload stones, clean them of plaque and soot, remove broken and porous specimens - they are of little use.

Advice! You can extend the life of the stones and clean them less often if you make the bottom of the heater solid and add hot water to the steam.

Which form is better?

We have already discussed this issue in the article devoted to the choice of stones. Let us remind you that the choice most often lies between chopped and tumbled varieties. Polished ones are less common and we would not recommend taking them, because they do not retain water on their surface at all. The stone should be at least slightly rough.

As for the advantages of the chipped version, they all lie in the larger surface area of the uneven stone. It has many more disadvantages - where it is thin, it will break off, chipped samples often have cracks (the strongest ones remain when tumbling), in general, the tumbling version is better, and its only drawback is its higher price.

Briefly about the main thing

The main rule for laying stones in a bathhouse is that the largest elements should be placed closest to the heat source, leaving free passages between them for the movement of hot air. As it rises, it will heat up the next layers, composed of a smaller fraction. It is also advisable to take into account the thermal conductivity and heat resistance of stones, laying down the strongest rocks that easily give off heat. Ideally, you should choose the filling for the heater taking into account its design, so that one condition for proper installation does not contradict another.

Source