The Vesuvius sauna stove is produced by the domestic enterprise Litkom in the Moscow region. Experts studied global trends in the production of bath equipment: types of stoves, quality, design. Marketing research has been carried out. The basis for the production of our own line of stoves was taken from models of heating equipment for baths from Finnish manufacturers and domestic craftsmen. The products had to be of high quality, practical and functional. In addition to heating equipment under the Vesuvius brand, the company produces chimneys, heat exchangers, tanks, accessories, and components. If any component breaks down, you can replace it with “original” parts, make changes to the design, or add to the package.

Features of Vesuvius stoves

Vesuvius models are distinguished by the complete absence of sharp corners. The design of the stove has a round shape, which allows thermal radiation to be evenly distributed throughout the room, warming the air to the specified temperatures. The outer casing of the unit is made of all-welded steel plates. The metal thickness is 8 mm. The plates are secured with bolts. Fastening provides increased strength of products.

Thanks to the outer mesh, the stones in the oven are heated evenly. They dampen the infrared radiation of hot metal. The disadvantage of the outer mesh is dry steam. You won't be able to get a light, damp cloud without additional devices. For lovers of Russian steam rooms, it is better to give preference to models with a closed heater. Full use of an open-type heater in a Russian bath requires the additional installation of a steam generator.

The body of the Vesuvius furnace is coated with a protective silicone compound. The coating protects it from exposure to high temperatures and humidity. Some models are decorated with forged parts. Typical for models with a fireplace function. If necessary, you can hide the equipment behind a brick screen; models without complex decor are purchased.

All Vesuvius models have a standard chimney diameter of 115 mm and a combustion tunnel depth of 290 mm. This is convenient when replacing components.

The warranty period for cast iron models is 35 years.

Bath stove Vesuvius Legend

The Vesuvius Legend stove model is constructed of 3 cast iron parts. The thickness of the material is 12 mm. The joints of the fragments are sealed with ceramic cord. The operating temperature that the cord can withstand is 1200 degrees. This is enough for a sauna stove. All parts are secured with bolts. The pipe from the chimney firebox is separated by a bumper. The design allows for rotation of the flame in the firebox. This increases the efficiency of heating equipment four times. Cast iron maintains a high temperature in the steam room for a long time.

The stone net is installed outside. When heated, the stones provide uniform heat and shield the radiation from the firebox. The large mass of stones provides light steam. The humidity of the vapor cloud depends on the heating temperature and the amount of water in the tank. You can add water to the stones from above. In this case, the steam will turn out heavy and watery. The steam room warms up within an hour.

In the “Legend” series, the manufacturer produces models of stoves with forged elements.

The manufacturer provides a 30-year guarantee for the Vesuvius Legend model. The model from the “Forging” series has an external firebox. The element makes it possible to heat the steam room from the adjacent room.

Furnace Vesuvius Skif

The Vesuvius Skif model series is a budget line of the manufacturer. They are made from engineered steel. The thickness of the sheets is 12 mm. This type of steel lasts a long time. The walls do not bend outward or become deformed. The stove is made using Finnish technology. The joints are laid with heat-resistant cord. The part can withstand temperatures up to 1200 degrees. The parts are connected to each other with bolts. The firebox is remote. The steam room is heated from the adjacent room.

The stone net is installed outside. The steam turns out to be dispersed. Due to the design of the stove, it is suitable for a Finnish steam room. For a classic Russian steam room, the unit does not have enough humidity. This is compensated by the additional installation of a steam generator or pipe system. The volume of the steam room for the standard model ranges from 8 to 18 square meters.

The advantage of the Skif stove is considered to be its price. It is cheaper than a cast iron product. Warranty period 2.5 – 3 years.

Vesuvius 16

“Vesuvius” 16 – closed heater. Consists of three elements: body, firebox, pipe. The parts are secured with a bolted connection. It increases the strength of the structure. A ceramic cord is laid at the joints. The operating temperature of the wire is 1200 degrees.

The model is equipped with a sealed door made of cast iron. The design includes heat-resistant glass. The body is made of steel. The ventilated oven casing is made of textured metal sheets. They are coated with heat-resistant bronze-colored paint. The stove is heated from the room adjacent to the steam room. For this purpose it is equipped with a combustion tunnel.

Vesuvius 16 will warm up a steam room up to 18 cubic meters in size in 50 minutes. The heat-resistant glass built into the door allows you to observe the burning of firewood in the stove.

Advantages and disadvantages

The advantage of the Vesuvius sauna stove is undoubtedly its modern design . Some internal components are manufactured in Finland. Another advantage is the different models of casings.

This company offers models in different price categories.

The disadvantages include inadequate quality control . Many negative reviews are due to manufacturing defects.

But in general, all the happy owners of the Vesuvius sauna stove give good reviews, believing that these stoves are universal and have shown themselves to be excellent in operation. On the websites of this company you can always get acquainted not only with the appearance of the furnace, but also better find out the detailed operational characteristics.

Installation of the Vesuvius furnace

Installing a stove is the most important undertaking. The equipment interacts with flammable materials indoors. Fire safety standards must be strictly observed during installation. But before describing the installation process, a few words should be said about choosing a model.

The market offers the installation of metal heaters in bathhouses and stone ones. Metal models benefit from their practicality and safety. The choice of model depends on factors:

- volume of the steam room;

- type of thermal insulation;

- area of the entire bath;

- desired temperature and humidity levels in the steam room;

- heating time.

Attention!

If you decide to install the device yourself, you need to carefully read the manufacturer’s instructions. It indicates the installation features of a specific model. The first step is to prepare the floor. The furnace installation area is covered with a metal sheet, or brickwork is installed. Indentations are made by 15-20 centimeters on all sides. The top is covered with a steel sheet or a cement screed is poured.

The oven is installed on the surface, observing the indentations. They are specified in the installation instructions for a specific model.

Important! The distance from the stove to the ceiling is 120 centimeters, from the heating device to the partitions is at least 32 cm.

It is possible to reduce the distance by several centimeters if there is additional protection in the form of a metal sheet.

When installing the stove, you should take into account the direction of the heating chamber. Models may involve loading fuel from adjacent rooms. This condition complicates installation, but provides more advantages when operating the furnace.

The next step is the installation of a mounted tank. It is installed in an adjacent room, or, in accordance with the instructions, for a specific stove model.

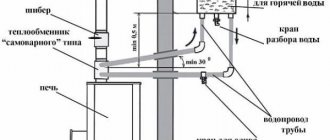

The heat exchange system consists of the following parts:

- heat exchanger;

- fittings;

- remote tank;

- connection elements.

When installing a heat exchange system, you should not use flexible plastic or rubber liners. In order to avoid freezing of water in the system in winter, a drain valve is built into the lower part of the fitting.

The last step is to install the pipe. It must be at least 5 meters. It is worth paying attention to the chimney pipe. It is made from fire-resistant materials. The height of the pipe must exceed the roof level of the nearest houses.

Start the oven only after thoroughly checking all connections and fasteners. During the first heating, an unpleasant smell of burning and chemical industry products may be felt. These are burning oils that got into the unit during the manufacturing process. It should be heated for an hour. During this time, the tank, heat exchange system and other parts of the furnace are checked.

Characteristics of the Legend Lux model

This Vesuvius stove is suitable for steam rooms with an area of about 12 square meters. meters. The convector in the device is installed on the lower frame. The oven is easy to use. The ash pan for this purpose is of a pull-out type. The external tunnel is 2.2 cm in diameter. The immediate rear wall is not wide. The grate in the design is located next to the convector.

The cut-off valve in the oven has three holes. The afterburner is large, so heating is quick. In this case, steam can be easily obtained using a dispenser. The model has a blower with a vault. The ceiling on the frame is made of steel and is not subject to deformation. On the market, this stove will cost the buyer about 42 thousand rubles.

Heat exchanger for Vesuvius furnace

The heat exchanger for the Vesuvius stove looks like a geometric stainless steel container. Material thickness 1 mm. It is designed to heat water in rooms adjacent to the steam room. The heat exchanger is attached to heating and water supply systems using a fitting. To prevent depressurization of welding seams, water is poured into the heat exchanger before starting the system.

Plastic pipes must not be placed close to the heat exchanger. The material is not able to withstand high temperatures. A metal corrugated pipe is used for the tank.

Model "Lava-16 SV"

These Vesuvius stoves have good reviews, but it should be borne in mind that they are suitable for rooms whose area does not exceed 15 square meters. meters. The lower frame of the model is made of stainless steel as standard. Many buyers praise this oven for its high-quality convector. It is installed on the model immediately above the frame. If necessary, you can clean the ash pan yourself.

The back wall of the stove is low. Three hole cutter. In this case, the design does not provide for a dispenser. The stove's vent is small. Installing a chimney is quite simple. According to the owners of the model, the valve rarely overheats. During installation, the chimney apron should be very tight. Today a stove costs about 33 thousand rubles.

Recommendations for use

The manufacturer of equipment for Vesuvius steam rooms prescribes recommendations for operating the device in the instructions for the models. You should familiarize yourself with them in advance and strictly follow them. This affects the service life of the device and the company’s warranty obligations. When working with company equipment, it is prohibited:

- Use peat, coke, gaseous and liquid materials as fuel. This does not comply with fire safety regulations. The combustion temperature may exceed that for which the device is designed.

- Firewood must not exceed the permissible dimensions of the firebox.

- Do not use the device if the tank is not filled with water.

- Install in residential areas for heating.

- The chimney can only be closed when the fire has completely gone out.

- Do not burn soot from the smoke duct.

- Make changes to the original design of the furnace.

Important! To prevent the destruction of cast iron, you should familiarize yourself with the rules for laying stones. You can water the stones for steam generation at a minimum interval of 5 minutes.

If these simple requirements are met, the company undertakes to eliminate all defects during the entire warranty period or replace the device free of charge.

Add a comment or ask a question

- One-story houses

- Two-story houses

- Houses with an attic

- Small houses

- Big houses

- Country houses

- Garden houses

- Inexpensive houses

- Houses without finishing

- Houses made of laminated veneer lumber

- Houses made of dry timber

- Houses with a bay window

- Houses 6x6

- Sort up to 30 m2

- Sort from 30 to 40 m2

- Sort from 40 to 50 m2

- Sort from 50 to 60 m2

- Sort from 60 to 70 m2

- Sort from 70 to 80 m2

- Sort from 80 to 90 m2

- Sort from 90 to 100 m2

- Sort from 110 to 120 m2

- Sort from 120 to 130 m2

- Sort from 130 to 140 m2

- Sort from 140 to 150 m2

- Sort from 100 to 110 m2

- Log houses

- Frame houses

- Houses made of aerated concrete

- Baths made of timber

- Baths with sloping roofs

- Baths with terrace

- Baths with bay window

- Two-story baths

- Sort up to 20 m2

- Sort from 20 to 30 m2

- Sort from 30 to 40 m2

- Sort from 40 to 50 m2

- Sort from 60 to 70 m2

- Sort from 70 m2 and above

- Log baths

- Transportable baths

- Baths barrels

- Ready-made baths made of timber

- Foundations

- Strip foundation

- Bored foundation

- Monolithic slab

- Columnar foundation

- Foundation on driven reinforced concrete piles

- Wooden cabins

- Block containers

- Fences, gates, wickets

- Fences

- Gates

- Sale of screw piles

- Piles 108e

- Piles 89e

- Piles 76e

- Fence

- Heating furnaces

- Vesuvius

- Teplodar

- Brandenburg

- Meta

- Zota

- Termofor

- Bath stoves

- Dobrostal

- Harvia

- Vesuvius

- Bonfire

- Heat

- Teplodar

- Pechnov

- Ermak

- Termofor

- Chimneys

- Mono chimney elements

- Chimney 112mm

- Chimney 150mm

- Sandwich chimney elements

- Sandwich 112mm-200mm

- Sandwich 150mm-250mm

- Insulation

- Chimney passage units

- Chimney fasteners

- Grill houses

- Septic tanks

- Unilos

- Forum

Description of a frame house

We are building frame houses, we are working on the division of houses, we will soon fill it with projects and the equipment will appear.

Hello! I'm interested in this house in a frame for a winter stay, turnkey. What's the price? Mat. do you accept capital? Thank you.

Hello, Nadezhda. We have sent you a response by email.

Hello! I'm interested in this house in a frame for a winter stay, turnkey. What's the price? And how much will the foundation cost?

Hello, Ekaterina! We will send you information by email shortly. Thanks for reaching out!

Hello. Interested in the turnkey price frame 40

Hello. Sent you all the information by email

Hello! I'm interested in the price together with the foundation of a 150-150 turnkey laminated timber house "Cottage 40". What kind of foundation are you doing?

Hello Andrei. We make 5 types of foundations. We wrote to you in more detail by email.

Hello, Natalia. We responded to you by email. Thanks for reaching out!

Good afternoon I am interested in the cost of a turnkey project made of dry timber 150x150. Thank you.

Hello, Pavel. We will send the cost to you by email as soon as we calculate it. Thank you for reaching out!

Hello, all prices are current (indicated to the right of the photo).

Hello, I am interested in foundation piles, construction in Sochi, please write the price

Cottage 40

| Price from timber 100x150: | from 705,000 rub. |

| Price from timber 150x150: | from 776,000 rub. |

| Price from dry timber 100x150: | from 783,000 rub. |

| Price from dry timber 150x150: | from 818,000 rub. |

| Price for laminated veneer lumber 100x150: | from 881,000 rub. |

| Price of laminated veneer lumber 150x150: | from 952,000 rub. |

Our works

Veliky Novgorod, Pankovka. ST Michurynets, 4

Moscow, Pyatnitskoye shosse, turn to Barantsevo village 7 (921) 730-41-01

St. Petersburg, sh. Moskovskoe, 296 B 7 (

Reviews

The quality of Vesuvius stoves depends on the model and compliance with operating rules. Skif class models are a budget option. They require careful handling and periodic maintenance. Cast iron stoves “Legend” are highly resistant to temperature changes. Let's consider the reviews.

Banshchikov Zakhar, 53 years old, Moscow.

I have a stove installed - a Vesuvius Legend fireplace made of cast iron. It's been standing for three years now. There were no changes in it during use. Once a year I paint the grille to prevent rust. Heat for a long time. There are no other complaints.

Kravtsov Ilya, 30 years old, Kamyshin.

I bought a Skif stove. It burned out after a year and a half of operation in two places.

Bondarenko Roman, 30 years old Nizhny Novgorod.

Vesuvius "Skif" 28. They provide a two-year guarantee. In the third year, three walls burned through. You can't lay it with bricks. The walls are warped by the waves. The far support burned out. The unit is only suitable for waste.

Problems with holes forming in the stove body may be due to improper placement of stones. A dense, mosaic distribution of stones without ventilation leads to the formation of holes in the walls of the body. The second cause of the problem is frequent watering of stones with water in order to create a steam cloud. The interval between watering should be five minutes. Otherwise, frequent changes in temperature and humidity lead to the destruction of the cast iron material.

Reviews about Vesuvius sauna stoves are different. The quality of the model depends on the material from which it is made and the nuances of operation. The cheapest models of the “Skif” line are considered the “weakest” in the line. These are simple units. They are suitable for those who rarely heat the bathhouse and do not bring it to high temperatures.

How long the stove will last depends on the installation. Incorrect installation can reduce the service life of the system several times.

Opinion about “Legend of VK”

Users have different opinions about this stove. When considering the advantages, it is important to note the high-quality overlap. According to the owners, it is easy to clean. The vault in this case is installed wide, and air circulates normally in the system. The gate deserves special attention. It is installed as standard under the camera, and a thermal insulation layer is provided under it.

If we talk about the disadvantages, it is important to note the rather weak valve. Sometimes the ash pan in the device does not extend. The model has a cutter with three holes. The rear wall of the structure is small. The convector is located near the frame and is very narrow. This Vesuvius stove costs about 35 thousand rubles on the market.

Manufacturing process

To begin with, it is necessary to say that there are a number of similar products that differ in their design and operating principle. Therefore, the drawings of stoves for metal baths are different. However, they all have approximately the same operating principle (see also the article “Pipe sauna stove: manufacturing tips”).

The simplest drawing of a sauna stove

Firebox

- First of all, you need to make a firebox. Everyone determines its dimensions himself, but professionals advise making it the same height for a width of 0.5 meters.

- Many drawings of a homemade metal sauna stove involve the use of some ready-made elements. These include grilles and doors. At the same time, craftsmen advise choosing these parts made specifically from metal, since cast iron products will have to be fixed in a special way.

Project for the manufacture of a metal structure with a detailed indication of the necessary elements and their dimensions

- A typical drawing of a stove for a metal bath assumes that the firebox will consist of two sections. In the first of them, fuel is burned, and the second is needed to collect ash. Taking this into account, they are separated by a grill and made into separate doors.

- It is worth noting that the window of the ash collection sections is often used to create draft, which is necessary for combustion.

- If the drawing of a metal sauna stove involves the placement of a heater, then the upper part of the firebox is also made of a grate

Advice! To make a stove, you should use thick metal. This way the structure will not behave when heated, and it will be able to generate more heat.

Detailed drawing in correct format

Heater and water tank

- Above the firebox it is necessary to make a separate chamber with a door, which will be separated by a grille.

- Special stones will be placed in it to maintain the temperature for a long time.

- At the same time, the drawings of a metal sauna stove recommend making a closing window that can be used to supply water and create steam.

- It should be noted that ordinary stones are not suitable for such furnaces. This especially applies to material containing silicon or other inclusions.

- The top of this compartment is made with a hole for the pipe. It will remove smoke and at the same time heat the water.

Mesh heater

The furnace firebox is surrounded by a grid, which is filled with stones. Firstly, it looks beautiful and authentic in the bathhouse. Secondly, a large mass of stones is placed in the mesh. It cools down 1.5-2 times longer than a stove with a convector casing.

The convector casing is a protective metal casing around the firebox of a sauna stove. It creates convection, thanks to which the stove quickly heats the steam room, and protects the steamer from the burning infrared radiation coming from the firebox.

The only disadvantage of the heater grid is the increase in the heating time of the oven and, accordingly, the steam room. But everything is logical here. Since the oven takes longer to cool, it must also take longer to heat up.

Vesuvius Legend is available in two mesh designs: thin bar and wide forged. The second one looks more solid and costs a little more. From 2022, all stoves are equipped with a tray that prevents stones from spilling onto the floor.

Fig 3. Bath stoves Vesuvius Legend Standard and Forging