Our portal is replete with examples of the construction and operation of small, or, as they are now commonly called, mini-houses, but usually these are either frame-modular or frame structures. As it turns out, logs are also a suitable wall material, especially when the construction concept is environmentally friendly and natural. One of our craftsmen, with the nickname mike099, shared his experience with everyone interested. His topic collected all the stars, which indicates its relevance, so it makes sense to expand the reach of the audience by considering the construction process in stages:

- Eco-hut.

- Preparation.

- Foundation.

- Box.

- Roof.

- Interior work.

Eco-hut only 30 m²

mike099FORUMHOUSE user

The dream has long crept in about building a wooden house - environmentally friendly, practically without paints, mineral wool, polystyrene foam and other “benefits” of modern industry. The task is to build a solid, comfortable house with minimal effort, suitable for winter visits and year-round living, therefore shingles, boulders, mezzanines, Russian stoves and other delights of centuries past were not included in the project.

The craftsman immediately decided on the design:

- Pile foundation.

- Box made of hand-cut logs.

- Metal roofing.

- Sawdust with clay and sawdust with lime are used as insulation for floors.

At the beginning began

Experts never tire of repeating: any construction must begin with a project. And in the case of a log house, this should not be a three-page sketch, limited only to breaking up the wall elements, but a full-fledged detailed document with calculations of expected loads, indicating the size of the crown joints and gaps in the cups, etc. It follows from this that the preparation of the project should be entrusted to an architect , specializing specifically in log buildings and well acquainted with the requirements of the relevant SNiPs.

Moreover, this also explains another important point. “Flying squads” of “broad-profile” craftsmen usually work on the basis of just sketchy “projects”, sometimes drawn by the customer himself and little reminiscent of professional construction documentation, so it is strongly recommended to order the construction of a log house only from specialized companies that have solid experience in field of wooden house construction.

Of course, it will cost more, but in this way you will save yourself from very likely and very serious problems that cannot be solved without spending a lot of money, time and nerves. Or maybe they will turn out to be unsolvable in principle. (For example, with the foundation laid as for a high-rise building, you can’t do anything and you won’t get back the money spent on it. Or if you have to put support pillars under the ceiling so that it doesn’t collapse, then goodbye to the transparent, open interior - after all, the reliability of the structures and safety is incomparably more important.)

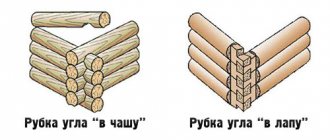

However, the “order and forget” principle does not work even if you contact a specialized company. The responsible customer will have to master a lot of specific information and terminology (just look at the methods of cutting corners - “in the paw”, “in the head”, “in the hook”, etc.) in order to communicate with the performers knowledgeably, competently control the process and do not allow yourself to be forced into wrong decisions and unnecessary expenses.

Houses made by hand, which does not disturb the structure of the tree, will last longer and will be warmer than those made on machines. In central Russia, houses for year-round use are built from logs Ø 22–24 cm

Preparation

The preparation stage included clearing the site, digging a well, installing a purchased wooden cabin and toilet, after which the project selection stage began. Initially, the craftsman set his sights on a one-and-a-half-story log house, 8x9 meters, with five rooms, but as he began to think about it, a completely different design emerged. I refused the second floor, even though it was an attic, both due to my reluctance to do staircase fitness, and for other reasons. In addition, with planned stove heating there will be a large temperature difference between levels. Plus, it is problematic to insulate a pitched roof with sawdust; with a ceiling and a cold attic it is much easier. Next, it was the turn of quadrature, and the result of selecting the optimal layout was a project for a 6x6 meter log house, with a set of functional rooms.

The vital meters needed for a comfortable existence were taken into account, as well as savings on operation by reducing heating costs, and the specifics of a dacha - a house for “drinking tea and sleeping.” However, this adjustment in scale led to the abandonment of the planned log cutting into a cup. A six-meter log just fits into the plan, but a seven-meter log is much more expensive, and only a few people work with it. Yes, visually cutting into a cup wins, but the “dovetail” with a crossover is quite functional, and the ends can be covered with platbands.

Tools for building a log house

All the tools listed below are mandatory and basic for construction, without which you cannot do.

Basic list of tools, but not exhaustive

- Axe

- Trait

- Chainsaw and hand saws

- Measuring tool

- Electric drill

- Screwdriver

- Scrape and plane

- Chisel, mallet and hammer

- Tesla ax

- Log turner

- Bulgarian

- Related and consumable tools

Let's consider the purpose of the listed tool in the construction of a log house.

1. Ax

Tool number when cutting a log house is the most versatile of the carpenter’s entire kit, so special attention is paid to it. In the old days, the ax replaced most of the carpentry tools. The ax served as a chisel, plane, hammer, mallet and others. All listed and not listed carpentry tools could be replaced, but the ax cannot be replaced with anything.

When choosing an ax, it is necessary to take into account both the individual characteristics of the builder and the specifics of construction. The weight of the ax should not be heavy, so as not to get tired quickly, and not too light, so as not to slow down the completion of the work. You should pay attention to the physical abilities of the builder. Different people will get tired of the same ax in different ways. Recommended ax weight is from 0.5 kg to 1.75 kg. The ax handle should not slip and should sit comfortably and firmly in your hand. In practice, if the entire set of tools is available, the ax is used not only for chopping the bowl, but the carpenter also hammers the dowel with the butt instead of the hammer.

axes for log house

an ax is necessary for chopping bowls and locks

2. Trait

The second name of the doodle. Also a special and extremely important tool. Used for measuring and drawing the dimensions of the log bowl. You can either purchase the trait in construction stores or make it yourself in the old fashioned way.

A dash is a kind of compass, similar to a fork, consisting of two pointed ends. One of which is necessary for fixing in the central part of the base of the log, the second end of the line serves as a writing element, measuring the size of the bowl and marking it on the log. At the base of the line, at the junction of the two ends of the fork, there is a special screw-type lock, with or without markings. Previously, the function of a latch was performed by a wooden wedge, and the pointed metal ends were connected at the base into a ring. Currently, the measuring line is produced and sold even with a built-in level.

feature for log house

old version of the feature for a log house

3. Chainsaw and hand saws

Currently, it is almost impossible to imagine building a log house without a chainsaw. It is with a chainsaw that the bowls and connecting locks are cut out. The tool significantly speeds up working with the material and cutting it out. For construction, you should choose a semi-professional (farm) chainsaw, which is suitable for building a house. such a tool is relatively light in weight and will be convenient. It is not recommended to purchase and use a professional industrial chainsaw, since its weight is up to 15 kg and will not allow you to work with it for a long time without a break. Household chainsaws, the cheapest type, may not withstand the entire construction site and fail at the most inopportune moment.

It is not recommended to use a power saw, since the power supply cable will create inconvenience during operation and there is a high risk of damage.

During construction, you will need either a regular saw or a two-handed one, which can often replace a chainsaw.

chainsaw

4.Measuring tool

These include: a plumb line, a measuring tape at least 10 meters long, a laser and a regular hand level. A level and tape measure are a must-have attribute of any construction or renovation project.

5. Electric drill

Necessary for drilling vertical holes for dowels that connect the crowns of logs. Not every electric drill is suitable for these purposes. Here you need a drill with low speed and high power from 750 W and a twist drill of 25-30 mm, with a minimum length of 36 cm. The length and diameter of the drill depends on the thickness of the log. The hole must connect two logs, which means the length of the drill must be greater than the sum of the diameters of the two logs.

7. Screwdriver.

It will be convenient to use a cordless screwdriver or a drill as a screwdriver.

8. Scraper and plane

This tool is necessary if you are using unscraped wood with bark. But even when using already prepared and cleaned logs, a scraper and especially a plane can be useful at a construction site. Cleaned round timber may have blemishes in the form of remaining pieces of bark and other minor defects that require removal.

log cleaning scraper

9. Chisel, hammer, mallet.

Necessary for installing related building fasteners: dowels, nails, construction staples and others.

10. Adze ax

Can be used for the convenience of cutting a longitudinal groove. It is an ax with a semicircular blade located perpendicular to the ax handle.

Tesla ax

11. Log turner

Necessary for convenience when turning a log before processing it. The tool is not mandatory, but popular experience suggests that it greatly facilitates working with a log and saves energy. It is possible to make the edging either yourself or purchase it in construction stores.

log turner

12. Grinder and grinding discs

It is also not a mandatory tool and may be needed only if you decide to grind the surface of the log coils after assembling it. An angle grinder with a power of 700 W to 1000 W is suitable for these purposes. For rough grinding, discs with a grain size of up to 60 are suitable; for more delicate grinding, a grain size of up to 120 is suitable. Discs should be purchased at the rate of one disc per 5 meters of log, depending on the initial condition of the surface being treated.

grinding of a log house

13. Related tools and consumables.

This category includes: a crowbar or nail puller, nylon thread, several pairs of construction gloves, construction pencils, knives, whetstones for sharpening tools, a stapler, respiratory protection, comfortable shoes and clothing, and others.

Stage 3

Foundation

Preference was given to screw piles due to the desire to try an “ultra-modern solution” and save money, as well as due to the speed and relative ease of installation. A total of nine piles were screwed in - three support points for each load-bearing beam, pile diameter 108 mm, thickness - 4 mm. Despite some problems when installing the piles and the flimsiness of the coating, which is positioned as a durable protective layer, but in fact can be easily removed with a fingernail, the craftsman is satisfied with the choice. Moreover, perhaps the bathhouse will also be placed on stilts, although he admits that a tape or slab “will be more reliable.”

Do you want everything ready?

Wanting to reduce the construction time of a house and bring the housewarming closer (and this can take place no earlier than one and a half to two years after the final assembly of the building), some are considering purchasing a ready-made log house. Is it worth doing?

First of all, it is unknown what quality of the project was used and whether it was used at all. In addition, many still want to “modernize” the log house for themselves, adding various extensions, balconies, etc. to it. In particular, this creates an increased load on the supporting structures; the junctions of new elements with log walls often become cold bridges, it is also possible emergence of other problems.

It is especially not recommended to purchase a log house that is offered to you as an already established one. Most likely, these are piles of logs that did not find their buyer in time, stacked in crowns on supports and stood there for a year or more without proper shelter. There is no need to explain what kind of house this material will make. Remember: the log house should only stand on its foundation and under a temporary roof.

Box

The frame was collected using moss that had been ordered in advance from another region; before installation, the moss was poured out to dry, since when it was delivered it was still fresh and had not dried out much during the two weeks spent waiting in the wings. Making log partitions turned out to be problematic due to the small dimensions of the four-wall, and the cost of the box in this case would have jumped by almost half. Therefore, in one day, the hired team delivered and in another day assembled just a box, and although the moss after assembly hung picturesquely all over the walls, it took significantly less than planned, as practice has shown - they obviously did not report it.

To dry the log house, ventilation holes measuring 30x30 cm were cut out, with gratings. Mike099 advises everyone who is just in the process to do more of them. I did the curling (the initial caulking of a log house with moss) on my own, driving the hanging moss into the voids and cutting off the excess with a utility knife.

Basic methods of dressing corners

Corner dressings are divided into two types:

- With the remainder (the logs protrude beyond the formed corner).

- Without a trace.

The functional difference is minimal and the decision is made based on aesthetic considerations .

The first method is also called “ in oblo ”. It is presented more clearly in the picture:

The second type of dressing is called “ in the paw ”:

Roof

The craftsman refused the now popular soft tiles for several reasons.

mike099

I rejected the soft roof immediately, due to its less environmental friendliness and higher price. The binders, the basis of soft tiles, are far from natural materials. Its installation is more expensive, and you need a smooth flooring made of OSB or plywood.

Therefore, I preferred metal tiles that imitate the ceramic source. A wide, semicircular ridge, instead of sub-rafter elements there is a central supporting ridge beam. Waterproofing, counter-lattice along the rafters (50×50 mm), lathing with pitch to match the covering profile (35 cm). As planned, the eaves overhangs are 70 cm long; in the future there will be a metal drainage system.

After assembling the frame “under the roof”, I protected the ventilation windows with awnings, and also installed temporary flashings made of waterproofing along the ends, cracks of the flashings and at the junction of the frame and trim. No matter how much I wanted to avoid the use of chemicals, I had to treat the imitation timber gables with protective impregnation.

Briefly about the main thing

The log house is most often made from pine or other coniferous wood.

The main advantage of a wooden log house is thermal insulation and environmental friendliness.

When choosing a log manufacturing technology, it is recommended to take into account the level of knowledge and skill. If it is not high enough, then it is better to contact specialists.

It is necessary to use high-quality thermal insulation and means to combat fungus and insects. This will extend the life of the building.

All logs for a log house must be treated with a fire retardant to avoid fire in the structure.

Ratings 0